When you pick valves and fittings, start by knowing what your system needs. Check the fluid type, pressure, and temperature in your system. The STAMPED method helps you remember what to look for. It stands for Size, Temperature, Application, Media, Pressure, Ends, and Delivery. For example, a ball valve or butterfly valve works for different temperatures and jobs. Always make sure everything fits together and has the right certifications. Some systems have special needs. A control valve in a tough place must not rust and should keep working. Think about how you will put in the valves and how to take care of them later. This helps your valves and fittings last longer.

Key Takeaways

- Use the STAMPED method to pick valves and fittings. Check Size, Temperature, Application, Media, Pressure, Ends, and Delivery.

- Choose materials that fit your fluid and where you use them. This helps stop leaks, rust, and early damage.

- Always match the valve size and pressure to your system. This keeps flow steady and stops expensive problems.

- Follow standards and certifications for safety and reliability. This also makes maintenance easier.

- Plan how you will install and take care of the system. Make sure you have good access and the right connections. This helps your system last longer and work better.

Project Requirements

Fluid and Media

Start by knowing what fluid is in your system. The chemical makeup of the fluid decides which materials you need. Water, oil, gases, and chemicals all need different materials to work safely. If you use toxic or harsh fluids, check that every part can handle them for a long time without breaking or rusting.

- Find out what fluid you have, like water, air, oil, or chemicals.

- Be careful with toxic or strong fluids. You might need stainless steel, nickel-plated brass, or special plastics.

- Make sure the materials can handle the fluid and the system’s pressure and temperature.

- Pick valves and fittings that match your fluid system’s needs.

Tip: Always look at chemical compatibility charts before you choose. This helps stop leaks, rust, and early breakdowns.

Different jobs need different materials. For example:

- Oil and gas systems need valves that can take high pressure and don’t rust.

- Water systems often use stainless steel so they don’t rust.

- Chemical plants need materials that can stand up to strong acids or solvents.

| Media Type Characteristics | Suitable Valve Material | Reason/Notes |

|---|---|---|

| Non-corrosive, low-pressure, low-temperature | Cast Iron | Cast iron resists rust and costs less; it’s not good for high heat or strong chemicals |

| Mildly corrosive or non-corrosive, medium to low temperature | Carbon Steel | Carbon steel is strong and resists stress; it needs a coating to stop rust |

| Corrosive, high temperature, high pressure | Stainless Steel | Stainless steel is very strong and resists rust; it works well with acids, bases, and solvents |

| Highly aggressive environments (e.g., high chloride, acidic gases) | Duplex/Super Duplex Steel | Duplex steel resists rust even better; it’s great for offshore, chemical, and oil & gas jobs |

The STAMPED method helps you remember what to check when picking valves. It stands for Size, Temperature, Application, Media, Pressure, Ends, and Delivery. This way, you don’t forget anything important and avoid problems with how things fit together.

Pressure and Temperature

Pressure and temperature are very important when picking valves. Every valve and fitting has a limit for safe use. If you go past these limits, you could get leaks, cracks, or even break your system. Always match the pressure and temperature ratings to what your system needs.

- Steel valves can take heat up to 375°F (190°C).

- Aluminum and copper valves work up to 400°F (204°C).

- 304 stainless steel valves can go up to 800°F (427°C).

- 316 stainless steel and special metals can work up to 1000°F (538°C).

- Plastic valves like PVC are good for water and some chemicals but only up to 140°F (60°C).

