An international standard valve follows rules used around the world. These rules make sure the valve is safe and works well. People who make, design, or buy valves trust these rules. They know the valves will work the same way in many places. International standards help companies sell valves in different countries. They also make sure valves like butterfly valve, ball valve, electric valve, and pneumatic valve fit together.

| Region | Certification / Standard Examples | Impact on Market Access and Compliance |

|---|---|---|

| European Union | CE, ISO, Digital Product Passport | Makes rules the same, protects the environment, and helps trade between countries. |

| United States | ASME, API, ISO | Lets valves be used in projects, follows local rules, and supports ‘Made in USA’ laws. |

| China | GB, ISO, energy efficiency labels | Wants valves to save energy and use safe materials. |

| Southeast Asia | SNI, QCVN, ISO hygiene standards | Needs local tests and changes how companies buy and follow rules. |

| Middle East | ISO, API, local certifications | Needs many rules together, uses local materials, and asks for reports about being green. |

- Buyers in other countries need certified valves to follow local laws and stay safe.

- Companies use digital certificates and outside checks to show they follow rules and give better warranties.

Key Takeaways

- International valve standards make sure valves are safe and work well everywhere.

- Big groups like API, ISO, ASME, and CEN make rules for valves.

- These rules help valves meet safety and quality needs.

- There are different valve types like gate, ball, butterfly, and check valves.

- Each type has its own standards for design and testing.

- Certifications like CE Marking, API Monogram, UL, and NSF/ANSI show valves follow strict safety and quality rules.

- Certified valves let companies sell products in many countries.

- They also help companies follow local laws more easily.

- Using valve standards lowers the chance of leaks, accidents, and expensive problems in important systems.

- Makers and buyers should look at certification papers closely.

- They should also keep up with new rules to avoid trouble.

Standards Bodies Overview

API

The American Petroleum Institute (API) is a top group for valve standards in oil and gas. API’s Subcommittee on Piping and Valves (SCOPV) makes important rules like API 600 and API 607. These rules sometimes show both API and ISO names, which means they work together. API cares about safety, being green, and making sure valves work well. API valve standards have tough rules for how valves are made and tested. Many companies around the world use API standards to meet global needs. API also helps make worldwide rules by working with other big groups. This teamwork helps make valves more alike and helps sell them everywhere.

ISO

The International Organization for Standardization (ISO) makes rules for many industries, including industrial valves. ISO’s Technical Committee TC153 writes rules for valves, actuators, testing, and quality. ISO works with groups like NACE and API to make valve rules match and work together. For example, ISO uses NACE’s rules about corrosion, so more people accept them. ISO valve standards help makers and buyers use the same rules everywhere. This makes trading easier and keeps valve rules the same in different countries. ISO’s rules are used in many places, so it is very important in the valve market.

ASME

The American Society of Mechanical Engineers (ASME) helps set ansi valve standards for mechanical engineering and industrial valves. ASME makes rules that focus on safety, strength, and how well valves work. ASME started helping with worldwide rules by leading U.S. work in ISO’s Technical Committee TC153. Later, ASME gave this job to the Manufacturers Standardization Society (MSS) to keep helping with global valve rules. ASME often works with API and ISO to make sure ansi valve standards fit with worldwide rules. This teamwork helps makers by letting them sell one kind of valve in many places. ASME’s rules help keep important systems safe and working well everywhere.

Note: These groups work together to make valve rules match. This helps makers sell valves around the world and helps buyers trust that valves are safe and good quality in every country.

EN/CEN

The European Committee for Standardization (CEN) makes rules for many products in Europe. EN standards are made by CEN. These rules tell how to use industrial valves in the European Union and other places with European laws. The standards help companies make safe valves that fit with other machines. EN valve standards say how to design, test, and mark valves. They also tell how to check if a valve is safe and good quality.

CEN works with groups like ISO to match their rules. This teamwork lets companies sell industrial valves in many countries without changes. EN standards often become part of local laws in Europe. If a valve meets EN standards, it can get the CE mark. This mark shows the valve follows European safety and quality rules. Many buyers in Europe want this mark before buying a valve.

Tip: Companies wanting to sell valves in Europe should check the newest EN valve standards. These rules change to keep up with new technology and safety needs.

MSS

The Manufacturers Standardization Society (MSS) is a group in the United States. It writes rules for industrial valves and fittings. MSS valve standards focus on things like testing, marking, and measuring valves. These rules help make sure valves from different companies work together. MSS works with groups like ASME and API to keep valve rules clear and helpful.

MSS valve standards fill in gaps left by bigger groups. For example, MSS might write a rule for a special valve or a new test. Many companies use MSS valve standards to make sure their products meet what customers want. These rules help buyers trust that a valve will work as promised.

Here is a table with some common MSS valve standards:

| MSS Standard | What It Covers |

|---|---|

| SP-61 | Pressure testing of valves |

| SP-25 | Marking system for valves |

NACE

The National Association of Corrosion Engineers (NACE) makes rules for materials that fight corrosion. NACE valve standards help companies pick the right materials for valves in tough places, like oil and gas plants. These rules explain how to test materials and what to look for when choosing a valve for hard jobs.

NACE works with ISO and API to match their rules. Many companies use NACE valve standards to protect their equipment from rust and damage. If a valve meets NACE standards, it can last longer and work better in places with chemicals or saltwater.

NACE industrial valve standards help keep workers safe and protect the environment. Companies that follow NACE standards show they care about safety and quality.

UL

UL, or Underwriters Laboratories, is important for safety checks. UL makes rules about fire safety, electrical safety, and if products work well. Many companies trust UL to test valves for fire protection and water systems. UL also checks valves used in dangerous places. These rules help makers show their valves are very safe.

UL tests valves in hard situations. They see if valves work with high pressure and heat. UL also checks if valves can handle strong chemicals. They look at how valves act in fires or leaks. If a valve passes, it gets a UL mark. This mark tells buyers and officials the valve is safe.

Makers want UL certification to sell in places with strict safety rules. Insurance and government groups may ask for UL valves in buildings. UL rules help stop accidents and keep people and things safe.

UL works with other groups to match rules. For example, UL may use rules from ISO or EN/CEN. This teamwork helps companies sell valves in many countries. UL is known around the world, so makers can find more buyers.

Note: UL certification does not take the place of other valve standards. It gives extra safety and trust. Companies should check all rules before selling valves.

NSF/ANSI

NSF International and the American National Standards Institute (ANSI) make health and safety rules. NSF/ANSI standards are for valves in drinking water and food systems. These rules make sure valves do not add bad chemicals to water or food.

NSF/ANSI rules need tough tests for materials and design. They check if valves let out lead or mercury. They also test how valves work in real life. If a valve passes, it gets a special mark. This mark shows the valve is safe for homes, schools, and hospitals.

Makers use NSF/ANSI marks to show they care about safety. Many places need NSF/ANSI valves in plumbing. Buyers look for these marks when picking valves for important jobs.

NSF/ANSI works with other groups to keep rules new. They look at new science and change rules when needed. This helps keep people safe and makes sure rules are right.

| NSF/ANSI Standard | Application Area |

|---|---|

| NSF/ANSI 61 | Drinking water systems |

| NSF/ANSI 372 | Lead-free requirements |

NSF/ANSI valve rules help companies earn trust. These rules help keep water and food safe everywhere.

Key International Standard Valve Types

Gate Valves

Gate valves are used in many industries. They control flow by moving a gate up or down. The gate is shaped like a wedge. This design makes a tight seal. Gate valves are good for turning flow on or off. People use gate valves in water, wastewater, and oil and gas systems. Standards like ASME B16.34, API600, and ISO set safety rules. These rules say valves must pass tests. One test checks for leaks with high pressure. Another test checks if the valve shuts tightly. Groups like ISO and CEN make these rules match. This helps companies sell gate valves everywhere.

