Choosing between gate valve vs butterfly valve depends on the specific requirements of the job. Gate valves are ideal for high-pressure applications and are commonly found in oil, gas, or petrochemical plants. On the other hand, butterfly valves are widely used in water, wastewater, and chemical industries because they operate faster and take up less space. The table below compares how each valve type addresses key factors:

| Factor | Gate Valve | Butterfly Valve |

|---|---|---|

| Pressure | High | Low/Medium |

| Speed | Slow | Fast |

| Space | Large | Compact |

| Cost | Higher (large size) | Lower (large size) |

| Flow Control | Simple shut-off | Precise, efficient |

When selecting the right valve, engineers should consider cost, space, and operational speed. In some cases, a ball valve or a pneumatic control valve might be more suitable for specialized applications, offering different advantages depending on the system’s needs.

Key Takeaways

- Gate valves seal tightly and can handle high pressure and heat. This makes them good for important shut-off jobs.

- Butterfly valves open and close fast with a quarter turn. They save space and cost in many uses.

- Pick gate valves when you need full open or closed flow. Do not use them to partly control flow, or they might get damaged.

- Butterfly valves are good for quick use, flow control, and small spaces. They might let small leaks happen.

- Gate valves are heavier and bigger than butterfly valves. They also cost more to put in and take care of.

- Butterfly valves are lighter and easier to take care of. They are better for often use and for machines.

- Think about the fluid, pressure, heat, space, and money before you pick a valve.

- Use the right industry rules and match valve materials to the job. This keeps things safe and helps valves last longer.

Gate Valve vs Butterfly Valve Overview

Key Differences

The gate valve vs butterfly valve discussion looks at many important things. The table below shows how these two industrial valves are different:

| Aspect | Gate Valve | Butterfly Valve |

|---|---|---|

| Operation | Needs many turns to open or close. It works best for turning flow on or off. It is not good for changing flow amount. | Needs only a quarter turn to work. It opens and closes fast. It is good for controlling flow and stopping it. |

| Pressure Rating | Can handle very high pressure, even above 100 bar. | Works with low or medium pressure. Some special models can handle higher pressure. |

| Temperature | Works well in places with high heat. There are materials for very hot conditions. | Can work in high heat, but not as much as gate valves. |

| Space Requirement | Needs more room to install, especially if it has a rising stem. | Small and light. Fits in tight spaces easily. |

| Cost | Costs more because it has a complex design and uses strong materials. | Costs less. It has a simple design and uses lighter materials. |

| Flow Resistance | Has very low resistance when open. It lets flow move like a straight pipe. | Has more resistance than gate valves. But it still works well for many jobs. |

| Maintenance | Needs more care and fixing. Rising stem types make it easier to add grease to the stem. | Needs less care. It has a simple build. |

| Suitability | Best for sealing tightly, stopping leaks, and pigging jobs. | Good for quick shutoff and controlling flow. Not as good for pigging. |

Note: How the valve works, how much pressure it can take, and how much space it needs help decide which valve is best for each job.

Pros and Cons

When looking at gate valve vs butterfly valve, engineers should think about what is good and bad about each one.

Gate Valve:

- ? Advantages:

- Makes a tight seal and stops leaks. This makes it good for important shutoff jobs.

- Lets flow move easily when open, like a straight pipe.

- Can handle high pressure and high heat.

- Used a lot in petrochemical and refining plants. About 60% of valve orders ask for gate valves.

- ? Disadvantages:

- Not good for changing flow. Opening it part way can cause problems and damage.

- Needs more space to install and is heavier.

- Costs more and needs more fixing and care.

Butterfly Valve:

- ? Advantages:

- Works fast with just a quarter turn.

- Small and light. Good for places with little space.

- Costs less and is easier to fix because it has fewer parts.

- Works well for stopping flow and controlling it in many systems.

- ? Disadvantages:

- Has more flow resistance than gate valves.

- Not as good for stopping all leaks or for pigging.

- Usually works with lower pressure and heat, unless it is a special kind.

Knowing these good and bad points helps engineers pick the right valve. The choice between these industrial valves depends on what the system needs, like pressure, heat, space, and cost.

Gate Valve Basics

What Is a Gate Valve

A gate valve is used to start or stop fluid in pipes. It has a flat or wedge-shaped gate that moves up and down. This gate opens or closes the path for the fluid. When the gate is up, fluid flows straight through. There is very little resistance when it is open. This makes it good for jobs that need full flow. Gate valves are used in oil, gas, power, and chemical plants. These places need a valve that shuts off well.

The gate valve has many parts. Each part does something important. The table below shows these parts and what they do:

| Gate Valve Part | Function |

|---|---|

| Valve Body | Holds the inside parts and lets fluid move between pipes. It is made from strong metals. It connects to pipes in different ways. |

| Bonnet | Covers and supports the inside parts. It gives an opening for the stem. It attaches to the body with threads, bolts, or welding. |

| Gate (Valve Disc) | Moves up or down to let fluid pass or block it. It sits on seats to seal the flow. |

| Stem | Connects the handwheel or actuator to the gate. It turns to lift or lower the gate. |

| Valve Seat | Gives a place for the gate to seal and stop leaks. There are usually two seats, one at each end. |

| Packing | Seals around the stem to stop leaks along the stem. |

Gate valves can block flow from both directions. This makes them good for important shut-off jobs in pipelines.

