Engineers sometimes get confused when picking the right valve standard. API 6D is for pipeline valves like ball valves and butterfly valves. API 600 is about gate valves. API 598 gives inspection rules for control valves and other valves. Knowing why api standards matter helps companies stay safe and reliable. Following api standards gives steady quality and performance people trust.

Key Takeaways

- API 6D is for pipeline valves like ball, gate, plug, and check valves. It focuses on safety and stopping leaks in oil and gas pipelines.

- API 598 gives rules for testing many valve types. This includes globe and butterfly valves. Some designs can have a little bit of leakage.

- API 600 is only for steel bolted bonnet gate valves. These are used in places with high pressure and heat, like refineries and power plants.

- Each standard has its own ways to test valves and set leak limits. This helps make sure valves are safe and work well in their jobs.

- Picking the right valve standard depends on the valve type. It also depends on what the industry needs, pressure, and safety rules.

- Leakage classes show how much fluid can leak from a closed valve. This helps engineers pick valves that keep people, equipment, and nature safe.

- Testing and taking care of valves using the right API standard keeps them safe. It also lowers leaks and helps valves last longer.

- Using the correct API standard follows industry rules. It makes systems safer and helps things run and get fixed more easily.

API 6D Overview

Purpose

API 6D gives rules for valves in oil and gas pipelines. This standard helps keep pipelines safe and working well. API 6D valves control how liquids or gases move in long pipes. Companies use API 6D to make sure valves are strong and safe. Engineers pick valves using this standard for high pressure and heat.

Scope

API 6D covers how to design, make, and test pipeline valves. It applies to ball, gate, plug, and check valves. These valves work in places with high pressure, like oil and gas pipelines. API 6D valves must be tough and stop leaks. The standard has rules for materials, building, testing, and checking quality. API 6D also tells how to label and record each valve.

Main Requirements

Valve Types

API 6D valves come in four main types:

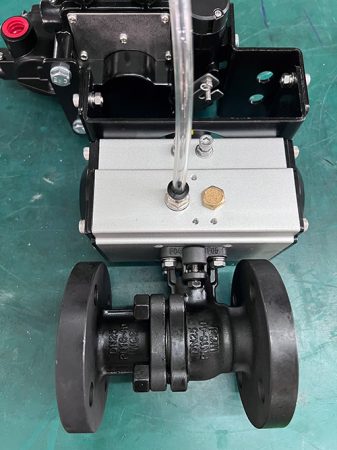

- Ball valves use a ball that turns to control flow.

- Gate valves use a gate that slides to open or close flow.

- Plug valves use a plug that is round or shaped to control flow.

- Check valves let flow go one way and stop it from going back.

Each valve type does a special job in oil and gas pipelines. API standards make sure valves are safe and work well.

Testing Media

API 6D says valves must be tested with water, air, or another fluid. The test fluid depends on the valve type and how it will be used. Water is used for pressure tests. Air or gas is used to check for leaks at the seat. Testing makes sure the valve can handle high pressure and does not leak.

Leakage Standards

API 6D says most pipeline valves must not leak at all. During tests, no leaks can be seen at the valve seats. These strict rules help stop product loss and protect nature. API 6D valves must pass these tests before being used in pipelines.

Applications

Engineers use API 6D valves in long, high pressure pipelines for oil and gas. These valves help keep pipelines safe and working well. API standards make sure valves can handle tough jobs and shut tightly. Companies trust API 6D to follow rules and lower the chance of leaks or problems.

Note: API 6D is a key API valve standard for pipelines. It gives clear rules for testing and checking quality in oil and gas work.

Applications

API 6D valves are very important in oil and gas work. Engineers use these valves to control how liquids and gases move in long pipelines. These valves are made to handle high pressure and hard jobs. Companies pick these valves to keep things safe and running well.

In oil and gas pipelines, API 6D valves help stop leaks and keep nature safe. These valves must pass hard tests before they are used. Workers trust API 6D valves to close fast if there is an emergency. Shutting off parts of a pipeline helps stop spills and keeps equipment safe.

Different valves do different jobs in oil and gas work. Ball valves close tightly and let things flow easily. Gate valves are good for shutting off flow, like in refineries and water plants. Globe valves help control how much liquid or gas moves. Check valves stop flow from going backward and protect pumps. Butterfly valves are used in big pipes and in chemical plants.