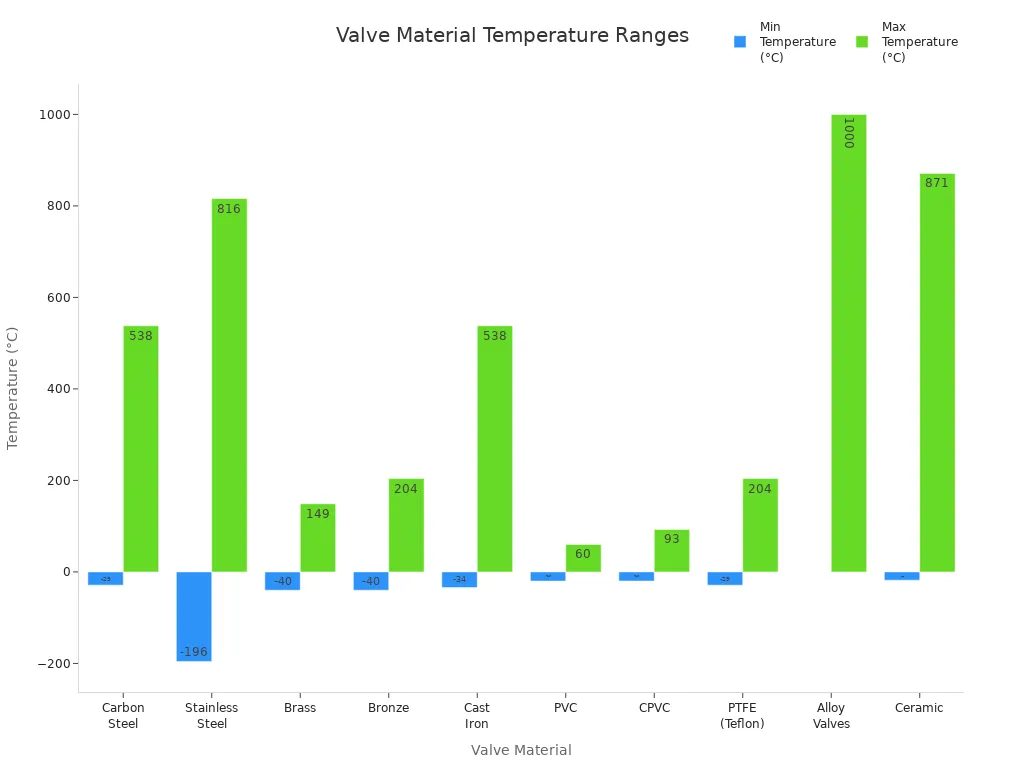

| Valve Material | Temperature Range (°C) | Temperature Range (°F) |

|---|---|---|

| Carbon Steel | -29 to 538+ | -20 to 1000+ |

| Stainless Steel | -196 to 816 | -321 to 1500 |

| Brass | -40 to 149 | -40 to 300 |

| Bronze | -40 to 204 | -40 to 400 |

| Cast Iron | -34 to 538 | -30 to 1000 |

| PVC | -20 to 60 | -4 to 140 |

| CPVC | -20 to 93 | -4 to 200 |

| PTFE (Teflon) | -29 to 204 | -20 to 400 |

| Alloy Valves (e.g., Inconel, Hastelloy, Monel) | Cryogenic to >1000 | Cryogenic to >1832 |

| Ceramic | -18 to 871+ | 0 to 1600+ |

Note: Always use a safety factor for pressure ratings. For important jobs, use at least 1.5 times the system pressure. This keeps things safer and helps valves last longer.

Push connect fittings and seals must also match your system’s pressure and temperature. High pressure or heat can wear out seals faster. If you use plastic valves, remember they don’t last as long and can’t take high heat. Check seals and gaskets often to keep valves working well and stop leaks.

Flow and Layout

Good piping layout helps your system work well and makes fixing things easier. Plan where valves and fittings go to help flow and make maintenance simple. Bad layout can cause more friction, waste energy, and make leaks more likely.

- Leave enough space around valves and fittings so you can reach them.

- Keep pipes short and use fewer fittings to lower friction and save energy.

- Don’t use sharp bends. Sweep elbows help keep flow smooth and lower pressure drop.

- Put valves where you can use and fix them easily.

- Add expansion loops or joints to let pipes grow when they get hot.

- Follow safety rules and codes for all setups.

- Label pipes and show which way the fluid goes for safety and easy use.

Pro Tip: Use piping sections or flanges you can remove to make repairs faster. This saves time and lets you change your system if needed.

Always pick valves and fittings based on flow, pressure, temperature, and material. Safety features like pressure relief valves and emergency shutdown valves give extra protection. Good pipe supports stop damage from pipes getting bigger or smaller when hot or cold.

If you follow these steps, your valves will work well now and last longer. Planning your flow and layout helps you avoid problems and get better results from your fluid system.