How Gate Valves Work

Gate valves work by moving a gate up or down inside the valve. When you turn the handwheel, the stem lifts the gate out of the way. This lets fluid flow through. Lowering the gate blocks the path and stops the flow. The opening is as wide as the pipe, so there is little pressure loss when open.

People use gate valves to turn flow on or off. They are not for changing how much fluid flows. If you open a gate valve only part way, it can shake, make noise, or get damaged. That is why engineers say to use gate valves only fully open or fully closed.

Types of Gate Valves

There are different types of gate valves for different jobs. The most common types are:

- Rising Stem Gate Valve: The stem goes up and down with the gate. You can see if it is open or closed. It needs more space above.

- Non-Rising Stem Gate Valve: The stem turns but does not move up or down. It fits in small spaces. You need a marker to know if it is open or closed.

- Wedge Gate Valve: Has a wedge-shaped disc for a tight seal. It works well with thick or dirty fluids.

- Parallel Slide Gate Valve: Has a flat gate that slides between two seats. It is used in places with high pressure and heat, like power plants.

Gate valves can also be different by disc shape, bonnet type, and seat material. Discs can be solid, split, or flexible. Bonnets can be union, bolted, or screwed-in. Seats can be metal or soft, depending on the job. Makers use cast steel, forged steel, stainless steel, or bronze to match what each industry needs.

Picking the right gate valve depends on pressure, heat, space, and what kind of fluid is in the pipe.

Butterfly Valve Basics

What Is a Butterfly Valve

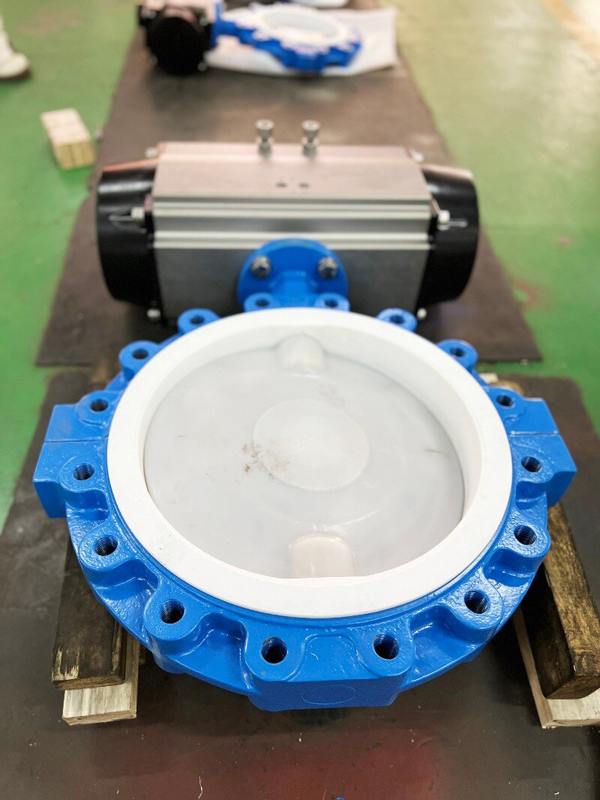

A butterfly valve helps control how liquids or gases move in pipes. Engineers make sure butterfly valves follow strict rules like API 609 and ISO 5752. These rules say what materials, sizes, and seals are needed to keep things safe. Makers often use stainless steel or ductile iron for the valve body. These metals help the valve handle pressure, heat, and chemicals. The main parts are the valve body, disc, stem, and seat. The disc turns inside the body to open or close the flow. The stem links the disc to the handle or actuator. This lets people move the disc exactly how they want. The seat makes a seal between the disc and the body. This stops leaks from happening.

Butterfly valves go through tough tests like pressure and leak checks. These tests make sure the valve works well and does not leak. Outside groups check and certify that each butterfly valve is safe and meets all the rules.

How Butterfly Valves Work

Butterfly valves use a simple quarter-turn to work. When someone turns the handle or actuator, the disc spins 90 degrees inside the valve. When open, the disc lines up with the flow. This lets fluid move through easily. When closed, the disc blocks the path and stops the flow. This design lets people open or close the valve quickly. It also helps control how much fluid moves. Butterfly valves can shut off flow or control it in many systems. People can use hand levers, gears, or automatic actuators. These can be electric, pneumatic, or hydraulic for remote or exact control.

The seat inside the valve makes a tight seal when the disc closes. Makers pick seat materials based on the job. Soft seats are used for low pressure. Metal seats are used for high pressure and heat. This means butterfly valves work well in water plants, chemical factories, and HVAC systems.

