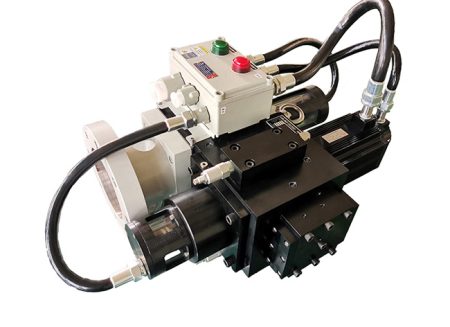

An electro hydraulic actuator uses electric power to make hydraulic pressure. This pressure moves valves with very exact control. The device is self-contained. It replaces old pneumatic valve and electric valve systems. This makes moving valves faster and more dependable. People use it for butterfly valves, ball valves, and pneumatic control valve automation. It is used in many industries. The global market for electro hydraulic actuators is growing fast. This is because more people want electric solutions and better valve actuation.

| Metric | Value | Year/Period |

|---|---|---|

| Market Size | USD 334.2 million | 2023 |

| Market Size Forecast | USD 471.4 million | 2033 |

| Control Electrohydraulic Actuator Share | 71.3% | 2023 |

Electro Hydraulic Actuator Basics

Definition

An electro hydraulic actuator is a small power unit. It has electric and hydraulic parts in one device. The electric motor runs a hydraulic pump. The pump pushes hydraulic fluid. This fluid moves a piston or makes something turn. Old hydraulic actuators needed many separate parts. They needed pumps, tanks, and pipes. The electro hydraulic actuator puts everything together. It gives strong and exact movement for valves and machines.

Electro hydraulic actuators are special because they have all parts inside. The electric motor, pump, control system, and cylinder are in one box. This makes it smaller and easier to use. It is cleaner and simpler to put in than old systems.

Main Function

The main job of an electro hydraulic actuator is to change electricity into movement. This movement can be straight or turning. In factories, these actuators work like muscles. They follow control signals. They move valves or machines very accurately.

- Electro hydraulic actuators:

- Use an electric motor to run a pump.

- Push hydraulic fluid to move a piston or shaft.

- Give strong force for big jobs.

- Use sensors and feedback for exact movement.

- Make fast and steady motion for machines.

This technology helps people do less work by hand. It makes factories safer and faster. The system gives lots of power in a small space. It works well even in tough places.

Unique Design

Electro hydraulic actuators have a special design. They are different from old hydraulic or electric actuators. The table below shows the main differences:

| Design Feature | Electro Hydraulic Actuators | Traditional Hydraulic Actuators | Traditional Electric Actuators |

|---|---|---|---|

| Integration | Small, sealed unit with all parts inside | Big, needs outside pumps and pipes | Motor and parts are separate |

| Power Source | Electric motor runs inside pump | Outside pump runs with motor | Only uses electric motor |

| Control System | Smart controllers with real-time feedback | Few or no electronic controls | Electronic control, less force |

| Leakage & Maintenance | Sealed, low leaks, easy to care for | Leaks often, needs more care | No fluid leaks, not as strong |

| Power Density | High, lifts heavy things in small size | Strong, but needs big setup | Not as strong, for lighter jobs |

| Noise Level | Quiet (under 65 dBA) | Louder from pumps and fluid | Quieter, but not as strong |

| Design Compactness | Four-in-one small design | Big, spread out parts | Small, but not as powerful |

| Energy Efficiency | Saves up to 30% energy | Less efficient, pump always runs | Efficient, but not as strong |

| Application Versatility | Easy to install anywhere | Needs lots of pipes and setup | Only for light jobs |

- The electro hydraulic actuator has a closed, sealed system. All pumps, motors, valves, and sensors are on the cylinder. There are no outside pipes. This means fewer leaks.

- The design is modular, so you can add more power or features easily. Standard parts make fixing it simple and cheap.

- Smart controllers and sensors help it move exactly right. It can hold its spot without using more energy. This is because of special shut-off valves.

- The strong build and waterproof parts let it work in hard places. It can handle wet or shaky spots.

