Choosing the right valve is very important for efficient system operation and cost savings on repairs. When comparing globe valve vs gate valve, engineers in factories consider how each controls flow and pressure to prevent issues. Globe valves offer excellent flow control but cause a higher pressure drop, while gate valves are ideal for stopping flow with minimal pressure loss. Maintenance workers also evaluate other options such as butterfly valves, ball valves, and pneumatic control valves, assessing which valves are more cost-effective and easier to maintain.

Key Takeaways

- Globe valves are good at controlling flow. They help adjust how much fluid moves in a system.

- Gate valves are best for turning flow fully on or off. They do this with almost no pressure loss.

- Globe valves make fluid change direction inside them. This causes a bigger drop in pressure.

- Gate valves have a straight path for fluid to move. This keeps pressure loss low when open.

- Globe valves close tightly. They work well with high pressure, heat, and clean fluids.

- Gate valves work better with thick or dirty fluids. They let fluid move both ways.

- Globe valves are easier to fix where they are used. This saves time and money on repairs.

- Picking the right valve depends on what you need for flow, fluid type, pressure, and fixing.

Globe Valve vs Gate Valve Overview

Globe Valve Basics

A globe valve is a type of linear motion valve. Engineers use it to start, stop, or control how much fluid moves. Inside, there is a disc that moves up and down with the flow. This helps control the speed and direction of the fluid. The fluid path inside a globe valve bends, often in a Z or T shape. Because of this, the pressure drops more than in other valves. Globe valves seal tightly, so they work well with high pressure, high heat, or thick fluids. Maintenance workers like the top-entry design. It makes it easy to reach the inside parts.

Gate Valve Basics

A gate valve is also a linear motion valve. People use it mostly to open or close the flow all the way. Inside, it has a simple disc that moves across the flow. When open, the gate valve lets fluid go straight through. This means there is very little pressure drop. Gate valves are good when you need low flow resistance and fluid can move both ways. The body is usually shaped like a rectangle or wedge. Gate valves need more space above to install. They are not good for controlling or slowing down flow.

Core Functions

Globe valves and gate valves do different jobs in fluid systems. Globe valves are best for changing flow speed and direction. You can set them halfway open for careful control. This is why globe valves are used for control jobs. Gate valves are made to block or allow flow only. They work best when fully open or closed. Gate valves cannot handle pressure if left partly open. They are not used to control flow. The disc in a gate valve moves across the flow, so it does not block much when open.

Note: Globe valves and gate valves may look alike, but they work differently. Globe valves are good for controlling flow and sealing tightly. Gate valves are best for blocking flow with little pressure loss.

Below is a table that shows the main design and function differences:

| Feature | Globe Valve | Gate Valve |

|---|---|---|

| Primary Use | Start, stop, and control flow | Start or stop flow only |

| Internal Structure | Complex, changes flow direction and controls flow | Simple, open space when on |

| Sealing Surface | Strong seal from inside valve core | Seal on the disc surface |

| Pressure Drop | High, because flow changes direction | Low, straight path |

| Flow Directionality | One-way | Two-way |

| Throttling Capability | Good for controlling flow | Not good for controlling flow |

| Application | High heat, pressure, or thick fluids | Blocking flow, low pressure drop needed |

The table shows the big differences between globe valves and gate valves. Globe valves are better for controlling flow. Gate valves are better for blocking flow with little resistance.

Design Differences

Internal Structure

A globe valve has a more complicated inside. The valve core moves up and down. This makes the fluid turn around inside, sometimes even a full circle. Because of this, you can control the flow very well. But it also makes it harder for the fluid to move. All the main parts are inside the valve body. This helps keep them safe from damage.