Types of Butterfly Valves

Butterfly valves come in different types for different jobs. The most common types are:

| Butterfly Valve Type | Design Characteristics | Applications and Features |

|---|---|---|

| Wafer Type | Fits between two flanges and is held by bolts | Good for small spaces and low to medium pressure; saves space and money |

| Lug Type | Has lugs with threads for bolts around the body | Used when one side needs to be removed without stopping the other side |

| Double Offset (Double Eccentric) | The stem is off-center from the disc and valve center; disc leaves seat fast to avoid too much pressure | Used for high pressure and heat; can have metal seats; lasts longer |

| Triple Offset (Triple Eccentric) | Three offsets stop rubbing between the seat and seal; moves like a cam | Makes a tight seal; has metal seat; safe for fire, high heat, cold, and nuclear jobs |

| Concentric Butterfly Valves | Stem and disc are centered; disc seals by pressing into a soft seat; full friction during use | Good for chemicals, food, coatings, some solids, and rough fluids; soft seat helps reduce wear |

| Metal-Seated Butterfly Valves | Both seat and disc are made of metal | Handles harsh chemicals, high heat, and pressure; strong and seals well |

| Soft-Seated Butterfly Valves | Seat is made of rubber or PTFE | Seals well at low heat and pressure; no leaks; easy to change the seat |

People pick the butterfly valve type based on pressure, heat, and what is flowing. Double and triple offset valves seal better and last longer for tough jobs like oil, gas, or power plants. Wafer and lug types are good for water and HVAC systems. Metal-seated valves work with harsh or rough fluids. Soft-seated valves seal well when things are not too hot or under high pressure.

Picking the right butterfly valve helps things run smoothly, last longer, and follow the rules.

Industry-Specific Applications

Oil & Gas

Typical uses of gate valves in oil & gas

In oil and gas, engineers use gate valves for important shut-off jobs. These valves make a tight seal and let oil flow without blocks. This is needed for crude oil pipes and mainline shut-offs. Gate valves work well with high pressure and heat. They are used where the valve must be all the way open or closed. You see them in block valve stations and emergency shut-off spots. Their design stops clogging, even with thick fluids or slurries. These fluids are common in oil production. Gate valves also lower pressure loss when open. This helps move oil and gas far without wasting energy.

| Aspect | Gate Valve Use in Oil & Gas |

|---|---|

| Main Function | Shut-off, isolation, leak-proof pipelines |

| Pressure Handling | High-pressure, high-temperature systems |

| Flow Path | Full bore, minimal pressure drop |

| Fluid Suitability | Viscous, slurry, and corrosive fluids |

| Operation Frequency | Infrequent, critical operations |

Gate valves must follow rules like API 6D and ASME B16.34. These rules keep people safe and make sure valves work in dangerous places.

Typical uses of butterfly valves in oil & gas

Butterfly valves are used in oil and gas when quick action and saving space matter. Engineers pick butterfly valves for big pipes, tank farms, and systems that open and close a lot. Their quarter-turn design lets them work fast. This is helpful in emergencies or when changing flow. Butterfly valves are lighter and smaller than gate valves. This makes them cheaper to put in and good for tight spots like offshore platforms. Most butterfly valves do not handle very high pressure or heat. But special metal-seated types can work in tough jobs. These valves also help control flow, which is good for mixing or sending oil to different places.

- Butterfly valves must meet safety and performance rules like API 609 and OSHA.

- Metal-seated butterfly valves can take more heat and pressure. This means they can be used in harder oil and gas jobs.

- Operators like butterfly valves for jobs that need lots of opening and closing. They are also easy to fix.

Water & Wastewater Treatment

Gate valve roles in water systems

Water plants use gate valves to shut off main lines and high-pressure pipes. These valves seal tightly and stop leaks in important parts of the system. Gate valves are good for big pipes that carry raw or clean water. Their full-bore design keeps pressure loss low. This saves energy in pump stations. Maintenance teams pick gate valves when they want strong valves that last a long time. Heavy-duty seals and materials that fight rust help gate valves work well in tough water jobs.

Butterfly valve roles in water systems

Butterfly valves are popular in water and wastewater plants because they are small and work fast. People put butterfly valves in tight places like filter rooms and pipe branches. These valves turn quickly with just a quarter turn. This makes them great for changing flow often and for emergency shut-offs. Butterfly valves cost less to put in and fix, which helps city budgets. Their design makes it easy to add automation and connect to control systems. Polymer seals in butterfly valves help stop leaks. Lug-type designs let workers fix one side of the pipe without shutting down everything.

- Butterfly valves work with medium pressure and fast-moving water, up to 6 m/s.

- Their safety features help protect workers in dangerous wastewater jobs.

- It is easier to fix butterfly valves than gate valves, which helps plants run smoothly.

Power Generation

Gate valves in power plants

Power plants use gate valves for important pipes, especially where steady flow and low pressure loss are needed. Gate valves give a clear path for fluid, which keeps flow smooth and clean. Workers use these valves in steam pipes, feedwater lines, and main shut-off spots. Gate valves are strong and can handle the high heat and pressure in power plants. They open and close slowly, which is fine when you do not need to move them often but need them to work every time.

Butterfly valves in power plants

Butterfly valves are used in power plants where fast action and small size are needed. Engineers put butterfly valves in cooling water pipes, extra lines, and tight spaces. The quarter-turn design lets them open and close quickly. This is good for jobs that need lots of cycling or quick response in emergencies. Butterfly valves cost less and are easier to fix, especially in big pipes. They do slow flow more than gate valves. But their speed and small size make them a smart pick for many jobs that are not as critical.