Electro hydraulic actuators mix the best parts of electric and hydraulic systems. They give strong force, exact control, save energy, and stay quiet. They are easy to take care of in one package.

Working Principle

Step-by-Step Process

An electro hydraulic actuator turns electric energy into movement. Each part works together for exact and steady action.

- The actuator gets electric power. A special motor starts spinning very fast, about 2800 times each minute.

- The motor makes a hydraulic oil pump work. This pump builds up strong pressure, up to 35 MPa.

- A proportional valve controls how much fluid moves. The valve reacts quickly, in less than 80 milliseconds, to change the flow.

- The actuator checks its position many times each second. It uses a closed-loop feedback system to watch movement 125 times every second.

- A PID control algorithm uses this feedback. It keeps the actuator’s position very close, within ±0.02 mm.

- The system checks the oil temperature. If it gets hotter than 65°C, a cooling system turns on. This system uses copper pipes, fast oil flow, and an air-cooling part to keep things cool.

- The control system uses a Mitsubishi FX5U controller. It sends and gets commands in just 0.8 milliseconds. This helps the actuator move fast and stay exact.

- All these steps turn electric energy into controlled pressure and flow. This makes the actuator move with high accuracy and trust.

The actuator’s design lets it work in hard places. It keeps moving valves or machines with exact control, even if things change.

Electric Motor Activation

The actuator begins with electric power. The motor inside spins very fast. This is the first step to make movement. The motor gives the main push for the system.

Hydraulic Pump Operation

The spinning motor makes the hydraulic pump work. The pump builds up pressure. This pressure moves fluid through the actuator. The proportional valve changes the flow for better control.

Fluid Pressure and Motion

Hydraulic fluid moves inside the actuator. The pressure pushes a piston or turns a shaft. Sensors and feedback check the position. They make sure the actuator moves just right. The cooling system keeps everything working well, even when it gets hot.

Simple Analogy

Think about using an electric blender to crush ice. You plug in the blender and press a button. The motor spins the blades. The blades crush the ice with force. In the same way, an electro hydraulic actuator uses electric power to spin a motor. The motor runs a pump, which pushes hydraulic fluid. The fluid moves parts inside the actuator with care. The actuator can move heavy valves or machines, just like the blender crushes ice with power and control.

This example shows how electric energy starts the process. Hydraulic force does the hard work. The actuator uses both to make things move exactly.

Energy Conversion Efficiency

How well an electro hydraulic actuator works depends on its design and controls. The table below shows how energy efficiency compares:

| Aspect | Description | Efficiency / Performance |

|---|---|---|

| Average efficiency of mobile hydraulic drives (centralized systems) | Low energy efficiency because one pump powers many things and control valves waste energy | ~21% |

| Electro-hydraulic actuators (EHAs) | Use electric motors as main movers, so they work better than old hydraulic systems | Better than old centralized hydraulic systems |

| System improvements | Use special pumps, load sensing, energy saving, and new setups | Cut down energy waste and make the system work better |

| Specific component efficiency | Some systems use double-variable hydraulic transformers | Peak efficiency changes less than 5% |

| Power reduction example | A new EHA system cuts motor power by 37% (from 138 kW to 87 kW) with only a small drop in total efficiency | Shows better system efficiency by using smaller motors |

Electro hydraulic actuators often work better than old hydraulic systems. They use smart controls and new designs to save energy and move more exactly.

Electro-Hydraulic Actuators: Components

Electric Motor

The electric motor is like the main part of the actuator. It gives the power to start everything. When the actuator gets a signal, the motor starts spinning. This spinning makes the hydraulic pump work. Most motors use DC or brushless DC types. They work with voltages from 18 to 37 volts. These motors can handle up to 50 amps of current. The motor gives steady power so the actuator works fast. It helps the actuator answer control signals quickly. Motors in these systems can spin up to 2800 times each minute. They also keep out dust and water with ratings like IP56 or IP69. This means the actuator can work in tough places like factories or outside.

