You use various valve types every day, even if you don’t always notice them. Valves help control, stop, or guide liquids and gases through pipes. Among the most common valve types are the ball valve and butterfly valve, each designed to manage flow in its own way. Additionally, electric valves and pneumatic valves offer automated control options depending on your needs. The table below highlights how frequently these valves are installed across different industries:

| Valve Type | Units Installed (2024) | Key Applications |

|---|---|---|

| Ball Valve | Over 685 million | Oil & Gas, pipelines |

| Gate Valve | Around 482 million | Power, pipeline systems |

| Butterfly Valve | More than 384 million | Water, HVAC, offshore rigs |

Choosing the right valve type is essential for your project. You might select an electric valve for precise control or a pneumatic valve for quick, reliable operation. Your decision should consider safety, materials, and how you plan to use the valve.

Functions of a Valve

Start and Stop Flow

Valves help start or stop liquids or gases in pipes. This is a basic job for valves. You turn a handle or use a control to open or close the valve. When the valve opens, flow can move. When it closes, flow stops. Ball valves and gate valves are shutoff valves. They use different ways to control flow. A ball valve turns a hollow ball to open or close the path. A gate valve moves a flat gate up or down. These valves are found in water lines, gas pipes, and factories. Quick shutoff keeps people safe during repairs or emergencies. The table below shows how some valves start and stop flow:

| Valve Type | Mechanism to Start/Stop Flow | Key Feature |

|---|---|---|

| Ball Valve | Rotates a hollow sphere | Quick on/off control |

| Gate Valve | Moves a flat gate vertically | Good for on/off service |

| Check Valve | Closes automatically if flow reverses | Prevents backflow |

| Butterfly Valve | Rotates a disk to open or close | Compact design, can regulate or stop flow |

| Diaphragm Valve | Raises or lowers a flexible diaphragm | Precise control, handles solids in fluids |

Each valve type uses its own way to start or stop flow. This job is important for safety and control.

Regulate Flow and Pressure

Valves do more than just open or close. They also help control flow and pressure in pipes. Sometimes you need to change how much liquid or gas moves. For example, in a chemical plant, you may need to add chemicals slowly. Globe valves, butterfly valves, and diaphragm valves help by changing the size of the opening. Some valves use hydraulic or electronic controls for small changes. These systems can react fast to changes in flow or pressure. This keeps things safe and steady. Valves also help control pressure. They can lower or keep pressure steady to protect equipment. A pressure relief valve lets out extra pressure if it gets too high. Using the right valve keeps your system safe and working well.

Control Flow Direction

Valves also control which way fluids move. You want liquids or gases to go the right way. Backflow can cause problems or damage. Check valves are made to stop backflow. They let flow go one way and close if it tries to go back. Ball valves and plug valves can also control direction by opening or closing certain paths. In bigger systems, you might use three-way or multi-port valves to mix or send flow where needed. Control valve stations use many valves and tools to manage flow, pressure, temperature, and direction at once. Picking the right valve helps your system work safely and well.

Tip: Always pick the valve that fits your system best. This gives you better flow control and keeps things safe.

Throttle Flow Rates

Sometimes you need to change how much liquid or gas moves. This is called throttling. Throttling helps you match the flow to your system’s needs. You may want to slow water in a cooling system. You may need to control steam in a power plant. Throttling is a key job for valves.

Some valves are better for throttling than others. Not every valve can do this job well. You should pick the right valve so your system works safely. The table below shows how different valves work for throttling:

| Valve Type | Throttling Capability and Suitability | Limitations and Notes |

|---|---|---|

| Globe Valves | Mainly used for throttling; disk moves up and down | Needs power for high pressure; may leak; can vibrate with gas |

| Butterfly Valves | Good for throttling; turns a disk inside | Disk always in flow path; can wear out; hard to clean; needs flow checks |

| Gate Valves | Not good for throttling; works only when almost closed | Can wear out; may vibrate; not for long-term throttling |

| Pinch Valves | Works well for throttling between 10%-95% flow | Not for sharp particles, gas, or high pressure |

| Diaphragm Valves | Like pinch valves; uses a soft diaphragm | Best for clean systems; same limits as pinch valves |

Globe valves give you the most control for throttling. You turn a wheel to move a disk up or down. This changes the opening size and lets you adjust flow. Butterfly valves are also good for throttling. They are easy to use and fit in small spaces. You turn the handle to move the disk inside. Pinch valves and diaphragm valves use soft parts to squeeze or block flow. These work best in clean places like food or medicine factories.

Gate valves are not good for throttling. They are made to be open or closed. Using them for throttling can cause damage or vibration. Ball valves can throttle flow in low-pressure systems. They do not give fine control. V-port ball valves are better, but globe or butterfly valves work best.

