A tilting disk check valve has a disk that tilts open. This lets water move in only one direction. If water tries to go backward, the disk shuts fast. This stops water from flowing the wrong way. It helps keep water and wastewater systems clean. Many engineers pick a tilting disk check valve. It works faster than a butterfly valve or a ball valve. In new systems, an electric valve is used with these valves. This helps keep water systems safe and working well.

Tilting Disk Check Valve Basics

Definition

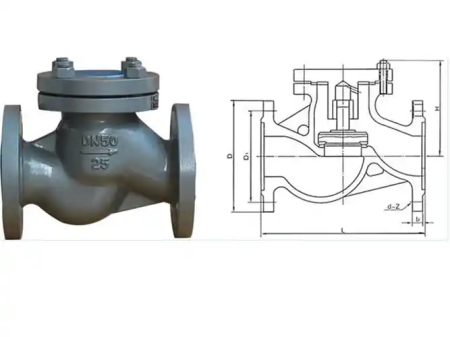

A tilting disc check valve is a type of check valve that allows fluid to flow in only one direction. The valve opens when water or gas moves forward and closes quickly if the flow reverses. This fast closure protects pumps and other equipment from damage. Industry standards such as API 594 and API 598 guide the design, size, and testing of these valves. The tilting disk check valve works well with liquids and gases but does not suit fluids with suspended solids. Many water systems use this valve because it helps prevent backflow and keeps the system safe.

Key Components

A tilting disc check valve has several important parts. Each part plays a role in how the valve works and how long it lasts.

Disk and Hinge

The disk is the main moving part. It sits on a shaft or hinge, which lets it tilt open and closed. The disk is often made from stainless steel or other materials that resist corrosion. The hinge or shaft supports the disk and allows smooth movement. Some valves use a spring to help the disk return to the closed position when there is no pressure.

Valve Body

The valve body holds all the parts together. It is usually made from strong materials like cast iron, ductile iron, stainless steel, or carbon steel. The body has flanged ends that connect to pipes in the water system. Inside the body, a seat ring forms a tight seal with the disk to stop leaks.

Tip: Choosing the right material for each part helps the tilting disc check valve last longer and work better in different water conditions.

| Component | Common Materials |

|---|---|

| Body | Cast Iron, Ductile Iron, Stainless Steel, Carbon Steel |

| Disc / Plate | Stainless Steel, Carbon Steel, Bronze |

| Shaft / Stem | Stainless Steel, Monel, Inconel |

| Seat / Lining | Elastomers such as NBR, EPDM, VITON |

| Bolts | Carbon Steel |

| Nuts | Stainless Steel |

How It Works

The tilting disc check valve uses a simple but effective mechanism. The disk sits on a rocker axis inside the valve body. When water flows forward, the pressure pushes the disk to tilt open. This lets water move through the valve with little resistance. If the flow stops or reverses, the disk tilts back to the closed position. This action blocks the flow and prevents backflow.

The valve needs a small amount of pressure, called cracking pressure, to open. The disk stays closed if the pressure is too low or if there is flow reversal. Some designs use a spring, gravity, or a counterweight to help the disk close faster. This quick response protects pumps and pipes from sudden changes in pressure.

- The tilting disc check valve works well in high-pressure and high-velocity water systems.

- The double-eccentric design helps the disk open and close smoothly.

- The valve only opens when the pressure is strong enough to overcome the closing force.

A tilted disc check valve provides automatic protection for water systems. It ensures that water flows in one direction and stops backflow. This keeps the system safe and efficient.

Features of Tilting Disk Check Valves

Low Pressure Drop

Tilting check valves help water move easily. Their special shape lets water pass with little push. The disk tilts open without much force. This means water keeps most of its pressure as it goes through. Pumps and pipes work better because of this. Many engineers pick tilting check valves for their low cracking pressure. They need less force to open than swing check valves. In vertical pipes, the valve opens even easier. This makes the pressure drop lower than other check valves. The disk is light and shaped to stop water hammer. Water hammer can hurt pipes, but this valve helps prevent it.

Note: When pressure drop is low, less energy is needed. This saves money and helps equipment last longer.

Fast Response

Tilting check valves close very quickly. They react fast when water flow changes. If water tries to go backward, the disk shuts right away. This stops backflow and keeps pumps safe from sudden pressure. These valves close faster than swing check valves. They also do not slam shut as hard. The disk moves on a rocker axis, so it closes smoothly and tightly. This makes tilting check valves good for systems that need non-slam check valves.

