Selecting the right check valve for corrosive fluids needs careful thought. You must look at both material compatibility and system needs. Lined check valves, like those with PTFE or fluoroplastic linings, help stop common failures. Many places have problems like losing mechanical strength or valves breaking. These problems often happen because of these mistakes:

- Swapping materials without a technical review, like using a butterfly valve or ball valve instead of a lined check valve.

- Thinking stainless steel works for all corrosive fluids.

- Not checking the pressure and temperature limits of lined check valves.

You protect your process by matching the valve’s type and material to your use. You should also think about both technical and money factors.

Lined Check Valves: Key Criteria

Corrosion Resistance

Corrosion resistance is very important when picking lined check valves for corrosive fluids. The right check valve keeps your system safe from chemicals and stops it from breaking. Experts say to use rubber-lined or plastic-lined valves, like PTFE, PFA, or FEP, for fluids such as hydrochloric acid. Stainless steel or titanium alloys are best for nitric acid, but it depends on how strong and hot the acid is. For acetic acid, stainless steel or fluorine plastic-lined valves work best, especially if the temperature is high.

Tip: Always pick a lining material that matches the chemical you use. PTFE and other fluoroplastics can handle many chemicals, but you still need to check if they work with your fluid.

You should also think about using coatings, special surface treatments, and corrosion inhibitors. These things give extra protection. The way the valve is made is important too. Try not to have small spaces where corrosion can start. The best check valve uses materials and linings that keep the metal safe from the fluid, so it lasts a long time.

Application Fit

Application fit means you need to pick lined check valves that work with your system. You have to look at the fluid type, flow rate, pressure, temperature, and where the valve will be used. Chemical compatibility guides help you choose the best lining and body materials. Talking to experts helps you get the right check valve for your needs.

Here is a table that shows the main things to think about:

| Factor | Details |

|---|---|

| Lining Material | PTFE, PFA, FEP (full coverage of wetted surfaces) |

| Valve Body Material | Ductile Iron, WCB, Stainless Steel |

| Design Standards | API 594, EN 12334 |

| Size Range | 1” to 12” (DN25 to DN300) |

| Pressure Ratings | PN 10 / ANSI 150 |

| Temperature Range | -20°C to +180°C |

| Leakage Class | EN 12266 / Class A |

| Flow Direction | Horizontal or vertical (upward flow) |

| Key Features | Full lining coverage, bubble-tight sealing, low cracking pressure, corrosion-free operation |

Pick lined check valves that cover all the metal inside so nothing gets exposed. Find valves that seal tightly and open with little pressure. These things help stop corrosion and keep your system working well.

Common Mistakes

People often make mistakes when picking lined check valves for corrosive fluids. These mistakes can cause big problems:

- Using the wrong materials can cause corrosion, cracks, and fast damage.

- Picking valves that are too big or too small can cause leaks, backflow, and pressure loss.

- Not checking pressure and temperature limits can cause leaks, bending, or even break the valve.

- Forgetting about the fluid’s features, like how rough or strong it is, can wear out the valve too soon.

- Not thinking about where the valve is installed, like if it is wet or salty, can make the valve break down.

Note: If you pick the wrong lined check valve, it can break, wear out fast, waste energy, or even cause big failures.

Always match the valve size to the flow rate, pick materials that work with your fluid, and follow the pressure and temperature rules. Picking the right valve keeps your system safe from corrosion and saves you from expensive repairs.

Fluid Properties

Chemical Composition

You need to know what chemicals are in your fluid. The chemicals decide which lined check valve you should use. Some chemicals, like strong acids or bases, can damage metal parts fast. For example, pipes that move corrosive fluids often use spherical check valves. These valves have stainless steel shells and PTFE seals. They work well from -101°C to 150°C and up to 4.0 MPa pressure. Picking the right valve lining and body material keeps your system safe from corrosion.

If you choose the wrong materials, you can get corrosion or cracks. These problems may cause leaks or even stop your process. Fixing these issues can cost a lot of money. Always make sure the valve body, seat, and stem tip match your fluid. Use the table below to see what matters when picking a valve:

| Factor | Influence on Valve Selection |

|---|---|

| Chemical Compatibility | Valves must resist corrosion and damage from certain chemicals; stainless steel (like 316) is common, but very corrosive fluids need fluorine-lined valves or PTFE. |

| Temperature & Pressure | The material depends on how hot or high-pressure your system is; carbon steel works for high pressure but not for corrosive or hot fluids; alloys like Hastelloy or Inconel handle tough conditions but cost more. |

| Mechanical Strength | How strong and hard the material is decides how long it lasts; alloy steels are tougher and last longer. |

| Cost-Effectiveness | You need to balance cost and performance; sometimes coatings or linings on cheaper materials give enough protection. |

Concentration and pH

The concentration and pH of your fluid affect how long your lined check valve lasts. If the pH is too high or too low, it can hurt the valve lining. Even small changes in concentration can make the fluid more harmful. For example, glass linings can get damaged if the pH is not right. You need to keep the pH safe to protect your valve.

Tip: Always watch pH and concentration closely. Set alarms to warn you if levels go outside the safe range.

Thermoplastic valves can handle many acids and alkalis, but some chemicals can make them swell or get weak. If you use the wrong fluid, the valve may not work well or last long. You should also think about temperature and pressure limits along with chemical compatibility. Pick materials like PVC or CPVC only if they fit your fluid’s concentration and pH.

Here is a quick guide:

| Challenge | Impact on Lined Equipment | Recommended Action |

|---|---|---|

| Fluctuations in pH and concentration | Can damage glass lining and shorten its life | Watch pH and temperature all the time; keep levels within what the manufacturer says; use alarms for changes |

| Extreme pH levels | Hurt glass lining and make it work less well | Keep pH at the right level as the technical data sheets and manufacturer say |

| Chemical incompatibility | Makes lining wear out faster | Make sure the lining matches your chemicals and check technical data for your glass type |

Temperature Effects

Temperature changes can affect lined check valves a lot. When it gets hotter or colder, the seals and linings in the valve get bigger or smaller. This can cause leaks if the seal cannot keep up. Sometimes, the valve body or lining can bend, crack, or change shape. This can let fluid leak and may break the valve.