Electric motors help the actuator work well and need little care. They let the actuator move valves and machines very exactly.

Hydraulic Pump

The hydraulic pump works with the electric motor. When the motor spins, it turns the pump too. The pump makes pressure by moving fluid inside the actuator. Most pumps use radial piston or gear designs. These pumps can make up to 3000 psi of pressure. They can move up to 20 liters of fluid each minute. The pump gives enough force for the actuator to lift heavy things. Control valves on the pump change how much fluid moves. This helps the actuator react fast and right to changes.

| Specification Aspect | Power-Packer DC Series | Power-Packer BLDC Series |

|---|---|---|

| Motor Type | Brushed DC | Brushless DC |

| Pump Type | Radial piston | Gear pump |

| Dynamic Force | Up to 18.5 kN push, 9.8 kN pull | Up to 14.4 kN push, 1.7 kN pull |

| Maximum Load | 23-25 kN | 23-25 kN |

| Speed | Up to 20 mm/s | Up to 50 mm/s |

| Environmental Protection | IP69 | IP56 with cover |

| Operating Temperature | -25 to +70 °C | -25 to +70 °C |

| Service | Maintenance free | Maintenance free |

| Size & Weight | Stroke up to 450 mm, ~7 kg | Stroke up to 450 mm, ~6 kg |

Hydraulic pumps help the actuator give strong force and move fast. They make sure the actuator works safely, even when it is very hot or cold.

Fluid Reservoir

The fluid reservoir holds the hydraulic oil inside the actuator. It keeps enough fluid ready for the system to use. The reservoir also helps keep pressure and temperature steady. Some actuators use a thermal compensating accumulator. This part stores extra fluid and gives it when needed. The accumulator helps keep pressure steady, even if it gets hot or cold. The reservoir connects to the pump and other parts with a manifold. This lets the actuator send fluid to all the right places.

- The fluid reservoir:

- Holds oil for the actuator.

- Helps keep pressure steady.

- Works with the accumulator for temperature changes.

- Connects to the pump and manifold.

A good fluid reservoir helps the actuator work smoothly and safely. It stops air from getting in and lowers the chance of leaks. This makes electro-hydraulic actuators safer and easier to take care of.

Electro-hydraulic actuators use a sealed reservoir to keep things clean and working well. This helps the actuator last a long time and work at its best.

Actuator Mechanism

The actuator mechanism is the part that makes things move. It takes pressure from the hydraulic pump and turns it into motion. Inside, a piston or rotary shaft moves when fluid pushes on it. This movement can be straight, like pushing or pulling. It can also turn, like spinning a valve.

Most actuator mechanisms have a strong piston in a cylinder. When fluid goes in one side, it pushes the piston forward. If fluid moves to the other side, the piston goes back. Some actuators use a rotary design. In these, the fluid turns a shaft instead of moving a piston. This kind works well for turning valves, like butterfly or ball valves.

Key features of the actuator mechanism are:

- High force in a small space

- Fast reaction to control signals

- Sealed design to stop leaks

- Can hold position without extra energy

The actuator mechanism gives the system its power. It lets the actuator move heavy valves easily. It keeps the movement steady and exact.

Some actuator mechanisms have sensors inside. These sensors check where the piston or shaft is and how fast it moves. They send this data to the control system. This feedback helps the actuator stay on track and not make mistakes.

Control System

The control system is like the brain of the actuator. It tells the actuator when and how to move. Modern control systems use electronic controllers, sensors, and smart software to manage everything.

Many actuators use closed-loop control. This means the system checks itself and makes changes if needed. Sensors measure where the actuator is and how fast it moves. The controller looks at this data and compares it to the target spot. If the actuator is off, the controller sends new signals to fix it.

Some advanced control systems use special math tools. These include model predictive control, adaptive control, and neural networks. These tools help the actuator move smoothly and stop at the right place every time.