Gate valves shut off flow well in important systems. Their simple shape makes fixing them easy. They last a long time.

Ball Valves

Ball valves have a round ball inside. The ball turns when you move the handle. This opens or closes the valve. Ball valves shut off flow quickly. They let liquid move with little pressure loss. Ball valves are used in water, gas, and chemical plants. Standards like ASME B16.34, API600, and ISO set rules for ball valves. These rules say ball valves must pass pressure and leak tests. Ball valve standards also say how to make them safe from fire and rust. API 6D gives rules for pipeline valves. It tells how to design and check valves for high pressure. Ball valve standards help make sure valves are safe and good quality everywhere.

| Valve Type | Description | Common Applications | Relevant Standards |

|---|---|---|---|

| Ball Valves | Ball inside controls flow; shuts off fast | Water, gas, chemical plants | ASME B16.34, API600, ISO, CEN |

Ball valve standards are important in oil and gas. They set rules for how well valves work and how safe they are. Ball valve standards say how much a valve can leak and how much pressure it can take. Ball valve standards also say how valves work with machines that control them. Makers use ball valve standards to sell valves in many countries.

Butterfly Valves

Butterfly valves have a disc that spins on a shaft. This lets the valve open or close fast. You only need to turn it a little. People use butterfly valves in big pipes, HVAC, and water plants. Standards like ASME B16.34, API600, and ISO set rules for butterfly valves. These rules say valves must pass leak, pressure, and strength tests. Butterfly valves must also use the right materials and have clear marks. Many industries pick butterfly valves because they are small and cheap. Standards groups work together to make sure butterfly valves are safe and work well everywhere.

Tip: Butterfly valves control flow well in big pipes. They are light, so putting them in and fixing them is easy.

Globe Valves

Globe valves help control flow in a straight line. They use a disk that moves and a ring that stays still. You turn the handwheel to move the disk up or down. This changes how much liquid goes through. Many places use globe valves for careful control. Power plants, chemical factories, and water centers need globe valves to work safely.

Globe valves must follow strict rules. ASME B16.34 and ISO 6002 set these rules. The rules say globe valves must pass pressure and leak tests. Makers use strong materials for globe valves. Each valve needs clear marks with information. Globe valves are good for systems that change often. Their design makes fixing them easy.

Tip: Globe valves let workers control flow very well. They last longer if used in clean systems.

| Feature | Description |

|---|---|

| Flow Control | Precise, adjustable |

| Common Materials | Stainless steel, bronze, cast iron |

| Typical Standards | ASME B16.34, ISO 6002 |

| Main Applications | Power plants, chemical processing |

Globe valves do not take the place of ball valve standards. Each kind of valve does a different job. Ball valve standards are for quick shut-off. Globe valves are for fine control. Engineers pick globe valves when they need to change flow, not just stop it.

Check Valves

Check valves let flow go one way only. The valve shuts by itself if flow goes backward. This keeps pumps and machines safe from harm. Water systems, oil pipes, and chemical plants use check valves to stop backflow.

Makers follow rules like API 594 and ISO 10631. These rules say check valves must pass tough tests. The rules also say what materials to use for each place. Stainless steel and brass are used a lot. Check valves need clear marks so people know what they are.

Check valves work well with pipeline valves. They help keep systems safe by stopping flow from going backward. Ball valve standards do not cover this job. Check valves work without anyone turning them. Their design makes them good for automatic systems.

- Main benefits of check valves:

- Stop backflow

- Keep equipment safe

- Need little fixing

Note: Check valves are needed in systems with pumps. They lower the chance of damage and help things run well.

Pressure Relief Valves

Pressure relief valves keep systems safe from too much pressure. The valve opens by itself when pressure gets too high. This lets out extra liquid or gas. Pressure relief valves stop accidents and protect equipment.

Oil and gas, water treatment, and factories use pressure relief valves. Rules like ASME BPVC and ISO 4126 set how to make and test them. These rules say pressure relief valves must open at the right pressure. Makers test each valve to make sure it works right.

Pressure relief valves do not use ball valve standards. Their job is to let out pressure, not control flow. Engineers pick pressure relief valves based on what the system needs. The right valve stops explosions and keeps machines working.

| Pressure Relief Valve Facts | Details |

|---|---|

| Main Function | Release excess pressure |

| Common Standards | ASME BPVC, ISO 4126 |

| Typical Materials | Stainless steel, brass |

| Key Industries | Oil & gas, manufacturing |

Safety Alert: Pressure relief valves should be checked often. Regular checks make sure they work when needed.

ISO Valve Standards

ISO 6002

ISO 6002 is a rule for testing bolted bonnet gate valves. It tells how to make sure the valve seals well and does not leak. The rule says what kind of gaskets to use. Some gaskets are spiral wound and made from graphite and 304 steel. Others are metal ring gaskets like Inconel 718. These materials help the valve stay tight when under pressure.

ISO 6002 also explains how to check bolt force using ISO 898-1. This makes sure bolts hold the valve together with enough strength. When companies follow these steps, they lower the chance of leaks and keep people safe. ISO valve standards like ISO 6002 help stop dangerous leaks and protect workers and nature.

Tip: Companies that want strong valves for oil, gas, or water often pick ones tested to ISO 6002. This rule helps with iso compliance and meeting world rules.

ISO 1721

ISO 1721 is a rule for cast iron gate valves used in many places. It tells how to design, size, and test these valves. Makers use ISO 1721 to build valves that fit lots of pipes. The rule helps companies make valves for water, plumbing, and HVAC systems.

ISO 1721 has ways to test valves for leaks and pressure. These tests show if a valve can work in normal jobs. The rule also says how to mark valves so people know what kind they are. ISO valve standards like ISO 1721 help buyers compare and pick safe valves.

- Key features of ISO 1721:

- Cast iron makes the valve strong

- Standard sizes make it easy to put in

- Clear marks help people know the valve

ISO 1721 helps companies trade valves in many countries. This rule helps meet what customers and laws need.

ISO 10631

ISO 10631 is a rule for check valves in factories. It tells how to design, what materials to use, and how to test the valves. Engineers use ISO 10631 to pick valves that stop backflow and keep machines safe. The rule lists materials like stainless steel and brass for long life.

ISO 10631 has tests for pressure, leaks, and how long the valve lasts. These rules help makers show their valves are safe for oil, gas, chemical, and power plants. ISO valve standards like ISO 10631 help keep important systems safe and working.

| ISO Standard | Valve Type | Main Application Areas | Key Requirements |

|---|---|---|---|

| ISO 6002 | Bolted bonnet gate | Oil, gas, water | Sealed design, gaskets |

| ISO 1721 | Cast iron gate | Water, plumbing, HVAC | Dimensions, markings |

| ISO 10631 | Check | Oil, gas, chemical, power | Backflow prevention, tests |

ISO valve standards are very important in oil, gas, chemical, power, water, plumbing, food, and HVAC. These rules help make sure valves are safe and work well. Makers use ISO rules to keep quality high and help the environment. ISO compliance helps companies meet what customers and laws want in many fields.

ISO 4401

ISO 4401 gives rules for how hydraulic valves are mounted. This rule helps engineers make sure valves fit together. ISO 4401 tells the size, shape, and where holes go for mounting. These details help companies build valves that work with many machines. ISO valve standards like ISO 4401 make changing or upgrading valves easier in hydraulic systems.

Many places use ISO 4401. Factories, building machines, and moving equipment all need valves that follow this rule. ISO 4401 helps stop mistakes when putting in valves. Workers know valves will fit if they use the same iso valve standards. This rule also helps keep things safe. When valves fit right, leaks and problems happen less.

Note: ISO 4401 does not say how the valve works inside. It only tells about the outside and how to mount it. Engineers need other iso valve standards for how well valves work and for valve testing methods.

