Hydraulic actuators are very important in many industries that require strong and accurate valve control. Workers use hydraulic actuators to open and close valves by themselves, especially when dealing with large valves that need more power than pneumatic valves or electric valves can provide. These actuators are commonly used in gas pipelines and chemical plants, where tough equipment is essential. Hydraulic actuators deliver a steady force because hydraulic oil cannot be compressed, ensuring reliable operation. They also work quickly, which is crucial during emergencies. When people need strong and dependable force, they choose hydraulic actuators over electric valves or pneumatic valves.

Hydraulic Actuator Functions

Valve Automation

Hydraulic actuators help automate how valves work in many places. They use pressurized fluid to move valves, so people do not need to do it by hand. Workers can control valves from far away, which keeps them safe and saves money. These actuators connect to special motion control systems for better control of valve movement and position.

- Hydraulic actuators use fluid pressure to move the valve stem or disc.

- A piston inside the actuator changes fluid pressure into movement.

- Solenoids control how hydraulic fluid flows into the actuator.

- Springs push the valve back if the system loses pressure.

- Automated hydraulic actuators work with motion control systems for better operation.

- Remote control keeps workers away from dangerous places and makes things safer.

- Automated systems make maintenance easier and help stop long delays.

Note: Hydraulic actuators are best for jobs that need a lot of force when electric or manual actuators are not strong enough. They also keep the valve in place if the power goes out, which makes important systems safer.

Force and Precision

Hydraulic actuators give strong force and good control when moving valves. They can make forces from 100 lbs. up to 150,000 lbs., so they work well for big or high-pressure valves. Their small size and strong power let them fit in tight spots and still work well.

Operators use hydraulic actuators to control valve position, speed, and force very carefully. Motion control systems help set the actuator just right, so the valve moves as needed. This careful control helps save materials and makes the process better. Hydraulic actuators also repeat the same movement every time, so each valve move is correct.

| Feature | Description |

|---|---|

| High Force Output | Hydraulic actuators move big valves and work in high-pressure systems. |

| Precise Control | Operators can set valve position, speed, and force very accurately. |

| Compact Size | Strong power in a small size fits in tight spaces. |

| Ruggedness | Hydraulic actuators last in tough work places. |

| Reliable Performance | They work the same way every time for safety and stability. |

Control Mechanisms

Hydraulic actuators use different control parts to make sure valves work right. Each actuator has a cylinder, piston, power source, and control valves. The cylinder holds the pressurized fluid, and the piston moves to open or close the valve. Control valves guide the fluid, so the valve moves smoothly.

Motion control systems watch how the actuator works and change settings if needed. These systems give feedback about valve position and movement, so operators can keep control. Double acting actuators use fluid on both sides of the piston for better movement, while single acting actuators use springs or gravity to return.

- Hydraulic actuators need pumps, reservoirs, and control valves to work.

- Motion control systems give real-time feedback and make changes.

- Double acting actuators control movement better than single acting ones.

- Operators can keep the valve in place even if power or pumps stop working.

- Hydraulic actuators move slower than pneumatic actuators but are stronger and last longer.

Tip: Check hydraulic actuators and motion control systems often to stop leaks and keep them working well for a long time.

How Hydraulic Actuators Work

Operating Principles

A hydraulic actuator uses pressurized fluid to move valves with power and accuracy. The system begins with a hydraulic pump. This pump changes mechanical energy into hydraulic energy by pushing oil under pressure. The pressurized oil moves through pipes and goes into the actuator. Inside, the actuator turns the fluid’s pressure into movement. The actuator can move in a straight line or turn, depending on what the valve needs.

Hydraulic valve control systems use special valves called proportional or servo valves. These valves change how much fluid goes into the actuator. By opening or closing these valves, the system controls how fast and how far the actuator moves. Pressure sensors watch the system and send information to a controller. The controller checks if the movement matches what is needed and makes changes to keep the valve in the right place. This closed-loop control helps the actuator work smoothly and correctly.

- The hydraulic actuator gets pressurized fluid from the pump.

- The piston or rotary part moves, which opens or closes the valve.

- Control valves change the flow and pressure of the fluid.

- Sensors and controllers watch and adjust the actuator’s position.