To sum up, picking a gate valve or butterfly valve depends on what each job needs. Safety, following rules, and how the system works all help decide which valve to use in each industry.

Chemical & Petrochemical

Gate valves for chemical processes

Gate valves are very important in chemical plants. Engineers pick these valves when they need strong shut-off. These valves work well with pipes that carry dangerous chemicals. The gate valve design lets fluid move straight through. This helps stop pressure drops and keeps thick fluids from clogging the pipe.

Many chemical jobs need valves that can take high heat and strong chemicals. Makers use stainless steel or special metals for these valves. These metals do not rust and help the valve last longer. Workers use gate valves to shut off main lines and for emergencies. The tight seal stops leaks, which keeps people and the environment safe.

Note: Gate valves in chemical plants must follow strict rules like API 600 and ISO 10434. These rules make sure the valves work well and keep everyone safe.

Butterfly valves for chemical processes

Butterfly valves are popular in chemical plants because they are small and fast. These valves fit in places where there is not much room. They are good when you need to open and close them a lot. Butterfly valves turn only a quarter to open or close. This makes them quick and easy to control.

Makers use many kinds of seats and discs for butterfly valves. Some have PTFE lining to handle strong chemicals. Metal seats work for hot or rough fluids. Workers use butterfly valves in transfer pipes, mixing tanks, and other systems. These valves are light, so they are easy to put in and fix, even in big pipes.

Butterfly valves can be controlled by machines. Many plants use electric or air-powered controls to move these valves from far away. This helps the plant run better and keeps workers safe.

Food & Beverage

Gate valves in food-grade applications

Food plants use gate valves when they need a clean, wide flow. These valves help stop food from building up inside. They are easy to clean. Makers use stainless steel to build food-safe gate valves. The smooth inside keeps germs away.

Workers put gate valves in main lines, ingredient pipes, and cleaning systems. The tight shut-off keeps food safe and stops leaks. Food safety rules from the FDA and 3-A tell how to make and use these valves.

Butterfly valves in food-grade applications

Butterfly valves are used a lot in food plants because they are simple and easy to fix. Their small size fits well in busy areas. Many butterfly valves have smooth finishes and handles that come off quickly for cleaning.

Engineers use butterfly valves in bottling, dairy, and drink mixing. These valves shut off and control flow well. Soft seats made from food-safe rubber help stop leaks and keep food pure.

Tip: Picking the right valve helps food plants stay clean and safe while working fast.

Design and Manufacturing Differences

Design Principles

Core design philosophy of gate valves

Engineers make gate valves to shut off flow tightly. The gate moves up and down inside the valve. This straight movement helps the valve handle high pressure and heat. Gate valves open and close slowly with many turns. This slow action stops water hammer and keeps the system safe. Gate valves are strong and last a long time. People use them when they need to stop flow completely in pipelines.

| Parameter | Gate Valve |

|---|---|

| Operating Mechanism | Linear motion, multi-turn |

| Flow Characteristics | Full-bore, very low pressure loss |

| Sealing Ability | Excellent, tight shut-off |

| Operation Speed | Slow, multiple turns |

| Weight & Size | Heavy, large footprint |

| Typical Applications | On/off isolation, high pressure/temperature |

Core design philosophy of butterfly valves

Butterfly valves work in a different way. The disc sits on a shaft and turns with a quick twist. This lets the valve open or close fast. The disc always stays in the flow, so there is some pressure loss. Butterfly valves are small and light. They fit well in tight spaces. People pick them when they need to open or close flow quickly or control it often. These valves are easy to automate and use many times.

| Parameter | Butterfly Valve |

|---|---|

| Operating Mechanism | Quarter-turn, rotational |

| Flow Characteristics | Disc in flow path, some pressure loss |

| Sealing Ability | Good, but minor leakage possible |

| Operation Speed | Fast, quarter-turn |

| Weight & Size | Light, compact |

| Typical Applications | Throttling, flow regulation, large pipes |

Manufacturing Processes

Key manufacturing steps for gate valves

Making a gate valve takes many careful steps. Workers cast or forge the body from strong metal. They shape the body to the right size. The gate, stem, and seats go inside the body. Each part must fit just right to seal well. The valve gets tested for leaks and pressure before it leaves the factory. Building a gate valve takes longer because it has more parts and is heavy.

Key manufacturing steps for butterfly valves

Butterfly valves are made with a simpler process. The body is cast or molded from lighter materials. The disc is put on the shaft and placed inside the body. A rubber or PTFE seat lines the inside to help seal. There are fewer parts, so assembly is fast. After putting it together, workers test the valve for leaks and pressure. The simple design makes it easy to build and check quality.

Material Selection

Common materials used in gate valves

Gate valves often use stainless steel, carbon steel, or cast iron for the body. The disc can be stainless steel, ductile iron, or bronze. Seats are metal or soft, depending on what flows through. The stem is usually stainless steel or a special alloy to stop rust. The materials chosen affect how well the valve handles pressure, heat, and chemicals. Stainless steel costs more but lasts longer in tough places.