The table below shows where each valve type is used in oil and gas:

| Valve Type | Typical Applications in Oil & Gas Industry |

|---|---|

| Ball Valves | On/off service, applications requiring minimal flow resistance and tight sealing |

| Gate Valves | Pipeline isolation, especially in refineries and water treatment facilities |

| Globe Valves | Flow regulation in steam, water, and gas systems |

| Check Valves | Preventing backflow in pump systems to avoid damage and operational issues |

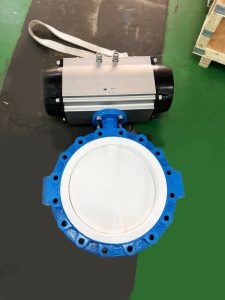

| Butterfly Valves | Suitable for larger pipe diameters, used in water distribution and chemical processing |

Engineers choose API 6D valves based on what each job needs. Ball valves are best when a tight seal is needed. Gate valves are good when the valve must be fully open or closed. Globe valves help control how fast things move. Check valves stop flow from going the wrong way. Butterfly valves are used for big pipes with lots of flow.

API 6D valves also help with fixing and safety. Workers can close off part of a pipeline to fix it without stopping everything. This saves time and money. In emergencies, these valves can stop flow fast to keep people and equipment safe.

Oil and gas companies trust API 6D valves to follow safety rules. Using these valves helps meet safety and environmental laws. Good valves keep work going and stop delays. API 6D valves are a big part of safe and smooth pipeline work.

Tip: Picking the right valve for each job makes things safer and cheaper to fix. Engineers should match the valve to what their project needs.

API 598 Overview

Purpose

API 598 gives rules for checking and testing valves. The main goal is to make sure each valve holds pressure and seals well. This is true for both high and low pressures. Engineers use this standard to see if a valve works before it is put in place. API 598 covers all valve types, not just pipeline valves. The standard helps keep things safe and reliable by making sure every valve passes tough tests.

| Aspect | Details |

|---|---|

| Purpose | Make sure valves hold pressure and seal at different pressures |

| Test Media | High pressure: air, inert gas, kerosene, water, or safe liquid; Low pressure: air or inert gas |

| Test Pressures | Iron valves: tested at set pressures; Steel/alloy valves: shell test at 1.5 times rated pressure, backseat at 1.1 times or 80±20 psig |

| Test Duration | Depends on valve size and type, from 15 to 600 seconds |

| Allowable Leakage | Check valves have different rules because of how they seal |

| Additional Notes | Standard is for new valves; be careful with designs that may break under high pressure; ask the maker about extra high pressure tests |

API standards like API 598 help companies keep equipment safe and working well. The standard also mentions MSS-SP 55 for checking castings. This adds another step for quality control.

Scope

API 598 is used for checking and testing all new valves. It covers many kinds, like gate, globe, ball, plug, and check valves. The standard tells how to test each valve. API 598 does not say how to design or build valves. It makes sure valves pass strict tests before being used. The scope includes checking pressure boundaries and seat leaks.

API standards like API 598 are important in many jobs. Engineers use this standard to check valves in oil and gas, water plants, and chemical factories. The rules help stop leaks and problems that could be unsafe.

Main Requirements

Testing Procedures

API 598 explains how to test valves for leaks and strength. Each valve gets a shell test and a seat test. The shell test checks if the valve body holds pressure without leaking. The seat test checks if the valve closes tight and stops flow. Test times depend on valve size and type, from 15 to 600 seconds. The standard warns that some valves may break under high pressure, so engineers should ask the maker before testing.

Test Media

API 598 lets engineers use different things to test valves. For high-pressure tests, they can use air, inert gas, kerosene, water, or another safe liquid. For low-pressure seat tests, air or inert gas is used. The test media depends on the valve type and job. Using the right media helps find leaks and makes sure the valve will work safely.

Acceptance Criteria

API 598 gives clear rules for passing tests. The standard sets limits for how much leakage is allowed. Most valves must not show any leaks at the seat. Check valves have special rules because of their design. If a valve passes all tests, it meets API standards and can be used. If it fails, it must be fixed or changed. These rules help keep equipment safe and working well.

Tip: Always use API 598 for testing and checking valves. This helps stop leaks and keeps systems safe.