Valve and Fitting Standards

Why Standards Matter

When you pick valves and fittings, standards are very important. Standards help keep your system safe and easy to fix. They tell companies how to make and test products. This helps you trust that what you buy will work well.

Keeping Things Safe and Working

You want your system to be safe every day. Standards make sure valves and fittings are made with strict safety rules. This lowers the chance of leaks or accidents. Following standards protects people, equipment, and nature.

- Standards help you know products meet exact rules.

- They make your project safer and more reliable.

- Using standards helps you avoid legal trouble and wasted time.

Making Parts Work Together

Sometimes you need to change or fix parts in your system. Standards make this simple. They help valves and fittings from different brands fit together. This saves you time and money when you fix things.

- Standards let parts from different places work together.

- They help you find new parts in many countries.

Meeting Rules for Projects

Many jobs must follow local or world rules. Standards help you meet these rules. They also make it easy to show inspectors your system is built right.

Tip: Always check which standards you need before you buy valves or fittings.

Main Valve Standards

There are many well-known standards for valves around the world. Each one comes from a trusted group and covers different needs.

| Valve Standard | Country/Region | Responsible Organization |

|---|---|---|

| ASME (American Society of Mechanical Engineers) | United States | ASME |

| API (American Petroleum Institute) | United States | API |

| ISO (International Organization for Standardization) | International | ISO |

| DIN (Deutsches Institut für Normung) | Germany | DIN |

| BS (British Standards) | United Kingdom | BSI |

ASME (American Society of Mechanical Engineers)

ASME standards focus on safety and how things work. ASME B16.34 is for valves and covers design and pressure. These rules are used a lot in North America.

API (American Petroleum Institute)

API standards, like API 6D, are used in oil and gas jobs. They need strong testing and paperwork. API rules help make sure valves can do hard work.

ISO (International Organization for Standardization)

ISO standards give you world rules for quality and safety. ISO 5208 sets rules for how valves should work and be tested. ISO rules help you use products in many countries.

DIN (Deutsches Institut für Normung)

DIN standards come from Germany and are used in Europe. They cover materials, sizes, and testing for valves. DIN rules help you get good quality and fit.

BS (British Standards)

British Standards are used in the UK and other places. They set rules for design and testing. BS rules help you meet project needs in many places.

Note: Some jobs may need more than one standard, especially for world projects.

Main Fitting Standards

Fitting standards are just as important as valve standards. They help make sure all parts of your pipes fit and work together.

| Standard | Description and Application |

|---|---|

| ASME B16.9 | Butt-welding fittings, covers dimensions and tolerances for sizes NPS 1/2 to 48 |

| ASTM A234 / A234M | Material specification for carbon and alloy steel fittings, used in high temperature service |

| ISO 49 | Malleable cast iron fittings, threaded to ISO 7-1 |

| ISO 7-1 | Pipe threads for pressure-tight joints |

| API 5L | Line pipe specification for oil and gas pipelines |

ASME B16 Series

The ASME B16 series covers many types of fittings. This includes elbows, tees, and flanges. These rules set sizes, materials, and pressure. You use them a lot in big piping jobs.

ASTM (American Society for Testing and Materials)

ASTM rules, like ASTM A234, tell you what materials and tests to use. They help you pick the right material for your system.

ISO Standards for Fittings

ISO rules, like ISO 49 and ISO 7-1, set world rules for fittings and threads. These rules help you use fittings from many countries.

DIN Standards for Fittings

DIN rules cover sizes, materials, and how close things must fit. They are used a lot in Europe and help you get good quality.

Remember: Fitting standards help stop leaks and rust by making sure all parts match.

How to Pick the Right Standards

You must make sure your valves and fittings meet the right rules for your job. Here are some steps you can follow:

Check Project Rules and Local Codes

Start by reading your project papers. Look for any needed standards or certificates. Local rules may also tell you what you must use.

Ask Suppliers or Engineers for Help

Talk to your suppliers or an engineer. They can help you pick products that follow all the rules. Ask for papers or certificates to prove it.