Common materials used in butterfly valves

Butterfly valve bodies can be made from cast steel, aluminum alloy, or plastic. The disc might be stainless steel, ductile iron, or PVC for light jobs. Seats use EPDM, NBR, or PTFE to match the fluid and heat. The stem is often stainless steel or another rust-proof metal. The materials change the valve’s weight, price, and how well it resists chemicals. Plastic butterfly valves are good for low pressure and harsh fluids. Metal ones work better for higher pressure.

Picking the right materials for each valve keeps things safe, helps valves last longer, and saves money.

Complexity and Standardization

Complexity of components and assembly

Gate valves and butterfly valves are different in how hard they are to put together. Gate valves have more moving parts than butterfly valves. They need careful work to make sure everything fits right. Each gate valve has a body, bonnet, stem, gate, seats, and packing. The stem must fit the gate just right, and the seats must seal well. Workers often need special tools and skills to build these valves. It takes longer to put together a gate valve. This means there is a bigger chance for mistakes. Heavy-duty gate valves may need extra steps like welding or pressure tests before leaving the factory.

Butterfly valves are easier to build. Most butterfly valves have a body, disc, stem, and seat. The disc connects right to the stem, so it is faster to put together. With fewer parts, there is less chance for leaks or problems. Workers can build butterfly valves quickly, even big ones. This simple design helps save money and makes production faster. Many companies pick butterfly valves for jobs that need quick delivery and easy setup.

| Valve Type | Number of Main Parts | Assembly Difficulty | Time to Assemble | Risk of Error |

|---|---|---|---|---|

| Gate Valve | 6 or more | High | Longer | Higher |

| Butterfly Valve | 4 | Low | Shorter | Lower |

Note: Simple valves usually mean fewer problems when putting them in or fixing them.

Level of standardization in production

Standardization is very important in the valve market. Gate valves follow many world rules like API, ASME, and ISO. These rules cover size, pressure, and materials. But gate valves come in many shapes and sizes. Not all parts fit between brands. Special features like unique seats or coatings can make standardization harder.

Butterfly valves are more standardized. Many makers use the same sizes and bolt patterns. This means you can swap one butterfly valve for another brand without changing the pipes. Using common materials and sizes helps keep prices low and repairs easy. Standardization also helps with automation, since many actuators fit different butterfly valves.

- Gate valves: More custom choices, parts do not always fit other brands.

- Butterfly valves: More standard, easier to change and automate.

Tip: High standardization helps companies save money and time when fixing or upgrading systems.

Detailed Comparison

Design

Engineers look at both gate valve and butterfly valve designs before choosing. A gate valve has a flat or wedge-shaped gate. This gate moves up and down, not sideways. It moves across the flow of liquid or gas. When the gate is up, it is out of the way. This means nothing blocks the flow. A butterfly valve uses a disk that spins on a shaft. The disk turns 90 degrees to open or close. Even when open, the disk stays in the flow path.

The table below shows the main design differences:

| Design Aspect | Gate Valve | Butterfly Valve |

|---|---|---|

| Structural Design | Flat or wedge-shaped gate moves perpendicular to media flow | Rotating disk mounted on a shaft |

| Flow Control Mechanism | Gate lifts out of flow path for unobstructed media flow | Disk rotates to open/close; disk remains in flow path |

| Pressure Drop | Lower pressure drop when fully open | Higher pressure drop due to disk obstruction |

| Size and Weight | Bulkier and heavier, especially in larger sizes | Compact and lighter |

| Sealing Method | Gate presses against valve seat for tight seal | Disk compresses against a resilient seat |

| Operation Speed | Slower operation due to vertical gate movement | Faster operation due to rotational disk |

| Typical Applications | Isolation requiring full unobstructed flow, pipelines for water, oil, gas | Flow regulation in large pipelines, water treatment, HVAC, chemical processes |

Gate valves are best when you need a tight seal and little pressure loss. Butterfly valves are good when you need to save space and work fast.

Flow Control

Gate valves and butterfly valves control flow in different ways. Gate valves use a straight up-and-down motion. The gate moves all the way out of the flow when open. This means there is almost no blockage. There is very little pressure drop. Gate valves shut off flow very well. They are good for thick fluids and slurries. But they open and close slowly. They should not be used to control flow part way. If you do, the valve can shake and break.