Many industries use throttling to keep things safe and working well. You can find throttling valves in:

- Refrigeration and air conditioning

- Hydraulic machines

- Steam plants

- Medicine and chemical factories

- Food factories

- Fuel oil systems

Tip: Pick the right valve for throttling. This saves energy, protects your equipment, and keeps your process smooth.

Valve Types

When you look at the different types of valves, you find that each one works in its own way. Some valve types are better for quick shut-off, while others help you control flow with more precision. Here, you will learn about three of the most common valve types: ball valves, gate valves, and globe valves. These types of valves play a big role in many industries, including as types of water valves in homes and factories.

Ball Valves

Operation

Ball valves use a round ball with a hole through the center. You turn the handle 90 degrees to open or close the flow. This simple quarter-turn action makes ball valves fast and easy to use. The ball inside rotates to line up the hole with the pipe for flow, or turns sideways to block it. You can find different designs, such as floating ball valves for lower pressure and trunnion ball valves for high pressure. Some ball valves have soft seats for a tight seal, while others use metal seats for high temperatures or rough fluids. You can choose from one-piece, two-piece, or three-piece ball valves, which affects how easy they are to maintain.

- Ball valves give you quick on/off control.

- You can use lever handles for fast operation or handwheels for more control in tough jobs.

- Full port ball valves keep the pipe size the same, so you get less flow resistance.

Pros and Cons

| Feature | Ball Valves |

|---|---|

| Operation | Quarter-turn, fast and simple |

| Sealing | Excellent, very low chance of leaks |

| Maintenance | Easy, fewer moving parts |

| Pressure & Temperature | Handles high pressure and temperature |

| Flow Control | Good for on/off, less precise for throttling |

| Cost | Moderate to high |

| Size | Can be large |

Tip: Ball valves work well when you need quick shut-off and a tight seal.

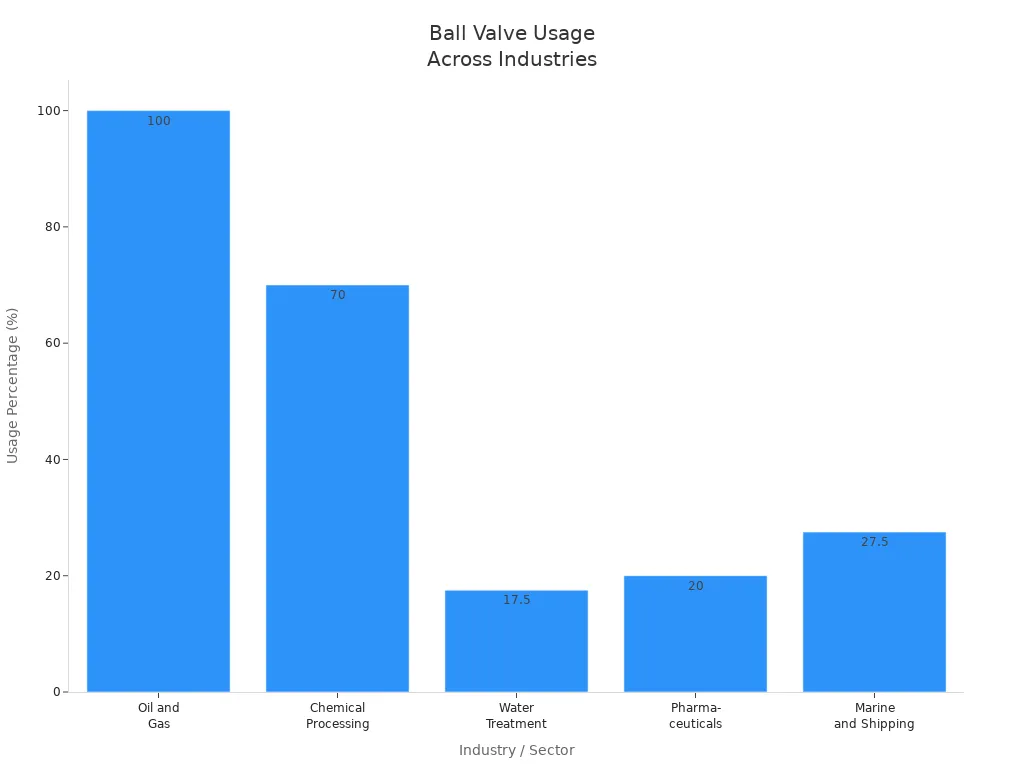

Applications

Ball valves are used in many industries because they are strong and reliable. You see them in oil and gas, chemical plants, water treatment, and power stations. They are also common as water valves in homes and factories. Ball valves handle high pressure, hot or cold fluids, and even corrosive chemicals. You find them in:

- Oil and gas pipelines for safe shut-off

- Chemical processing for leak-proof control

- Water treatment plants for easy flow control

- Food and beverage factories for clean, safe flow

- Marine and shipping for saltwater systems

Ball valves are one of the most common valve types because they last long, need little care, and work well in tough places.