A gate valve is much simpler inside. The gate or disc moves straight up and down. Fluid goes right through the valve body. Most parts are at the top of the valve. This makes fixing it easier. The straight path means fluid moves easily. Gate valves work best when fully open or closed.

| Aspect | Globe Valve | Gate Valve |

|---|---|---|

| Internal Structure | Complex; core moves in a rising stem, causing flow to change direction (often 180° turn). | Simple; gate or disc moves straight up/down; straight flow path. |

| Flow Path | Flow changes direction, causing higher resistance. | Straight flow path, resulting in lower resistance. |

| Component Location | Components contained within the valve body. | Most components located on top of the valve body. |

| Flow Characteristics | Suitable for throttling and flow control; higher resistance. | Designed for fully open or closed positions; low resistance; not for throttling. |

Note: The globe valve’s complex inside lets you control flow well. The gate valve’s simple design keeps pressure drop low.

Body and Materials

Both globe valves and gate valves can be made from many materials. Some common ones are stainless steel, carbon steel, bronze, iron, and PVC. These materials make the valves strong and help them last longer. They also stop rust and work with different fluids. The material you pick depends on the fluid, pressure, heat, and if you need chemical safety.

- Stainless steel is strong and does not rust.

- Carbon steel is tough and good for high pressure.

- Bronze and iron are used for water and low pressure.

- PVC is best for fluids that are not hot or harsh.

Globe valves and gate valves often use the same materials. This is because they are used in similar places. Picking the right material helps the valve last and stay safe.

Sealing Mechanisms

Sealing is very important for how well a valve works. A globe valve uses a small, special sealing surface on its core. This makes a tight seal, even when pressure is high. It is great for stopping leaks.

A gate valve seals on the side of the gate plate. It works well with clean fluids and not too much pressure. But the seal can wear out faster if used a lot or with dirty fluids. This can cause leaks over time.

| Feature | Globe Valve | Gate Valve |

|---|---|---|

| Sealing Efficiency | Superior, tight and reliable seal minimizing leakage risk even under high pressure | Good sealing with clean fluids under moderate pressure but prone to degradation and leakage over time, especially with frequent use or contaminated media |

Gate valves have a wedge-shaped gate. This helps them cut through thick or dirty fluids. They can handle slurries, thick liquids, and fluids with bits in them. Knife valves, a type of gate valve, are best for these jobs. Globe valves are better for controlling flow and stopping leaks. They do not work as well with thick or dirty fluids.

Tip: Pick a globe valve if you need to control flow and stop leaks. Use a gate valve if you need to fully block flow, especially with thick or dirty fluids.

Operation and Flow

Flow Control

Engineers pick globe valves or gate valves by how they control flow. A globe valve has a disc that moves up and down. This lets you control how much fluid goes through. You can open it a little or a lot. This is good for changing the flow speed. Globe valves are great for throttling.

A gate valve works best for turning flow on or off. Its disc moves across the path of the fluid. When open, fluid moves easily with almost no block. Gate valves do not work well if left partly open. The disc can shake and wear out fast. This may cause leaks or break the valve. So, engineers use gate valves to stop or start flow, not to control it.

The table below shows how each valve controls flow:

| Feature | Globe Valves | Gate Valves |

|---|---|---|

| Flow Regulation Ability | Controls flow well with a disc that moves up and down; good for changing flow speed | Not made for flow control; best for full open or closed; can break if left partly open |

| Suitability | Best for changing flow in tough systems with high pressure or thick fluids | Best for stopping or starting flow; not strong if left partly open |

| Operational Concerns | Can stay partly open without breaking; helps slow changes in flow | Should not stay partly open; can break and leak; may cause water hammer |

Tip: Pick a globe valve if you need to change flow speed. Use a gate valve if you only need to turn flow on or off.

Pressure Drop

Pressure drop means how much pressure is lost as fluid moves through a valve. The shape of the valve changes how much pressure is lost.

- Globe valves make fluid turn inside, so pressure drops more. Even when open, globe valves lose more pressure than other valves.

- Gate valves let fluid go straight through. This means very little pressure is lost when open. Gate valves are best if you want to keep pressure loss low.

Think about pressure drop when picking a valve. If you need to control flow and can handle some pressure loss, use a globe valve. If you need to keep pressure loss very low, use a gate valve.

Directionality

Directionality means if fluid can move one way or both ways through a valve. This changes how you put the valve in your system.