Note: Closed-loop control systems help keep valve positions correct, even if things change.

Main Components

Hydraulic actuator systems have several important parts. Each part has a job to help the actuator work well and move the valve as needed.

Cylinder and Piston

The cylinder and piston are the main parts of most hydraulic actuators. The cylinder holds the pressurized fluid. The piston sits inside the cylinder and moves when fluid comes in. This movement pushes or pulls the valve stem, so the valve opens or closes. Some actuators use one port for fluid, while others use two ports for more control both ways.

Power Source

The power source is usually a hydraulic pump. The pump makes the fluid move and builds up the pressure needed for the actuator. The pump takes fluid from a reservoir and sends it through the system. The reservoir also cools the fluid, removes air, and lets dirt settle.

Control Valves

Control valves act like traffic guides for the system. They send the fluid to the actuator, control which way it moves, and set the pressure. There are different types of control valves, like directional, pressure, and flow control valves. These valves work together to make sure the actuator moves the valve the right way.

| Component | Function |

|---|---|

| Pump | Pressurizes fluid and creates flow for the actuator. |

| Control Valve | Directs and regulates fluid flow and pressure. |

| Actuator | Changes fluid power into movement to move the valve. |

| Reservoir | Stores and takes care of the hydraulic fluid. |

| Pressure Regulator | Keeps fluid pressure at safe levels. |

Tip: Check each part often to stop leaks and keep the actuator system working well.

Types of Hydraulic Actuators

Hydraulic actuators are very important for moving valves automatically. They use pressurized fluid to make things move in many industries. There are different types of actuators for different jobs and places. Knowing about these types helps engineers pick the best one for each job.

Linear Hydraulic Actuators

Linear hydraulic actuators move things in a straight line. They have a piston inside a cylinder that pushes or pulls a valve stem. This design helps them lift, push, or move valves very accurately. Many industries use them when they need to move something in a straight line, like lifting heavy gates or moving big valves in water plants.

The table below shows how linear and rotary actuators are different:

| Aspect | Linear Actuators | Rotary Actuators |

|---|---|---|

| Motion Type | Move in a straight line using lead screws, belts, or rack and pinion. | Move in a circle using motors with gears, cams, or belts. |

| Design | Motor and parts that change spinning to straight movement. | Motor and parts that make spinning movement. |

| Applications | Used for lifting, pushing, or pulling in a straight line; found in cars, robots, medical tools, and home devices. | Used for turning valves, opening doors, moving robot arms, and steering. |

| Advantages | Good for accurate straight movement and easy to set up. | Good for spinning movement in small spaces; can spin a lot or a little. |

| Disadvantages | Can only move so far and may bend if not supported. | Can only spin so much and may be harder to set up. |

Linear hydraulic actuators are easy to install and control. They are great for jobs that need strong and exact movement.

Rotary Hydraulic Actuators

Rotary hydraulic actuators make things turn. They spin a shaft to turn valves, which is good for ball, butterfly, and plug valves. These actuators make a lot of turning force, which is needed for big valves and high pressure. Rotary hydraulic actuators give smooth and careful control when turning.

Some good things about rotary hydraulic actuators are:

- They make strong turning force.

- They help set valves in the right spot.

- They last a long time in tough places.

- They work in many different jobs and setups.

- They keep valves in place if the power goes out, which is safer.

Rotary hydraulic actuators are used in oil, gas, power, and mining. They are strong and work well, so people use them for hard jobs.

Double Acting Hydraulic Actuators

Double acting hydraulic actuators use fluid on both sides of the piston. This lets them move valves both ways with the same force. Single-acting actuators use a spring to go back, but double acting ones use fluid for both directions.

Some benefits of double acting hydraulic actuators are:

- They push and pull with the same strength.

- They move valves both ways for better control.

- They react fast, which is good for quick jobs.

- They are built strong for tough places.

- They save energy by using just the right amount of fluid.