When things get bigger or smaller from heat, it also puts stress on pipes and fittings. If you do not plan for this, the valve can wear out faster. In systems with corrosive fluids, chemical attack and rubbing make things worse. Some lined check valves use special designs to handle heat changes and need less fixing. Always check the temperature range for your valve and make sure it fits your process.

Note: Quick temperature changes can make damage happen faster. Try to heat or cool slowly when you can.

Particulates and Viscosity

When you pick a lined check valve for corrosive fluids, you need to think about particulates and viscosity. These two things can change how your valve works and how long it lasts. If you do not pay attention, you might get leaks, damage, or even a broken valve.

Particulates are tiny solid bits in your fluid. They can be sand, rust, or other small pieces. If your fluid has particulates, you need a valve that can handle scratching. PTFE-lined valves are good at stopping chemical damage, but you should also look for valves with hard surfaces or special coatings. These help the valve fight off damage and keep a good seal.

Viscosity is how thick or sticky your fluid is. Water is thin and moves fast. Syrup is thick and moves slow. Thick fluids make it harder for the valve to open and close. Viscosity helps you pick the right valve type and seat material. Swing check valves are good for thin fluids. Ball or spring-loaded check valves work better for thick fluids because they open with less force. Soft seats like PTFE seal well with sticky fluids. Metal seats are best for hot or rough conditions.

Tip: Always check how big and how many particulates are in your fluid. Pick a valve with the right seat and lining for your fluid’s thickness and roughness.

Here is a quick guide to help you match valve features to your fluid:

| Fluid Challenge | Valve Feature Needed | Benefit |

|---|---|---|

| High particulates | Hard-facing, wear-resistant coating | Prevents erosion, extends life |

| Abrasive solids | Metal-to-metal seat | Handles wear, resists damage |

| Thick/viscous fluids | Soft seat (PTFE, EPDM, FKM) | Better sealing, easy operation |

| Corrosive chemicals | PTFE lining | Chemical resistance |

You should also think about how particulates and viscosity change how often you need to check your valve. Valves that see rough fluids may need more checks. If you pick the wrong seat, you might get leaks or bad sealing. PTFE seats work for most corrosive fluids. EPDM or FKM seats give different heat and chemical resistance. Metal seats last longer in hot or rough jobs, but you must use the right body material.

- The type of check valve matters. Swing valves are best for clean, thin fluids. Ball or spring-loaded valves are better for thick or dirty fluids.

- The seat material changes how well the valve seals and how long it lasts. PTFE gives chemical resistance. Metal seats are good for heat and rough use.

If you match your valve to the particulates and viscosity in your fluid, you keep your system safe from harm. You also cut down on repairs and save money. Always check your process before you choose a valve.

System Parameters

Pressure Rating

You need to check the pressure rating before picking a lined check valve for corrosive fluids. The pressure rating shows how much force the valve can take before it leaks or breaks. If you pick a valve with a low rating, it might break when the pressure is high. Always make sure the valve’s pressure rating matches your system.

Groups like API and ASME set pressure classes for valves. These classes help you choose the right valve for your job. Stainless steel, like ASTM A351 CF8M, is strong and fights corrosion. Alloy steels such as ASTM A217 WC6 are good for higher pressure and heat. Seal materials like FKM and Teflon help keep the valve sealed tight.

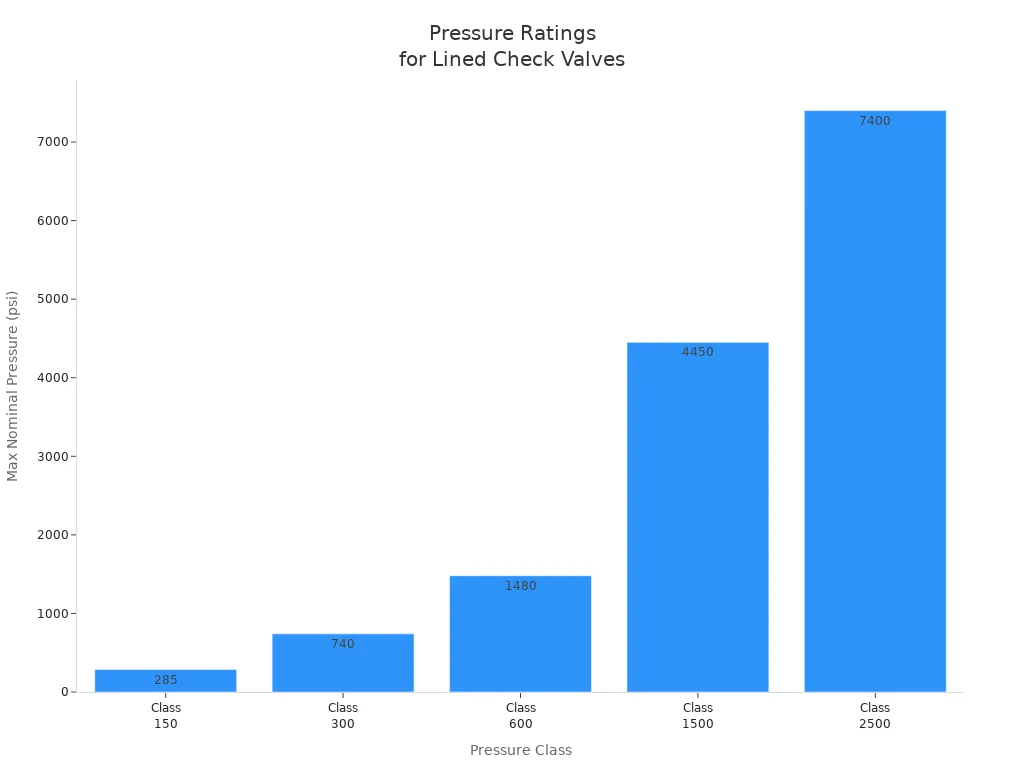

Here is a table that shows common pressure classes and their limits:

| Pressure Class | Maximum Nominal Pressure (psi) | Typical Temperature Range |

|---|---|---|

| Class 150 | Up to 285 | -20°F to 450°F |

| Class 300 | Up to 740 | -20°F to 450°F |

| Class 600 | Up to 1480 | -20°F to 450°F |

| Class 1500 | Up to 4450 | -20°F to 450°F |

| Class 2500 | Up to 7400 | -20°F to 450°F |

Tip: Always look at the pressure and temperature ratings on the valve’s data sheet. This helps you stop leaks and damage.

You should also pick valves that meet API 6D standards. These rules help make sure the valve is safe and lasts long in tough systems. When you choose materials, think about the fluid, pressure, temperature, and where the valve will be used.

Temperature Range

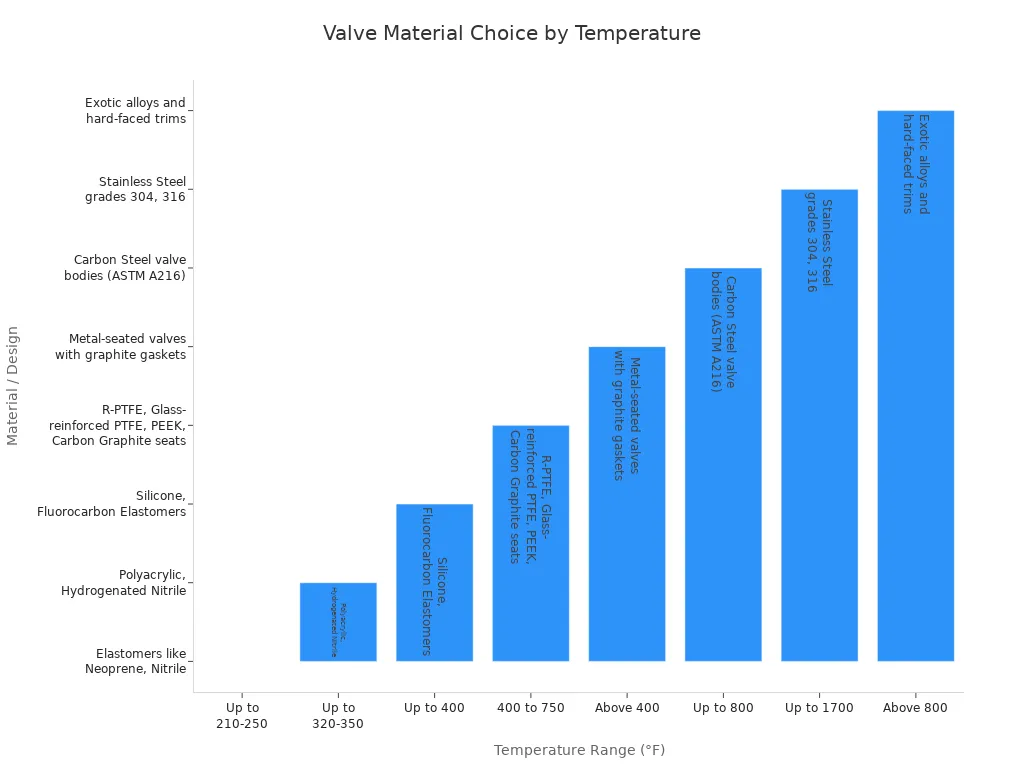

Temperature range changes how well your lined check valve works. If it gets too hot or cold, the valve parts might get weak or crack. You need to pick a valve that fits your system’s temperature.

Valve seats and bodies use different materials for different heat levels. Elastomers like Neoprene and Nitrile work for cold jobs. Polyacrylic and Hydrogenated Nitrile are better for warmer jobs but have limits. Silicone and Fluorocarbon elastomers work up to 400°F. For even hotter jobs, R-PTFE, glass-reinforced PTFE, and PEEK are used. Metal-seated valves with graphite gaskets are best for very high heat.

Here is a table to help you pick the right material:

| Temperature Range (°F) | Valve Material / Design Consideration | Explanation |

|---|---|---|

| Up to 210-250 | Elastomers like Neoprene, Nitrile | Good for cold seats; may crack if too hot. |

| Up to 320-350 | Polyacrylic, Hydrogenated Nitrile | Better for warmer jobs; not for very hot work. |

| Up to 400 | Silicone, Fluorocarbon Elastomers | Work at the highest heat for elastomers. |

| 400 to 750 | R-PTFE, Glass-reinforced PTFE, PEEK, Carbon Graphite seats | Handle medium-high heat. |

| Above 400 | Metal-seated valves with graphite gaskets | Best for high heat and pressure. |

| Up to 800 | Carbon Steel valve bodies | Can take steady heat up to 800°F. |

| Up to 1700 | Stainless Steel grades 304, 316 | Handle very high heat. |

| Above 800 | Exotic alloys (Inconel, Hastelloy, Stellite) | Used for extreme heat and tough chemicals. |

Note: Pressure ratings go down as temperature goes up. Always check both ratings before you put in the valve.

How the valve is made matters too. Lug, wafer, and flanged ends help with heat changes. Special linings and coatings, like high-temp epoxy, give extra safety for tough fluids.

Flow Rate

Flow rate tells you how much fluid moves through your system in a certain time. You need to know your flow rate and speed to pick the right lined check valve. If the flow rate is too high, the valve can wear out faster. If it is too low, the valve might not open or close right.