Butterfly valves use a spinning disk to control flow. The disk turns 90 degrees to open or close. The disk always stays in the flow path. This causes a small pressure drop and some swirling. Butterfly valves open and close quickly. They let a lot of fluid move through. But they do not seal as tightly as gate valves. Some leaks can happen, especially if you need zero leaks. Butterfly valves are not good for thick fluids or slurries. They do not control flow as exactly as gate valves.

| Feature | Gate Valve | Butterfly Valve |

|---|---|---|

| Operation Mechanism | Linear motion with gate fully retracting for unobstructed media flow | Rotary motion with disk at pipe center, aligns parallel to flow when open |

| Flow Obstruction & Pressure Drop | Zero obstruction and minimal pressure drop when fully open; higher pressure drop when partially open | Minor but unavoidable pressure drop and slight turbulence due to disk in flow path |

| Flow Control Accuracy | High accuracy with tight shut-off; ideal for complete isolation and viscous fluids/slurries | Less accurate for tight shut-off; some leakage possible; not suitable for viscous fluids/slurries |

| Throttling Capability | Not recommended for throttling; partial opening causes damage | Not ideal for long-term throttling; less precise flow control |

| Operation Speed | Slower operation due to linear motion | Quick operation due to 90-degree rotary motion |

| Typical Applications | Oil, gas, chemical plants requiring tight shut-off and handling viscous fluids | HVAC, water treatment, large diameter pipes requiring frequent operation |

Gate valves give tight shut-off and good control, even with hard-to-move fluids. Butterfly valves work fast and are good for jobs that do not need perfect sealing.

Pressure and Temperature

Engineers must think about pressure and temperature when picking a valve. Gate valves can handle higher pressure and more heat than butterfly valves. For example, some bronze gate valves can take up to 300 PSI for cold water and 150 PSI for steam. They work in temperatures from -20°F to 406°F. Cast steel gate valves come in different classes for even higher pressure.

Butterfly valves are better for lower pressure and medium heat. A 4” or 5” butterfly valve with a nitrile seat can take up to 200 PSI and work from -20°F to 200°F. Some special butterfly valves can handle more pressure and heat, but these are not common.

| Valve Type | Size/Model | Pressure Rating | Temperature Range |

|---|---|---|---|

| Butterfly Valve (Dixon) | 4” and 5” | 200 PSI | Nitrile seat: -20°F to 200°F |

| 8” | 175 PSI | FKM seat: 0°F to 200°F | |

| Domestic Bronze Gate Valve | N/A | 300 PSI CWP, 150 PSI steam | -20°F to 406°F |

| Cast Steel API Gate Valve | Classes 150, 300, 600 | Class 150, 300, 600 (varies) | N/A |

| Forged Steel Globe Valve | N/A | Up to 1975 PSI | Up to 800°F |

- Gate valves seal tightly and work well in high-pressure, high-heat places.

- Butterfly valves open and close fast and cost less, but cannot take as much pressure or heat.

- Engineers should pick the right valve for the system’s pressure and temperature to keep things safe and working well.

Size and Weight

Engineers look at size and weight when picking valves. Gate valves are big and heavy. The body, bonnet, and gate make them weigh more. Large gate valves can be hundreds of pounds. Workers need machines to lift and put them in place. These valves need lots of room in the pipe. Rising stem types need even more space above.

Butterfly valves are small and light. The disc and body use less metal. Even big butterfly valves weigh less than gate valves. Workers can fit butterfly valves in small spaces. Their light weight makes moving and shipping easier. Many companies pick butterfly valves for big pipes. They save space and cost less to install.

| Valve Type | Typical Size Range | Weight (for 12″ valve) | Space Needed | Installation Difficulty |

|---|---|---|---|---|

| Gate Valve | 2″–60″ | 300–500 lbs | Large | High |

| Butterfly Valve | 2″–72″ | 80–150 lbs | Compact | Low |

Tip: Lighter valves help workers finish jobs faster and save money.

Sealing and Leakage

How well a valve seals is very important. Gate valves use a gate that pushes on seats. This makes a tight seal. Engineers use gate valves when no leaks are allowed. The valve can stop flow both ways. Gate valves are used for important shut-off jobs.

Butterfly valves use a disc that turns and presses on a seat. The seal depends on the seat and how hard the disc pushes. Soft-seated butterfly valves seal well in low pressure. Metal-seated butterfly valves work with higher pressure but may leak a little. Butterfly valves do not seal as tightly as gate valves. Some leaks can happen, especially with high pressure or rough fluids.

- Gate valves: Seal very well, almost no leaks, good for dangerous fluids.

- Butterfly valves: Seal well in low pressure, may leak a little in hard jobs.

Note: If you need no leaks, gate valves work better than butterfly valves.

Operation Speed

How fast a valve works matters for many jobs. Gate valves need many turns to open or close. The gate moves up or down slowly. This slow movement stops water hammer but takes longer. Workers use gate valves when speed is not needed.

Butterfly valves work with one quick turn. The disc spins 90 degrees to open or close. This fast action lets workers shut off or change flow quickly. Many places use butterfly valves for emergencies or automatic systems. Fast valves help keep people and machines safe.

| Valve Type | Operation Method | Time to Open/Close | Suitable Applications |

|---|---|---|---|

| Gate Valve | Multi-turn | Slow (10–30 sec) | Isolation, infrequent use |

| Butterfly Valve | Quarter-turn | Fast (1–5 sec) | Emergency shut-off, frequent use |

Fast valves can make factories safer and help things run better.

Installation Space

Engineers sometimes do not have much room to put in valves. Gate valves need a lot of space because they are long. They also need extra room above for the stem to move up and down. Rising stem gate valves need even more space at the top. This makes it hard to install them where the ceiling is low or pipes are close together.