Valve Types

API 598 covers many kinds of valves used in different jobs. This standard is for gate, globe, check, ball, plug, and butterfly valves. These valves are found in oil and gas, water plants, chemical factories, and power stations. API 598 makes sure every valve passes tough checks before being used.

Engineers use API standards to make sure valves are safe and good quality. API 598 is special because it is not just for pipeline valves. It includes valves with many shapes and uses. Globe valves help control how fast things move. Butterfly valves work best in big pipes with low pressure. Ball and plug valves shut off flow tightly, so they are good for turning flow on or off. Gate valves block parts of a system. Check valves stop flow from going backward.

API 598 covers more than API 6D. API 6D is for pipeline valves in oil and gas. It covers gate, plug, ball, and check valves. API 598 adds globe and butterfly valves, which API 6D does not have. This means API 598 works for more jobs in more places.

The table below shows how API 598 and API 6D are different:

| Aspect | API 598 Valve Types | API 6D Valve Types | Key Differences |

|---|---|---|---|

| Valve Types Covered | Gate, Globe, Plug, Ball, Check, Butterfly | Gate, Plug, Ball, Check | API 598 has Globe and Butterfly valves, but API 6D does not. |

| Seating Types | Resilient-seated, Non-metallic-seated, Metal-to-metal | Not specifically detailed in this context | API 598 covers more seating types. |

| Industry/Application | General valve inspection and testing across industries | Pipeline valves for petroleum and natural gas industry | API 6D is only for pipeline valves with special rules. |

| Focus | Inspection, examination, pressure testing to ensure leak-free valves | Design, manufacturing, testing, documentation for pipeline safety and reliability | API 6D is about pipeline safety; API 598 is about valve quality. |

| Additional Valve Types | Includes Butterfly and Globe valves | Does not include Butterfly and Globe valves | API 598 has more valve types than API 6D. |

Note: API 598 works with different seat types like resilient-seated, non-metallic-seated, and metal-to-metal seats. This helps engineers pick the right valve for each job.

API 598 helps companies keep valves working well. By covering more valve types, this standard keeps systems safe in many places. Engineers know valves tested with API 598 will work right, no matter the job.

API 600 Gate Valves

Purpose

API 600 gate valves are used in places with high pressure and heat. These valves are important in refineries, power plants, and chemical plants. The standard makes sure each valve can handle tough jobs. API 600 has strict rules for how these valves are made. This helps the valves last a long time and work well. Engineers use API 600 gate valves to keep systems safe and running smoothly.

Scope

API 600 tells how to make bolted bonnet steel gate valves. These valves work in places with lots of pressure and heat. The standard is for valves with flanged or butt-welded ends. API 600 gate valves come in many sizes, from small to very big. This means they can be used in many different jobs. These valves are found in oil and gas, chemical plants, and power plants. API 600 does not cover valves made from other materials or for low pressure.

Main Requirements

Design

API 600 gate valves must follow strict design rules. The standard says how thick the walls and body should be. It also tells how to build the bonnet. Each valve needs a bolted bonnet so workers can fix and check it easily. The design helps the valve handle high pressure without leaks. Engineers pick API 600 gate valves for hard jobs. The wedge gate design helps the valve close tightly, even when pressure or heat changes.

Materials

API 600 gate valves are made from strong steel. The standard lists which steel types can be used for each part. These materials do not rust or wear out fast. This is important in chemical plants and other tough places. The stem and seat rings also have to be made from good materials. Using the right steel helps the valve last longer and work better.

Applications

API 600 gate valves are best for high pressure and heat. Refineries, power plants, and chemical plants use these valves to shut off parts of pipes or machines. The valves help keep things safe during repairs or emergencies. API 600 gate valves are also used in steam lines and other big systems. Their strong build and good materials make them great for hard jobs.

Note: API 600 gate valves are trusted by engineers for safety and strength. These valves help protect people and equipment in places with high pressure.

| Feature | API 600 Gate Valves Benefit |

|---|---|

| Bolted Bonnet | Easy to fix and check |

| Steel Construction | Handles high pressure and heat |

| Wedge Gate Design | Closes tightly |

| Approved Materials | Does not rust in chemical plants |

| Wide Size Range | Works for many jobs |

API 600 Gate Valves in Industry

API 600 gate valves are very important in many industries. These valves are used when strong shutoff is needed under high pressure and heat. They follow strict design rules, so they are picked for tough jobs. Engineers use API 600 gate valves when they need something strong and reliable.