A globe valve only lets fluid go one way. There are arrows on the valve to show which way fluid should go. This helps the valve seal tight and keeps parts safe. If you put it in backwards, it might leak or not work well.

A gate valve lets fluid move both ways. There is no right or wrong way to put it in. This makes it easy to use in many pipe setups.

The table below shows direction and flow resistance for both valves:

| Feature | Gate Valve | Globe Valve |

|---|---|---|

| Flow Direction | Works both ways; no special direction needed. | Must follow arrows for correct flow direction. |

| Flow Resistance | Has very little resistance and almost no pressure drop when open. | Makes fluid lose more pressure because of its shape. |

Note: Always look for arrows before putting in a globe valve. Gate valves can go in any way and still work.

Globe vs Gate Valve: Applications

Typical Uses

Engineers look at globe and gate valves for different jobs. Globe valves are good when you need to control flow carefully. You can open a globe valve partway without breaking it. This helps change how fast things move in pipes. People use globe valves for steam, water, or chemicals. They work well when you need a tight seal and exact control.

Gate valves are used to turn flow on or off. They work best when fully open or closed. If you leave a gate valve partway open, it can get damaged. Gate valves are found in water pipes, oil and gas lines, and fire systems. They are picked when you want little pressure loss.

Tip: Use a globe valve if you need to change flow often. Pick a gate valve if you only need to open or close it for a long time.

| Feature/Aspect | Globe Valves | Gate Valves |

|---|---|---|

| Throttling and Flow Regulation | Good for changing flow; can be partly open safely; best for control | Not good for changing flow; can break if left partly open |

| Application Preference | Best where careful flow and safety matter most | Best for turning flow on or off with little pressure loss |

Media Suitability

Choosing between globe and gate valves depends on what flows inside. Globe valves work best with clean fluids like steam or treated water. They do not work well with thick, sticky, or dirty fluids. Dirt or thick stuff can hurt the seal inside a globe valve. People do not use globe valves for thick or dirty fluids.

Gate valves can handle more types of fluids. They work with clean water and also with thick or dirty fluids. Gate valves are used in oil pipes, wastewater, and places with fluids that are not clean.

- Globe valves: Best for clean things like steam or treated water.

- Globe valves: Not good for thick or dirty fluids.

- Gate valves: Work with clean, thick, or dirty fluids.

- Gate valves: Used in oil, gas, and water pipes with tough fluids.

Industry Examples

Many jobs need either globe or gate valves. Power plants and chemical factories use globe valves to control steam and chemicals. Globe valves help stop leaks and let you change flow easily. Water plants and building cooling systems use globe valves for the same reasons.

Gate valves are used in oil and gas pipes, water systems, and ships. Their simple shape lets lots of fluid move with little pressure loss. Ships use special gate valves that save space and shut off flow well.

- Power plants: Globe valves control steam and high-pressure fluids.

- Chemical plants: Globe valves handle dangerous or harsh fluids.

- Oil and gas: Gate valves shut off pipes and work with thick fluids.

- Water systems: Gate valves control main pipes and networks.

- Ships: Gate valves save space and shut off flow on board.

Note: Pick the right valve by thinking about what flows inside, the pressure, the heat, and if you need to control or just stop the flow.

Globe Valve vs Gate Valve: Comparison Table

Key Differences

System designers look at globe valve and gate valve to see which works best. These valves have different designs, so they work in different ways. The table below shows the main differences:

| Technical Aspect | Globe Valve | Gate Valve |

|---|---|---|

| Function | Designed for throttling and precise flow control | Primarily for flow isolation, not flow control |

| Flow Control Capability | Excellent for regulating flow | Not suitable for flow control |

| Closure Element | Uses a disc or plug | Uses a flat gate or wedge-shaped gate |

| Pressure Drop | Moderate to high pressure drop when partially closed | Low pressure drop when fully open |

| Shut-Off Capability | Excellent when fully closed | Excellent when fully closed |

| Leakage Prevention | Effective but can sometimes leak | Very effective, can achieve zero leakage |

| Flow Isolation | Less efficient for isolation | Ideal for complete flow isolation |

A globe valve has a more complex inside. Its disc moves up and down to control how much fluid goes through. This lets you change the flow very carefully. A gate valve is simpler inside. Its gate moves up or down to block or let fluid pass. This makes it good for stopping flow, but not for changing flow speed. Engineers pick globe valves when they need to adjust flow. They use gate valves when they want to stop flow with little pressure loss.