Butterfly valves are much smaller. Their thin bodies fit between pipes easily. The disc turns inside the valve, so you do not need extra space above or below. This means butterfly valves can go in tight places where gate valves cannot fit.

| Valve Type | Space Needed for Installation | Typical Use Case |

|---|---|---|

| Gate Valve | Large (especially vertical) | Open areas, underground mains |

| Butterfly Valve | Compact, minimal clearance | Tight spaces, retrofits, skids |

Tip: If there is not much space, butterfly valves are a better choice. Their small size helps save money on putting them in and makes them popular in factories.

Cost

Cost is very important when picking valves for big jobs. Gate valves cost more than butterfly valves, especially if they are big. They are more expensive because they are built with more parts and heavy metal. It also takes longer to make them. Putting in gate valves costs more because they are heavy and hard to move.

Butterfly valves are cheaper to buy and put in. They have a simple shape and use less metal and fewer parts. Workers can put them in fast, so labor costs are lower. For big pipes, the price gap is even bigger. Many companies pick butterfly valves when they need to save money.

Key cost factors:

- Gate Valve: Costs more to buy, put in, and fix, especially if it is big.

- Butterfly Valve: Cheaper to buy and put in, good for big pipes.

Note: Always think about the total cost, not just the price to buy. This means looking at what it costs to put in and fix later.

Maintenance

Gate valves and butterfly valves need different care. Gate valves have more parts that move, like the stem, gate, and seats. These parts can break or rust after some time. Workers must check for leaks, change the packing, and sometimes take out the valve to fix it. Gate valves are heavy, so fixing them takes longer and needs special tools.

Butterfly valves have fewer parts and are easier to fix. The main parts that wear out are the disc and seat. Workers can often change the seat without taking out the valve. This makes butterfly valves faster and easier to fix. They are light, so repairs are not as hard.

Maintenance comparison:

- Gate valves: Need more checks, are harder to fix, and take longer to repair.

- Butterfly valves: Easy to look at, quick to fix, and do not stop work for long.

Checking valves often keeps them safe and working longer. Many companies like butterfly valves for jobs where they need fast and easy repairs.

Application Guidance

High Pressure Systems

Engineers have to pick the right valve for high pressure jobs. The guide says some valves work better in these tough places. Gate valve is a top pick because it seals tight and handles high pressure well. Other valves like globe, plug, needle, and ball valves are also used. Makers change these valves for high pressure by adding special stems and packing. Shutoff parts help stop leaks.

The valve body and seat must be made from strong materials. Metals like 316 stainless steel, monel, and Inconel do not rust and stay strong when hot. Welded and flanged ends stop leaks in big pipes. Threaded ends are good for small pipes. Rules like MSS SP-61 and ANSI 70-2 tell how much a valve can leak. These rules help engineers pick the right valve.

Gate valve works well in high pressure jobs. It seals tight and can take very hard conditions. Butterfly valve is not used much here, but some special ones can take medium pressure. Most of the time, gate valve is the best choice for high pressure.

Tip: Always check if the valve can take the right pressure and if the material matches the job. This helps stop leaks and keeps things safe for a long time.

Large Diameter Pipes

Big pipes are hard to work with in factories. The guide shows how gate valve and butterfly valve work in these pipes. Tests show gate valve is good when you need a tight seal and do not open or close it often. It is best for high pressure and flow in both directions. Butterfly valve is better when you need to open and close fast, control flow, and save space.

| Valve Type | Application in Large Diameter Pipes | Key Performance Points | Cost and Installation Considerations |

|---|---|---|---|

| Gate Valve | Good for tight sealing and not opening often; works with high pressure and flow both ways. | Seals well; almost no leaks; slow to use; not good for quick shutoff or changing flow. | Costs more as it gets bigger; takes up more space; can be used by hand or by machine. |

| Butterfly Valve | Best for big pipes that need fast use, flow control, and saving space. | Light; opens and closes fast; good for changing flow and emergency stops; can take medium pressure. | Cheaper for big pipes; easy to put in; small size. |

Gate valve lets all the flow go through and does not block the pipe when open. It can take high pressure and does not leave stuff behind. But it is slow and costs more when big. Butterfly valve is light and works fast. It is good when space and price are important. It may cause some pressure drop and swirling, but it is easy to put in.

Fast Operation Needs

Some jobs need valves that open and close very fast. The guide says butterfly valve is best for these jobs. Its quarter-turn design lets it work quickly in emergencies or when used a lot. People can use a handle or a machine to move butterfly valve from far away. This makes it great for systems that need speed and to work all the time.

Gate valve is slow because you have to turn it many times. It is better for jobs where speed does not matter and sealing is more important. Butterfly valve shuts off fast and is easy to control. It is used in water plants, HVAC, and chemical factories where quick action keeps things safe.

Note: For emergencies or jobs that need fast moves, butterfly valve is quick and works well. Gate valve is better when you need a tight seal and strong valve, not speed.

Space-Constrained Installations

Engineers sometimes have trouble putting valves in small spaces. Many factories have pipes close together or small rooms with little space. In these places, picking the right valve is very important.