Check for Certification and Labels

Always look for marks or labels on valves and fittings. Certified products often have a stamp or label showing the rule they meet. For example, NSF-certified products are checked often to keep their certificate. This gives you extra peace of mind.

Pro Tip: Never skip checking certifications. This helps you avoid problems and keeps your system safe.

By following these steps and picking products that meet known rules, you help keep your system safe, reliable, and ready for the future.

Types of Valves

Common Valve Types

There are many kinds of valves in big and small systems. Each valve is made for a special job. Picking the right valve helps your system work well and last longer.

- Ball valve: This is the most used valve. It is good for turning flow on or off fast. It closes tightly and works best when fully open or closed.

- Butterfly valve: This valve has a disc that turns. It is light and fits big pipes. You often see it in water and HVAC systems.

- Diaphragm valve: This valve uses a soft part to stop flow. It is good for strong chemicals because it keeps the moving part away from the fluid.

- Gate valve: This valve starts or stops flow. It is best for shutting off flow, not for changing how much flows.

- Globe valve: This valve helps you control how much flows. It is good when you need to be exact.

- Check valve: This valve lets flow go one way only. It stops flow from going backward and protects your equipment.

- Plug valve: This valve controls flow. It is simple and works fast.

- Balancing valve: This valve helps keep flow even in your system.

Tip: Pick the valve type that matches your system. This helps stop leaks and keeps things safe.

Valve Functions

Valves help you control liquids or gases in pipes. Each valve works in its own way. Rotary valves, like ball, butterfly, and plug valves, turn to open or close fast. Linear valves, like globe and gate valves, move up or down to change flow. These help you control flow very well. Some valves, like check valves and pressure relief valves, work by themselves. They stop flow from going the wrong way or let out extra pressure.

Here is a table to help you compare the main types of valves:

| Valve Type | Operation Method | Best Use | Advantage | Limitation |

|---|---|---|---|---|

| Ball valve | Rotary | On/off control, tight sealing | Fast, reliable | Some pressure loss |

| Butterfly valve | Rotary | Large pipes, water, HVAC | Lightweight, compact | Less precise throttling |

| Globe valve | Linear | Flow regulation | Precise control | Higher pressure loss |

| Gate valve | Linear | Isolation, infrequent use | Low pressure loss | Not for throttling |

| Check valve | Automatic | Backflow prevention | Self-operating | One-way flow only |

| Plug valve | Rotary | On/off, slurries | Quick shutoff | Can clog |

| Diaphragm valve | Linear | Corrosive fluids, slurries | Leakproof, safe | Sensitive to pressure |

You should always think about what the valve does, its shape, and how it works. This helps you pick the best valve for your project.

Types of Fittings

Common Fitting Types

Plumbing systems use many kinds of fittings. Each fitting does a special job. Elbows help pipes turn corners. Tees split pipes into more than one way. Couplings join two pipes so they stay together. Unions let you take pipes apart for fixing. Reducers join pipes that are not the same size. Adapters connect pipes with different widths or types. Caps and plugs close pipe ends to stop flow.

Here are the most used fitting types and what they do:

| Fitting Type | Primary Use / Function |

|---|---|

| Elbows (90°, 45°, Long-radius, Short-radius) | Turn flow; 90° for sharp turns, 45° for softer turns, long-radius for less pressure drop, short-radius for tight spots |

| Tees (Equal, Reducing, Side Outlet) | Split pipes; equal tees for same size, reducing tees for different sizes, side outlet for small spaces |

| Reducers (Concentric, Eccentric, Swage) | Join pipes of different sizes; concentric for lined-up pipes, eccentric to keep pipe bottom flat, swage for smaller joins |

| Unions | Make pipes easy to take apart and fix |

| Couplings | Join two pipes for good, often where you can’t reach |

| Adapters | Connect pipes with different widths or types |

| Nipples | Join two pipes with threads in a straight line |

| Caps and Plugs | Close off pipes |

Tip: Pick the right fitting for your plumbing job. This helps stop leaks and makes fixing things easier.

Fitting Functions

Fittings do many things in a pipe system. Elbows help flow go around things in the way. Tees split flow into more pipes. Reducers change pipe size to fit your needs. Caps and plugs close pipe ends to stop flow. Unions and couplings join pipes, making the system strong and easy to fix.