A table can show what ISO 4401 covers:

| Feature | Description |

|---|---|

| Mounting Surface | Size and hole pattern |

| Valve Type | Hydraulic directional control |

| Application | Industrial, mobile, construction |

| Benefit | Easy replacement and compatibility |

ISO 4401 works with other iso valve standards. This teamwork helps companies build safe and strong hydraulic systems.

ISO 15848

ISO 15848 is about valves that stop leaks into the air. This rule is important for valves used with dangerous gases or chemicals. ISO 15848 gives strict rules for how much a valve can leak. It also tells valve testing methods for checking leaks. These tests use special tools to measure gas that gets out.

ISO 15848 has two main parts. The first part tells how to test valves for leaks. The second part tells how to mark and label valves that pass. Companies use iso valve standards like ISO 15848 to show their valves are safe for the environment. Many chemical plants and refineries want valves that meet this iso rule.

Key points about ISO 15848:

- Sets limits for how much gas can leak

- Lists valve testing methods for fugitive emissions

- Needs clear marks for tested valves

ISO 15848 helps keep workers and the environment safe. Valves that meet this rule lower the risk of air pollution and accidents.

ISO 10497

ISO 10497 is about fire type-testing for valves. This iso rule tells how to test valves in fire situations. The goal is to see if a valve still works after a fire. ISO 10497 gives step-by-step valve testing methods for fire safety. These tests check if the valve can stop leaks during and after a fire.

Many places use ISO 10497. Oil and gas, chemical plants, and power stations need valves that pass fire tests. ISO valve standards like ISO 10497 help companies show their valves are safe for hard jobs. This rule also helps buyers pick the right valve for places with fire danger.

Safety Tip: Always look for ISO 10497 certification when picking valves for fire safety.

ISO 10497 works with other iso valve standards to cover all parts of valve safety. Companies that follow these rules help keep people and equipment safe.

API Valve Standards

API valve standards help keep oil and gas work safe. They set rules for how valves are made and tested. These rules make sure valves work well in tough places. API standards are needed for oil and gas jobs. Companies must follow them to meet the law. Here are three important API valve standards.

API 6D

API 6D is for pipeline valves like gate, plug, ball, and check valves. This rule says valves must be strong and safe. Valves must pass tests for high pressure and hard conditions. API 6D helps companies use valves that work well in pipelines.

API 6D needs lots of paperwork and tests for each valve. Valves must pass pressure and leak tests. They also check if the valve works right. These steps help stop spills and accidents.

| API Standard | Valve Type/Application | Importance in Oil & Gas Industry |

|---|---|---|

| API 6D | Pipeline valves (gate, plug, ball, check) | Makes sure pipeline valves are safe and tested for oil and gas jobs |

API 6D is special because it puts testing rules in the design. This helps companies follow the law and keep pipelines safe.

API 600

API 600 is for bolted bonnet steel gate valves. These valves are strong and used in places with high pressure. API 600 sets rules for how thick the valve should be. It also says what materials and building steps to use. Valves must pass leak and strength tests.

Engineers pick API 600 valves because they last long and work well. These valves are used in refineries and gas plants. Safety is very important in these places. API 600 works with other rules like ASME B16.34 to help pick the right valve.

Tip: API 600 valves are good for hard jobs. Their strong design stops leaks and helps them last longer.

API 607

API 607 is for fire testing soft-seated, quarter-turn valves. This rule checks if valves work after being in a fire. API 607 is important for safety in oil and gas places.

The rule tells how to test valves with fire. It also says how to measure leaks. Valves that pass API 607 give people trust in emergencies.

- Main facts about API 607:

- Used for ball and butterfly valves with soft seats

- Valves must not leak much during or after fire

- Works with ISO 10497 for worldwide use

API valve standards like API 6D, API 600, and API 607 are very important in oil and gas. They make sure valves are safe and work well. These rules are different from ISO standards. ISO rules are more general and not always needed. API standards put testing and checks in the design. This makes them needed for safety and following the law.

ASME and EN Valve Standards

ASME B16.34

ASME B16.34 gives main rules for valves with flanged, threaded, and welding ends. It tells how to design, build, and test valves for many jobs. Engineers use ASME B16.34 to make sure valves handle high pressure and heat. The standard lists good materials for safety and long life. It also explains how to check valves for leaks and strength. ASME B16.34 matches with ANSI and ISO standards. Most rules are the same as ANSI codes. This helps companies use the same valves in many countries. When engineers follow ASME B16.34, they make fewer mistakes and finish projects faster. The standard helps buyers and sellers use the same technical words. This makes trading valves between countries easier.

Tip: Many projects in different countries need valves that meet ASME B16.34. This helps keep things safe and makes sure valves fit in global supply chains.

ASME B16.10

ASME B16.10 gives the sizes for face-to-face and end-to-end valve parts. These measurements help engineers make sure valves fit in pipelines without changes. The standard covers gate, globe, and check valves. By using ASME B16.10, companies can swap valves from different makers easily. This standard helps global trade by making valves more alike. When valves follow ASME B16.10, installers save time and money. The standard also helps stop mistakes when putting in valves. Many contracts for big projects ask for valves that meet these sizes.

- ASME B16.10 helps:

- Lower installation mistakes

- Make projects faster

- Help valves work together in many countries

ASME BPVC

The ASME Boiler and Pressure Vessel Code (BPVC) is a set of rules for making pressure vessels and some valves. BPVC covers safety, materials, and tests for valves in boilers and pressure systems. This code helps protect workers and equipment from accidents caused by high pressure. New BPVC updates match with EN and ISO standards. The code now uses new ways to check stress and allows more leak tests. It also gives more help for using valves in systems with European laws. These changes help companies use the same valves in American and European projects. ASME BPVC works with other valve standards to keep valves safe and strong. The code asks designers to check that valves meet all safety needs. This helps lower risks in big systems.

Note: Always look at the newest BPVC and valve standards before starting a project.

EN 1983

EN 1983 is a rule for metal ball valves in Europe. CEN made this rule to help engineers and makers build safe ball valves. EN 1983 covers floating and trunnion-mounted ball valves. These valves move liquids or gases in pipes under pressure.

EN 1983 gives simple rules for design, materials, and tests. The rule lists what metals companies can use. It tells how to check valve strength and look for leaks. EN 1983 says each valve must have marks showing pressure, size, and maker.

Some main parts of EN 1983 are:

- Design rules for full bore and reduced bore ball valves

- Pressure and temperature ratings for safety

- Test steps for strength and tightness

- Rules for marking and identification

Engineers use EN 1983 to make sure ball valves fit with other equipment. The rule helps buyers compare valves from different makers. Companies that follow EN 1983 can sell valves in many European countries.

Tip: Always look for EN 1983 marks when picking ball valves for Europe. This shows the valve meets safety and quality rules.

Here is a table with EN 1983’s main points:

| Feature | EN 1983 Requirement |

|---|---|

| Valve Type | Metal ball valves |

| Pressure Classes | PN 10 to PN 100 |

| Testing | Strength, tightness, operation |

| Marking | Size, pressure, manufacturer |

EN 12266

EN 12266 is a rule for testing industrial valves in Europe. This rule is for many valve types like gate, globe, ball, and check valves. EN 12266 focuses on pressure and leak tests.

EN 12266 has two parts:

- EN 12266-1: This part is about pressure tests for valve shells and seats. It tells how to test for leaks and strength. The rule gives easy steps for each test.

- EN 12266-2: This part lists extra tests for special needs or requests.

Makers use EN 12266 to show their valves do not leak and can take high pressure. The rule helps engineers trust valves will work safely. EN 12266 also helps people compare valves from different companies.

Note: Many European jobs need valves to pass EN 12266 tests before use. Always ask for test papers from the seller.