Refineries use API 600 gate valves to control oil, gas, and steam. These valves work well even when pressure and heat are very high. Their strong build and bolted bonnet help stop leaks and keep things safe. Workers use these valves to close off pipes during repairs or emergencies.

Power plants use API 600 gate valves for steam and water lines. These valves must handle high pressure and quick changes in temperature. The steel body and wedge gate design make a tight seal. This helps protect machines and keep the system working right. People pick these valves because they last a long time.

Chemical plants have special problems like strong chemicals and high pressure. API 600 gate valves do not rust and keep working in these hard places. The good materials and careful making help these valves work well, even with harsh chemicals.

Tip: Checking and taking care of API 600 gate valves often can help them last longer and keep high pressure systems safer.

Many industries use API 600 gate valves because they come in many sizes and can handle different pressures. Engineers can pick the right valve for each job. These valves help with safe shutdowns, closing off parts of a system, and acting fast in emergencies.

The table below shows how API 600 gate valves are used in different industries:

| Industry | Typical Application | Why API 600 Gate Valves? |

|---|---|---|

| Refineries | Oil, gas, and steam isolation | Handles high pressure and temperature |

| Power Plants | Steam and water line control | Durable under rapid temperature shifts |

| Chemical Plants | Corrosive and high pressure fluid control | Resists corrosion, meets design requirements |

| Industrial Plants | System isolation and maintenance | Reliable shutoff, long service life |

API 600 gate valves are known for working well in hard places. They are trusted in refineries, power plants, and chemical plants. Because they follow strict rules, these valves help keep people, machines, and nature safe.

Valve Testing Requirements by Type

Ball Valves

Pressure Test Procedures

Engineers use ball valves in many systems because they open and close quickly. For pressure tests, they fill the valve with water or air. They close the valve and raise the pressure to a set level. This test checks if the valve body can hold the pressure without breaking. The test time depends on the size of the valve. API 6D and API 598 both require this step for ball valves.

Leakage Test Criteria

Ball valves must not leak during the seat test. The seat is the part that seals when the valve is closed. Engineers apply pressure to one side and check for leaks on the other. If any fluid comes out, the valve fails. API 6D allows zero leakage for pipeline ball valves. API 598 also sets strict limits for leaks. These tests help keep systems safe.

API 6D vs API 598 vs API 600: Ball Valve Testing

API 6D focuses on ball valves used in pipelines. It requires strong pressure tests and no leaks at the seat. API 598 covers ball valves in many industries, not just pipelines. It allows some small leaks for certain valve types, but not for ball valves. API 600 does not cover ball valves. Only API 6D and API 598 apply to ball valve testing and quality assurance.

Gate Valves

Pressure Test Procedures

Gate valves control flow by lifting or lowering a gate inside the valve. For pressure tests, engineers fill the valve with water or air. They close the valve and increase the pressure. The test checks if the valve body and bonnet can hold the pressure. API 600 gate valves must pass this test to show they are strong enough for high pressure jobs.

Leakage Test Criteria

The seat test for gate valves checks if the gate seals tightly. Engineers apply pressure to one side and look for leaks on the other. API 600 gate valves must have no visible leaks at the seat. API 598 also requires tight sealing for gate valves. These tests make sure the valve will not leak in service.

API 6D vs API 598 vs API 600: Gate Valve Testing

Check Valves

Pressure Test Procedures

Check valves let flow go one way and stop it from going back. For pressure tests, engineers fill the valve with water or air. They apply pressure to the body to check for leaks. The test makes sure the valve is strong and safe.

Leakage Test Criteria

The seat test for check valves checks if the valve stops backflow. Engineers apply pressure in the reverse direction and look for leaks. API 598 gives special rules for check valves because of their design. Some small leaks may be allowed, but only if the standard says so.

API 6D vs API 598 vs API 600: Check Valve Testing

It allows small leaks for some check valves, but only within limits. API 600 does not cover check valves. Only API 6D and API 598 apply to check valve testing.

Tip: Always follow the right standard for each valve type. This helps keep systems safe and working well.

Plug Valves

Pressure Test Procedures

Plug valves help control flow in pipes and systems. Engineers use them because they work well for hard jobs. These valves can shut off flow safely. For pressure tests, workers fill the plug valve with water or air. They close the valve all the way. Then, they make the pressure go up to a set level. This checks if the valve body can hold the pressure. The valve should not leak or break. How long the test lasts depends on the valve’s size and type. Both API 6D and API 598 say this test is needed for plug valves. API 6D is for pipeline plug valves. API 598 is for plug valves in many places.