- Elbows turn flow. Long-radius elbows make flow smoother and lower pressure. Short-radius elbows fit in small spaces.

- Reducers change pipe width. Concentric reducers keep pipes lined up. Eccentric reducers keep the pipe bottom flat, so water does not pool.

- Tees split flow for different jobs.

- Caps and plugs close pipe ends.

- Unions and couplings join pipes for easy fixing or for good.

Note: The right fitting keeps your plumbing safe and working well. Always match the fitting to how the flow goes and how your pipes are set up.

Connection Methods

There are different ways to join fittings in plumbing. Each way has good and bad points. You should pick the way that fits your system best.

| Connection Method | Advantages | Disadvantages | Typical Applications / Notes |

|---|---|---|---|

| Threaded Connection | Easy, old way, simple to put on and take off | Not good for thin pipes, may leak if pressure is high | Used in small plumbing jobs and repairs |

| Welded Connection | Very strong, no leaks, good for high pressure and heat | Hard to take off, needs skilled workers, costs more | Used in big plumbing and high-pressure systems |

| Flange Connection | Easy to put on and take off, strong, handles shaking well | Big, needs more space, costs more | Used in big pipes and places where you need to take fittings off often |

| Push-to-Connect | Quick to put on, no tools needed, good for small pipes | Not as strong as welded or threaded, may not work for high pressure | Used in home plumbing and quick fixes |

| Compression | No heat needed, easy to put on, works with many pipe types | May leak if not put on right, needs checks | Used in water lines and places where you need to take pipes off easily |

Pro Tip: For high-pressure or important jobs, welded and flange connections are safest and strongest. For quick fixes or small jobs, push-to-connect and compression fittings save time.

Always match the way you join fittings to what your plumbing needs. This keeps your system safe, easy to fix, and ready for changes later.

Valves and Fittings Selection

Material Compatibility

You must pick valve and fitting materials that match your fluid and where you use them. The right material helps your valves last longer and work better. If you pick the wrong one, you might get leaks or rust, and your valves could break early.

- Steel valves are strong and last long. They work best in hot, high-pressure steam pipes.

- Cast iron valves do not wear out fast. They are good for rough fluids in water or plumbing systems.

- PVC and other plastics do not rust. They are good for harsh chemicals in low-pressure water or chemical jobs.

- Stainless steel valves do not rust and are clean. You see them a lot in food, drink, and medicine jobs.

- Always check that seals and valve parts match your fluid. If not, seals can swell, break, or stop working.

- Sun, heat, cold, or wet air can hurt some materials. Make sure your valves can handle these things.

If you use the right materials, you stop rust, seal problems, and early valve breaks. Metals like steel, brass, and bronze are good for strong chemicals or high pressure. Plastics like polyethylene or nylon are fine for easy water or air jobs. If you use the wrong material, you might get leaks, cracks, or swelling. Always ask the maker for help with special jobs to get the best valve for you.

Tip: Picking the right material keeps your valves safe and working for a long time.

Connection Types

Picking how you connect your valves and fittings is just as important as picking the material. The connection type changes how easy it is to put in, fix, or swap parts in your pipes.

| Factor/Consideration | Description/Impact |

|---|---|

| System Pressure | The connection must handle your system’s highest pressure. |

| Leak Prevention | Welded connections stop leaks best. Flanged ones are good for big pipes. Threaded ones fit small pipes but may leak later. |

| Installation & Maintenance | Flanged connections are easy to put in and fix. Threaded ones can be hard to use. Welded ones are hard to take off and may need cutting. |

| Cost | Welded connections cost less but are not flexible. Threaded ones are cheaper than flanged. Cost changes with valve size. |

| Pipe Size | Big pipes (over 4 inches) use flanged or welded connections. Small pipes often use threaded ones. |

| Standardization | Always match connection rules to your pipe and plant needs. |

| Operational Requirements | Think about how often you need to take out the valve, if it should stay forever, and if it will handle dangerous or high-pressure flow. |

You should also think about these things:

- Use welded or flanged connections for high-pressure or dangerous jobs.

- Threaded connections are fine for small water jobs but may leak if not put in right.