Main points of EN 12266:

- Makes pressure and leak tests the same for all valves

- Sets clear rules for passing or failing each test

- Helps keep pipelines safe and reliable

Here is a table for EN 12266:

| Test Type | What It Checks | Who Uses It |

|---|---|---|

| Shell Test | Valve body strength | Makers, buyers |

| Seat Test | Leak tightness | Engineers, inspectors |

| Special Tests | Extra conditions | Custom projects |

EN 12266 gives everyone a simple way to test and trust valves. This rule helps keep water, gas, and industrial systems safe in Europe.

Other Industrial Valve Standards

MSS SP-61

MSS SP-61 is a rule for testing valve pressure. The Manufacturers Standardization Society made this rule. It tells how to check valves for leaks before shipping. Engineers use MSS SP-61 to make sure valves pass tough pressure tests. This rule is for many valves like gate, globe, ball, and check valves.

MSS SP-61 works with iso and ASME rules. It gives easy steps for water and air tests. These tests help find leaks in the valve body and seats. The rule says how long to test and what counts as a pass or fail. Many companies use MSS SP-61 with iso rules to keep valves safe for pipelines and plants.

Tip: Always ask for MSS SP-61 test papers when buying valves for important jobs. This proves the valve is safe and follows industry rules.

MSS SP-25

MSS SP-25 is about marking valves and fittings. This rule tells makers what to put on each valve. Marks show the maker’s name, material, size, pressure rating, and year made. These marks help people know what the valve is and if it meets iso or other rules.

Clear marks make it easy to track valves when fixing or changing them. MSS SP-25 works with iso and ASME rules to keep info the same. When valves have the right marks, engineers can check if the valve fits the job. This lowers mistakes and helps with safety checks.

- Common marks needed by MSS SP-25:

- Maker’s name or logo

- Material type

- Valve size

- Pressure rating

- Year made

MSS SP-25 helps global trade by making sure valves from different places follow the same marking rules. This helps buyers compare valves and check if they meet iso and local rules.

NACE MR0175/ISO 15156

NACE MR0175, also called iso 15156, is a rule for picking valve materials for sour gas. Sour gas has hydrogen sulfide, which can hurt metal parts. This rule helps companies pick materials that do not crack or break.

NACE MR0175/iso 15156 lists metals and treatments that work best in sour gas. It also tells how to test materials for cracking. Many oil and gas jobs need valves that meet this rule. The rule helps stop accidents and keeps workers and machines safe.

This rule works with iso and API rules. It helps companies follow both world and local safety laws. NACE MR0175/iso 15156 helps global projects by making sure valves work in tough places everywhere.

Note: Valves that meet NACE MR0175/iso 15156 often have other iso and local marks too. This makes sure they are safe in many places, even with strict pressure test rules.

Engineers often see differences between local and world rules. For example, GOST and JIS have their own rules for materials and design. These local rules may need extra tests or papers besides iso. Companies sometimes need to certify valves to both iso and local rules to meet all project needs.

NACE MR0103/ISO 17945

NACE MR0103 is also called ISO 17945. It gives rules for valves and materials in sour petroleum refining. Sour places have hydrogen sulfide, or H?S. H?S can cause sulfide stress cracking. This standard helps companies pick safe materials for valves in hard conditions.

NACE MR0103/ISO 17945 is for valves in oil refineries. It does not cover upstream oil and gas jobs. The standard lists metals and treatments that stop cracking from H?S. It explains how to test materials and what to check during inspections. Companies that use this standard lower the risk of valve problems. They help keep workers and equipment safe.

Key points of NACE MR0103/ISO 17945 are:

- Material Selection: The standard lists steels and alloys that are approved. These must have low hardness and special treatments to stop cracking.

- Testing Requirements: Companies test materials for hardness and cracking. The standard gives clear steps for these tests.

- Documentation: Each valve needs records to show it meets the standard. This includes test results and details about the materials.

- Marking: Valves that pass must have clear marks. These marks show the valve is safe for sour service.

Tip: Always ask for NACE MR0103/ISO 17945 certificates when buying valves for refineries. This proves the valve will last in sour places.

Here is a table showing the main differences between NACE MR0175/ISO 15156 and NACE MR0103/ISO 17945:

| Standard | Main Use Area | Key Focus |

|---|---|---|

| NACE MR0175/ISO 15156 | Oil & gas production | Sour gas, upstream |

| NACE MR0103/ISO 17945 | Oil refining | Sour service, downstream |

NACE MR0103/ISO 17945 works with other valve standards like API and ISO. Many refineries need valves that meet this standard. Companies that follow these rules show they care about safety and quality. This helps them sell valves in more places and lowers the chance of big problems.

Note: Not all valves need NACE MR0103/ISO 17945. Only use this standard for valves in sour refinery service. Always check project needs before picking materials.

JIS

JIS means Japanese Industrial Standards. These rules help companies in Japan make and test valves. The Japanese Standards Association, or JSA, is in charge of JIS. Many places in Japan use JIS valve standards. Water plants, oil plants, and chemical plants all use these rules. JIS valve standards help companies make safe and strong valves.

JIS valve standards cover lots of valve types. Here are some common JIS standards:

| JIS Standard | Valve Type | Main Use Area |

|---|---|---|

| JIS B2002 | General valves | Industrial piping |

| JIS B2238 | Ball valves | Water, oil, gas |

| JIS B2071 | Gate valves | Water, steam, oil |

JIS standards tell companies how big valves should be. They say what materials to use. They also explain how to test for leaks. These rules help Japanese valves fit with pipes and machines. JIS says each valve must have clear marks. The marks show the size, pressure, and who made it.

Many companies outside Japan use JIS standards too. Some jobs in Asia and the Middle East need JIS valves. JIS standards help companies sell valves to other countries.

Tip: If you work in Japan or with Japanese partners, check if you need JIS valve standards. This helps stop problems when putting in valves.

JIS standards change as new technology comes out. The JSA updates the rules to keep valves safe. Companies should always use the newest JIS standard.

GOST

GOST stands for “State Standard” in Russian. These rules come from Russia and some nearby countries. Kazakhstan and Belarus also use GOST standards. GOST valve standards help companies make valves that work well in these places.

GOST covers many valve types. These include gate, globe, ball, and check valves. Here are some common GOST standards:

| GOST Standard | Valve Type | Main Application |

|---|---|---|

| GOST 5762 | Gate valves | Oil, gas, water |

| GOST 21345 | Ball valves | Pipelines, industry |

| GOST 9544 | General valves | Industrial systems |

GOST standards tell companies how to design valves. They say what materials to use and how to test valves. These rules help valves work in cold weather and high pressure. GOST also says how to mark valves and what papers to give. Each valve must show its GOST number, size, and pressure.

Many jobs in Russia and CIS countries need GOST valves. Companies must follow GOST rules to sell valves there. Some world projects also ask for GOST valves to match local laws.

Note: GOST standards are not always the same as ISO or EN rules. Always check what your project needs before picking a valve standard.

GOST standards help companies make valves that last in hard places. These rules help keep workers safe and make sure valves are good quality.

Valve Certification Systems

CE Marking

CE Marking is very important for valves sold in Europe. Makers must prove each valve meets the EU Pressure Equipment Directive. There are several steps in this process. First, companies decide if the valve is a pressure vessel, pipe, or safety part. Next, outside experts check the technical papers and test results. They make sure the valve is safe and meets all rules. Engineers do hydrostatic and pneumatic pressure tests. These tests follow rules like API 598, ISO 5208, and ASME B16.34. Sometimes, fire and emission tests are needed too. Companies must have a quality system in place. Auditors visit the factory and look at the paperwork. Each valve gets a special mark and batch number. This helps track the valve from start to finish. After all steps are done, the maker puts the CE mark on the valve. This mark lets the valve move freely in Europe.

CE Marking shows the valve is safe and follows strict rules. Buyers and officials trust this mark for safety and quality.