Here are the steps for testing plug valves:

- Fill the valve with water or air.

- Close the valve tight.

- Make the pressure go up to the test level.

- Keep the pressure for the right time.

- Look at the valve body for leaks or damage.

This test helps make sure the plug valve will be safe to use.

Leakage Test Criteria

Leakage tests check if the plug valve seals well when closed. Engineers put pressure on one side of the valve. They look for leaks on the other side. The seat is the part that must stop all flow when shut. API 6D says pipeline plug valves must have no leaks at the seat. API 598 has strict rules for leaks. It allows very small leaks for some plug valves, based on how they are made. The worker must look closely during the test. If any fluid gets past the seat, the valve fails. It must be fixed or replaced.

Important steps for leakage testing plug valves:

- Put pressure on one side of the valve.

- Check for leaks at the seat and body.

- Write down any leaks found.

- Match results to the standard’s rules.

A plug valve that passes this test helps keep systems safe and stops product loss.

API 6D vs API 598 vs API 600: Plug Valve Testing

API 6D and API 598 both talk about plug valves in their rules. API 6D is for plug valves in pipelines. It has tough rules for pressure and leak tests. API 6D needs zero leaks at the seat. This makes these valves good for important pipeline jobs. API 598 is for plug valves in many places, like water, chemical, and power plants. API 598 lets some plug valves have tiny leaks, but only if the rules say so.

API 600 does not talk about plug valves. It is only for gate valves used in high-pressure and high-heat jobs. Engineers should use API 6D for pipeline plug valves. They should use API 598 for plug valves in other places.

The table below shows the differences:

| Standard | Plug Valve Coverage | Pressure Test | Leakage Criteria | Typical Application |

|---|---|---|---|---|

| API 6D | Yes | Required | Zero leakage | Pipelines |

| API 598 | Yes | Required | Minimal leakage allowed (design-dependent) | General industry |

| API 600 | No | Not covered | Not covered | Not applicable |

Tip: Always pick the right standard for plug valve testing. This depends on where the valve is used and how safe it needs to be.

Leakage Classes in Valve Testing

Definition of Leakage Classes

What is a Leakage Class?

A leakage class shows how much fluid can get through a closed valve. Standards use leakage classes to set limits for leaks during tests. Each class has its own rule for the most fluid that can leak. These rules help engineers know if a valve will seal well when used.

Why Leakage Classes Matter in Valve Testing

Leakage classes help engineers and companies pick the best valve for each job. If a valve meets a leakage class, people know how well it stops leaks. This matters for safety, keeping products good, and protecting nature. Using the right leakage class also helps companies follow rules and avoid big problems.

Common Leakage Classes and Their Criteria

Class I to VI: Overview and Differences

Valve standards have six main leakage classes, from Class I to Class VI. Each class sets a different limit for leaks through a closed valve. The table below shows the main differences:

| Leakage Class | Maximum Allowable Leakage | Test Medium | Test Pressure | Testing Procedure Summary |

|---|---|---|---|---|

| Class I | No test needed if user and supplier agree (dust tight) | N/A | N/A | No test needed if agreed |

| Class II | 0.5% of rated capacity | Air or water (50-125°F) | 45-60 psig or max operating differential (whichever is lower) | Pressure goes to valve inlet, outlet open or with low loss device, full closing force used |

| Class III | 0.1% of rated capacity | Air or water (50-125°F) | 45-60 psig or max operating differential | Same as Class II |

| Class IV | 0.01% of rated capacity | Air or water (50-125°F) | 45-60 psig or max operating differential | Same as Class II |

| Class V | 0.0005 ml/min water per inch port diameter per psi differential | Water (50-125°F) | Max service pressure drop, not over ANSI body rating | Valve body filled with water, valve closed, max actuator force, wait for leak rate to settle |

| Class VI | Leak limits based on port diameter (see table) | Air or nitrogen (50-125°F) | 50 psig or max rated differential pressure | Actuator set for normal use, full closing force, wait for leak rate to settle, use measuring device |

Typical Test Methods for Each Class

Engineers use different ways to test each leakage class. Most tests use air, water, or nitrogen at set pressures and temperatures. For Class II, III, and IV, the test uses air or water at 45-60 psig. The valve closes with normal force, and the tester checks for leaks at the outlet. For Class V, the test uses water at the highest service pressure drop. The valve fills with water, closes all the way, and the tester measures any leaks. For Class VI, the test uses air or nitrogen at 50 psig. The tester measures leaks in milliliters per minute or counts bubbles per minute with a special tube.