The table below shows how they work:

| Performance Aspect | Explanation |

|---|---|

| High Thrust Strength | They push hard both ways, so they can move big valves, unlike single-acting ones that use springs. |

| Handling High Torque Loads | They handle big turning jobs with less fluid, which saves energy and works faster. |

| Stable and Precise Control | They use fluid to control the piston, so they move valves exactly, better than spring ones. |

| Maintaining Last Fail Position | If power goes out, they keep the valve in place with fluid, so the valve does not close too fast. |

| Enhanced Safety and Reliability | No springs to wear out, and they can stop in the middle if power fails, which is safer for important jobs. |

Double acting hydraulic actuators are used for big, tough valves in factories and chemical plants. They give steady, exact, and safe control, so they are needed for hard valve jobs.

Hydraulic Actuators for Ball Valves

Principles of Hydraulic Ball Valve Control

Hydraulic actuators help ball valves work in many places. They use oil under pressure to move a piston inside a cylinder. The piston moves in a straight line. A rack-and-pinion system changes this straight movement into turning. This turning spins the ball inside the valve. When the ball turns, it opens or closes the path for flow. Hydraulic actuators can make a lot of force. This makes them good for big or high-pressure valves.

The control system uses electric signals to run pumps or valves. Operators can send commands from far away. The actuators react fast to these commands. If the main hydraulic system stops working, a hand pump can still move the valve. Oil does not get squeezed, so the valve stays in place even if power is lost. This helps keep things safe in important jobs.

| Aspect | Description |

|---|---|

| Actuation Mechanism | Hydraulic actuators use oil pressure on a piston, converting linear to rotary motion for ball valve operation. |

| Force Generation | High-pressure oil creates large forces, ideal for big valves. |

| Position Stability | Oil’s incompressibility locks the valve in place. |

| Control Logic | Electrical signals or manual pumps manage actuator movement. |

| Manual Override | Hand pumps allow manual valve operation. |

| System Limitations | Requires leak-free tubing and careful setup. |

| Comparison to Pneumatic | Hydraulic actuators offer higher force and better stability. |

Advantages in Ball Valve Automation

Hydraulic actuators have many good points for ball valve control. They give strong force and are very accurate. This is important for big valves and high-pressure systems. Their small size lets them fit in tight spots. They are tough and do not rust easily, even in harsh places. Oil does not get squeezed, so the valve moves just right. If power goes out, the actuator can put the valve back in a safe spot.

- Hydraulic actuators give strong turning force for big or stuck valves.

- Their small size fits into tight spaces.

- Oil’s incompressibility helps control the valve exactly.

- They do not rust and work well in hard places.

- Hydraulic actuators keep the valve safe if power fails.

| Feature | Hydraulic Actuators | Pneumatic Actuators |

|---|---|---|

| Power Source | Pressurized fluid | Compressed air |

| Best For | Heavy-duty valves | Fast, light valves |

| Torque | Very high | Medium |

| Maintenance | Low | Medium |

| Cost | Higher | Lower |

Typical Applications and Industry Use Cases

Many industries use hydraulic actuators to control ball valves. In oil and gas, they help control flow in pipelines and drilling. They work with fluids at very high pressure, sometimes over 3,000 psi. Chemical plants use them to move raw materials and finished products. These actuators also help store and move dangerous chemicals safely. They seal well and use strong force.

- Oil and gas pipelines use hydraulic actuators for flow and safety shutoff.

- Drilling and wellhead jobs need these actuators for mud, water, and gas.

- Chemical plants use hydraulic actuators for high-pressure and hot valve control.

- Refineries use hydraulic actuators to move fluids during making and storing.

Tip: Hydraulic actuators are best for ball valve control when pressure is high, the valve is big, or safety is very important.

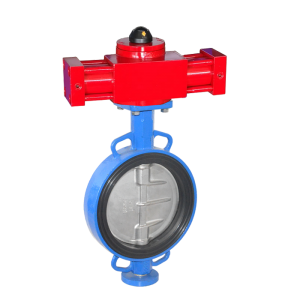

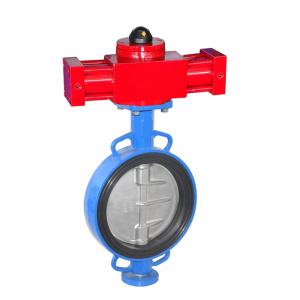

Hydraulic Actuators for Butterfly Valves

Principles of Hydraulic Butterfly Valve Control

Hydraulic actuators are important for moving butterfly valves in big systems. They use pressurized fluid to push a piston inside a cylinder. The piston moves and turns a shaft. This shaft spins the disc inside the butterfly valve. When the disc turns, it opens or closes the valve. This lets flow start or stop. Operators can use remote controls to send signals to the actuators. The actuators react fast and work well, even in tough places.