Gate Valves

Operation

Gate valves use a flat or wedge-shaped gate that moves up and down to open or close the flow. You turn a wheel to lift the gate out of the path or lower it to block the flow. Gate valves work best when fully open or fully closed. They do not control flow well in between. The straight-through design means water or gas flows in a straight line with almost no resistance when open. You often see gate valves as types of water valves in large pipes.

- Gate valves need more turns to open or close than ball valves.

- The stem moves up or down, but the handwheel may stay in place.

- You can use gate valves for flow in both directions.

Pros and Cons

| Feature | Gate Valves |

|---|---|

| Operation | Multi-turn, slower to open/close |

| Sealing | Good, but can wear with use |

| Maintenance | Needs more care, more moving parts |

| Pressure & Temperature | Handles high pressure and temperature |

| Flow Control | Not good for throttling |

| Cost | Moderate to high |

| Size | Often large, needs more space |

- Gate valves have simple designs but can fail if not cared for.

- You need to check for stem breakage, leaks, or stuck gates.

- Regular cleaning and lubrication help gate valves last longer.

Note: Use gate valves when you want full flow or complete shut-off, not for adjusting flow.

Applications

You find gate valves in many places where you need to start or stop flow in big pipes. They are used in:

- Water supply systems for homes and cities

- Oil and gas pipelines for safe shut-off

- Power plants for steam and cooling water

- Chemical plants for handling tough fluids

Gate valves are a top choice for main water valves and other large systems because they let you move a lot of fluid with little resistance.

Globe Valves

Operation

Globe valves use a round disc that moves up and down inside the valve body. You turn the handwheel to raise or lower the disc, which changes the size of the opening. This lets you control how much fluid passes through. The flow path in globe valves is not straight. The fluid must turn inside the valve, which helps you adjust flow but causes some pressure drop. Globe valves can have different shapes, like T-pattern, Y-pattern, or angle types, to fit different needs.

- Globe valves give you fine control over flow.

- You can use them for both on/off and throttling.

- The design helps you get a tight seal when closed.

Pros and Cons

| Feature | Globe Valves |

|---|---|

| Operation | Multi-turn, precise control |

| Sealing | Very good, tight shut-off |

| Maintenance | More complex, heavier than other valves |

| Pressure & Temperature | Handles high pressure and temperature |

| Flow Control | Excellent for throttling |

| Cost | Higher due to complex design |

| Size | Needs more space, heavier |

- Globe valves cause more pressure drop than gate or ball valves.

- You need more force to close them under high pressure.

- The design makes them heavier and more costly.

Applications

Globe valves are perfect when you need to adjust flow often and keep it steady. You see them in:

- Chemical plants for dosing and mixing chemicals

- Power plants for steam and cooling systems

- Water treatment for controlling flow rates

- Fire protection systems for safe shut-off

- HVAC systems for fine flow adjustment

Globe valves work well with tough fluids, high pressure, and high temperatures. You can trust them for accurate flow control in many valve applications.

Butterfly Valves

Operation

Butterfly valves control flow by turning a disc inside the pipe. The disc sits in the middle and connects to a rod. When you turn the handle, the disc turns. This opens or closes the valve. The disc stays in the flow path, but it does not block much. You can use handles, motors, or pneumatic actuators to move the disc. Butterfly valves work for on/off and throttling control.

Pros and Cons

Butterfly valves have many good points, especially in big pipes:

- They save space because they are slim. You can fit them in small places.

- You spend less money since they are light and often cheaper.

- Maintenance is easy. The simple design means less downtime.

- They cause less pressure drop than globe valves. This helps your system work better.

- You can automate them with actuators for better control.

- New butterfly valves use strong materials, so they last longer.

- They work well in water treatment and fire protection.

But butterfly valves also have some problems:

| Advantage | Drawback |

|---|---|

| Compact and lightweight | Disc always in flow path (can cause wear) |

| Low cost and easy installation | Not ideal for very high-pressure systems |

| Good for large pipes | May not seal as tightly as ball valves |

| Simple maintenance | Can be harder to clean in some designs |

Tip: Pick butterfly valves when you want reliable and cheap flow control in big pipes.

Applications

Butterfly valves are used in many industries. You see them in water plants, HVAC systems, and fire protection. They are also in chemical plants, food factories, and power stations. Butterfly valves handle water, air, steam, and some chemicals. They are a top choice for water valves in city and factory systems. You can use them for shut-off or flow control in big pipes.

Check Valves

Operation

Check valves let fluid move in only one way. You do not need to use them by hand. When fluid goes forward, the valve opens. If flow tries to go back, the valve shuts by itself. This stops backflow and keeps your system safe. There are swing, lift, and ball check valves. Each type works differently, but all stop reverse flow.

Pros and Cons

Check valves help keep water and fluid systems safe:

- They stop backflow and keep water clean.