The table below shows leak rates for Class VI by port size:

| Nominal Port Diameter (inches) | Nominal Port Diameter (mm) | Maximum Leak Rate (ml/min) | Equivalent Leak Rate (bubbles/min) |

|---|---|---|---|

| 3 | 76 | 0.9 | 6 |

| 4 | 102 | 1.7 | 11 |

| 6 | 152 | 4 | 27 |

| 8 | 203 | 6.75 | 45 |

| 10 | 254 | 9 | 63 |

| 12 | 305 | 11.5 | 81 |

Note: Bubble counts can change with different test tools.

Leakage classes help engineers pick valves that fit each system’s needs. Picking the right class keeps systems safe and working well.

Practical Implications of Leakage Classes

Selecting the Right Leakage Class for Your Application

Engineers need to pick the right leakage class for each system. The correct class helps stop leaks and keeps things safe. Every job has its own rules for how much leaking is okay. For example, a pipeline with dangerous chemicals needs a valve that seals very tight. But a water system can have a little bit of leaking.

When picking a valve, engineers look at a few things:

- Type of fluid: If the fluid is toxic or can catch fire, a stricter leakage class is needed.

- System pressure: High-pressure systems need valves that leak less.

- Valve seat material: Soft-seated valves can reach higher leakage classes, like Class VI.

- Industry standards: Oil and gas pipelines use API 6D, which means no leaks are allowed.

Engineers often use a chart to match leakage classes to jobs:

| Application | Recommended Leakage Class | Reason |

|---|---|---|

| Oil & Gas Pipelines | Class IV or tighter | Stops product loss |

| Chemical Processing | Class V or VI | Keeps the environment safe |

| Water Distribution | Class II or III | Small leaks are okay |

| Steam Systems | Class IV | Works with high heat |

Tip: Always check what fluid is in the system and how much pressure it has before picking a leakage class. This helps avoid mistakes and keeps everyone safer.

Impact on Safety and Performance

Leakage classes are important for safety and how well things work. The right class keeps dangerous fluids inside the pipes. This lowers the chance of accidents and protects nature. Tight valves also help companies follow safety rules.

Valves with lower leakage classes make systems work better. They stop product loss and save money on repairs. In high-pressure systems, a leaking valve can break equipment or shut things down. Engineers test valves to make sure they meet the right leakage class before using them.

Some good things about picking the right leakage class are:

- Enhanced safety: Less chance of leaks and spills.

- Regulatory compliance: Follows industry and legal rules.

- Cost savings: Saves product and cuts down on repairs.

- Longer valve life: Less leaking means less damage.

Note: Testing and checking valves often helps keep the right leakage class. Engineers should plan regular checks to make sure valves keep working well.

Picking the right leakage class helps systems run safely and protects people, machines, and nature. Engineers who know about leakage classes make better choices for every job.

Comparison Table

Key Features

Engineers look at API 6D, API 598, and API 600 gate valves to find the best one for their work. Each standard has special things that make it different. The table below shows how these features are not the same.

| Feature | API 6D | API 598 | API 600 Gate Valves |

|---|---|---|---|

| Focus | Pipeline valves | Valve inspection and testing | Steel bolted bonnet gate valves |

| Valve Types | Ball, gate, plug, check | Ball, gate, plug, check, globe, butterfly | Gate valves only |

| Design Requirements | Yes | No | Yes |

| Testing Requirements | Strict, zero leakage | Strict, some leakage allowed | Strict, zero leakage at seat |

| Material Requirements | Yes | No | Yes (steel only) |

| Application Specific | Yes (pipelines) | No (general use) | Yes (high pressure, high temp) |

| Documentation | Required | Not required | Required |

Note: API 600 gate valves have the most rules for design and materials. API 6D covers more valve types for pipelines. API 598 is about testing and checking many kinds of valves.

Applications

- API 6D: Used in long pipelines for oil or gas. These valves must stop leaks and work in hard jobs.