Many hydraulic actuators have feedback devices. These devices check where the valve is and send this information back. This helps the control system know the valve’s position. Feedback makes sure the valve moves just right and stays in the correct spot. If the power goes out, the actuator can keep the valve where it was. This keeps things safer in important jobs.

Advantages in Butterfly Valve Automation

Hydraulic actuators have many good points for butterfly valve automation, especially for big valves:

- They make very strong turning force, so they work for large valves under high pressure.

- Their tough build lets them work in hard places like power plants and mines.

- Hydraulic fluid cushioning helps the valve move smoothly and exactly, which lowers damage.

- These actuators can hold the valve in place if power or pumps stop, making things safer.

- They give more turning force than pneumatic, electric, or manual actuators for the same size valve.

Hydraulic actuators also work well for a long time. They move slower, usually taking tens of seconds to a minute. This is good when careful movement matters more than speed. Operators pick these actuators based on valve size, how much force is needed, where they will be used, how fast they need to move, how exact they must be, and how easy they are to take care of.

| Feature | Hydraulic Actuators for Butterfly Valves |

|---|---|

| Torque Output | Very high, ideal for large-diameter valves |

| Durability | Excellent in harsh and demanding conditions |

| Control Precision | Smooth, with hydraulic fluid cushioning |

| Safety | Maintains position during failures |

| Application Suitability | Best for high-pressure, large-scale systems |

Tip: Hydraulic actuators work best for butterfly valves when strong force and steady control are needed.

Typical Applications and Industry Use Cases

Many industries use hydraulic actuators to move butterfly valves in important systems. Some common uses are:

- Big irrigation water systems use hydraulic actuators to open and close shut-off valves.

- Hydropower stations put these valves before turbines for emergency shut-off and to protect equipment.

- Water management systems use hydraulic actuators to control water flow between reservoirs and canals.

- Power plants use hydraulic-controlled butterfly valves to control water flow to turbines, helping make energy.

- Factories and dam systems use these valves because they are small and work quickly.

Hydraulic actuators help save energy by lowering flow resistance and making sure valves work right. Using them in automated systems helps keep water, energy, and factory processes safe and efficient.

Industry Applications of Hydraulic-Controlled Valves

Chemical Processing

Chemical plants use hydraulic-controlled valves to mix and blend chemicals. These valves help control how fluids move in pipes and tanks. This makes products better and helps the plant work well. Hydraulic actuators stop leaks and spills, which keeps people and nature safe. Many plants pick valves made from special metals that do not rust. These metals can handle strong chemicals and hot temperatures. Workers check and fix valves often to stop problems and make them last longer.

| Industry | Application Areas and Roles of Hydraulic-Controlled Valves |

|---|---|

| Chemical Processing | Precise control in mixing, blending, and reacting chemicals; improves product quality and operational efficiency; prevents leaks and spills for safety. |

Valves in chemical plants must follow strict rules like API 6D, ASME B16.34, and ISO 15848. These rules make sure valves can handle high pressure, heat, and strong chemicals. SIL certification is also needed for safety systems. This lowers risks and helps the plant run longer without stopping.

Tip: Chemical plants use hydraulic-controlled valves in machines that work by themselves. This helps keep products the same and protects the environment.

Marine and Offshore

Ships and oil platforms use hydraulic-controlled valves for moving water, fuel, and cargo. These valves work in tough places with saltwater and bad weather. Workers use metals like nickel-aluminum bronze or super duplex stainless steel. These metals stop rust and last longer. Hydraulic actuators help close valves fast in emergencies to keep everyone safe.

- Valves must be made for certain pressure and heat levels.

- The right metal is picked for salty or rough fluids.

- Saltwater needs special coatings to protect valves.

- Valves must meet rules like API 6D, ISO 9001, and SIL.