Tip: Think about what you need most—controlling flow or stopping it. Globe valves are best for changing flow. Gate valves are best for blocking flow and keeping pressure drop low.

Key Similarities

Even though they are different, globe valve and gate valve have some things in common. Both are multi-turn linear valves. This means you turn them many times to open or close them. The table below shows what they share:

| Feature/Aspect | Globe Valve | Gate Valve |

|---|---|---|

| Operation Type | Multi-turn linear valve | Multi-turn linear valve |

| Flow Obstruction Mechanism | Uses a globe-shaped disc moving linearly | Uses a plate-like barrier moving linearly |

| Primary Function | Start, stop, and throttle flow | Start and stop flow (throttling less effective) |

| Typical Industrial Use | Wastewater plants, cooling water, process plants | Wastewater plants, power plants, process plants |

| Shut-off Capability | Good shut-off and throttling capabilities | Primarily for blocking flow, less effective for throttling |

| Head Loss When Open | Higher pressure drop | Lower head loss |

| Relevance to System Design | Linear multi-turn operation aids control precision and actuation considerations | Linear multi-turn operation aids control precision and actuation considerations |

Both valves work by moving a part inside to block or let fluid pass. You can find both in places like water plants and factories. Their multi-turn design helps you control them more exactly. Even though each has its own strengths, both are strong and reliable for many jobs.

Note: Both valves can shut off flow well and are built to last. Their design helps system designers get accurate control and dependability.

Design and Manufacturing Standards

Relevant International Standards

Valve makers must follow important world rules for safety and quality. Three big groups make these rules: API, ASME, and ISO. Each group gives special instructions for globe valves and gate valves.

API (American Petroleum Institute) standards for gate and globe valves

API rules are for oil and gas work. They talk about how to design, build, check, and test valves. For example, API 600 is for bolted bonnet steel gate valves. API 602 is for small carbon steel gate valves. API 603 is for gate valves that do not rust. API 15761 covers small steel gate, globe, and check valves. API 598 explains how to check and test valves. API 607 and API 6FA are about fire tests. These rules help keep valves safe in hard jobs.

ASME (American Society of Mechanical Engineers) codes

ASME rules help make valves safe and strong. ASME B16.34 is about valves with flanged, threaded, or welded ends. It talks about pressure, materials, and size. ASME B16.10 tells how long valves should be from end to end. This helps when putting valves in pipes. These rules make sure valves fit and can handle the right pressure.

ISO (International Organization for Standardization) guidelines

ISO rules are used all over the world. ISO 6002 and ISO 12149 are for bolted bonnet steel gate and globe valves. ISO 10434 and ISO 15761 also talk about design and testing. These rules help companies everywhere make safe valves that work together.

| Standard Type | Standard Code(s) | Description |

|---|---|---|

| API | API 600, API 602, API 603, API 15761, API 598, API 607, API 6FA | Steel gate valves, compact carbon steel gate valves, corrosion-resistant valves, inspection, and fire testing |

| ASME | ASME B16.34, ASME B16.10 | Flanged, threaded, and welding end valves, face-to-face dimensions |

| ISO | ISO 6002, ISO 12149, ISO 10434, ISO 15761 | Bolted bonnet steel gate and globe valves, design, and testing |

Testing and Certification Requirements

Valve makers must test and approve every valve before it is used. These steps show the valve can work in real life.

Pressure and leakage testing procedures

Makers do many tests:

- Shell Test: Checks if the valve body leaks under pressure.

- Backseat Test: Makes sure the backseat seal works when closed.

- Low-Pressure Closure Test: Checks if the valve seals at low pressure.

- High-Pressure Closure Test: Checks if the valve seals at high pressure.