Measure flow rate in gallons per minute (GPM) or liters per second (L/s). The right valve size and type depend on your system’s needs. Swing check valves are good for steady, medium flows. Ball or spring-loaded check valves are better for changing or low flows.

Tip: Always match the valve size to your flow rate. This helps stop leaks, backflow, and pressure loss.

If you pick a valve that fits your flow rate and speed, your system stays safe and works well. You also cut down on repairs and save time.

Pipe Size

Choosing the right pipe size is a key step when you select a lined check valve for corrosive fluids. You need to match the valve size to your piping system. If you skip this step, you risk leaks, noise, and even valve failure. Always check the pipe size and flow rate before you make your choice. This helps you avoid costly repairs and keeps your system running smoothly.

When you install a lined check valve, you should avoid sudden changes in pipe size near the valve. Sudden changes can cause swirling, shaking, and extra noise. These problems can wear out the valve faster and reduce its service life. You want the fluid to flow smoothly through the valve. This keeps the valve working well and helps it last longer.

You also need to match the flange bolt pattern and pressure class of the valve to your pipes. If the bolt holes do not line up, you cannot get a tight fit. A poor fit can lead to leaks, which are dangerous in corrosive environments. Always check the valve’s pressure and temperature ratings to make sure they match your system.

Tip: Leave enough straight pipe before and after the valve. This helps the fluid flow in a straight line and reduces wear on the valve.

Here are some important points to remember when you look at pipe size and lined check valves:

- Check that the valve size matches your pipe size and flow rate.

- Avoid sudden pipe size changes near the valve to prevent swirling and noise.

- Make sure the flange bolt pattern and pressure class fit your piping system.

- Leave enough straight pipe before and after the valve for smooth flow.

- These steps help keep your valve reliable and safe in corrosive environments.

If you follow these guidelines, you improve flow, reduce wear, and keep your system safe. Pipe size may seem simple, but it plays a big role in how well your lined check valve works.

Material Selection

Picking the right materials for lined check valves is very important. You must match the lining and body to your fluid, temperature, and pressure. This helps stop corrosion, leaks, and early valve problems.

Lining Materials

The lining inside a check valve keeps the metal safe from corrosive fluids. When you pick a lining, think about chemical compatibility, temperature, and wear.

PTFE, PFA, FEP

PTFE, PFA, and FEP are often used as linings in tough chemical places. These fluoropolymers resist chemicals and heat very well.

- PTFE can handle most acids, bases, and solvents. It does not stick and keeps things clean. You can use PTFE for acids, water, chemicals, and oils.

- PFA is like PTFE but bends better and takes more heat.

- FEP also resists chemicals and is easy to shape for tricky valve designs.

Tip: PTFE and PFA linings are good for very corrosive fluids and clean jobs. Always check the temperature and pressure before you pick.

PVC, Composite, Alloys

You can also use PVC, composite linings, or special alloys.

- PVC works for less strong chemicals and costs less. It handles medium heat and is simple to put in.

- Composite linings mix plastics and metal strength. They fight corrosion and wear, so they fit many fluids.

- Alloys like Hastelloy or Monel are for the toughest jobs. These metals resist both corrosion and high pressure.

Other linings include rubber, ceramic, and polypropylene. Each type has special benefits, like stopping wear or handling high heat.

- Rubber protects against rough and corrosive fluids.

- Ceramic is best for rough slurries or powders.

- Polypropylene works with saltwater, acids, and bases at high heat.

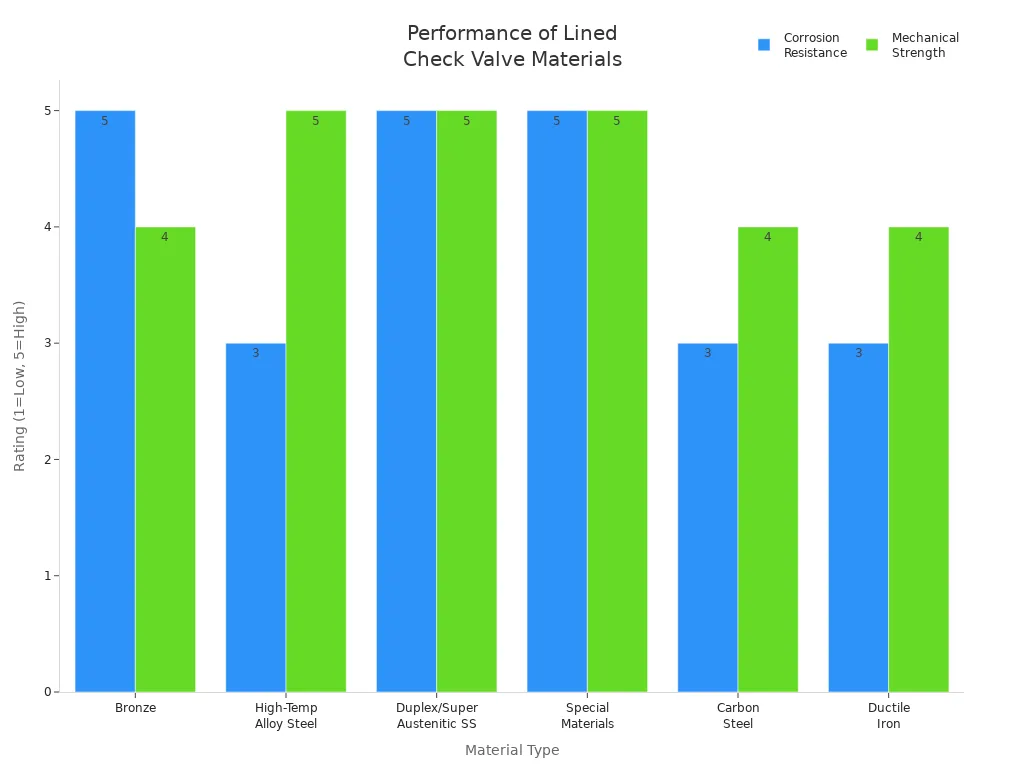

Body Materials

The valve body must handle the fluid and system pressure. What you pick here changes how safe and long-lasting the valve is.