Big underwater valves need a lot of fluid to move. HIPPS systems use big pipes and extra valves to close fast. These systems make oil platforms safer and more reliable.

| Industry | Application Areas and Roles of Hydraulic-Controlled Valves |

|---|---|

| Marine and Offshore | Controls valves in ballasting, cargo handling, and fuel management; ensures efficient operations and safety by managing emergency shut-off valves. |

Mining and Minerals

Mines use hydraulic-controlled valves in machines that crush and grind rocks. These valves move thick fluids with tiny rocks that can wear things out. Workers pick valves with strong seals like nitrile or Viton. These seals help the valves last longer with rough fluids. Hydraulic actuators also control air flow and shut-off valves for safety.

- Saltwater and other harsh fluids need valves made from special metals.

- Thick, rough fluids need coatings and regular checks.

- Watching valves helps find problems early and stop breakdowns.

| Industry | Application Areas and Roles of Hydraulic-Controlled Valves |

|---|---|

| Mining | Used in ore processing equipment (crushers, grinders, flotation cells); controls ventilation and emergency shut-off valves to enhance safety and efficiency. |

Mining companies follow rules like ASME Section VIII and ISO 14001. These rules make sure valves work well with high pressure and rough fluids. They also help keep workers safe and protect the environment.

Note: Hydraulic-controlled valves are very important in mines. They help machines work well even in hard places.

Pulp and Paper

The pulp and paper industry uses hydraulic-controlled valves for many important jobs. These valves help move water, chemicals, and pulp during the whole process. Mills use hydraulic actuators to run big valves that control wood chips, steam, and chemical liquids. This makes things safer and faster, especially where it is risky or slow to do by hand.

Hydraulic-controlled valves work with hot and high-pressure fluids in digesters, bleaching towers, and paper machines. The valves must not rust from strong chemicals like chlorine and caustic soda. Makers often pick stainless steel or special alloys for these valves so they last longer. Hydraulic actuators give enough force to open and close big valves fast, even if pulp or trash tries to block them.

Workers in pulp and paper mills use remote controls to run valves. They can do this from a control room, so they do not have to go into dangerous or hard places. This also lets them act quickly if there is an emergency, like a sudden pressure jump or a machine problem.

Note: Hydraulic-controlled valves help mills fix or clean parts fast by closing off sections quickly.

The table below shows where hydraulic-controlled valves are used and what they need:

| Area of Use | Valve Function | Special Requirements |

|---|---|---|

| Digesters | Control steam and chemicals | Corrosion resistance, high pressure |

| Bleaching towers | Regulate chemical flow | Leak-tight sealing, remote automation |

| Paper machines | Manage water and pulp flow | Fast actuation, debris tolerance |

| Effluent treatment | Direct wastewater streams | Abrasion resistance, reliability |

Hydraulic control has many good points for pulp and paper mills:

- Strong force for big or sticky valves

- Works well in wet, rusty, or rough places

- Keeps valve in place if power goes out

- Needs less fixing because there are fewer moving parts

Rules like TAPPI, ASME B31.1, and ISO 9001 help design and test valves for pulp and paper mills. Many mills also want valves to meet SIL ratings for safety.

Tip: Check and take care of hydraulic-controlled valves often to stop shutdowns and keep mills safe and working well.

Advantages of Hydraulic Actuators

High Force Output

Hydraulic actuators can make a lot of force. They use pressurized fluid to move heavy things easily. This is why people pick them for tough jobs. Other actuators cannot give as much power. Engineers use hydraulic actuators to move or hold big valves that need strong force.

The table below shows how much force hydraulic actuators can make:

| Parameter | Typical Range / Example Values |

|---|---|

| Operating Pressure | 1800 to 3000 psi (124.1 to 206.8 bar) |

| High-Pressure Systems | Up to 5000 psi (344.7 bar) |

| Force Output (3-inch bore) | Approx. 15,000 lbf (66,723 N) at 2200 psi |

| Force Output (5-inch bore) | Approx. 43,000 lbf (191,274 N) at 2200 psi |

| Usage Note | Typically oversized for better control, not used at full force capability |

Hydraulic actuators can make more force than electric or pneumatic ones of the same size. This helps move big or stuck valves better. Operators often pick bigger hydraulic actuators for smoother and easier control. This makes the whole system work better.