- You do not need to use them by hand, so they work even if you forget.

- They protect pumps and equipment from damage by reverse flow.

- You find them in many types of valves in water plants, chemical plants, and factories.

But check valves have some limits:

| Advantage | Drawback |

|---|---|

| Prevent backflow and contamination | Can get stuck if debris enters the valve |

| No manual operation needed | May cause water hammer if not sized right |

| Simple and reliable | Some types need regular inspection |

| Used in many valve types | Not suitable for throttling or flow control |

Backflow prevention devices use designs like air gaps and double check valve assemblies. These keep drinking water safe from bad stuff. In water plants, backflow can cause health risks like chemical or germ problems. Regular checks and care keep these valves working and help you follow safety rules.

Applications

You use check valves in water lines, wastewater plants, and irrigation systems. They are important in fire protection, chemical plants, and oil pipelines. Check valves protect pumps, stop contamination, and keep systems safe. In big buildings and factories, you see double check valve assemblies for more safety. You also find check valves in home plumbing to keep drinking water clean.

Plug Valves

Operation

Plug valves use a plug with a hole in the middle. You turn the plug to line up the hole with the pipe for flow. Turn it again to block the flow. Most plug valves need only a quarter turn to open or close. You can use handles, levers, or actuators to move them. Some plug valves use grease or special sleeves to make turning easier and seal better.

Pros and Cons

Plug valves are good for tough fluids:

- Lubricated plug valves work with hot, rough, or corrosive fluids.

- You can pick plugs made from plastic or coated for better resistance.

- Sleeved plug valves use a soft sleeve to seal tight and stop leaks.

- Lined plug valves use Teflon or other plastics to fight corrosion.

- The simple design makes them easy to use and fix.

But plug valves have some downsides:

| Advantage | Drawback |

|---|---|

| Excellent for corrosive and abrasive fluids | Can require more force to operate |

| Tight sealing with sleeved or lined designs | May wear out faster with dirty fluids |

| Simple and compact design | Not ideal for precise throttling |

| Easy to automate | Can be heavier than other valve types |

Note: Plug valves are smart when you need to move harsh chemicals or rough fluids.

Applications

Plug valves are found in chemical plants, oil pipelines, and wastewater plants. They are used in systems that move rough or corrosive fluids. You also see them in food factories where clean flow matters. Plug valves work well for on/off jobs and can handle many fluids. You can use them in water valves for factories where strength and chemical resistance are needed. Plug valves are one of the most useful valves for hard jobs.

Needle Valves

Operation

Needle valves help you control flow very carefully. You turn a screw to move a thin needle into a small hole. This lets you change the flow slowly and with great care. The needle fits tightly, so you can make tiny changes. This helps you let just the right amount of fluid or gas through. Needle valves are used in labs and testing tools. They move slowly, so you do not get sudden changes in flow or pressure.

Pros and Cons

Needle valves are good when you need careful control:

- You can adjust flow very accurately.

- The tight fit stops leaks and keeps things clean.

- You can use them with both gases and liquids.

- They work well when pressure is high.

But needle valves also have some problems:

- They do not shut off flow quickly.

- The small hole can get blocked if there are particles.

- You must turn the screw many times to open or close it.

Tip: Pick needle valves for systems that need careful flow control.

Applications

You see needle valves in lab tools and gas testing machines. They help you measure and control small amounts of fluid or gas. You also find them in hydraulic and air systems. Here, you need to change flow or pressure slowly. Needle valves are important for jobs that need careful work.

Pinch Valves

Operation

Pinch valves use a soft rubber tube to control flow. You squeeze the tube to stop the fluid. When you let go, the tube opens and fluid moves. Only the tube touches the fluid, so there is no rust or damage. You can use your hand or air to squeeze the tube.

Pros and Cons

Pinch valves are good for tough fluids:

- The rubber tube does not wear out fast with rough stuff.

- The tube opens wide, so solids can pass easily.

- The tube keeps fluids clean and stops rust.

- It is easy to fix; you just change the tube.

But there are some downsides:

- They do not work well with high pressure.

- The tube can wear out and needs to be changed.

- They are not good for very hot fluids.

| Benefit | Explanation |

|---|---|

| Abrasion Resistance | The rubber tube takes hits from rough stuff, so it lasts longer than metal. |

| Wide and Linear Flow Control | Pinch valves open all the way, so flow is smooth and easy to control. |

| Low Life Cycle Cost | The tube is cheap and easy to swap, so you save money and time. |

Note: Pinch valves are best for moving slurries, powders, and harsh fluids.

Applications

You use pinch valves in mines, water plants, and chemical factories. They control flow where there are rough slurries or powders. You also see them in food factories where clean flow is needed. Pinch valves are great when you want easy care and strong parts.