A typical control system in an electro-hydraulic actuator has:

- Electronic controller (like a PLC or microcontroller)

- Feedback sensors for position, pressure, and speed

- Proportional or servo valves to change fluid flow

- Many input options, like 4-20 mA or 0-10 VDC signals

- Failsafe modes, like fail open or fail close, for safety

Many actuators can work in continuous modulating mode. This means they can make small changes, not just on or off moves. This level of control is important for jobs that need high accuracy, like emergency shutdown systems.

Some control systems also let you check the actuator from far away or nearby. Operators can see how the actuator is working and if it needs care. This makes fixing problems easier and helps stop issues before they get worse.

Electro-Hydraulic Actuators: Key Features

High Power Density

Electro-hydraulic actuators give lots of force in a small size. They can move heavy valves or machines without needing much space. The actuator uses a small electric motor and a strong hydraulic pump. This setup lets it move things with great accuracy and power. Many industries pick these actuators for their power and efficiency. The actuator can lift or turn big loads but stays small and easy to put in. Factories can fit more machines in tight spots because of this high power density. The actuator works well even with heavy or high-pressure valves. Operators get the exact movement they want every time because of high-precision control.

Low Maintenance

Electro-hydraulic actuators need less care than old hydraulic systems. Their design keeps away many usual problems. The actuator does not have outside pipes or tanks, so leaks do not happen often. The sealed system keeps out dirt and dust, which helps it last longer. Many jobs like checking for leaks or cleaning up fluid are not needed anymore.

- Electro-hydraulic actuators do not need checks for fluid leaks.

- The inside design stops jams and leaks seen in old systems.

- These actuators need very little care overall.

- No outside fluid or parts makes the system cleaner and stronger.

- Breakdowns are rare, so workers spend less time fixing things.

Workers see that these actuators save time and money. The system stays clean and works well for a long time. When repairs are needed, special skills may be needed, but this does not happen often. The actuator’s good efficiency and simple design help machines keep working smoothly.

Safety and Reliability

Safety is very important for electro-hydraulic actuators, especially for big jobs. The actuator has many features to keep things safe and working well. Fail-safe parts let the actuator go back to a safe spot if power stops. The actuator can shut down quickly in tough places. High torque and thrust help control big or high-pressure valves fast. Quick response makes the actuator good for safety systems.

| Safety Feature Category | Description |

|---|---|

| Fail-safe configurations | Spring return, double-acting options for safe shutdown |

| Manual overrides | Handwheel, gearbox, or hydraulic manual controls |

| Construction robustness | All-steel build, no external threads to resist corrosion |

| Environmental protection | Weatherproof housings, IP66 rating |

| Diagnostics and monitoring | Onboard systems for troubleshooting |

| Position feedback | Valve stem indicators for switches or transmitters |

| Partial stroke testing | Optional feature for regular safety checks |

| Power source flexibility | Works with many power types, including solar and battery backup |

| Hazardous location compliance | Meets strict safety standards for dangerous areas |

The actuator’s strong build means less care and a longer life. Many models meet SIL rules for tough jobs. Workers trust these actuators because they work well and give exact control, even in hard places. The actuator’s good efficiency and safety features make it a smart pick for new automation.

Cleanliness and Versatility

Electro hydraulic actuators are known for being clean and flexible. Many factories need machines that do not make a mess. These actuators help keep work areas safe and tidy. Their design does not use open hydraulic fluids. This means there are no leaks or spills to worry about. Workers do not have to clean up oil or slip on wet floors.

These actuators have sealed metal parts that fit together tightly. Most of the time, they do not need much oil or grease. This helps keep places very clean. Factories that make food, drinks, or medical tools need this kind of cleanliness. Electronics factories also need clean machines. Even a little oil or dirt can ruin their products.

Many electro hydraulic actuators come in sealed units. These units keep out dust, water, and chemicals. This makes them good for chemical plants and welding shops. The sealed design also keeps the inside parts safe from harsh air. The actuator keeps working well, even if the air is dirty or wet.

- Electro hydraulic actuators do not use open fluids, so there are no leaks.

- Sealed metal parts need little or no oil.

- They work well in clean places like food, drink, medical, and electronics factories.

- Sealed units with strong protection are good for chemical plants and welding shops.