Valves can fail certification for many reasons. Some common problems are missing papers, wrong tests, or mistakes in classifying the product. Companies must follow every step to avoid problems or delays.

API Monogram

API Monogram certification is needed for valves in oil and gas. The American Petroleum Institute makes tough rules for design and quality. The steps for this certification are clear. First, companies send in details about their products and how they are made. API checks the design and technical papers. Valves go through hydrostatic, pneumatic, and fire tests. These tests check for leaks, strength, and fire safety. API auditors visit the factory to check quality and how things are made. API looks at the test results and audit notes. If everything is good, companies sign a contract and get listed. API checks the factory every year to keep the certification.

API Monogram means the valve meets all API rules. Auditors check if the right materials and sizes are used. They also look at how well the valves are put together. If tests are missed or tools are not set right, the valve can fail.

Buyers and officials check API Monogram using the API Composite List. This online list shows which companies have real certifications. People can search by company or number to make sure the certification is real.

API Monogram gives buyers trust in the valve’s quality. Many oil and gas jobs need this certification to buy or use valves.

Valves can fail if they miss tests or use the wrong materials. Companies must follow all steps to keep their certification.

ISO 9001

ISO 9001 certification shows a company has a strong quality system. This covers everything from design to customer service. The steps are simple. First, companies write down how they design, make, test, and help customers. Teams check their own work and look for ways to get better. Outside experts visit the factory and check the papers. If there are problems, the company must fix them. After passing all checks, the company gets ISO 9001 certification.

ISO 9001 helps companies make good products every time. It also helps them follow iso rules and world standards. Buyers and officials check ISO 9001 using the API Composite List or other official lists.

ISO 9001 helps people trust the company can make good valves. Many big jobs and rules need this certification.

Valves can fail if records are missing or if the process is not controlled. Companies must keep good records and follow all test steps to pass.

| Certification Type | Main Focus | Key Steps Involved | Verification Method |

|---|---|---|---|

| CE Marking | EU safety and compliance | Categorization, testing, QA, traceability | CE mark, technical documents |

| API Monogram | Petroleum industry | Application, testing, audit, listing | API Composite List |

| ISO 9001 | Quality management | QMS setup, audits, corrective actions | API Composite List, directories |

Tip: Always check official lists and audit papers before buying valves to make sure certifications are real.

UL Certification Process

UL stands for Underwriters Laboratories. UL gives a trusted certification for valves. These valves are used in fire protection and water systems. UL also checks valves for dangerous places. The UL certification process makes sure valves follow strict safety rules. Companies must do several steps to get UL certification.

- Application: The company sends valve details and test plans to UL.

- Testing: UL experts test the valve for fire resistance and pressure. They also check chemical safety. UL uses real-life tests to see if the valve works under stress.

- Factory Inspection: UL visits the factory to see how valves are made. Inspectors look for good quality control and safe work.

- Ongoing Audits: After approval, UL comes back for regular checks. These audits make sure the company keeps making safe valves.

- Labeling: If the valve passes all tests, UL lets the company use the UL mark. This mark shows buyers and officials the valve meets high safety standards.

UL certification helps companies sell valves in places with strict safety laws. Insurance and government groups often ask for UL-certified valves in buildings and fire systems.

A table can show the main steps:

| Step | What Happens |

|---|---|

| Application | Company sends valve information |

| Testing | UL tests for fire, pressure, safety |

| Factory Inspection | UL checks how valves are made |

| Ongoing Audits | Regular checks for quality |

| Labeling | UL mark added to approved valves |

UL certification gives buyers confidence. They know the valve will work in emergencies and follow legal rules. Companies that skip steps or fail tests cannot get UL certification.

NSF/ANSI Certification

NSF/ANSI certification is important for valves in drinking water and food systems. NSF International and the American National Standards Institute set these rules. The certification process checks if valves are safe for people. It also makes sure valves do not add bad chemicals to water or food.

The steps for NSF/ANSI certification are:

- Material Review: Experts check all materials in the valve. They make sure nothing can hurt people.

- Product Testing: The valve is tested for lead, mercury, and other chemicals. It must also pass leak and pressure tests.

- Facility Audit: Inspectors visit the factory. They look at how the company controls quality and keeps records.

- Certification Decision: If the valve passes all tests, NSF/ANSI gives the certification. The company can use the NSF/ANSI mark on its valves.

- Annual Review: NSF/ANSI checks the factory and valves every year to keep the certification.

Many cities and states need NSF/ANSI certification for valves in public water systems. Hospitals, schools, and food factories also want this mark.

A checklist for NSF/ANSI certification:

- Safe materials

- No bad chemicals

- Leak and pressure tests

- Factory quality control

- Yearly audits

NSF/ANSI certification helps keep people healthy. It also helps companies sell valves in more places by meeting strict safety rules.

ATEX

ATEX certification is needed for valves in explosive places. These places include chemical plants, oil refineries, and mines in Europe. The ATEX Directive sets rules for equipment that could cause explosions. Valves must follow these rules to get ATEX certification.

The ATEX certification process has these steps:

- Risk Assessment: The company checks how the valve could cause sparks or heat.

- Design Review: Experts look at the valve design to lower explosion risks.

- Testing: The valve is tested for static electricity, heat, and pressure. These tests make sure the valve will not start a fire or explosion.

- Documentation: The company writes technical files and safety reports.

- Notified Body Review: An approved agency checks all papers and test results.

- CE Marking: If the valve passes, it gets ATEX certification and the CE mark for explosive places.

ATEX certification is very important for safety in places with flammable gases or dust. Without this certification, companies cannot sell valves for these places in Europe.

A summary table for ATEX certification:

| Step | Purpose |

|---|---|

| Risk Assessment | Find explosion risks |

| Design Review | Check for safe design |

| Testing | Prove valve will not cause explosions |

| Documentation | Record all safety details |

| Notified Body Review | Independent check of compliance |

| CE Marking | Shows valve is safe for explosive areas |

ATEX certification keeps workers and property safe. It also helps valve makers sell in Europe.

SIL

SIL means Safety Integrity Level. It shows how well a valve lowers the chance of failure. Many places use SIL ratings to pick safe valves. Chemical plants, oil refineries, and power stations need these ratings.

Valve makers must follow hard steps to get SIL certification. First, they check how the valve works in real safety systems. They look at how often the valve could fail and what might happen. Next, they test the valve in real-life jobs. These tests see if the valve can stop accidents or lower risks. After testing, experts look at the results and give a SIL rating.

SIL ratings go from SIL 1 to SIL 4. SIL 1 is basic safety. SIL 4 is the highest safety. Most factory valves need SIL 2 or SIL 3. A higher SIL rating means less chance of failure.

| SIL Level | Risk Reduction | Typical Use Area |

|---|---|---|

| SIL 1 | Basic | Simple safety systems |

| SIL 2 | Moderate | Industrial plants |

| SIL 3 | High | Oil, gas, chemicals |

| SIL 4 | Very High | Nuclear, critical ops |

Getting SIL certification is more than just passing a test. Companies must keep records of every test and change. They must show how the valve fits in the safety system. Outside experts, called third-party assessors, check the papers and watch the tests. These experts give the final certification if all rules are met.

Tip: Always ask for SIL certification papers when buying valves for safety. These papers prove the valve passed all tests and meets the right SIL level.

SIL certification helps buyers trust the valve will work when needed. Many jobs and laws need SIL-rated valves for key safety work. Without this certification, companies may not get approval to use their valves.

To check SIL certification, buyers should look for these things: a clear SIL rating on the valve or in the papers, test reports from a trusted third-party assessor, and records showing how the valve was tested and used.

Valve makers must update SIL certification if they change the design or how the valve is made. Regular audits help keep the certification valid. If a company skips steps or fails a test, they lose their certification.

SIL certification works with other systems like CE marking and ISO 9001. These certifications together help keep people and equipment safe. They also help companies sell valves in more places.