- API 598: Used in water plants, chemical factories, and power plants. This standard checks if valves work before they are used.

- API 600 gate valves: Used in refineries, power plants, and chemical plants. These valves shut off flow in high-pressure and hot systems.

The table below shows where each standard is used.

| Standard | Typical Applications |

|---|---|

| API 6D | Oil and gas pipelines, pipeline isolation |

| API 598 | Water treatment, chemical processing, power plants |

| API 600 Gate Valves | Refineries, steam lines, high-pressure shutoff |

Tip: Always pick the valve standard that fits the system’s needs. This keeps people and equipment safe.

Testing Requirements

Each standard has its own testing rules. API 6D and API 600 gate valves need very strict tests. They must have zero leaks at the seat. API 598 lets some valves have tiny leaks, but not API 600 gate valves. Each standard uses different things and pressures for testing.

- API 6D: Needs hydrostatic and seat tests. Valves must not leak at all. Water and air are used for tests.

- API 598: Needs shell and seat tests. Some valves can have small leaks, based on how they are made. Air, water, or inert gas are used for tests.

- API 600 gate valves: Needs hydrostatic shell and seat tests. No leaks are allowed at the seat. Only steel valves are tested with this standard.

| Standard | Pressure Test Type | Leakage Allowed | Test Media |

|---|---|---|---|

| API 6D | Hydrostatic, seat | Zero | Water, air |

| API 598 | Shell, seat | Minimal (design-based) | Air, water, inert gas |

| API 600 Gate Valves | Hydrostatic shell, seat | Zero at seat | Water, air |

Engineers trust API 600 gate valves because they have the toughest tests. These valves keep systems safe in the hardest jobs.

Valve Types

Engineers need to know which valves each API standard covers. This helps them pick the right valve for their job. API 6D, API 598, and api 600 gate valves all focus on different valve types.

API 6D is for pipeline valves. It covers ball, gate, plug, and check valves. Each valve type does a special job in oil and gas pipelines. Ball valves shut off flow fast and let things move easily. Gate valves are good for blocking off parts of a pipeline. Plug valves work with hard-to-handle fluids and are easy to fix. Check valves stop flow from going backward and protect machines.

API 598 is used for almost every valve in factories and plants. It covers ball, gate, plug, check, globe, and butterfly valves. This standard tells how to test and check valves, not how to make them. Engineers use API 598 to make sure valves are good before using them. Because it covers so many valves, API 598 is used in water plants, chemical factories, and power stations.

The api 600 gate valves standard is only for one kind of valve. It is for steel bolted bonnet gate valves. These valves are made for places with high pressure and heat. Refineries, power plants, and chemical plants use api 600 gate valves to shut off flow safely. The standard has strict rules for how these valves are made and tested. Engineers pick api 600 gate valves when they need something strong that lasts a long time.

Valves each standard covers:

| Standard | Valve Types Covered | Typical Use Case |

|---|---|---|

| API 6D | Ball, Gate, Plug, Check | Oil and gas pipelines |

| API 598 | Ball, Gate, Plug, Check, Globe, Butterfly | General industry, inspection/testing |

| api 600 gate valves | Steel bolted bonnet gate valves | High-pressure, high-temperature service |

Note: Only api 600 gate valves are for just one valve type. API 6D and API 598 cover more types, but api 600 gate valves have the strictest rules for gate valves.

Engineers should always match the standard to the valve and job. For example, api 600 gate valves are best for shutting off flow in refineries. API 6D valves are good for long pipelines. API 598 valves help check quality in many places. Picking the right standard keeps things safe and working well.

Choosing the Right Standard

Picking the right API standard is very important for engineers. Each standard is made for different jobs and valve types. Engineers must think about what the job needs, which valve to use, and how to test it. Choosing the right one keeps people safe and makes sure things work well. It also helps companies follow the rules.

Decision Factors

Industry Needs

Every industry has its own rules and dangers. Oil and gas companies use API 6D a lot. This standard is for pipeline valves that face high pressure and tough jobs. API 6D valves can shut off fast in emergencies. This is important for long pipelines that move oil or gas.

Other places, like water plants, chemical factories, and power stations, use API 598. This standard works for many valve types, not just pipelines. API 598 sets clear rules for checking and testing valves. It helps stop leaks and keeps things safe in places where a leak could be dangerous.