- Programmable controls and exact movement help them work in many special places.

These actuators are also very flexible. They use controls that can be programmed. Workers can change how the actuator moves without changing parts. The actuator can do different jobs by changing its settings. This saves both time and money. It also means the actuator can work in many places, from clean rooms to outside.

Being able to control movement exactly is a big plus. The actuator can move valves or machines with great accuracy. This helps keep products safe and work smooth. Exact movement also means less waste and better results. The actuator works well even in hard places. It uses energy smartly and does not waste power on leaks or rubbing parts.

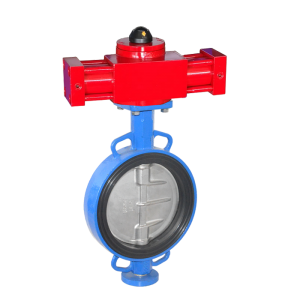

Electro-Hydraulic Actuation in Valves

Butterfly Valves

Electro-hydraulic actuation is important for butterfly valves. Factories use these actuators to move lots of liquid or gas. The system has an electric motor and a hydraulic pump. This setup makes strong force to move the valve disc. The valve can be set in the right spot every time. The actuator is quiet and does not need much care. Many factories pick this for tough jobs.

Benefits of using electro-hydraulic actuation for butterfly valves are:

- Strong force for exact valve movement

- Quiet, so work areas are less noisy

- Needs little care, which saves time and money

- Can be controlled from far away and works with other machines

- Has safety features and a tough build for hard places

- Lets workers check how it works in real time

- Saves energy by changing to match flow

Automated butterfly valves help stop mistakes by people. They answer fast to control signals and keep things working well. Workers can watch the valves from a control room, which makes things safer and more reliable.

Ball Valves

Ball valves need strong and steady actuation to work right. Electro-hydraulic actuation gives the power and control needed in many jobs. The actuator is small and puts all main parts together. This means fewer outside parts and makes putting it in easier.

| Feature/Component | Description & Benefit |

|---|---|

| Integrated “four-in-one” design | Puts the hydraulic unit, cylinder, control circuit, and limit switch in one small unit. This cuts down on outside parts and makes it stronger and easier to install. |

| Hydraulic Unit | Has a pump and valve block that can give exact hydraulic power up to 700 bar. This helps the ball valve handle heavy loads. |

| Cylinder | Made from strong materials and built to last. The inside is smooth to lower friction and make it last longer. |

| Intelligent Electronic Module | Uses smart DDC tech and feedback from limit switches. This helps control the valve’s movement and keeps it safe. |

| Working Principle | The control unit gets commands and runs the motor. The motor powers the pump, which moves oil to push the piston. This makes the valve move just right. |

| Application Suitability | Good for factories and ships where strong, safe, and small actuators are needed. |

Electro-hydraulic actuation lets ball valves move exactly and last a long time. The actuator can handle high pressure and tough places. People trust these systems for important jobs.

ESD and Quarter-Turn Valves

Electro-hydraulic actuation is needed for emergency shutdown and quarter-turn valves. These valves keep people and equipment safe in emergencies. The actuator moves fast and shuts off dangerous flows quickly. It uses both hydraulic force and electric power for good control. All parts fit in a small block, which saves space and stops leaks.

These actuators are made for places where explosions could happen. They have parts that workers can change easily. The system meets strict safety rules like SIL 2 or SIL 3. The actuator has a backup part to keep working if power goes out. Workers can control the valve close by or from far away. The actuator stops the motor when the valve is not moving, which saves energy.

Quarter-turn valves, like ball, butterfly, plug, and triple-offset types, use electro-hydraulic actuation to work well. The actuator gives strong turning force and quick action. This makes it good for oil, gas, chemical plants, and other places that need safe and steady valve movement.

Other Industrial Uses

Electro-hydraulic actuators are used in many industries, not just for valves. These devices help machines do hard jobs that need strong force and careful control. Factories, power plants, and ships use them for jobs that must move things the right way every time. Many conveyor belts use these actuators to move heavy things. The actuator can push or lift items with steady power. Workers use switches or remotes to change speed and position. This makes work safer and helps lines run better. In steel mills, actuators open and close furnace doors fast. This keeps heat inside the furnace.