Note: SIL certification does not replace other safety rules. It adds another layer of trust for buyers and regulators.

Importance of International Standard Valve Certifications

蝶閥-300x300.jpg)

Quality Assurance

International standard valve certifications are important for quality. These certifications show a valve meets tough rules for design and materials. They also show the valve passed hard tests. When a company follows these rules, it proves the valve is strong and safe. The valve can work in hard jobs and will not break easily.

Manufacturers use certifications to prove their products are good and safe. These rules help companies follow safety standards for control valves. This lowers the chance of big accidents from broken valves. Companies with certifications get a good name for making products people can trust.

- Certifications help companies:

- Meet world safety and quality rules.

- Show they use good materials and smart designs.

- Lower the risk of big safety problems.

- Plan and build better by knowing what the valve can do.

- Stand out from other companies in the market.

Certifications also help companies avoid recalls and legal trouble. They make manufacturers keep checking and improving their work. Customers trust certified valves because they know these valves passed hard tests.

Safety and Risk Reduction

Certified valves help keep people, machines, and nature safe. These valves go through hard tests for pressure, heat, and tough jobs. For example, pressure relief valves open by themselves if pressure gets too high. This stops machines from breaking and keeps people safe.

Certified valves often use smart tools to watch for problems. These tools warn workers before something bad happens. This helps companies fix things early and stop accidents. Certified valves also help stop leaks and lower the chance of fires. By following international valve rules, companies make the workplace safer for everyone.

- Key safety benefits of certified valves:

- Stop damage to machines and lost work time.

- Lower the chance of leaks and spills.

- Keep workers from getting hurt.

- Help companies follow strict safety laws.

- Protect the environment by stopping bad gases.

Training and support for workers also help stop mistakes. Certified valves make it easier for companies to follow safety rules and keep everyone safe.

Market Access

International valve certifications help companies sell in more countries. Many places need these certifications before a company can sell or use a valve. For example, Europe needs CE marking. The United States looks for ASME or API standards. These certifications show the valve meets local laws and safety rules.

| Certification / Standard | Role / Requirement | Market Access Impact |

|---|---|---|

| PED (Pressure Equipment Directive) | Needed for pressure equipment in Europe; requires CE marking | Allows legal sales and free movement in the EU |

| ISO (e.g., ISO 4126) | Sets global safety and performance rules | Makes it easier to sell in many countries |

| API, ASME | Matches with ISO and European rules | Helps companies meet rules in the US and worldwide |

| CE Mark | Shows compliance with EU laws | Acts as a passport for European markets |

| SIL, ATEX, NSF | Meets special industry needs | Builds trust and meets sector rules |

With these certifications, companies can sell valves in more places. They can find more customers. Certifications help companies keep up with new rules and changes. They also lower the cost and time for checks. Certified valves are trusted by buyers and officials. This helps companies grow and build a good name.

Regulatory Compliance

Regulatory compliance is a main reason companies want international standard valve certifications. Governments and industry groups make strict rules for valves. These rules keep people, property, and nature safe. Companies must follow these laws to sell or use valves in many countries.

Valve certifications help companies show they follow all the laws. Every country or region has its own rules. For example, the European Union uses the Pressure Equipment Directive (PED). The United States uses rules from OSHA and the EPA. Many Asian and Middle Eastern countries have their own codes too. Certified valves prove a company knows and follows these laws.

Note: Regulatory compliance is required. Companies that do not follow rules can get big fines, recalls, or be banned from selling.

Certifications help companies pass inspections faster. Inspectors look for marks like CE, API Monogram, or UL. These marks mean the valve passed all the needed tests. When a valve has the right certification, officials can approve it quickly. This saves time and helps avoid project delays.

The table below shows how certifications help with regulatory compliance in different places:

| Region | Key Regulation | Required Certification |

|---|---|---|

| European Union | PED, ATEX | CE Marking |

| United States | OSHA, EPA, ASME | ASME, API, UL |

| Middle East | Local safety codes | ISO, API, CE |

| Asia | National standards (JIS, GB) | JIS, ISO, CE |

Using certified valves also lowers legal risks for companies. If something goes wrong, they can show proof they followed the rules. This helps protect them in court or with insurance. Certified valves also help companies get more jobs. Many buyers only want valves with the right certifications.

Regulatory compliance helps keep everyone safe. Certified valves stop leaks, explosions, and pollution. They also help make trade fair by making sure all companies follow the same rules.

Tip: Companies should always check the newest rules before picking valves. Laws can change, and new certifications might be needed.

Special Certifications and Applications

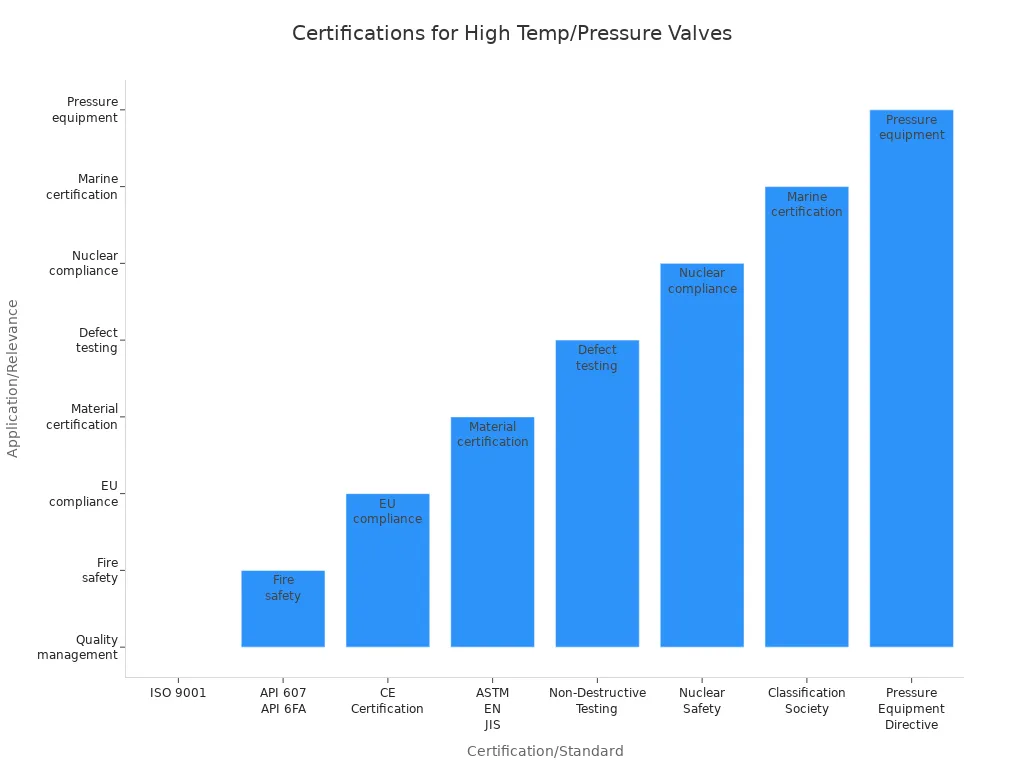

High Temperature/Pressure

Valves used in high temperature or high pressure places need special rules. These rules help keep people and machines safe. They also help valves last longer in tough jobs. Engineers pick valves that pass hard tests and have certifications from trusted groups. The table below lists important certifications and tests for these valves:

| Certification/Standard/Test Type | Description | Application/Importance |

|---|---|---|

| ASME B16.34 | Shows how much pressure and heat valve materials can take | Makes sure valves work under certain pressure and temperature |

| API 6A | Rules for valves in very hard jobs | Designs valves for very hot (up to 900°C) and high pressure (up to 10,000 psi) places |

| MTR (Material Test Reports) | Papers that show what the valve is made of | Checks if the material is right and good quality |

| NDE (Non-Destructive Examination) | Tests like X-rays and magnet checks | Finds problems inside or outside without breaking the valve |

| Pressure Testing | Tests valves with high pressure | Proves the valve can work safely at its rated pressure |

| Radiography Testing | Uses X-rays to look at welds and parts | Checks welds are strong and have no problems |

| Magnetic Particle and Dye Penetrant Tests | Looks for cracks on the surface | Finds small cracks or flaws on the outside |

| PMI (Positive Material Identification) | Checks what chemicals are in the valve | Makes sure the right materials are used for tough jobs |

| Hardness Testing | Measures how hard the valve material is | Checks if the valve will last and not wear out |

| Failure Analysis | Studies why a valve broke | Helps make safer and better valves next time |

| Pressure Seal Bonnet (Breech Lock Valves) | Special design for safety in high pressure and heat | Used in steam and boiler water jobs, follows ASME codes |

| ANSI Power Piping Code | Follows safety rules for pipes | Makes sure valves are safe for power piping systems |