Durability

Hydraulic actuators are built strong. They work well in hard places like factories and outside. Their design lets them handle high pressure and heavy loads. They do not break down often. But oil leaks can happen and hurt the environment. So, workers must check and fix them often.

Pneumatic actuators are also tough and work in wet or hot places. Their seals can wear out and need checking. Electric actuators are easy to fix and their seals last longer. But they do not handle shocks or side loads as well as hydraulic actuators. The table below shows how they are different:

| Aspect | Pneumatic Actuators | Electric Actuators | Hydraulic Actuators |

|---|---|---|---|

| Durability in Harsh Environments | Rugged; withstands water and extreme temperatures; seal wear is main concern requiring preventive maintenance | Durable torque components; seals less critical; easier maintenance; sensitive to shock and side loads | High force-to-torque ratio; robust but environmental risk due to fluid leaks |

Hydraulic actuators are still the best for jobs that need strength and toughness. They keep working well under stress. This helps save time and keeps machines running.

Reliability

Hydraulic actuators are very reliable for important valve control. Their design helps keep things safe and lowers the chance of failure. Engineers use special setups like 1oo2 or 2oo3 for extra safety. If one part fails, the system can still work.

Hydraulic actuators can have problems like coil burnout, seal leaks, or worn-out parts. Hot temperatures and lots of use can make them wear out faster. Checking and fixing them often helps stop these problems. In safety systems, hydraulic actuators can keep the valve safe if power goes out. This protects people and equipment.

Note: Good design, regular checks, and fixing problems help hydraulic actuators stay reliable and work well.

Hydraulic actuators help things run smoothly, even in tough places. Their reliability is why many industries use them when failure is not an option.

Safety

Hydraulic actuators move valves with strong and steady force, but safety is always most important. Engineers add many safety parts to these systems to stop accidents and protect people and machines. Each safety part helps with a different risk, so hydraulic valve automation is very safe for hard jobs.

Many hydraulic actuator systems have relief valves. These valves keep the system safe from too much pressure. If the pressure gets too high, the relief valve opens and lets out fluid. This stops hoses from bursting or other parts from breaking. Sequence valves are also important. They make sure each part moves in the right order. This stops actuators from moving at the wrong time, which could hurt people or damage equipment.

Counterbalance valves help control heavy things. They stop valves or machines from dropping if a hose breaks or pressure goes down. This keeps workers and equipment safe from sudden moves. Directional control valves, run by solenoids, can shut off the system in an emergency. In a crisis, these valves stop the actuator fast and lock the valve in a safe spot.

Hydraulic locking systems give even more safety. These systems stop the valve from moving if the power goes out. Some use mechanical locks that grab the piston rod. Others use positive locking devices that work by themselves when power is lost. These locks fight vibration and hold the valve still, even during big shakes or earthquakes. Spring-loaded locks can also grab the piston rod right away, giving extra safety if something goes wrong.

Tip: Check and test safety parts often to keep the system working well and stop surprise problems.

The table below shows common safety parts in hydraulic actuator systems:

| Safety Feature | Purpose |

|---|---|

| Relief Valve | Stops too much pressure and broken parts |

| Sequence Valve | Makes sure parts move in the right order |

| Counterbalance Valve | Stops heavy loads from dropping |

| Directional Control Valve | Shuts off system fast in emergencies |

| Hydraulic Locking System | Stops movement if power is lost |

| Mechanical Lock | Holds position by hand or by itself |

| Positive Locking Device | Works when power is lost to fight vibration |

| Spring-Loaded Lock | Grabs piston rod for extra safety |

Hydraulic actuator systems use all these safety parts to make work safer. Workers trust these systems in important jobs because they lower accident risks and keep things under control. Safety is a big reason why people use hydraulic valve automation, helping everyone work better and feel safe.