The table below shows how fast different check valves close and how well they stop water hammer:

| Check Valve Type | Response Time | Water Hammer Control |

|---|---|---|

| Tilting Check Valves | Faster than swing check valves, less slamming | Better than swing check valves |

| Swing Check Valves | Moderate; can slam on flow reversal | Poor without damping |

| Lift Check Valves | Fast, especially with spring assist | Good with spring assist |

Flow Efficiency

Flow efficiency is important in water systems. Tilting check valves are very good at letting water move fast. The disk tilts out of the way when open. This gives water a big, clear path to flow through. The valve does not block the water, so it moves quickly. High flow efficiency means more water moves with less work. This is helpful for both drinking water and wastewater systems. Non-slam check valves like these also make less noise and shake less. This keeps the system quiet and working well.

Tip: Using tilting check valves can help water flow better and lower how often you need repairs.

Compact Design

Tilting check valves are known for being small. Many water systems do not have much room. Engineers often need to fit valves in tight spots. The small size of tilting check valves helps with this problem. These valves have a special pivot point near the centerline. This lets the disk tilt open with less movement. It also means the valve does not need much space.

The offset pivot point makes the valve body smaller. Swing check valves need more room because their disk swings wide. Tilting check valves need less space because the disk tilts. The valve fits into small places easily. This is why they are good for modern water systems.

The small design has other good points too. The valve does not block water much. Water moves through it easily, so head loss is low. Lower head loss means the system uses less energy. Pumps do not have to work as hard. This can save money over time.

Tip: If space is tight, tilting check valves are a smart pick. Their small shape helps water systems work well.

Many engineers like tilting check valves for upgrades or repairs. Old systems may not have much space for new parts. The small size lets workers put in these valves without big changes. This saves time and lowers costs when installing.

Here are some reasons why the small size of tilting check valves matters:

- The disk pivots near the centerline, so the valve body is small.

- The valve fits well in tight or crowded places.

- The design blocks water less than swing check valves.

- Lower head loss helps the system work better.

- Fast closing and smooth flow make the valve dependable.

A table below shows how much space different check valves need:

| Valve Type | Space Needed | Flow Obstruction | Best Use Case |

|---|---|---|---|

| Tilting Check Valves | Low | Minimal | Confined spaces |

| Swing Check Valves | High | Moderate | Large, open systems |

| Lift Check Valves | Moderate | Moderate | Vertical installations |

The small size of tilting check valves makes them easy to install. Water systems do better with valves that save space and energy. These features make tilting check valves a great choice for new and old water systems.

Tilting Disc Check Valve vs. Other Check Valves

Swing Check Valves

A swing check valve has a disc that swings open. Water pushes the disc open when it flows forward. If water tries to go back, the disc swings shut. This type of valve is used in many water systems. It lets water move through with little resistance. But if water flow changes fast, the disc can slam shut. This slamming can cause water hammer. Water hammer can hurt pipes or pumps.

Engineers use swing check valves for big pipes or steady flow. The design is simple and easy to fix. The disc hangs from a hinge at the top. Gravity helps the disc close the valve. Swing check valves need more room because the disc swings wide. They may not fit in small spaces.

A tilting disc check valve is better in some ways. Its disc pivots near the center, not the edge. This helps the valve close faster and quieter. It also helps stop water hammer. The tilting disc check valve fits in tight spaces. It works in both flat and upright pipes.

Lift Check Valves

Lift check valves work differently to stop backflow. The disc or piston lifts straight up when water moves forward. When water stops or goes backward, gravity or a spring pushes the disc down. This seals the valve and blocks water from going back. Lift check valves work best in upright pipes.

These valves are strong and have few moving parts. They close fast, which helps stop water hammer. The disc does not move far, so it lasts longer. But lift check valves make water push harder to open. This means a higher pressure drop than tilting disc check valves.

The table below shows how tilting disc check valves and lift check valves compare in high-pressure water systems:

| Performance Aspect | Tilting Disc Check Valve | Lift Check Valve |

|---|---|---|

| Pressure Drop | Moderate; less than lift check valves but slightly higher than swing check valves. | Higher than tilting disc valves; can be reduced with special designs. |

| Sealing Capability | Moderate sealing; dual elastomeric seats available for tighter shutoff. | Good sealing with fast closure; rugged design. |

| Flow Reversal Response | Quick opening and closing; stable at low and pulsating flows; minimizes water hammer. | Shortest stroke and fastest closing time; excellent for rapid flow reversal. |

| Installation Orientation | Can be installed horizontally or vertically; vertical installation needs upward flow. | Requires vertical installation with neck upright for best closure. |

| Suitability for Pulsating Flows | Stable and effective at low and pulsating flows. | Excellent for low or pulsating flows; short stroke reduces wear. |

| Ruggedness and Maintenance | Moderate complexity with pivotal disc; some moving parts. | Rugged design; fewer components under impact loads. |

A tilting disc check valve gives a good mix of low pressure drop and fast action. It works well when flow changes or space is tight.