Valves in these places also need certifications like ISO 9001 for quality, API 607 and API 6FA for fire safety, and CE for Europe. Material certifications from ASTM, EN, or JIS show the valve can handle stress and rust. Non-destructive testing certifications prove there are no hidden problems. Some valves for nuclear or ships need even tougher rules.

These rules help keep people, machines, and nature safe. They also help companies follow laws and industry rules for tough jobs.

Tip: Always make sure valves for high temperature or pressure jobs have the right certifications and test papers.

Cryogenic Service

Cryogenic valves work in very cold places, like liquid nitrogen or natural gas systems. These valves need special rules because cold can make metal break and leak. Certification rules for cryogenic valves include:

- Must follow world and local rules like ASME, API, CE, PED 2014/68/EU, NACE MR0103, and Chinese GB/T 24925.

- Must pass cold tests to show the valve stays strong at -196°C.

- Use materials like ASTM A351 Gr.LC3, Monel K500, and Inconel 718 that stay strong and do not rust in cold.

- Use special seals like reinforced PTFE and flexible graphite that do not crack or leak.

- Must pass tests like corrosion checks and phase change tests to show the valve works well.

- Need good welding, non-destructive tests, and clean making steps.

- Must have safety features like emergency shutoff and over-pressure protection.

Cryogenic valves also need insulation and sometimes electric heating to stop freezing or water drops. These rules make sure the valve works safely and well in important jobs.

Note: Cryogenic valves must pass both normal and cold air-tightness tests before use.

Corrosive Environments

Valves used in places with strong chemicals, like chemical plants or oil platforms, need special rules. These rules focus on picking the right materials, using protective coatings, and stopping damage from harsh chemicals. Certifications like NACE MR0175/ISO 15156 and NACE MR0103/ISO 17945 show the valve can handle hydrogen sulfide and other bad chemicals. Material certifications from ASTM, EN, or JIS also help prove the valve can resist chemicals.

Engineers often pick stainless steel, alloy steel, or valves with anti-rust coatings for these jobs. Tests include checking for rust, pressure, and leaks. Some jobs need extra papers to show the valve meets all safety and strength rules.

Valves in these places help keep people and machines safe from leaks, breaks, and costly stops. Meeting the right rules helps companies do well in tough jobs.

Fire-Safe and Fugitive Emissions

Valves in many jobs must stop fires from spreading. They also need to keep dangerous gases from leaking out. Fire-safe and fugitive emissions certifications help companies show their valves can do these things. These certifications are very important in oil and gas, chemical plants, and refineries. They help protect people, machines, and the environment.

Fire-Safe Valve Certifications

Fire-safe valves keep working after a fire starts. These valves must close tight and not leak during or after a fire. Engineers use tough rules to test fire-safe valves. The most used rules are:

- API 607: Tests soft-seated, quarter-turn valves like ball and butterfly valves. The test burns the valve and checks for leaks.

- API 6FA: Tests fire safety for gate, globe, and check valves.

- ISO 10497: Is like API 607 but works for more valve types. Many companies use this rule for world jobs.

A fire-safe valve test has these steps: First, heat the valve with fire for a set time. Next, check for leaks while the fire is on. Then, cool the valve and check for leaks again.

If the valve passes, it gets a fire-safe certification. This mark tells buyers and inspectors the valve can protect systems in emergencies.

Fugitive Emissions Certifications

Fugitive emissions are small leaks of gases or vapors from valves. These leaks can hurt workers and make the air dirty. Many countries now want valves to meet strict emission rules. The main rules for fugitive emissions are:

- ISO 15848: Sets rules for testing and marking valves for low emissions.

- API 624: Checks fugitive emissions from rising stem valves.

- TA-Luft: Is a German rule for controlling emissions in factories.

Valves tested for fugitive emissions must use special seals and packing. Engineers test these valves by opening and closing them many times while checking for leaks. The valve must stay tight even after lots of cycles.

| Standard | Focus Area | Typical Valve Types |

|---|---|---|

| API 607 | Fire safety | Ball, butterfly |

| ISO 10497 | Fire safety | Many types |

| ISO 15848 | Fugitive emissions | All industrial valves |

| API 624 | Fugitive emissions | Gate, globe |

Tip: Always look for fire-safe and fugitive emissions marks when picking valves for oil, gas, or chemical work. These marks help keep people safe and protect the environment.

Fire-safe and low-emission valves help companies follow laws and lower risks. They also help buyers and officials trust the valves. Picking certified valves means safer plants and cleaner air.

Compliance and Selection Strategies

Achieving Certification

Manufacturers must follow steps to get certification for new valves. First, they build a team with special skills. Machinists need to read blueprints and use tools. Welders must learn safe and good welding. Millwrights use both machining and welding to put valves together. Certified workers check each valve and use careful methods. Outside experts check the work to add trust.

The steps for valve certification are:

- Send in an application with all valve details.

- Experts look at the product and check it.

- Test the valve in a lab for leaks and pressure.

- Inspectors visit the factory and check how valves are made.

- Look at the test results and accept them.

- Sign a contract and list the valve as certified.

- Get ready for yearly checks and more tests to keep the certificate.

Manufacturers should always hire skilled and certified workers. They must check valves closely and use outside checks if needed. This helps meet rules and keeps up with industry standards.

Tip: Working with a certified ball valve maker makes certification easier and helps meet all the rules.

Maintaining Compliance

Keeping up with world valve rules takes hard work all the time. Companies must follow strict rules from groups like API, ASME, and ISO. Regular tests, like factory and site acceptance tests, help check if valves work right.

A good maintenance plan helps with compliance:

- Follow rules like ANSI, ASME, API, and ISO.

- Pick valve materials and sizes that fit the job.

- Check valves often for leaks or damage.

- Use sensors and flow meters to watch valves and stop problems.

- Store valves in clean, dry places to stop rust.

- Test valves with FAT and SAT to make sure they work.

- Work with suppliers who offer help and training.

Regular checks, cleaning, and fixing keep valves safe and working. Training helps workers know the rules and keep valves certified. Companies that do these things lower the risk of breaking rules and help valves last longer.

Note: Keeping up with rules is not just one job. It needs regular checks and updates to match new rules.

Selecting Certified Valves

Picking the right certified valve takes planning and checking. The process starts early when engineers plan the system. They decide what type of valve, what it will carry, and what conditions it must handle.

A step-by-step plan helps get good results:

- Make lists and datasheets for valves during planning.

- Ask suppliers for bids using clear details.

- Use inspection rules when checking the valves.

- Pick sellers with a good record for safety and certified valves.

- During building, check valves meet all rules and fix mistakes fast.

- Collect all needed papers, like test reports and certificates.

- Work with trusted sellers who give good support and clear papers.