Selection and Trends

Selection Criteria

Picking the right hydraulic actuator for a valve is important. You have to think about many things before you choose. Each job is different because of where it is, what kind of valve it uses, and how it needs to work. The table below shows what engineers should look at:

| Criteria Category | Key Considerations |

|---|---|

| Operating Conditions | Temperature tolerance, pressure differential, hazardous environment (IP rating, explosion protection) |

| Connection Type | Compatibility with valve stem and mounting flange standards |

| Control Functions | On/off vs modulating control, need for positioners or end switches, signal type (digital/analog) |

| Sizing and Torque | Torque requirements based on valve size and pressure, actuator size to fit valve flange |

| Failure Modes | Fail-safe mechanisms such as spring return or battery backup, fail position (open/close) |

| Duty Cycle | Frequency of operation affecting actuator type choice |

| Available Power Source | Availability of hydraulic power vs electric or pneumatic supply |

| Space Constraints | Physical size of actuator relative to installation space |

| Safety Standards | Compliance with explosion-proof or hazardous environment certifications |

| Cost Implications | Impact of torque, size, features, and certifications on actuator cost |

Hydraulic actuators are best for big valves that need strong turning force and careful movement. They work well where there is no electric power or when air-powered actuators are not strong enough. Some actuators have special safety features like springs or batteries to keep things safe if something goes wrong. Engineers should always read the maker’s instructions and check what is already in place before picking an actuator.

Tip: Make sure the actuator’s strength and size match the valve so it works safely and well.

Innovations

New ideas in hydraulic actuators are changing how factories use valves. Electro-hydraulic actuators mix hydraulic power with electric control for better results. These new systems have built-in motors, oil pumps, controllers, and sensors. They give strong force and move valves very accurately. They also save energy by only using power when needed.

Smart hydraulic actuators have sensors and special control parts. These let the actuator watch how it works, find problems, and change its own settings. They can talk to other machines, so everything works together in real time. This helps the factory run better and stop problems before they happen.

Many new actuators connect to Industry 4.0 systems. With smart sensors and digital tools, workers can check how the actuator is doing, plan repairs, and even move valves from far away. These smart tools help stop surprise breakdowns and make the whole plant work better.

- Smart actuators use sensors to check and report how they work.

- Electro-hydraulic types give strong force and save energy.

- New designs are lighter and easier to put in and fix.

- IoT lets workers watch and fix actuators from anywhere.

Hydraulic actuators keep getting better to meet the need for more speed, safety, and smart control in today’s factories.

Hydraulic actuators give strong power and accurate control. They last a long time, so they are important for moving valves in places like oil and gas, factories, and ships.

- These actuators move big valves and work well even in tough places. They help keep things safe when it matters most.

- You can change them to fit different jobs.

Picking the right actuator helps everything work safely and well.

In the future, smart tools and new electro-hydraulic systems will help save energy, watch how things work in real time, and make factories run better.

FAQ

What is a hydraulic actuator?

A hydraulic actuator uses pressurized fluid to move a valve. It changes fluid power into motion. This device gives strong force and good control for opening or closing valves in factories.

Why do industries prefer hydraulic actuators for large valves?

Hydraulic actuators give high torque and work reliably. They handle big or high-pressure valves better than electric or pneumatic types. Industries pick them for hard jobs where strength and safety are important.

How often should hydraulic actuator systems receive maintenance?

Technicians should check hydraulic actuator systems often. Most places plan checks every three to six months. Regular maintenance stops leaks, keeps things safe, and helps equipment last longer.

Can hydraulic actuators operate in hazardous environments?

Yes, hydraulic actuators work well in dangerous or explosive places. Their design stops sparks and electrical problems. Many models meet strict safety rules for oil, gas, and chemical plants.

What happens if the hydraulic power fails?

If hydraulic power fails, many actuators use springs or locks to keep the valve safe. This protects equipment and people during emergencies.

Are hydraulic actuators suitable for remote or automated control?

Hydraulic actuators can be controlled from far away or by machines. Operators use electronic signals from control rooms to manage valves. This makes big places safer and more efficient.

What are the main advantages of hydraulic actuators over electric actuators?

Hydraulic actuators give more force, last longer, and are more reliable. They work well in tough places and move big valves easily. Electric actuators may have trouble with heavy loads or harsh conditions.

How do you select the right hydraulic actuator for a valve?

Engineers look at valve size, needed torque, where it will be used, and safety needs. They also check if it works with control systems. Picking the right one helps valves work safely and for a long time.