Dual Plate Check Valves

Dual plate check valves are also called wafer check valves. They use two plates with springs. The plates turn on a shaft in the middle. When water flows forward, the plates swing open. When water slows or reverses, the springs push the plates shut. This makes the valve quiet and helps stop water hammer.

The wafer check valve fits between two pipe flanges. Its thin body saves space and is easy to put in. Many engineers use dual plate check valves in big water systems. They cost less and do not need much fixing.

Both tilting disc check valves and dual plate check valves close fast and are small. The tilting disc check valve has one disc that pivots near the center. Water can flow above and below the disc for quick action. The dual plate check valve uses two plates and a spring. The plates close before water can go backward, making it quiet.

The table below shows the main differences:

| Feature | Dual Plate Check Valve | Tilting Disc Check Valve |

|---|---|---|

| Flow Characteristics | Two spring-loaded plates close before flow reversal; silent operation | Disc pivots near center; quick closing response; suited for pulsating flows |

| Installation Requirements | Wafer type; fits between flanges; compact and easy to install | Fits between flanges; compact for large pipes; works in horizontal and vertical lines |

| Operational Advantages | Silent operation; spring-assisted closure; cost-effective | Quick closure; better for pulsating flows; higher resistance to flow |

Tip: When picking between a tilting disc check valve and a wafer check valve, think about the flow, space, and if you need it to be quiet.

Key Differences

When you look at a tilting disc check valve and other check valves, you see some big differences. Each type has its own design and way of working. These things change how well they work in water systems.

A tilting disc check valve has a slanted disc that turns on a middle point. This lets the disc open easily when water moves forward. If water tries to go back, the disc shuts fast. This quick move stops backflow and keeps pumps safe. Other check valves, like swing or lift types, use discs or balls that move with the water. These may not close as quickly, so water hammer or leaks can happen.

The table below shows how a tilting disc check valve is different from other check valves:

| Aspect | Tilting Disc Check Valve | Common Check Valve |

|---|---|---|

| Structural Design | Inclined disc allowing smooth forward flow and quick closure upon flow reversal | Uses discs or spheres that close automatically in response to reverse flow |

| Working Principle | Utilizes fluid momentum to open; disc quickly closes due to reverse flow force | Disc or sphere moves automatically to close upon flow reversal |

| Scope of Application | Suitable for liquids, gases, steam; used in water supply, chemical, petroleum industries | Suitable for various media but applicability depends on structure and principle |

| Operating Mode | Can be operated manually or automatically, enabling remote control | Usually manual operation; some automatic variants exist |

A tilting disc check valve is special because it reacts fast. The disc tilts open with little pressure, so water moves easily. When water stops or goes backward, the disc closes almost right away. This helps stop water hammer, which can break pipes or pumps. Many engineers pick a tilting disc check valve for systems that need quick closing and strong backflow protection.

Another big difference is where you can use them. A tilting disc check valve works with liquids, gases, and steam. You see them in water, chemical, and oil systems. Other check valves may not work as well with all these things. The way each valve is built decides where it can be used.

How you use the valves is different too. A tilting disc check valve can be run by hand or by a machine. This means you can control it from far away in new water systems. Most other check valves are used by hand, but some can work by themselves.

Tip: Pick the right valve for your system. A tilting disc check valve closes fast, drops little pressure, and works in many places. That is why many engineers like to use it.

Applications of Tilting Check Valves

Power Plants

Power plants need strong valves to move water safely. Tilting disk check valves are important in these systems. Engineers use them to protect pumps and pipes from harm. These valves help control water flow and stop water from going backward.

The slanted seat inside the valve helps water move smoothly. This design lowers pressure loss and keeps water flowing steady. The disk tilts fast to close if water tries to go back. Quick closing stops water hammer, which can break pipes or hurt equipment.

Operators pick tilting disk check valves because they are small. The compact shape fits well in tight places. The smooth body also helps save energy. Power plants often have changing water needs. These valves keep water flow steady, even when demand changes.