API 600 is used for steel bolted bonnet gate valves. Refineries, power plants, and chemical plants pick these valves for high pressure and heat. API 600 has strict rules for how these valves are made. This helps keep people and machines safe in hard jobs.

Valve Selection

Engineers need to match the valve to the job. API 6D covers ball, gate, plug, and check valves for pipelines. These valves must stop leaks and work in emergencies. API 598 covers more valves, like globe and butterfly valves. This makes it good for many jobs where different valves are needed.

API 600 is only for steel bolted bonnet gate valves. These valves are best for shutting off flow in hot and high-pressure places. When a refinery or steam line needs a strong valve, engineers pick API 600 gate valves.

Tip: Always look at the valve type and job before picking a standard. This helps make sure valves fit and work together in a system.

Testing Needs

Testing is a big part of picking the right standard. API 6D and API 600 need very strict tests. These tests do not allow any leaks at the seat. This helps keep systems safe and working well. API 598 also has tough tests, but it lets some small leaks for some valves.

Engineers should check what kind of testing each job needs. Pipelines with oil or gas need the strictest tests. Water or chemical plants might allow tiny leaks, so API 598 can be enough. Picking the right standard helps follow the rules and keeps everything safe.

Typical Use Cases

API 6D is mostly used in oil and gas work. Engineers pick this standard for pipeline valves that must handle high pressure and emergencies. API 6D valves can shut off fast and have special pressure ratings. These features help keep pipelines safe and follow the rules.

API 598 is used in many places, not just oil and gas. Water plants, chemical factories, and power stations use API 598 to check valves. This standard covers many valve types and has clear testing rules. Companies use API 598 to make sure valves are good and safe for many jobs.

API 600 is picked for steel bolted bonnet gate valves in refineries, power plants, and chemical plants. These valves must handle high pressure and heat. API 600 has strict rules for how they are made and tested. This helps keep people and equipment safe in hard jobs.

The table below shows where each standard is used:

| Standard | Main Industry/Application | Valve Types Covered | Key Features |

|---|---|---|---|

| API 6D | Petroleum, natural gas (pipelines) | Ball, gate, plug, check | Emergency shutdown, high pressure |

| API 598 | Water, chemical, power, general industry | Ball, gate, plug, check, globe, butterfly | Broad testing, leak detection |

| API 600 | Refineries, power, chemical plants | Steel bolted bonnet gate valves | High pressure/temperature, strict design |

Note: API standards are very important. They help companies follow the rules, make sure valves are good, and help valves work together. Using API standards means safer systems, better work, and easier repairs.

API 6D has tough rules for pipeline valves. It makes sure there are no leaks and keeps high pressure safe. API 598 is used to check and test many kinds of valves. It sometimes allows a tiny bit of leaking. API 600 is only for steel gate valves. These valves work in places with high pressure and heat.

- API 6D is good for pipelines.

- API 598 is for testing all kinds of valves.

- API 600 is best for steel gate valves.

Engineers need to pick the right standard. They should think about where the valve is used, what kind it is, and how it will be tested. This helps the valve work well and stay safe.

FAQ

Which valves does API 600 cover?

API 600 is only for steel bolted bonnet gate valves. These valves work where pressure and heat are very high. Refineries and power plants use API 600 gate valves to shut off flow safely.

Can engineers use API 598 for pipeline valves?

Engineers can use API 598 to test valves in pipelines. But API 6D is the main standard for pipeline valve design and how they work. API 6D has tougher rules for leaks and paperwork.

Why do leakage classes matter in valve selection?

Leakage classes help engineers pick valves that are safe and work well. Lower leakage classes mean the valve seals better. This keeps people, machines, and nature safe.

Tip: Always check which leakage class you need before picking a valve.

How do API standards improve safety?

API standards give clear steps for making, testing, and checking valves. These steps help stop leaks, broken parts, and accidents. Companies trust API standards to keep their systems safe.

What test media do API standards recommend?

API standards say to use water, air, or inert gas for testing valves. The choice depends on the valve and where it is used. Water is often used for pressure tests. Air or gas is used to check for leaks at the seat.

Where are API 6D valves most commonly used?

| Industry | Common Use |

|---|---|

| Oil & Gas | Pipeline isolation |

| Chemical Plants | Flow control |

| Power Plants | Emergency shutdown |

API 6D valves help keep pipelines and equipment safe in these places.