| Material Type | Corrosion Resistance | Mechanical Strength / Application Highlights |

|---|---|---|

| Bronze | Great, especially in seawater | Strong, easy to shape |

| Alloy Steels | Good in steam or high heat | Strong, used in power plants |

| Stainless Steels (2205, 2507, 904L, ALLOY20) | Very high, stops pitting | Strong, for harsh chemicals |

| Titanium/Nickel Alloys | Excellent in tough fluids | Very strong, for hard jobs |

| Carbon Steel | Good for most uses | Strong, for medium or high pressure |

| Ductile Iron | Good for many fluids | Reliable in oil, gas, and water treatment |

Note: Bronze and stainless steel bodies work in many corrosive places. For the toughest fluids, use titanium or high-nickel alloys.

Compatibility Charts

You should always look at compatibility charts when picking materials. These charts help you match linings and bodies to your fluid and temperature.

- Stainless steel is good for general corrosion.

- Hastelloy and Monel are for very strong chemicals.

- Teflon linings (PTFE, PFA, FEP) are best for corrosive or clean fluids.

- Ceramics are for rough or hot fluids.

If you pick the wrong materials, you can get corrosion, clogs, or valve failure. Always check with suppliers and use charts to help you choose.

Tip: Picking the right materials keeps your system safe, makes valves last longer, and helps them work well with corrosive fluids.

Check Valve Types

Swing

Swing check valves have a disc that moves on a hinge. The disc opens when fluid flows the right way. If the flow stops or goes backward, the disc closes. Gravity or pressure helps push the disc shut. People use swing check valves in water and chemical systems. These valves work best with clean and thin fluids.

Pick swing check valves if you want easy care and low pressure loss. The design lets fluid move with little block. But swing check valves do not work well with thick fluids or fluids with solids. Solids can get stuck and cause leaks or harm.

Tip: Put swing check valves in pipes that go sideways for best results. You can use them in up-and-down pipes only if the flow goes up.

Swing check valves open with little force. This helps save energy in your system. Some swing check valves have PTFE or other linings to stop corrosion.

Ball

Ball check valves use a round ball to block flow. When fluid moves forward, the ball lifts and lets fluid pass. If the flow stops or goes back, the ball drops and seals the valve. Ball check valves are better than swing types for thick or dirty fluids.

Pick ball check valves for systems with solids or sticky fluids. The simple design means there are fewer parts to break. Ball check valves work in both sideways and up-and-down pipes.

Here is a quick comparison:

| Feature | Swing Check Valve | Ball Check Valve |

|---|---|---|

| Best for | Clean fluids | Dirty/thick fluids |

| Cracking Pressure | Low | Medium |

| Maintenance | Easy | Very easy |

| Installation | Horizontal best | Any orientation |

Ball check valves often have PTFE linings to fight chemicals. You can use them in chemical plants, mines, and wastewater jobs.

Wafer

Wafer check valves are thin and light. They fit between two pipe ends and save space. Wafer check valves use a disc or two plates that open with flow. When flow stops or goes back, the disc closes fast.

Use wafer check valves if you need to save space or weight. These valves are good for tight spots or where pipes cannot hold much weight. Wafer check valves close quickly to help stop water hammer.

Note: You must line up wafer check valves right when you put them in. Make sure the valve fits the flow and pipe size.

Wafer check valves can have PTFE or other linings to stop corrosion. People use them in chemical plants, HVAC, and water treatment systems.

Diaphragm

A diaphragm check valve uses a soft part called a diaphragm to control flow. When fluid moves forward, the diaphragm lifts up and lets it through. If the fluid stops or goes backward, the diaphragm pushes down and blocks the flow. This design makes a very tight seal. It helps stop leaks in systems with corrosive fluids.

You see diaphragm check valves in chemical plants and water treatment places. The diaphragm is made from rubber, PTFE, or other strong materials. These materials help the valve work with harsh chemicals. The valve works well at low pressure. The diaphragm needs only a little force to open or close. Some valves have a loose diaphragm that opens with almost no pressure. Others have a fixed diaphragm that needs more force to move.

Here is a table to compare diaphragm check valves with other types:

| Valve Type | Sealing Performance | Cracking Pressure | Best Use Case |

|---|---|---|---|

| Diaphragm Check Valve | Excellent, very tight seal | Very low, easy to open | Corrosive fluids, low-pressure lines |

| Swing Check Valve | Good, depends on design | Low to moderate | Clean fluids, horizontal pipes |

| Ball Check Valve | Good, needs maintenance | Moderate, spring-based | Thick or dirty fluids |

| Wafer Check Valve | Good, compact design | Moderate | Tight spaces, chemical pipelines |

Tip: Pick a diaphragm check valve if you want a leak-proof seal and need to handle strong chemicals. The flexible diaphragm stands up to many acids and bases.

Diaphragm check valves need less care than some other types. The simple design means there are fewer parts to break. You can put these valves in pipes that go sideways or up and down. This gives you more choices for your system.

Application Suitability

You should match the check valve type to your system’s needs. Each valve works best in certain jobs. Think about the fluid, pressure, space, and how much care you want to do.