Tilting disk check valves last a long time. The materials do not wear out or rust easily. Workers do not need to fix or replace them often. The tight seal inside the valve stops leaks and keeps water clean. This helps stop dirty water from getting into the system.

Engineers trust tilting disk check valves for many jobs in power plants. The valves protect the system and keep water moving the right way.

Key benefits of tilting disk check valves in power plants include:

- The slanted seat design helps water flow better and cuts down on turbulence.

- The disk closes fast to stop backflow and water hammer.

- The small body saves space and uses less energy.

- Strong materials last long and do not rust, so there is less fixing.

- The valve keeps a tight seal, even when water flow changes.

- Reliable valves help protect pumps and other parts.

Tip: Using tilting disk check valves in power plants keeps water systems safe and working well. These valves last long and help lower downtime.

Industrial Water

Industrial water systems are very important in places like factories and chemical plants. These systems move a lot of water for jobs like cooling and cleaning. Engineers need valves that keep water moving safely. They also want to stop leaks and backflow. Tilting disk check valves help with these problems because they have special features.

Tilting disk check valves let water go in just one direction. If water tries to go backward, the disk shuts fast. This quick closing stops backflow and keeps pumps and pipes safe. It also helps stop water hammer. Water hammer is a sudden pressure jump that can break pipes.

Many industrial water systems have tough conditions. High pressure, heat, and strong chemicals can damage normal valves. Tilting disk check valves use strong materials that do not rust. These materials help the valves last longer, even in harsh places. The valves work in both up-and-down and sideways pipes. This gives engineers more ways to set them up.

The tilting disk check valve is made to help water move easily. The disk opens when water flows forward and closes tight if flow reverses. This design does not block water much. Pumps do not have to work as hard. Less pressure loss means the system uses less energy and saves money.

Industrial water systems need to work well with little fixing. Tilting disk check valves are strong and have few moving parts. Many types do not need much care. This saves time and helps stop surprise problems.

Key benefits of tilting disk check valves in industrial water systems include:

- Let water move one way and close by themselves if water goes back.

- Fast closing stops backflow and lowers water hammer.

- Good sealing keeps leaks small and the system safe.

- Strong, rust-proof materials make the valves last long.

- Can be put in both up-and-down and sideways pipes.

- Low pressure loss helps the system use less energy.

- Need little or no fixing for long, steady use.

- Weighted or spring-loaded disks close faster and seal better.

Tip: Tilting disk check valves help keep industrial water systems safe and steady. Their quick action and tight seal protect equipment and lower downtime.

The table below shows how tilting disk check valves compare to other valves in industrial water systems:

| Feature | Tilting Disk Check Valve | Swing Check Valve | Lift Check Valve |

|---|---|---|---|

| Closure Speed | Fast | Moderate | Fast |

| Water Hammer Control | Excellent | Poor | Good |

| Pressure Loss | Low | Moderate | High |

| Maintenance Needs | Low | Moderate | Low |

| Installation Flexibility | High | Moderate | Low |

Tilting disk check valves give industrial water systems the safety and efficiency they need. Their special design and strong build make them a smart pick for modern factories and plants.

Installation and Maintenance

Installation Tips

Putting in a tilting disk check valve the right way helps it work well and last longer. Workers need to do some important steps:

- Cover the sealing surfaces before storing the valve. This keeps out dirt and dust. Lay the valve flat so it does not get damaged.

- Look at the valve before putting it in. Check for cracks or dents from shipping. Make sure the sealing surfaces are clean. See if the disc moves easily.

- Find the arrow on the valve body. It shows which way water should go.

- Put the valve on pipes that are flat or a little sloped. Only use vertical pipes if the valve is made for upward flow.

- Place the valve near the pump outlet. This helps stop water from going backward.

- Use the right gaskets between pipe flanges. Tighten bolts in a crisscross way so the valve does not bend.

- Make sure hydraulic dampers or counterweights can move freely.

- Check bypass line connections if your system has them.

- After you put the valve in, test the disc by hand or with water. Adjust the hydraulic damper throttle valve to control how fast the disc closes.

- Open the upstream valve slowly. Watch the valve work before letting water flow fast.

Tip: Careful installation stops leaks and helps the valve work smoothly.

Maintenance Guidelines

Taking care of tilting disk check valves helps them last longer. Workers should check the valve often and do these things:

- Clean the valve to get rid of dirt or solid bits. This helps the disc close tight.

- Lubricate moving parts so they do not rub too much. Smooth movement helps the valve seal better.