Pressure Relief Valves

Operation

Pressure relief valves keep your equipment safe from too much pressure. If pressure gets too high, the valve opens by itself. It lets out extra fluid or gas until things are safe again. Then the valve shuts to seal the system. You use these valves in oil, gas, and chemical plants to stop damage from high pressure.

Pros and Cons

Pressure relief valves have many good points:

- They stop equipment from breaking or blowing up.

- They keep people, nature, and buildings safe.

- They work on their own, so you do not need to open them.

- You can use them in pipes, tanks, and many other places.

But there are some problems too:

- You must check and test the valve often to make sure it works.

- The valve may let out fluids that need to be handled safely.

- They are not made for careful flow control.

Alert: Always use pressure relief valves where high pressure could be dangerous.

Applications

You find these valves in oil and gas fields, pipes, and refineries. They protect boilers, tanks, and pressure vessels. You also see them in water plants and fire safety systems. Pressure relief valves are very important for keeping people and equipment safe.

Valve Classification

Linear Motion Valves

Linear motion valves move their closing part in a straight line. The valve opens or closes by lifting or lowering a gate, disc, or diaphragm. You use these valves when you want to start or stop flow slowly. They help you control flow with care. Gate valves, globe valves, and pressure reducing valves are common examples. These valves work well when you need to adjust flow or pressure carefully.

Linear motion valves need several turns to open or close. This makes them slower to use. But you get better control. You see these valves in water supply lines, steam systems, and chemical plants. Air valves and backflow preventers can also use linear motion designs. These help keep your system safe and clean.

Tip: Use linear motion valves for careful flow control or when you want to avoid sudden pressure changes.

Rotary Motion Valves

Rotary motion valves turn a part inside the valve body. The closing part rotates around a center, usually with a quarter turn. Ball valves, butterfly valves, and plug valves are rotary motion types. You use these valves for fast on/off control and simple use.

Rotary motion valves are small and easy to put in. They need less space than linear motion valves. You can open or close them quickly. This helps in emergencies. Air valves and backflow preventers often use rotary motion for quick action. These valves are common in HVAC systems, pipelines, and water treatment plants.

Here is a table that compares linear and rotary motion valves:

| Feature | Linear Motion Valves | Rotary Motion Valves |

|---|---|---|

| Movement | Straight up and down | Rotates (usually 90°) |

| Operation Speed | Slower, needs many turns | Fast, needs only a quarter turn |

| Flow Control | Precise, good for throttling | Quick on/off, less precise |

| Space Needed | More | Less |

| Common Types | Gate, globe, pressure reducing valves | Ball, butterfly, plug, air valves |

Multi-Turn vs. Quarter-Turn

There are two main valve types: multi-turn and quarter-turn. Multi-turn valves need many full turns to open or close. Gate valves and globe valves are multi-turn types. These valves give you fine control. They are good for systems where you want to adjust flow slowly. You use multi-turn valves for pressure reducing valves and backflow preventers. Careful adjustment is important here.

Quarter-turn valves need only a 90-degree turn to open or close. Ball valves, butterfly valves, and some air valves use this design. These valves are fast and easy to use. You can shut off flow quickly. This helps in emergencies. Quarter-turn valves are less precise for flow control. But they work well for on/off jobs.

Here is a table to help you compare:

| Aspect | Quarter-Turn Valves | Multi-Turn Valves |

|---|---|---|

| Operation Speed | Fast, 90-degree turn | Slow, many turns needed |

| Flow Control | Less precise | Very precise |

| Effort Needed | Low | Higher |

| Best Use | Quick shut-off, air valves, backflow preventers | Pressure reducing valves, fine control |

Note: Pick quarter-turn valves for speed and easy use. Choose multi-turn valves when you need careful flow or pressure control.

The way a valve moves and how much you turn it changes how your system works. If you know these differences, you can pick the right valves, air valves, pressure reducing valves, and backflow preventers for your needs.

Manual, Automatic, Self-Actuated

Valves can be used in different ways. Manual valves have handwheels, levers, or handles. You move these by hand. People use manual valves in homes and schools. Small factories also use them. Manual valves are good when you do not need fast control. They work well for simple jobs.

Automatic valves use actuators. These can be electric, pneumatic, or hydraulic. Actuators open or close the valve for you. You can set automatic valves to follow signals. Sensors or control systems send these signals. Automatic valves help you control flow and pressure. You do not need to be there. Big plants and water treatment use automatic valves. HVAC systems use them too. Air valves often have automatic actuators. They respond quickly.

Self-actuated valves sense changes in pressure, flow, or temperature. These valves adjust themselves. They do not need outside power. Pressure reducing valves are a common type. They open or close based on pipe pressure. Self-actuated valves keep systems safe and steady. You see them in steam lines and gas systems. They are used where safety is very important.

Tip: Pick manual valves for easy jobs. Use automatic or self-actuated valves for fast or remote control.