Here is a quick guide to help you pick:

| Check Valve Type | Best For | Installation Orientation | Maintenance Needs | Material Tips |

|---|---|---|---|---|

| Diaphragm | Corrosive, low-pressure fluids | Horizontal or vertical | Low, simple design | PTFE, rubber, stainless steel |

| Swing | Clean, low-pressure fluids | Horizontal or vertical | Easy, regular checks | Stainless steel, PTFE-lined |

| Ball | Dirty, thick fluids | Any orientation | Low, check for debris | Stainless steel, PTFE-lined |

| Wafer | Tight spaces, chemical lines | Horizontal or vertical | Varies, check for surges | Stainless steel, PTFE-lined |

If you use strong acids or bases, diaphragm check valves give the best seal and chemical safety. For thick or dirty fluids, ball check valves work better with solids. Swing check valves fit simple, clean systems and need little care. Wafer check valves save space and fit small pipes.

Note: Always check the valve’s material with your fluid. PTFE and stainless steel work well for most corrosive fluids.

Pick the right check valve for your system. You will get better results, fewer leaks, and longer valve life.

Check Valve Selection: Installation & Maintenance

Installation Best Practices

Putting in a check valve the right way helps it work well. Always look at what your system needs first. Think about the fluid, how hot or cold it is, the pressure, and if it can cause rust. This helps you pick the best valve for your job.

Here are some easy steps for installing lined check valves:

- Get the area ready. Lower the pressure, close off the pipe, and clean it well. Take out any dirt or old stuff so nothing hurts the inside of the valve.

- Find the tools and things you need. Use gaskets and sealants that fit your valve. Grab a torque wrench, gloves, and safety glasses to stay safe.

- Put the valve in the right way. Follow the arrows that show which way the fluid goes. Line up the valve and use good gaskets. Tighten everything with a torque wrench as the maker says. This stops leaks and keeps parts from breaking.

- Slowly bring the pressure back up after you finish. Check the valve to make sure it does not leak and works smoothly.

- Teach your team how to handle and fix the valve safely. Remind them to lower the pressure and drain the system before they start any work.

Tip: Always clean out the pipe before and after you put in the valve. This gets rid of dirt that could hurt the valve or make it wear out faster.

Maintenance Needs

Doing regular checks helps your lined check valves last longer. Look at the valve often to see if it is worn out, rusty, or leaking. Listen for weird sounds and see if the valve sticks or the flow changes. These things can mean trouble is starting.

Some important jobs for maintenance are:

- Clean the valve and pipe nearby to get rid of buildup.

- Oil moving parts if the maker says you should.

- Look at seals and seats for damage or wear. Change them if needed so the valve shuts tight.

- Take apart and clean the valve if you see dirt or buildup inside.

- Put in a new valve if you find rust inside, lots of problems, or big damage.

Note: Always wear the right safety gear and follow rules when working with fluids that can cause harm.

Inspection Intervals

Check lined check valves often so you find problems early. How often you check depends on where you use the valve:

| Application Category | Recommended Inspection Frequency |

|---|---|

| Water Supply Systems | Every 1 to 2 years |

| Industrial Process Piping | Every 6 to 12 months |

| Critical Safety Systems | Every three months or as needed |

For most systems with fluids that can cause rust, use the industrial process piping rule. Look at your valves every 6 to 12 months. These times match rules like API 598 and ASME B16.34. If your system is very important or risky, check even more often.

Tip: Set reminders to check your valves and write down what you find. This helps you see how your valves are doing and fix things before they break.

Troubleshooting

When you use lined check valves with corrosive fluids, you might have some problems. It is important to know how to find and fix these problems. This helps keep your system safe and working right. Here is a table that shows the most common problems, what causes them, and how you can fix them:

| Problem | Cause | Solution |

|---|---|---|

| Leakage Issues | Worn seals, poor installation, valve body damage | Replace seals, follow correct installation, inspect regularly |

| Spring Failure | Weak or broken spring | Check spring condition, replace if needed |

| Clogging and Contamination | Debris or sediment in the fluid | Clean valve, use filters, keep pipeline clean |

| Valve Sticking or Jamming | Deposits, corrosion, or buildup | Clean deposits, use corrosion-resistant materials, maintain |

| Reverse Flow Problems | Wrong installation, pressure changes | Install correctly, use backflow preventers, monitor pressure |

| Improper Installation | Misalignment, wrong size | Follow guidelines, check sizing and alignment |

| Water Hammer | Sudden flow changes | Control flow, install dampeners, design system properly |

| Failing Seat Seals | Seal wear from friction or use | Replace seals, use corrosion-resistant materials |

| Corrosion and Material Fatigue | Fluid attacks valve materials | Use proper linings, inspect and replace parts as needed |

| Loose Fasteners | Vibration or time | Tighten bolts during maintenance |

| Faulty Gaskets or Washers | Damaged or worn sealing parts | Replace gaskets and washers |

| Excessive Pressure | Pressure above valve rating | Keep pressure within valve specs |

Tip: Clean and check your valves often. This helps you find most problems early. If you see leaks, hear strange sounds, or the valve does not move easily, fix it right away.

Sometimes, dirt or small pieces can build up inside the valve. This can make the valve get stuck open or closed. Clean out the valve and take away any dirt often. If you hear a loud banging noise, called water hammer, slow down when you open or close the valve. You can also put in dampeners to help stop this noise.

If you find leaks, look at the seals and gaskets first. Change them if they look old or broken. Always use the right materials for your fluid. Corrosive fluids can wear out seals and linings fast. If you see cracks or rust, change those parts right away.

Putting the valve in the wrong way is another problem. Always follow the maker’s instructions for lining up and sizing the valve. This helps you stop the valve from breaking too soon.

You should also watch for pressure changes. High pressure can hurt the valve. Keep the pressure in your system at the right level for the valve.

Troubleshooting is very important for picking and taking care of check valves. If you follow these steps, your lined check valves will work better and last longer.