- Check bolts and change any parts that are worn or broken, like gaskets, seats, or discs.

- Make sure the valve faces the right way and sits straight in the pipe.

- Check that the valve size matches the pipe and water flow. The wrong size can cause trouble.

- Test the valve after fixing it. Run water through to check for leaks and see if it closes right.

Here is a simple table that shows common maintenance jobs:

| Task | Purpose | Frequency |

|---|---|---|

| Cleaning | Remove debris | Monthly |

| Lubrication | Reduce friction | Quarterly |

| Bolt Tightening | Prevent leaks | Annually |

| Part Replacement | Fix wear or damage | As needed |

| Operation Testing | Ensure proper function | After service |

Note: Regular care helps the valve last longer and stops expensive repairs.

Troubleshooting

Sometimes, a tilting disk check valve does not close right. Workers can fix most problems by doing these things:

- Clean the valve to get rid of anything blocking the disc.

- Lubricate moving parts so the disc tilts easily.

- Tighten bolts and change any worn or broken parts, like gaskets or seats.

- Make sure the valve is put in the right way and faces the correct direction.

- Check that the valve size fits the pipe and matches the water flow.

- If the disc sticks or does not move, take the valve apart and clean it. Then put it back together.

- Test the valve after fixing it to make sure it seals tight and works well.

??? Checking the valve often helps find problems early. Workers should look for chattering, leaks, or slow closing and fix these problems fast.

Selecting the Right Check Valve

Sizing

Engineers need to pick the right size tilting disk check valve. This keeps water systems safe and working well. They look at pipe size, how fast water moves, and the system’s pressure. Manufacturers give numbers like K-value and Cv. These numbers help engineers figure out how much pressure the valve will lose. The formula for pressure loss is:

h = K * v2 / 2g

Here, h means pressure loss, v is how fast the water moves, and g is gravity.

If the valve is too big, the disk can shake or make noise. This can break the valve early. If the valve is too small, it can block water and raise pressure loss. Engineers should use the manufacturer’s data to check the valve fits the flow needs. Most tilting disk check valves work best in pipes that are flat. Some can go in up-and-down pipes if water flows up.

Tip: Always pick the valve size for the real water flow, not just the pipe size. This helps stop problems like water hammer and broken valves.