- Push-to-connect and compression fittings are fast to use but may not work for high pressure.

- Always follow the rules for connection types to keep your pipes safe.

Note: The right connection type makes it easier to put in and fix valves.

Environmental Factors

The place around your valves and fittings can change how well they work and how long they last. You need to think about heat, cold, wet air, and chemicals when you pick a valve.

- High heat can make some materials soft or weak. Stainless steel valves stay strong in hot or wet places.

- Cold can make PVC and some plastics break. These valves may crack in cold water or outside.

- Wet air can make things rust. Stainless steel and brass do not rust, and coatings help other metals.

- Chemicals can break down both metals and plastics. For strong chemicals, use CPVC, PTFE, or stainless steel.

- Sunlight can hurt plastics like PVC or nylon. Use UV-safe materials for pipes outside.

- Dust, salt, and other rough things can make materials break down faster. Rust-proof valves last longer in these places.

Always check that your valve and fitting materials match your fluid and the place you use them. This helps stop leaks, cracks, and early breaks. Good choices mean less fixing and better flow in your pipes.

Pro Tip: Always check your system’s place before you pick a valve. This step saves you time and money on repairs.

Valve Sizing

Sizing a valve for your project means you must match it to your pipe and system needs. If you choose the wrong size, you risk leaks, pressure loss, or poor flow. You want your valve to fit the pipe perfectly and handle the flow capacity your system demands.

Pipe Size Match

You should always match the valve size to your pipe size. This keeps your system safe and efficient. If the valve is too small, you get flow restrictions and pressure drops. If it is too large, you waste money and space. Here are steps to help you find the right match:

- Determine your system’s flow rate. This tells you how much fluid moves through the pipe.

- Calculate the flow coefficient (Cv). This number shows how much flow passes through the valve at a set pressure.

- Select the valve type and material that fits your application.

- Account for pressure drop and cavitation. These issues can damage your valve and pipe.

- Confirm the valve’s nominal pipe size matches your pipe diameter. This prevents turbulence and loss of pressure.

Tip: Use manufacturer sizing charts, Cv calculators, or software tools to help you pick the right valve size. For complex systems, ask a valve specialist or engineer.

You should also check that the valve fits the pipe ends, whether threaded, flanged, or welded. This ensures a tight seal and easy installation.

Pressure Ratings

Pressure ratings tell you how much pressure a valve can handle safely. You must check these ratings before you install any valve. Pressure ratings depend on standards like ANSI/ASME classes (Class 150, Class 300) or PN ratings (PN10, PN16). Higher ratings mean the valve can handle tougher jobs.

- Always check the material of the valve. Stainless steel valves handle more pressure than brass or plastic.

- Valve size affects pressure ratings. Smaller valves often handle higher pressure.

- Valve design matters. Rising stem valves usually have higher pressure ratings.

- Temperature changes pressure ratings. As temperature rises, the valve’s pressure rating drops.

- The application environment matters. Corrosive or abrasive fluids need valves with higher ratings.

You must follow standards like ASME and ANSI to keep your system safe and reliable. If you ignore pressure ratings, you risk leaks, valve failure, or safety hazards. Always check for certification marks like ASME V or UV stamps. These show the valve meets strict safety rules.

Note: Proper valve sizing and pressure rating checks protect your pipe system and keep your flow steady.

Installation and Maintenance

Installation Ease

You want your valves and fittings to work well from the start. Good installation keeps your system safe and easy to fix. Here are some steps to help you install things right:

1. Get the right tools. You need wrenches, pipe cutters, and tools to line things up. 2. Gather all your materials. Have sealants, gaskets, and the right pipes ready so nothing leaks. 3. Clean every part before you start. Dirt or dust can cause problems later. 4. Put sealant or Teflon tape on threaded parts. This helps stop leaks. 5. Line up valves and fittings with the flow. This keeps things working and stops damage. 6. Tighten fittings just as the maker says. If you make them too tight or too loose, you might get leaks or break something. 7. Support valves and fittings well. Good support stops damage from shaking or bumps. 8. Test for leaks after you finish. Slowly add fluid and check for leaks. 9. Follow the maker’s rules and use a checklist. This helps you avoid mistakes like bad alignment or too much sealant.