Materials

Valve material changes how it works and where you use it. You must pick the right material for your fluid. Pressure and temperature matter too. Some valves use metals like cast iron or stainless steel. Metals are strong and fight rust. Stainless steel makes a layer that stops rust. Superalloys like Hastelloy? and Inconel? work in strong acids and heat.

Thermoplastics like PTFE (Teflon?), PFA, and FEP resist chemicals well. These plastics are good for tough chemicals. They are not as strong as metals. Chemical plants and labs use thermoplastic valves.

Ceramics such as alumina and silicon carbide are very hard. They do not wear out fast. Ceramics fight chemical damage. Makers use ceramics for seals and bearings.

Elastomers are used for seals and O-rings. These materials bend and help stop leaks. Elastomer resistance changes with fluid and temperature.

Here is a table to help you compare valve materials:

| Material Type | Examples / Grades | Chemical Compatibility Influence and Usage |

|---|---|---|

| Metals | Cast iron, Stainless steel, Nickel alloys, Superalloys | Strong, corrosion resistance varies; stainless steel resists rust; superalloys handle acids and heat |

| Thermoplastics | PTFE (Teflon?), PFA, FEP | Great chemical resistance; good for harsh chemicals; less strong than metals |

| Ceramics | Alumina, Silicon carbide | Very hard; resists wear and chemicals; used for seals and bearings |

| Elastomers | Many types for seals and O-rings | Flexible; stops leaks; resistance depends on fluid and temperature |

You should check chemical charts and ask for advice. The right material keeps valves safe and working longer.

Connection Types

Valve connection types change how you put in and fix your system. You can choose threaded, flanged, welded, compression, union, or manifold-mount connections. Each type has good and bad points.

Threaded connections use screw threads. You install them with simple tools. You must seal them well to stop leaks. Threaded valves are best for small pipes.

Flanged connections use bolts and gaskets. You need skill and space to put them in. Flanged valves are easy to take apart. They are strong and used in big pipes.

Welded connections make a tight, leak-proof bond. You need welding skills to install them. Welded valves are hard to remove. Maintenance is tough. These work best in high-pressure systems.

Compression fittings let you install valves fast. You do not need soldering. Tighten the fitting to seal the pipe. Compression valves are good for homes and small systems.

Union connections make it easy to take valves off and put them back. Use them if you need to fix valves often. Union fittings are bigger than other types.

Manifold-mount connections put many valves in one spot. You use them in complex systems. This setup lowers leak points and helps things run better.

Here is a table that compares connection types:

| Connection Type | Installation Impact | Maintenance Impact | Key Considerations |

|---|---|---|---|

| Threaded | Easy with tools; needs sealing | Can leak; harder to maintain | Best for small pipes; cost-effective |

| Flanged | Needs alignment and space | Easy to dismantle | Good for large pipes; needs gasket |

| Welded | Permanent; needs welding | Hard to replace | Best for high pressure; no easy removal |

| Compression | Quick; no soldering | Easy to maintain | Good for homes; limited pressure |

| Union | Easy to disconnect | Simple maintenance | Bulkier; for frequent service |

| Manifold-Mount | Complex setup | Centralized maintenance | For complex systems; fewer leaks |

You should match the connection type to your system. Think about size, pressure, and how often you need to fix things. The right choice makes work easier.

Selecting Different Valve Types

Application Needs

You should first think about what your system needs. Every system has a job to do. Different valves work best for different jobs. Ask yourself what you want the valve to do. Do you need to start or stop flow? Do you want to control which way things move? Maybe you need to change how fast things move, or keep your system safe from too much pressure.

Think about these things when picking a valve:

- Decide if you want to turn flow on and off, change direction, or control speed.

- Think about how many times you will use the valve. If you use it a lot, pick a strong valve.

- Check what kind of fluid is in your pipes. Is it water, oil, gas, or something that can damage metal?

- Look at your pipe size and the space you have for the valve.

- Make sure the valve keeps your system safe. Some valves stop leaks or keep pressure from getting too high.

If you pick the wrong valve, you could get leaks or mix up fluids. Your system might even stop working. Always pick a valve that does what your system needs.

Tip: Use tools from the maker or ask experts for help with hard systems.

Flow Control

Flow control is very important when picking a valve. You need to know how much control you want over the flow. Some valves let you control flow very well. Others are just for turning flow on or off.

- Globe valves are good for changing flow and making small adjustments. They let you control flow well, but they slow things down more.

- Needle valves are best for very small and careful changes. These are used for adding chemicals or in labs.

- Gate valves are best for turning flow on or off. They do not work well for changing flow in between.

- How a valve changes flow as you move the handle is called its flow characteristic. Some valves change flow slowly and evenly. Others change flow quickly or not much at first.

- The pressure on each side of the valve changes how well you can control flow. If pressure stays the same, you get better results.