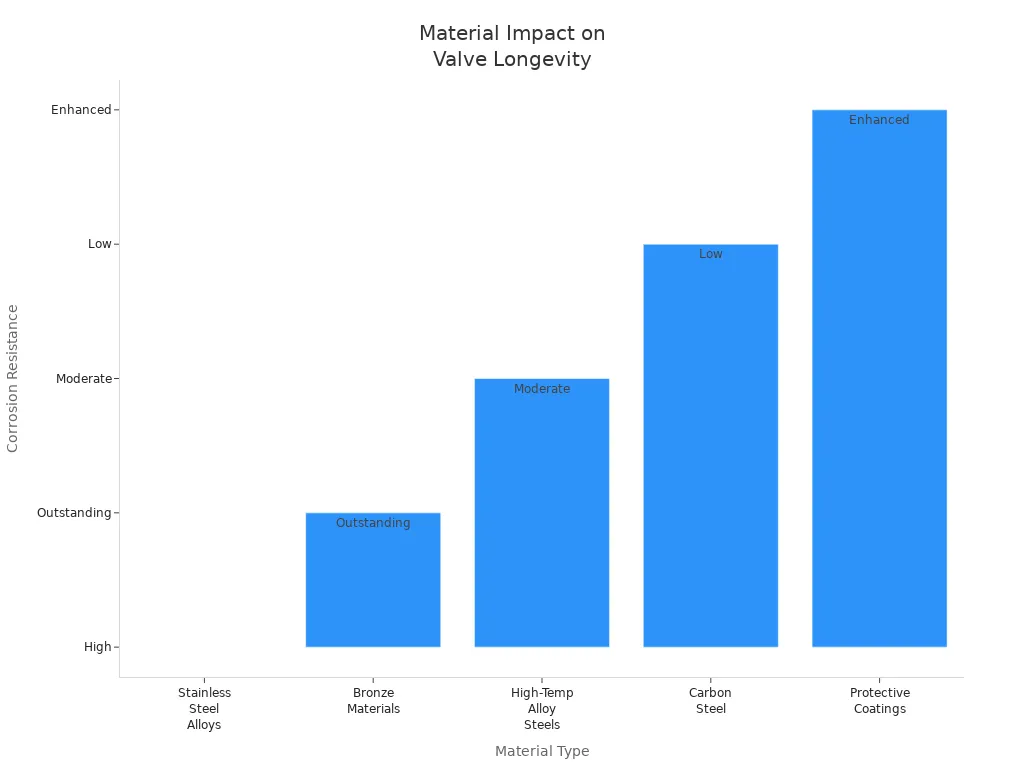

Material Choices

Picking the right material helps the valve last longer. This is important in places with strong chemicals or salt water. Stainless steel, bronze, and carbon steel are common choices. Stainless steel does not rust and works well with acids or seawater. Bronze is strong and good for ships. Carbon steel costs less but needs a coating to stop rust.

| Material Type | Examples / Grades | Application Environment | Effect on Valve Longevity and Corrosion Resistance |

|---|---|---|---|

| Stainless Steel Alloys | CF8, CF8M (316L), SS304 | Acid-base media, petrochemical, seawater | High corrosion resistance; resists pitting and crevice corrosion; extends lifespan |

| Bronze Materials | B62 C83600, B148 C95800, B148 C95400 | Marine engineering, shipbuilding, seawater | Outstanding corrosion resistance and mechanical strength; suitable for seawater |

| High-Temperature Alloy Steels | Cr-Mo steels (ASTM A217 WC5, WC6, WC9, etc.) | Steam pipelines, oil refineries, petrochemical plants | Heat-resistant, high strength; withstands high temperature and pressure; durable |

| Carbon Steel | WCB | General industrial use | Less corrosion resistant; often requires protective coatings |

| Protective Coatings (Paint) | Special corrosion-resistant paints | Acidic/alkaline media, humid and industrial atmospheres | Enhances surface protection; prevents erosion and chemical attack |

Good stainless steel valves, like CF8M, do not get pits and last longer in tough water or chemical systems. Special paint coatings also protect valves from damage. These coatings stick well and keep working when temperatures or pressures change.

System Compatibility

A tilting disk check valve must fit the system’s needs. Engineers check what kind of fluid is used, how fast it moves, and the pressure. These valves work best with clean water. Some can also handle chemicals or gases. The flow speed should be between 12 and 250 feet per second for best results. The valve material should match the pipes, like stainless steel or bronze.

It is important to install the valve the right way. Most tilting disk check valves need to be a few pipe widths away from pumps or bends. This helps stop water from swirling too much. The valve should match the system’s pressure and temperature limits. Engineers also check if the valve is easy to fix or change later.

Industry standards like API 6D, API 594, and AWWA C508 help engineers pick the right valve. These rules make sure the valve is safe and works well. Features like double eccentric discs, counterweights, and special seals help the valve close tight and stop water hammer.

Note: Picking a valve with the right features for your system keeps it safe, stops leaks, and helps it last longer.

Tilting disk check valves make water systems safe and work well. The disc closes fast to stop water from going backward. This helps stop water hammer and saves energy. It also keeps equipment safe from harm. These valves work in places with high pressure or heat. You can put them in many ways, and they last a long time. Picking the right valve, putting it in right, and checking it often keeps things safe. This also stops leaks and lowers repair bills.

- They help keep pressure loss and wasted energy low.

- They keep pipes and buildings safe from floods and damage.

Engineers should use tilting disk check valves for good and low-cost water control.

FAQ

What is the main purpose of a tilting disk check valve?

A tilting disk check valve stops water from flowing backward. It protects pumps and pipes from damage. This valve helps keep water systems safe and clean.

Can tilting disk check valves reduce water hammer?

Yes. The fast-closing disk design helps prevent water hammer. This action protects pipes and equipment from sudden pressure changes.

Where can engineers install tilting disk check valves?

Engineers can install these valves in horizontal or vertical pipes. The valve works best with clean water in water supply, wastewater, and industrial systems.

How often should workers maintain a tilting disk check valve?

Workers should inspect and clean the valve every few months. Regular checks help the valve last longer and work better.

What materials work best for tilting disk check valves?

Stainless steel and bronze resist rust and last longer. Carbon steel costs less but needs a protective coating. The right material depends on the water type and system needs.

Do tilting disk check valves work with chemicals?

Some tilting disk check valves handle chemicals. The valve material must match the chemical type. Stainless steel works well in many chemical systems.

How do you know if a tilting disk check valve is the right size?

Engineers check the pipe size and water flow rate. They use manufacturer charts to pick the correct valve size. The right size helps prevent leaks and noise.