Butterfly valves are better when there is not much room. Their thin bodies fit between pipes easily. The disc turns inside the valve, so you do not need extra space above or below. Workers can put butterfly valves near walls or other machines. This is why they are used a lot in water plants, HVAC, and chemical factories where space is tight.

Gate valves need more space to fit. If the stem rises, you need room above for it to move up. Even if the stem does not rise, the valve is still long and big. Large gate valves are heavy and hard to move in small areas. Workers might need special tools or lifts to put them in. This makes the job take longer and cost more.

The table below shows how each valve works in small spaces:

| Feature | Gate Valve | Butterfly Valve |

|---|---|---|

| Body Length | Long | Short |

| Vertical Clearance | High (rising stem) | Low |

| Weight | Heavy | Light |

| Ease of Installation | Difficult in tight areas | Easy in tight areas |

| Typical Applications | Underground mains | Skids, compact pipe racks |

Tip: If there is not much space, butterfly valves save time and money. Their small size also makes fixing them later much easier.

Engineers often pick butterfly valves for old plants that need new parts. These valves are easy to swap in without changing the pipes a lot. Their light weight also helps keep workers safe when putting them in.

Choosing the Right Valve

Decision Checklist

Picking the right valve for a factory system takes careful thought. Engineers should look at these important points before choosing:

- Fluid Characteristics

Check if the fluid is thick, hot, under pressure, or can cause rust. Thick or rough fluids work better with a gate valve. Clean or slightly rusty fluids are fine for a butterfly valve. - Flow Requirements

Decide if you need a tight shut-off or want to change flow often. Gate valve seals well and is best for fully open or closed use. Butterfly valve is good for quick changes and lots of use. - Operating Conditions

Think about shaking, pressure changes, and temperature swings. Gate valves work well with high pressure and heat. Butterfly valves do well in normal conditions. - Material Compatibility

Make sure the valve’s material matches the fluid. Use stainless steel or special metals for strong chemicals. - Space and Installation

Look at how much room you have. Gate valves need more space and are heavy. Butterfly valves are small and fit in tight spots. - Operation Speed

For emergencies or fast moves, butterfly valve is best because it turns quickly. Gate valves take longer to open or close. - Maintenance and Reliability

Pick valves from trusted brands. Butterfly valves are easier to fix and keep working. Gate valves need more checks, especially if used to change flow. - Cost and Budget

Compare all costs, like buying, installing, and fixing. Butterfly valves usually cost less, especially for big pipes. - Regulatory Compliance

Make sure the valve meets safety and quality rules.

Tip: Always pick the valve that fits the job’s needs. This helps stop mistakes and keeps things running smoothly.

Industrial Examples

Example 1: High-Pressure Steam Line in a Power Plant

A power plant needs a valve for a steam pipe with high pressure and heat. The system must not leak. Engineers pick a gate valve because it seals tight and handles tough jobs. The valve does not need to move fast.

Example 2: Water Distribution in a Municipal Plant

A city water plant upgrades its main pipes. Space is tight, and valves must open and close quickly for repairs. The team picks butterfly valves. These fit between pipes, cost less, and work fast.

Example 3: Chemical Processing Facility

A chemical plant deals with slightly rusty fluids at medium pressure. The process needs lots of flow changes. Engineers use butterfly valves with PTFE seats. These resist rust, make flow easy to control, and cut down on fixing time.

Example 4: Oil Pipeline Isolation

An oil pipeline needs a valve to block sections for repairs. The fluid is thick and under high pressure. The team picks a gate valve. It seals both ways and keeps pressure loss low, which is important for safety.

These examples show that picking the right valve helps systems work better and saves money.

Gate valves are best when you need to stop flow in high-pressure jobs. Butterfly valves are good if you need to open and close things fast. They also fit well in small spaces and cost less. Every factory or plant has its own needs for valves. Engineers should look at the valve’s details and talk to experts before picking one. Picking the right valve helps keep everyone safe and makes the system work better.

FAQ

What is the main difference between a gate valve and a butterfly valve?

A gate valve blocks flow with a gate. A butterfly valve uses a disc that spins. Gate valves are best for stopping leaks. Butterfly valves work fast and fit in tight spots.

Can butterfly valves handle high-pressure applications?

Most butterfly valves work with low or medium pressure. Some special ones can take higher pressure. But gate valves are still better for high-pressure jobs.

Which valve type is easier to maintain?

Butterfly valves are light and have fewer parts. This makes them easy to check and fix. Gate valves are heavier and have more parts, so they take longer to repair.

Are gate valves suitable for flow regulation?

Gate valves should not be used to control flow. They work best when fully open or closed. Using them part way can break them and make them last less time.

When should engineers choose a butterfly valve?

Engineers pick butterfly valves for quick use and small spaces. They also save money. Butterfly valves are good for water, HVAC, and chemical plants.

How does valve material affect performance?

The valve’s material helps it fight rust, heat, and pressure. Stainless steel and special metals last longer in tough places. The right material keeps the valve safe and working well.

Do both valves meet industry standards?

Makers build both valves to follow rules like API, ASME, and ISO. These rules help keep valves safe and make sure they work in factories.