Economic Considerations

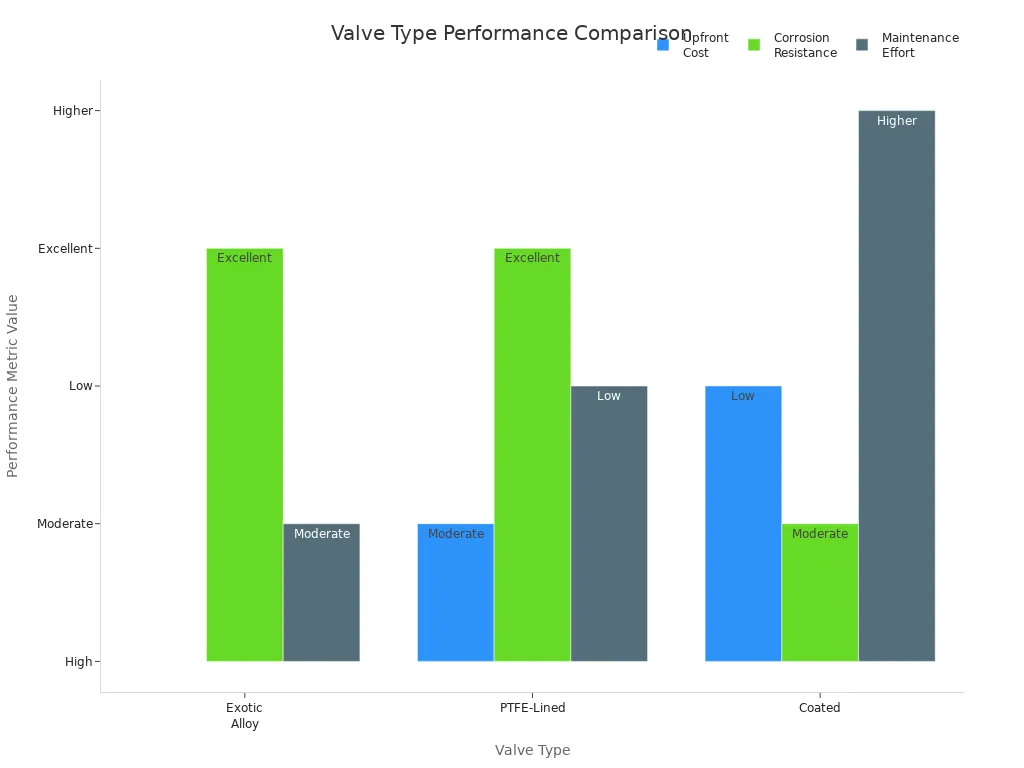

Cost vs. Performance

When you pick a lined check valve for corrosive fluids, you must decide between paying more now or saving money later. Lined check valves with stainless steel or PTFE linings cost more at first. But these valves protect better against corrosion and last longer in tough places. Cheaper valves, like cast iron ones, cost less at the start but break down faster with harsh chemicals.

Here is a simple table to help you compare:

| Cost Aspect | Lined (Corrosion-Resistant) Check Valves | Wafer Check Valves (Simpler Design) |

|---|---|---|

| Initial Cost | Higher due to special materials | Lower due to basic design |

| Performance | Superior in harsh, dirty, or high-pressure jobs | Adequate for clean, low-pressure jobs |

| Maintenance Cost | Lower over time because of durability | May need more repairs in tough jobs |

- Stainless steel swing check valves cost more but fight corrosion and last longer.

- Cast iron valves are cheaper but need more repairs or new parts in tough systems.

- Carbon steel valves are in the middle but may need coatings to stop rust.

- Spending more on good materials can help you save on repairs and lost time.

Tip: Think about how often you want to fix or change your valves. Paying more at first can mean fewer problems later.

Longevity

How long a lined check valve lasts depends on a few things. The material you pick is the most important. Linings like PTFE or PFA help the valve handle strong chemicals. How you use the valve also matters. High pressure, very hot or cold temperatures, and dirty fluids can wear out a valve faster.

You can help your valves last longer by:

- Picking the best material for your fluid and where you use it.

- Using coatings or special designs to stop corrosion.

- Cleaning and checking your valves often.

Some check valves can last 15 to 25 years. This only happens if you pick the right valve and take care of it. If you use the wrong material or skip checks, you might need a new valve much sooner.

Note: Checking your valves often and fixing them fast helps them last longer.

Total Cost of Ownership

When you think about the total cost, do not just look at the price tag. The real cost includes:

- The money you pay to buy the valve.

- The time and money for repairs and checks.

- The cost if your valve breaks and stops your work.

A lined check valve that costs more at first can save you money over time. You spend less on repairs, new parts, and lost work. You also lower the chance of leaks or spills, which can be costly and unsafe.

Key points to remember:

- Pick valves that fit your fluid and system.

- Buy good materials for fewer problems and longer use.

- Plan to check and care for your valves to avoid big costs.

Picking the right lined check valve saves your money and keeps your system safe. You get better results, longer use, and less worry.

PTFE-Lined Check Valves in Corrosive Media Applications

Typical Industries and Use Cases

Chemical processing plants

PTFE-lined check valves are used in chemical plants. These plants use strong acids and alkalis. PTFE linings keep the valves safe from damage. They help control flow and stop backflow in pipes and pumps.

Acid and alkali handling systems

These valves work well with acids and alkalis. The fluids can hurt metal parts fast. PTFE linings protect the valves and help stop leaks.

Pharmaceutical manufacturing

Pharmaceutical plants need clean and safe systems. PTFE-lined check valves stop chemicals from mixing in. They help keep medicines pure and safe.

Pulp and paper industry

The pulp and paper industry uses chemicals that can rust metal. PTFE-lined check valves help control these fluids. They make equipment last longer.