- Double Block and Bleed Test: Tests if the valve can block and release trapped fluid.

- Visual Examination: Looks for problems and checks the material.

Material traceability and documentation

Every valve needs papers that show what it is made of and how strong it is. Special tests like ultrasonic or magnetic checks look for hidden problems. These records help track each part back to where it came from.

Third-party certification processes

Outside groups sometimes check valves for extra safety. Certifications like ISO 9001, CE, or API monogram show the valve meets tough rules. For special jobs, like nuclear or ships, valves may need more checks from groups like ABS or DNV.

Compliance and Application Impact

How standards affect valve selection for different industries

When companies pick valves, they want ones that meet world rules. These rules make sure the valve can handle the job’s pressure, heat, and fluid. Oil and gas companies need valves that pass API and ASME tests. Power plants and chemical factories use ISO and ASME rules for safety.

Implications for safety, reliability, and regulatory compliance

Following these rules means valves are safer and last longer. Certified valves help stop leaks, breaks, and accidents. Standard sizes and checks make fixing valves easier and help companies follow the law. Outside certifications give extra trust, especially for important systems.

Tip: Always check if a valve meets world rules before using it in important places. This keeps things safe, reliable, and working well.

Material and Pressure Differences

Material Options

Manufacturers use many materials to make globe valves and gate valves. The most common metals are stainless steel, cast iron, alloy steel, and forged steel. Stainless steel does not rust and works in tough places. Cast iron is strong and cheap for water and low-pressure jobs. Alloy steel and forged steel are very tough and handle high pressure. Some valves use bronze or brass for plumbing and boats. Plastic valves like PVC cost less but do not last as long as metal ones. Metal valves are best for hard jobs because they are strong and last a long time. The best material depends on the fluid, heat, and pressure in the system.

Tip: Always pick a valve material that matches the fluid and system. This helps stop leaks or damage.