Pick a valve that fits your flow control needs. If you want steady and careful control, use a globe or needle valve. If you just want to stop or start flow fast, use a gate or ball valve.

| Valve Type | Best Use | Flow Control Precision |

|---|---|---|

| Globe Valve | Throttling, regulation | High |

| Needle Valve | Precise dosing | Very high |

| Gate Valve | On/off isolation | Low |

| Ball Valve | Quick shut-off | Moderate |

Note: Picking the right valve for flow control helps your system work well and stay safe.

Pressure and Temperature

Pressure and temperature are very important when picking a valve. You must know the highest pressure and heat your system will have. Every valve has a limit. Using the wrong valve can cause leaks or even break your system.

- Pressure ratings follow rules like ANSI or ASME classes. Higher classes mean the valve can take more pressure.

- When temperature goes up, the valve’s pressure limit goes down. Always check both numbers together.

- The valve’s material matters. Stainless steel and carbon steel are good for high pressure and heat. Plastics and brass are better for lower pressure and heat.

- The size and shape of the valve also change how much pressure it can take. Small valves can sometimes take more pressure.

- In power plants or steam systems, you need valves that can take very high pressure and heat. Always check the rules for your industry to make sure your valve is safe.

If you do not follow the pressure and temperature limits, your system could break and people could get hurt. Always match the valve’s ratings to your system.

Alert: Never use a valve if the pressure or temperature is too high for it.

Material Compatibility

When you pick a valve, think about what it will touch. The fluid can be water, oil, gas, or strong chemicals. If you choose the wrong material, the valve might rust or crack. It could also leak and cause big problems. This can make your system fail or spill dangerous stuff.

You should match the valve material to the fluid and temperature. Some materials work better with certain chemicals or heat. Here is a table to help you compare valve materials:

| Material | Chemical Resistance | Temperature Range | Cost Factor |

|---|---|---|---|

| Stainless Steel 316/316L | Great for acids, caustics, and chlorides | -425°F to 1200°F | High |

| PTFE | Works with almost all chemicals; stops buildup | -65°F to 450°F | Medium |

| PVC | Good for acids, bases, and salts; not for high heat | 32°F to 140°F | Low |

Stainless steel is strong and resists many chemicals and heat. PTFE works with almost any chemical and keeps the valve clean. PVC is good for acids and bases but cannot take high heat.

Tip: Always check chemical and temperature limits before picking a valve. This helps you stop leaks and keeps your system safe.

To help your valves last longer and stay safe, you should:

- Pick the right valve for your fluid and system.

- Use valves only within their temperature and pressure limits.

- Do regular maintenance to stop valve wear.

- Install and size valves correctly to prevent leaks.

If you follow these steps and pick the right material, your valves will last longer. You will lower the risk of leaks or dangerous problems. This is very important in places like chemical plants, where leaks can be harmful.

Safety

Safety is always most important when you pick valves, especially in risky places. You need to make sure your valves meet all safety rules for your industry. This protects people, equipment, and nature.

Here are some key safety points to think about:

- Make sure your valves follow rules like NFPA or IEC. These help you meet hazard class needs.

- Pick valves with strong seals and the right materials. Stainless steel and special coatings can make valves last longer and stay safe in chemical areas.

- Use valves with advanced sealing. Special rubber seals and surface treatments can cut leaks in places like oil refineries.

- Pick valves with good design features. Explosion-proof construction and the right port direction help stop leaks and keep dangerous fluids inside.

- Look for valves with position indicators. These show if the valve is open or closed and help you check safety. Position feedback systems can improve safety checks compared to manual checks.

- In emergencies, use special valves like 3-way valves. These help you contain or move dangerous materials quickly.

- Safety relief valves protect your system from too much pressure. They open by themselves if pressure gets too high, stopping damage and keeping people safe.

- Make sure your valves have strong covers. This protects them from weather, dust, and other damage.

- Use manual overrides and pressure relief features for extra safety in emergencies.

Alert: Always test and check your valves, including safety relief valves, on a regular schedule. This helps you find problems early and keeps your system safe.

If you follow these safety steps, you lower the risk of leaks, explosions, or other dangers. You also make sure your system meets legal and safety rules.

Valve Pros and Cons

Comparison Overview

When you pick a valve, you should look at the good and bad sides of each kind. Some valves cost more at first but save money later. High-performance valves can take more pressure and heat. They last longer and do not break as much. This means you pay less for fixing them and have fewer stops. You also lower the chance of leaks or safety issues.