Buyers should always check if valves are really certified before buying. They can ask for API papers, license numbers, maker info, and date made. Checking these in the API database makes sure they are real. Looking at the valve for API marks and serial numbers helps too. Outside inspectors can check the valve’s quality and tests.

A table can show key steps for buyers:

| Step | Purpose |

|---|---|

| Review certification papers | Make sure the valve is certified |

| Inspect valve markings | Check for API Monogram and serial number |

| Verify in API database | Confirm the certification is real |

| Use third-party inspectors | Check quality and how the valve works |

Working with a certified ball valve maker gives buyers good products and help. This helps avoid problems like wrong orders or missing details.

Tip: Always check if the seller is real and visit the maker if you can. This helps stop fraud and makes sure the valve meets all the rules.

Avoiding Pitfalls

Manufacturers and buyers can have problems with valve certification. These problems can cause delays, failed checks, or unsafe valves. Knowing about common mistakes helps companies keep a good name and work smoothly.

1. Overlooking Documentation Requirements

Some companies forget to keep important papers up to date. Missing test reports or old certificates can slow down certification. Always use a checklist for each valve’s papers. Update records after every test or check.

Tip: Pick someone to handle all certification papers. Regular checks help find missing or expired files before they cause trouble.

2. Relying on Unverified Suppliers

Some buyers trust suppliers without checking their certifications. This can lead to fake or non-compliant products. Always make sure the supplier has real certifications. Use official lists or ask for proof from trusted groups.

| Step | Action |

|---|---|

| Supplier Check | Ask for certification numbers |

| Database Search | Confirm in official certification lists |

| Physical Inspection | Look for certified marks on products |

3. Ignoring Local and International Compliance Differences

Valve rules can be different in each country. A valve certified in one place may not be accepted somewhere else. Always check local laws and compare them with world rules before buying.

Note: Talk to local experts or agencies to avoid problems during checks.

4. Skipping Regular Compliance Reviews

Some companies think a certified valve stays good forever. But rules and standards can change. Check all certifications often to keep valves up to date.

5. Failing to Train Staff

Workers who are not trained may install or fix valves the wrong way. This can cause compliance problems. Give regular training on certification and how to handle certified valves. Trained staff help keep everything safe and correct.

6. Overlooking Product Changes

Changing the design, material, or how a valve is made can affect certification. Always tell certification groups about changes and get new approval if needed. Skipping this step can cause legal trouble.

7. Not Verifying Certified Marks

Some products have fake or old certified marks. Always check the valve for the right and current marks. Match serial numbers and certification info with official records.

Alert: Never use a valve without the right certified marks and papers.

8. Underestimating the Cost of Non-Compliance

Not following the rules can mean fines, recalls, or stopping a project. Spending money on proper certification saves money and keeps the company’s good name.

Checklist for Avoiding Pitfalls:

- Keep all certification papers up to date and neat.

- Check supplier certifications before buying.

- Review local and world compliance rules.

- Plan regular compliance checks.

- Train workers on certification and compliance.

- Report and re-certify any product changes.

- Check certified marks and make sure they are real.

- Know the risks and costs of not following the rules.

By following these steps, companies can avoid mistakes and make sure every valve is safe and high quality.

Valve Standards Summary Table

Quick Reference Chart

Valve standards help people pick the right valve for each job. The chart below shows important valve standards, what they are used for, and who makes the rules.

| Standard / Certification | Valve Type / Application | Main Region / Body | Key Focus / Benefit |

|---|---|---|---|

| API 6D | Pipeline valves (gate, ball, check, plug) | USA / API | Safety, performance, oil & gas |

| API 600 | Bolted bonnet steel gate valves | USA / API | Strength, leak prevention |

| API 607 | Fire-safe ball and butterfly valves | USA / API | Fire safety, emergency reliability |

| ISO 6002 | Bolted bonnet gate valves | Global / ISO | Sealing, gasket standards |

| ISO 10631 | Check valves | Global / ISO | Backflow prevention, durability |

| ISO 15848 | All industrial valves | Global / ISO | Fugitive emissions, environmental |

| ASME B16.34 | Flanged, threaded, welded valves | USA / ASME | Pressure, temperature ratings |

| ASME BPVC | Pressure relief valves | USA / ASME | Boiler safety, pressure control |

| EN 1983 | Metal ball valves | Europe / CEN | Design, marking, pressure classes |

| EN 12266 | All industrial valves | Europe / CEN | Pressure, leak testing |

| MSS SP-61 | Pressure testing (all valves) | USA / MSS | Leak detection, test procedures |

| NACE MR0175/ISO 15156 | Sour service valves | Global / NACE, ISO | Corrosion resistance, H?S safety |

| UL Certification | Fire protection, water valves | Global / UL | Fire, electrical safety |

| NSF/ANSI 61, 372 | Drinking water valves | USA / NSF, ANSI | Lead-free, health safety |

| JIS B2002, B2238 | General, ball valves | Japan / JSA | Local compatibility, sizing |

| GOST 5762, 21345 | Gate, ball valves | Russia / EASC | Cold resistance, local standards |

| ATEX | Valves in explosive atmospheres | Europe / EU | Explosion safety, CE marking |

| SIL | Safety system valves | Global / IEC | Risk reduction, reliability |

Tip: Engineers should always pick a valve standard that fits the job’s safety, pressure, and environmental needs. This helps stop problems with rules and keeps the system working well.

Key Points to Remember:

- API and ASME standards are used for oil, gas, and safety in North America.

- ISO standards help valves work in many countries and protect the environment.

- EN and CE marking are needed for valves in Europe.

- NACE standards help stop rust in sour places.

- UL and NSF/ANSI certifications are for fire safety and clean water.

- JIS and GOST standards are for Japan and Russia and match local needs.

- ATEX and SIL certifications are important for dangerous and safety jobs.

Valve buyers and makers should always look at the newest rules for each standard. Certification marks and test papers show the valve follows the rules and help with checks. Good valves start with the right standards.

Valve certifications like ISO 9001, CE, API, and NSF help keep people safe. They also make sure valves are good quality and can be sold in many countries. These certifications help companies follow tough rules. They make products work better and help customers trust the company. Certified valves keep users safe from harm and legal trouble.

- Use this guide to help you pick, order, or make valves that follow world rules.

- Ask groups like the National Board, ASME, or Swagelok for help, papers, and tips to keep following the rules.

Keeping up with new certification rules helps makers avoid slowdowns and stay ahead of others.

FAQ

What is the difference between a valve standard and a valve certification?

A valve standard tells how to design and test a valve. It sets rules for how the valve should work. A valve certification shows the valve follows those rules. Certification means the valve passed tests and checks. It also means there is official paperwork.

Why do companies need international valve certifications?

International valve certifications help companies sell in more countries. These certifications show valves are safe and good quality. Buyers and officials trust certified valves for big projects.

How can someone verify if a valve is truly certified?

People can look for a certification number on the valve or its papers. Groups like API and NSF have online lists to check numbers. Inspectors and buyers use these lists to make sure the valve is certified.

Which valve certifications are required for drinking water systems?

NSF/ANSI 61 and NSF/ANSI 372 are needed for drinking water valves. These rules focus on health and lead-free safety. Many places ask for these marks on plumbing valves.

What happens if a valve fails certification tests?

If a valve fails tests, the maker must fix the problems. They may need to change the design or materials and test again. Without certification, the valve cannot be sold for jobs with strict rules.

Can a valve have more than one certification?

Yes, a valve can have more than one certification. For example, a valve might have CE marking, API Monogram, and ISO 9001. Having many certifications helps companies meet different rules.

How often do valve certifications need renewal?

Most certifications need renewal every year or after big changes. Groups do audits and checks to keep standards up to date. Companies must update their papers and test results often.

What is the role of third-party inspectors in valve certification?

Third-party inspectors check if valves follow the rules. They look at test results and how valves are made. They also check the paperwork. Their review helps people trust the certification.