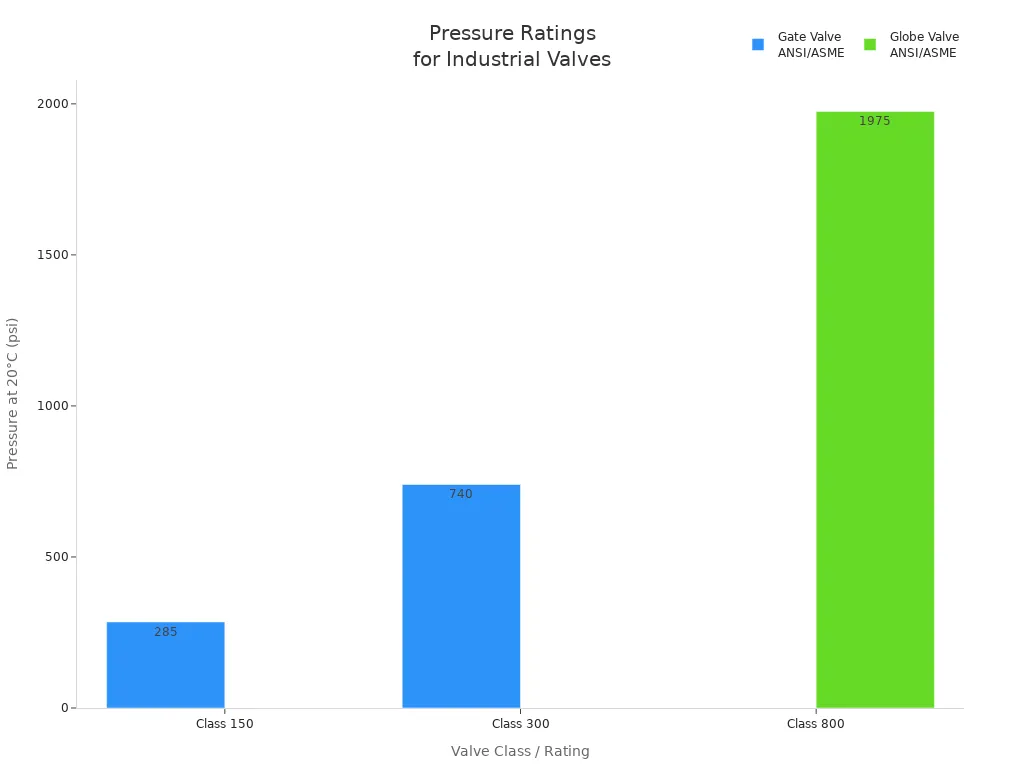

Pressure Ratings

Pressure rating shows how much pressure a valve can take. This number changes with the valve’s material and design. Gate valves and globe valves follow rules like ANSI/ASME and API. These rules set pressure classes like Class 150, 300, 600, and 800. For example, a bronze gate valve in Class 150 can take up to 300 PSI at room temperature. Forged steel globe valves in Class 800 can take up to 1975 PSI. Pressure ratings go down when it gets hotter, so engineers check both pressure and heat limits.

| Valve Type | Pressure Class(es) | Pressure Rating (psi) | Temperature Range (°F/°C) | Standards Referenced |

|---|---|---|---|---|

| Domestic Bronze Gate Valve | Class 150 | 300 PSI CWP | -20°F to 406°F (-29°C to 208°C) | ASME B1.20.1 |

| Cast Steel API Gate Valve | Classes 150, 300, 600 | N/A | N/A | API 600, ASME B16.5, B16.10 |

| Forged Steel Globe Valve | Class 800 | 1975 PSI | Up to 800°F (427°C) | ASTM A105, ANSI B120.1 |

| Bellows Sealed Globe Valve | Classes 150, 300, 600 | N/A | N/A | ASME B16.34, MSS SP-117 |

Engineers use charts to compare pressure ratings for different valves and classes.

Material-Pressure Relationship

The link between material and pressure rating is very important for safety. Pressure rating tells the highest pressure a valve can take. If the pressure goes too high, the valve can break and cause danger. The material you pick affects how well the valve works over time. For example, stainless steel does not rust and stays strong when hot. Cast iron is good for low pressure but can crack if stressed. Engineers also think about the fluid type. Some chemicals can eat away at some metals, so picking the right material stops leaks and damage.

- Pressure ratings get lower as temperature goes up because materials get weaker.

- Each valve part, like the body, disc, and seat, needs the right material for the job.

- Rules like API and ASME say trims and seals must resist rust and wear.

- Temperature-pressure tables help engineers choose the right valve.

- Using the wrong material or pressure rating can cause leaks, cracks, or even system failure.

Note: Always check both the material and pressure rating before picking a valve. This keeps the system safe, reliable, and working for a long time.

Choosing a Valve

Selection Factors

Engineers think about many things when picking a valve. They look at what the valve will do, how much it slows down flow, how hard it is to use, and how to put it in. The table below shows how globe valves and gate valves are different:

| Factor | Globe Valve | Gate Valve |

|---|---|---|

| Intended Function | Good for shut-off and flow regulation | Best for full shut-off (open/close only) |

| Flow Resistance | Higher (3-5 times more than gate valve) | Minimal when fully open |

| Operating Effort | Needs more effort due to short stroke | Easier when fully open |

| Throttling Suitability | Excellent for throttling and frequent use | Not recommended for throttling |

| Installation Direction | Must follow flow arrow | No direction needed, works both ways |

| Sealing Effectiveness | Tight sealing with stem torque | Sealing relies on gate pressing seat |

| Maintenance & Wear | Less wear on sealing surfaces | More friction and wear near closed position |

| Flow Path | Cylindrical, changes direction | Straight path when open |

Tip: If you need to change flow often or control it closely, pick a globe valve. If you just want to turn flow on or off with little slowing, use a gate valve.

Cost and Maintenance

How much a valve costs and how easy it is to fix matters a lot. Globe valves cost more at first, but they save money later. You can fix them without taking them out of the pipe. This means less time fixing and less work. Globe valves also seal better, so less energy is wasted and you fix them less.