Rolling machines use actuators to press and shape metal sheets. The strong force and careful moves help make metal the right size and shape. Mining sites use actuators for crushers and feeders. The actuator moves heavy parts to break rocks and move ore. The sealed design keeps out dust and water, so the actuator lasts longer. Ships use these actuators for hatch covers and cargo systems. The actuator lifts and locks covers to keep goods dry. Cargo cranes use actuators to move containers on and off ships. The system works well even when it is wet or salty.

Electro-hydraulic actuators also help with green energy. Wind turbines use actuators to turn the blades. This helps catch more wind and make more power. Solar farms use actuators to tilt panels toward the sun. The actuator’s careful moves help make more electricity.

Chemical plants use actuators for mixing tanks and reactors. The actuator stirs chemicals at the right speed and spot. This keeps reactions safe and even. The sealed system stops leaks and keeps things clean.

The table below gives more examples of how industries use these actuators:

| Industry | Application Example | Benefit |

|---|---|---|

| Food Processing | Automated cutting machines | Clean, precise movement |

| Water Treatment | Sluice gate control | Reliable, remote operation |

| Aerospace | Landing gear actuation | High force, compact design |

| Automotive | Robotic assembly arms | Fast, accurate positioning |

| Pulp & Paper | Press section automation | Strong, steady pressure |

Electro-hydraulic actuators can do many different jobs. Their sealed design and smart controls make them a good pick for places that need safe, clean, and strong movement. Many industries use these actuators to make work safer, cut down on repairs, and get more done.

Comparison with Other Actuators

Electric vs. Electro-Hydraulic

Electric actuators and electro-hydraulic actuators both move things. They work in different ways. Electric actuators use only electricity to make things move. Electro-hydraulic actuators use electricity to run a hydraulic system inside. Each type has good and bad points.

The table below shows how they are different:

| Aspect | Electric Actuators | Electro-Hydraulic Actuators |

|---|---|---|

| Design Complexity | Simple, compact, fewer parts | More complex, many moving parts |

| Contamination Risk | No risk, good for food and medical industries | Possible oil leaks, risk of contamination |

| Speed & Acceleration | Fast, good control, quick to start and stop | Slower, some delay from fluid movement |

| Maintenance | Needs little care | Needs regular checks for leaks and fluid |

| Energy Efficiency | Uses power only when moving, saves energy | Uses energy even when not moving |

| Noise | Quiet operation | Can be noisy |

| Cost | Lower total cost over time | Higher cost due to upkeep and complexity |

| Application Suitability | Best for clean, precise jobs in small spaces | Best for heavy-duty jobs needing strong force |

Electric actuators are great for clean and quiet places. They work well when you need exact moves. Electro-hydraulic actuators are better for tough jobs. They are good when you need lots of force.

Pneumatic vs. Electro-Hydraulic

Pneumatic actuators use air to move things. Electro-hydraulic actuators use oil under pressure. Both types turn energy into movement. They have different features.

- Pneumatic actuators:

- Respond fast and cost less at first.

- Have a simple design and are easy to fix.

- Make less force and are not as exact.

- Need a steady supply of compressed air.

- Electro-hydraulic actuators:

- Give more force and work well in hard places.

- Offer better control and can move heavy things.

- Need more care because of oil and extra parts.

- Are more complex and cost more to keep working.

The table below shows these points:

| Aspect | Pneumatic Actuators | Electro-Hydraulic Actuators |

|---|---|---|

| Efficiency | Fast, low cost, simple | High force, good for heavy loads |

| Control | Less precise, needs feedback for smooth motion | More precise, better for careful movement |

| Maintenance | Easy to fix, fewer problems | More complex, needs regular checks |

Pneumatic actuators are good for fast and cheap jobs. Electro-hydraulic actuators are best for strong and careful moves.