Tip: Careful installation saves time and money. You stop leaks and make fixing things easier later.

Maintenance Access

Easy access to valves and fittings keeps your system working well. You need to reach every part to clean, check, and fix it. Good access lets you use tools and smart devices to watch valve health.

1. Clean valves often. This stops stuff from blocking flow. 2. Check for leaks a lot. Finding leaks early stops damage and saves money. 3. Lubricate moving parts. Less rubbing means valves last longer. 4. Check and change seals when needed. Good seals stop leaks. 5. Follow the maker’s rules for care. Good access makes these jobs easy.

Note: Smart controllers and remote checks help you find problems early. You can plan repairs before things break, which saves money and time.

When you design your system, put valves where you can reach them. Leave space for tools and your hands. Good access means fewer problems and a system that lasts longer.

Common Mistakes

Material Mismatch

If you pick the wrong material, your valve or fitting can break. You need to match the material to the fluid and where it will be used. If you do not check if they work together, rust and damage can happen fast. Aluminum fittings can rust with some chemicals. Brass fittings do not last with strong chemicals or in the ocean because of dezincification. Stainless steel is best for ocean jobs. Brass and aluminum are fine for less harsh places. If you mix thread types, like straight threads with tapered threads, you get leaks and loose parts. Using carbon steel in salty or wet places makes it break down early. Always check what your fluid is made of and think about heat, wetness, saltwater, and sunlight before you pick a valve.

Tip: Pick the right valve material and thread type for your system. This helps stop leaks, rust, and broken parts.

Sizing Errors

If you pick the wrong size valve or fitting, your system will not work well. A valve that is too small will not open or close all the way. This can slow things down and waste time and money. If the valve is too big, it costs more, takes up space, and can slow how fast it works. If parts do not fit right, like the stem, they wear out or break. You need to think about how much force is needed, what fluid you use, air pressure, and how parts fit together. Picking the wrong size makes leaks and breaks more likely. Using automation and the right actuator helps you avoid mistakes and keeps things safe by letting you control and watch the system from far away.

- Small valves do not open or close right and move oddly.

- Big valves cost more and work slower.

- Parts that do not fit wear out or break.

- The right size keeps your valve safe and working well.

Overlooked Limits

If you forget about pressure and temperature limits, your system can get weak spots. Metals get weaker when hot, so they cannot take as much pressure. If you do not match all the ratings, you can get leaks, rust, or broken parts. If valves and fittings do not have the same ratings, you pay more for repairs and your system works worse. Always check the lowest rating to keep things safe. Your system only works well if every valve and fitting stays within its limits.

Note: Always check the pressure and temperature ratings for each valve and fitting. This keeps your system safe and stops expensive problems.

Picking the right valves and fittings helps your system work well. You should follow steps to make sure each part fits your project.

- Always check if the parts work together, meet rules, and can be put in easily.

- Look at certifications before you buy anything.

- If your project is hard, ask a supplier or engineer for help.

Remember: Good planning and asking experts can help you avoid big mistakes and keep your system safe.

FAQ

What is the STAMPED method for valve selection?

STAMPED stands for Size, Temperature, Application, Media, Pressure, Ends, and Delivery. You use this checklist to organize your selection process and make sure you choose valves and fittings that match your project needs.

How do you know which material to choose for your valve or fitting?

You check the fluid type, temperature, and pressure. Use a chemical compatibility chart. Stainless steel works for most chemicals. PVC suits water and low-pressure jobs. Always ask your supplier if you feel unsure.

Can you mix different brands of valves and fittings?

- You can mix brands if they follow the same standards.

- Always check for matching sizes and connection types.

- Look for certification marks to confirm compatibility.

What happens if you use the wrong valve size?

| Problem | Result |

|---|---|

| Too small | Flow restriction |

| Too large | Wasted money |

| Wrong fit | Leaks or damage |

You risk leaks, poor flow, and higher costs.

How often should you inspect valves and fittings?

You should inspect valves and fittings every six months. Regular checks help you find leaks, rust, or wear early. This keeps your system safe and reduces repair costs.