Gate valves are cheaper to buy, but harder to fix. Workers often have to take them out to repair them. The gate and seat wear out faster, especially if used a lot or under high pressure. This means more leaks and more money spent over time.

| Aspect | Globe Valve | Gate Valve |

|---|---|---|

| Maintenance | Easy on-site repair, less downtime | Removal needed for repair, more downtime |

| Lifecycle Costs | Higher initial, lower total cost | Lower initial, higher total cost |

| Sealing Surface Wear | Less wear, but sensitive to solids | More wear, frequent repairs |

| Energy Efficiency | Better sealing, less energy loss | More leaks, higher energy loss |

Note: Using special tools can help fix globe valves faster and save money. In places with lots of rust, globe valves need fewer repairs.

Decision Checklist

A checklist helps engineers pick the right valve for their job:

- What does the valve need to do?

- Pick a gate valve for just open or close.

- Pick a globe valve for changing flow or slowing it down.

- How often will you use the valve?

- Use a globe valve if you open and close it a lot.

- Use a gate valve if you do not use it much.

- What kind of fluid goes through?

- Globe valves are best for clean fluids.

- Gate valves work better with dirty or thick fluids.

- Is a tight seal important?

- Globe valves seal better.

- Is fixing and stopping work a problem?

- Globe valves are easier and faster to fix.

- Do you need to keep pressure drop low?

- Gate valves lose less pressure.

| Valve Type | Key Characteristics | Typical Applications | Checklist Item |

|---|---|---|---|

| Gate Valve | Straight flow, not for slowing flow | Oil, gas, water pipes | Use for full open/close, not for lots of use |

| Globe Valve | Great for changing and slowing flow | Steam, control jobs, clean fluids | Use for careful control, used often |

? Always pick the valve that fits your system’s job, flow, and fixing needs. This keeps things safe, reliable, and saves money.

Picking the right valve helps your system work well and last longer. Globe valves are great for controlling how much fluid moves. Gate valves are best for stopping flow with little pressure loss. You need to choose the right design, material, and size for your job. This helps stop leaks, rust, and expensive repairs.

- Always think about how fast the fluid moves, the pressure, the heat, and what kind of fluid you have.

- Ask experts or the company that makes the valves if your system is tricky or risky.

Choosing the right valve keeps machines safe, lowers repair needs, and helps every industry stay safe.

FAQ

What is the main difference between a globe valve and a gate valve?

A globe valve uses a disc to control flow and pressure. A gate valve uses a flat gate to block or let fluid pass. Globe valves are best for changing flow. Gate valves are best for turning flow fully on or off.

Can you use a gate valve for throttling?

Engineers say not to use gate valves for throttling. The gate can shake and wear out fast if left partly open. This may cause leaks or break the valve. Globe valves are safer for careful flow control.

Which valve is better for high-pressure systems?

Globe valves work better in high-pressure systems. Their design makes a tight seal and handles pressure changes well. Gate valves can take high pressure but work best when fully open or closed.

Are globe valves or gate valves easier to maintain?

Maintenance teams think globe valves are easier to fix. The top-entry design lets workers reach inside parts quickly. Gate valves often need to be removed from the pipe for repairs. This takes more time and effort.

What materials are commonly used for these valves?

Manufacturers use stainless steel, cast iron, bronze, and forged steel for both types. Stainless steel does not rust. Cast iron is good for low pressure. Bronze and forged steel work with different fluids and pressures.

Do both valves work with dirty or thick fluids?

Gate valves work better with dirty or thick fluids. The gate can move through solids and debris. Globe valves are best for clean fluids. Thick or dirty fluids can harm the sealing surfaces in globe valves.

How do you choose the right valve for your system?

Engineers look at flow control, pressure drop, fluid type, and maintenance. Globe valves are good for systems needing careful control. Gate valves are good for simple on/off jobs with low pressure loss. Always check what your system needs before picking a valve.

Can both valves be installed in any direction?

Gate valves can be put in any direction. Globe valves must follow the flow arrow on the body. This helps the valve seal and work right.

Tip: Always follow the maker’s instructions for putting in and fixing valves. This keeps your system safe and working well.