Hydraulic vs. Electro-Hydraulic

Old hydraulic actuators use pumps, hoses, and tanks spread out. Electro-hydraulic actuators put all these parts in one box. This makes a big difference in how they work.

| Aspect | Traditional Hydraulic Actuators | Electro-Hydraulic Actuators |

|---|---|---|

| System Complexity | Needs pumps, hoses, tanks, and lots of setup | Simple, all-in-one design |

| Maintenance | Prone to leaks, needs lots of care | Low maintenance, fewer leaks |

| Energy Efficiency | Uses energy all the time, even when not moving | Saves energy, works only when needed |

| Precision Control | Hard to control exactly | Very precise, responds quickly |

| Power Density | Very strong, good for the biggest jobs | Strong, but not for the heaviest loads |

| Operational Benefits | Tough and cost-effective for big force, but complex | Clean, energy-saving, precise, compact |

Hydraulic actuators are best for the biggest and hardest jobs. Electro-hydraulic actuators give many of the same benefits. They are cleaner and easier to take care of. Many factories now pick this kind for power, control, and easy setup.

Industry Applications of Electro Hydraulic Actuators

Oil and Gas Industry

Pipeline valve automation

Electro hydraulic actuators are important for pipeline valve automation. They help workers control oil and gas flow over long distances. These actuators can open or close valves by themselves or from far away. This makes pipelines safer and helps them work well. Workers use them for emergency shutdowns and stopping line breaks. They also help with compressor bypass control. Companies like ATI put these actuators on pipelines in risky and far-off places. The actuators work well in tough spots, like deserts or out at sea. They use designs such as linear, scotch yoke, and rack and pinion for different valves. These systems make things safer and mean fewer workers need to go to dangerous places.

Offshore platform safety systems

Offshore platforms need strong automation to stay safe. Electro hydraulic actuators help control valves on rigs and subsea wells. They also work on LNG facilities. These actuators let workers open or close important valves automatically or from far away. This is needed for emergency shutdowns and flow control in rough sea weather. The actuators give strong force and react quickly, which is important in emergencies. They also meet strict rules for reliability. Subsea actuators are made to handle deep water and salty sea. Workers trust these systems to keep offshore platforms safe and working well.

Power Generation

Turbine control systems

Power plants use electro hydraulic actuators to control turbines. These actuators move heavy parts with strong force and exact control. They help change turbine blades and valves to manage steam or water flow. The self-contained design means no big outside hydraulic systems are needed. This makes putting them in easier and lowers maintenance. The actuators work well near high heat or lots of shaking. They also support remote and automatic control, so workers can react fast to changes in power needs. Advanced sensors and electronics give feedback for exact positioning.

Cooling water flow regulation

Cooling systems in power plants need steady water flow. Electro hydraulic actuators control big valves that manage this flow. They give lots of power and can handle heavy loads. The sealed design keeps out dust and water, which protects the system. Workers can watch and change the actuators from a control room. This makes the plant safer and keeps machines at the right temperature. The actuators also save energy by using power only when needed.

Marine and Offshore

Shipboard valve actuation

Ships use electro hydraulic actuators for many onboard jobs. These actuators control valves for fuel, ballast, and cargo. Each actuator has its own power unit, so there are no long hydraulic pipes. This stops leaks and breaks. The actuators give steady and exact control, even in rough seas. They also have manual backup for emergencies. This setup makes ships safer and helps them work better.

Ballast and cargo system automation

Ballast and cargo systems on ships need careful control to keep the ship steady. Electro hydraulic actuators automate moving ballast water and cargo hatches. They let workers make quick and exact changes, which is important when loading or unloading. The sealed units protect against saltwater and bad weather. Workers can control these systems from the bridge or a remote spot. This means less manual work and makes ship operations safer.

Manufacturing and Process Industries

Automated assembly lines

Electro hydraulic actuators are important in assembly lines. These lines need machines to move parts fast and accurately. The actuators help robots pick up and place items. They also move things from one station to another. They give strong force in small spaces. This helps factories save space and energy. Car factories use these actuators to lift heavy doors. They also press metal parts together. The actuators answer quickly to control signals. This keeps the line moving without stopping.