The table below shows how different valves compare:

| Valve Type | Cost Considerations | Maintenance & Durability | Performance Characteristics & Suitability |

|---|---|---|---|

| Gate Valve | Moderate cost; simple design | Low maintenance; not for throttling | Low resistance when open; not for flow control |

| Globe Valve | Moderate to high cost | Needs more force; wears faster with throttling | Great shut-off and flow control; higher pressure drop |

| Needle Valve | Low to moderate cost | Many turns; needs careful maintenance | Precise control for small flows; slow operation |

| Ball Valve | Moderate to high cost | Low maintenance; very durable | Fast shut-off; tight seal; fits many uses |

| Butterfly Valve | Lower cost; compact | Moderate maintenance; simple parts | Good for large pipes; saves space; decent throttling |

| Plug Valve | Moderate cost | Durable; low maintenance | Handles high pressure and temperature; tight shut-off |

Note: The material you pick changes cost and how long the valve lasts. Plastic valves are cheaper but wear out faster. Metal valves cost more but last longer.

You should also think about how easy it is to fix a valve. Some valves let you change parts instead of buying a new one. This can help you save money over time.

Suitability for Applications

You need to pick the right valve for your job. Each valve works best in certain places. For example, globe valves are good when you want to control flow carefully. These valves help you change how much fluid moves in the pipe. Ball valves are great when you need to turn flow on or off fast. They seal well and last a long time.

Butterfly valves are good for big pipes and save space. You often see them in water plants or HVAC systems. Gate valves are used to start or stop flow in large pipes, but not for changing flow. Needle valves give you fine control in small pipes, like in labs or for adding chemicals.

If you pick the wrong valve, you might pay too much or have leaks and safety problems. Always check the pressure, temperature, and what fluid is in your system. Pick a valve that fits these needs. Do not buy extra features you do not need. Fixing a valve instead of getting a new one can also save money.

Tip: Picking the right size and material helps you avoid extra repairs and keeps your system working well.

Valve Functions in Practice

Industrial Examples

You see valves at work in many industries every day. In a power plant, you use globe valves to control steam flow. This helps keep the turbines running safely. In oil refineries, you rely on ball valves for quick shut-off during emergencies. These valves stop dangerous leaks fast. Chemical factories use butterfly valves to handle large flows of liquids. These valves save space and make maintenance easier. You also find check valves in water treatment plants. They prevent dirty water from flowing backward and keep the system clean. When you choose industrial valves, you help protect workers and equipment. You also make sure the process runs smoothly.

Tip: Always check the type of valve before you use it in a factory. The right valve can prevent accidents and save money.

Residential Uses

Valves play a big part in your home. You use gate valves to turn off the main water supply when you fix a leak. Under your sink, you find ball valves that let you stop water quickly if a pipe bursts. In your heating system, you use zone valves to control the flow of hot water to different rooms. These valves help you save energy and keep your house comfortable. You also see check valves in sump pump systems. They stop water from coming back into your basement. When you water your garden, you use simple shut-off valves on hoses. Each valve in your home has a job that keeps things safe and easy to manage.

Specialized Environments

Some places need special valves. In hospitals, you use needle valves to control the flow of oxygen and other gases. These valves let you make tiny changes for patient safety. In food factories, you use pinch valves because only the rubber tube touches the food. This keeps the process clean and stops contamination. In labs, you use pressure relief valves to protect equipment from sudden pressure spikes. You also find valves made from special materials in chemical plants. These valves resist strong acids and high heat. When you work in these environments, you must pick valves that meet strict safety and health rules.

Note: Always follow safety guidelines when you install or use valves in special settings. The right choice can protect people and products.

Knowing about valve types and how they work helps you pick the best one. You need to match the valve to your system’s job. This keeps your equipment safe and working right.

- Ask experts or manufacturers if your system is hard to figure out.

- Look at guides, watch videos, or visit manufacturer websites to learn more.

Remember: Picking the right valve saves you time and money. It also helps keep your system safe.

FAQ

What is the main job of a valve?

A valve controls the flow of liquids or gases. You can use it to start, stop, or adjust how much moves through a pipe. Valves also help keep your system safe.

How do you know which valve to choose?

You should look at your system’s needs. Think about the fluid, pressure, temperature, and how much control you want. Always check the valve’s material and safety features.

Can you use any valve for high-pressure systems?

No, you need a valve rated for high pressure. Stainless steel and special alloys work best. Always check the pressure rating before you install a valve.

Why do some valves need regular maintenance?

Valves have moving parts that can wear out. Dirt, heat, or chemicals can damage seals and seats. You should clean and check your valves often to prevent leaks or failures.

What is the difference between manual and automatic valves?

Manual valves use handles or wheels. You open or close them by hand. Automatic valves use motors or air pressure. These valves work by signals from sensors or control systems.

How do you prevent leaks in a valve system?

You should pick the right valve material and connection type. Tighten fittings and use proper seals. Regular checks help you find leaks early and fix them fast.

Are plastic valves safe for chemical use?

Plastic valves like PTFE or PVC resist many chemicals. You should check the chemical chart for your fluid. Some strong acids or high heat need metal or ceramic valves.

What happens if you use the wrong valve?

You might get leaks, damage, or unsafe conditions. The system could fail or stop working. Always match the valve to your fluid, pressure, and temperature needs.