Water treatment facilities

Water treatment plants use PTFE-lined check valves for harsh fluids. These valves handle chlorine and other strong cleaners. They help stop leaks and keep water clean.

| Industry | Use Cases / Applications |

|---|---|

| Chemical | Handling strong acids, alkalis, and other harsh chemicals; controlling flow in pipes |

| Pharmaceuticals | Handling tough chemicals in medicine making |

| Pulp and Paper | Using valves that do not rust in pulp and paper plants |

| Water Treatment | Managing strong cleaners and chemicals in water treatment |

Performance Advantages

Exceptional chemical resistance

PTFE-lined check valves resist many chemicals. The PTFE covers all inside parts. This keeps acids and alkalis away from the metal. You can use these valves with many harsh fluids.

Low maintenance requirements

You do not need to fix PTFE-lined check valves often. PTFE is slippery, so less dirt sticks to it. You get fewer shutdowns and longer times between checks.

Extended service life in harsh environments

PTFE-lined check valves last longer than most others. The lining does not wear out fast. You do not have to buy new valves as often. This saves you money.

Prevention of media contamination

PTFE does not react with most chemicals. This stops your fluids from getting dirty. It is important for making medicine and food.

Limitations and Considerations

Temperature and pressure constraints

PTFE-lined check valves cannot take very high heat or pressure. Most work up to about 392°F. If it gets hotter, the lining can break. Always check the valve’s limits before using it.

Potential for mechanical damage to lining

PTFE is soft and can get scratched by hard things. If your fluid has solid bits, the lining can wear out faster. You need to keep sharp things away from the lining.

Compatibility with abrasive or slurry media

PTFE-lined check valves are not good for rough or gritty fluids. The lining can get damaged by hard particles. For these fluids, you may need a different valve or extra protection.

Note: Always pick a valve that fits your job. PTFE-lined check valves are great for chemicals, but you must know their limits to get the best results.

Selection Tips for PTFE-Lined Check Valves

Verify chemical compatibility with process media

You should always make sure PTFE can handle your fluid. PTFE linings stop many acids, bases, and solvents because they do not react. This makes PTFE-lined check valves a good pick for systems with corrosive fluids. If you use the wrong lining, the valve can break and leak fast. Look at chemical compatibility charts before you choose. When you match the lining to your fluid, you keep your system safe and help the valve last longer.

Tip: Do not think PTFE works for every chemical. Some rare chemicals or mixes can still hurt the lining. Always check with the manufacturer’s data to be sure.

Assess operating temperature and pressure limits

You need to know your system’s temperature and pressure. PTFE-lined check valves work in many jobs, but each valve has its own limits. High heat or pressure can make the lining weak or change shape. If you go past the valve’s rating, you might get leaks or a broken valve. Always read the valve’s datasheet for the highest temperature and pressure. Pick a valve that fits or beats your system’s needs.

| Parameter | Typical PTFE-Lined Valve Limit |

|---|---|

| Max Temperature | Up to 392°F (200°C) |

| Max Pressure | Varies by design, often 150 psi (10 bar) |

Note: Pressure ratings often get lower when the temperature goes up. Always check both numbers together.

Consider installation orientation and flow direction

You must put PTFE-lined check valves in the right spot. Some types, like swing check valves, work best in sideways pipes. Others, like ball check valves, can go any way. Always follow the arrow on the valve body for flow. If you put the valve backward or at a bad angle, it may not seal or open right. This can cause backflow or damage.

- Read the manufacturer’s instructions for the best way to install.

- Make sure the flow matches the arrow on the valve.

- Leave enough straight pipe before and after the valve for smooth flow.

Consult manufacturer for custom requirements

Every job is different. If you have special needs, talk to the valve maker. They can help you pick the right valve type, lining thickness, or even make a custom valve. Good suppliers give technical help and answer questions about chemical compatibility, pressure, or temperature. You get better results and avoid mistakes when you ask experts.

Callout: Picking corrosion-resistant PTFE-lined valves from trusted makers helps your system work better, cuts down on repairs, and protects your money.

Summary Checklist:

- Make sure PTFE works with your fluid.

- Check temperature and pressure ratings for your job.

- Follow the rules for how to install and which way the flow goes.

- Ask experts for help with special jobs.

If you follow these tips, your PTFE-lined check valves will last longer, work safely, and do their job well with corrosive fluids.

You can pick the right lined check valve for corrosive fluids by using a simple plan. First, find out what your fluid is like and what your system needs. Next, choose valve materials that fit your job. Then, make sure the valve works with your pressure, temperature, and flow. Always use a checklist for every project.

If your system is tricky, talk to the manufacturer or an expert. Always think about safety and making things work well. Picking the right valve keeps your equipment safe and helps it last a long time.

FAQ

What is a lined check valve?

A lined check valve has a special layer inside. This layer protects the valve from harmful fluids. People use these valves to stop leaks and damage in places with strong chemicals.

How do I know which lining material to choose?

You need to know what is in your fluid and how hot it gets. Look at charts from the company to see what works. PTFE is good for most chemicals. If your fluid is special, ask an expert or supplier for help.

Can I use a lined check valve for abrasive fluids?

Do not use lined check valves with soft linings for rough fluids. Hard bits can scratch or wear out the lining fast. For slurries, pick valves with ceramic or metal linings instead.

How often should I inspect my lined check valve?

Check your valve every 6 to 12 months in most factories. For important safety jobs, check every three months. Write down what you find to keep track of the valve’s condition.

What happens if I install the valve backwards?

If you put the valve in backwards, it will not stop flow from going the wrong way. This can cause leaks and make your system fail. Always follow the arrow on the valve to match the flow.

Are PTFE-lined check valves safe for high temperatures?

PTFE-lined check valves work up to about 392°F (200°C). If your system is hotter, the lining can break. Always check the valve’s data sheet for the right temperature before you use it.

How do I prevent leaks in corrosive fluid systems?

Use the right lining and body materials for your fluid. Tighten bolts the way the maker says. Leave enough straight pipe before and after the valve. Check seals and seats often to see if they are worn out.