Electronics factories use these actuators too. The machines must handle tiny parts carefully. The actuators make smooth and steady moves. This helps stop damage to parts. In high-precision jobs, every move must be exact. The actuators help keep quality high and waste low. Workers can change the settings for different products. This makes the line flexible for new jobs.

Tip: Electro hydraulic actuators work well in clean rooms. Their sealed design keeps out dust and oil. This is important for making computer chips or medical tools.

Chemical process control

Chemical plants need safe ways to move and mix liquids. Electro hydraulic actuators help open and close valves. They also stir tanks and move mixers. The actuators give steady force, even if it gets hot or cold. They work with the plant’s control system. Workers can change the process from a control room.

These actuators help keep the process safe. If something goes wrong, the actuator shuts a valve fast. This stops spills and keeps workers safe. The sealed design keeps chemicals inside pipes and tanks. This helps the plant stay clean and safe.

Many chemical plants use these actuators for careful jobs. The actuators can make small changes to flow or pressure. This keeps the process steady and the product quality high.

Water and Wastewater Treatment

Remote valve operation

Water treatment plants are often very big. Workers cannot always be near every valve. Electro hydraulic actuators let them open or close valves from far away. The actuators use electric signals to move the valves. This saves time and keeps workers safe.

The actuators work well in wet and dirty places. Their sealed design keeps out water and mud. They keep working during storms or floods. The control system can send alerts if a valve does not move right. This helps workers fix problems early.

Floodgate and sluice control

Floodgates and sluices help control water flow in rivers and plants. Electro hydraulic actuators give power to lift or lower heavy gates. The actuators answer quickly to control signals. This helps stop floods and keeps water at safe levels.

Operators can set gates to open or close at certain times. The actuators hold gates steady, even when water pushes hard. The sealed units work well outside, even in rain or snow. This makes them good for water management systems.

Note: Electro hydraulic actuators help protect homes and roads from floods. Their strong and reliable design is important for public safety.

Electro hydraulic actuators take electric power and turn it into hydraulic force. This force helps move valves with great strength and accuracy. The actuator has both electric and hydraulic parts inside one sealed box. Some big benefits are strong power, less work to keep them running, and clean use. Many factories and plants use these actuators to control valves, like butterfly and ball valves.

Electro hydraulic actuators give a smart and dependable way to control valves today.

FAQ

What is the main benefit of using an electro hydraulic actuator?

Electro hydraulic actuators give a lot of force in a small size. They can move heavy valves with very good control. Many factories pick them because they do not need much care. They also work well in hard places.

Can electro hydraulic actuators work in outdoor or harsh environments?

Yes, these actuators have a sealed design. This keeps out water, dust, and dirt. Many types work in rain, snow, or hot and cold weather. That makes them great for outdoor jobs.

How do electro hydraulic actuators improve safety?

They have special safety features built in. These include fail-safe modes and ways to control them by hand. The actuator can stop fast if something is wrong. This helps keep workers and machines safe.

Do electro hydraulic actuators need a lot of maintenance?

No, they need less care than old hydraulic systems. The sealed box stops leaks and keeps out dirt. Workers do not have to check for leaks or add oil often.

What types of valves use electro hydraulic actuators?

Factories use these actuators for butterfly, ball, and quarter-turn valves. They also work with emergency shutdown valves. The actuator gives strong and steady movement for each kind.

Can workers control these actuators from far away?

Yes, many electro hydraulic actuators work with remote controls. Operators can open or close valves from a control room. This saves time and keeps workers safe.

Are electro hydraulic actuators energy efficient?

Yes, these actuators use power only when moving. They save energy compared to old hydraulic systems. Smart controls help use even less power.

What industries use electro hydraulic actuators the most?

Oil and gas, power plants, water treatment, ships, and factories use these actuators. They help run valves and machines in many different jobs.

Tip: Electro hydraulic actuators are great for places that need strong, clean, and reliable movement.