Industrial systems use different steam valves to control flow, pressure, and temperature.

- Globe valves help control how much steam moves through.

- Gate valves let a lot of steam pass with little blocking.

- Ball valves can stop steam fast and work with high pressure.

- Butterfly valve designs are simple to put in and can block steam easily.

- Check valves stop steam from going backward in the pipes.

- Diaphragm valves keep things clean even in tough places.

- Electric valve and pneumatic valve types let people control them from far away or by machine.

Picking the right steam valve keeps workers safe and stops problems. It also helps the system work better. The best valve depends on pressure, temperature, and if you want to use hands or machines to control it. New steam valves often have sensors to watch how they work and warn about problems. Choosing good materials and checking valves often keeps them working well and safely.

Steam Valves in Industry

Role and Importance

Steam valves are very important in many industries. They help move steam safely and make sure things work well. You can find these valves in power plants, heating systems, factories, and big buildings. Each type of steam valve does something special, like controlling steam or keeping machines safe.

Steam valves help keep people safe by letting workers shut them fast in emergencies. They also stop machines from breaking if there is too much heat or pressure. Many industrial valves are made from strong metals like stainless steel or cast iron. This makes them last a long time, even when steam is very hot or strong.

Here are some main jobs that steam valves do in industry:

- They control flow and pressure in power plants to make power safely.

- They manage steam in heating systems to keep rooms warm.

- They keep steam moving for chemical reactions, heating, and cleaning in factories.

- They give exact steam control in refineries and chemical plants.

- They help cook, pasteurize, and clean food and drinks.

- They control steam heat in big building HVAC systems.

- They let workers shut off steam fast to keep people and machines safe.

The table below shows the main jobs of industrial valves and what they mean:

| Primary Role | Explanation |

|---|---|

| Control Steam Flow | Steam valves open or close to let more or less steam through, so you can control the flow. |

| Regulate Pressure | They lower or control steam pressure to keep the plant safe. |

| Control Temperature | Steam valves help keep the right temperature by changing how much steam goes through. |

| Ensure Safety | By controlling pressure and flow, valves stop unsafe problems and let you shut off steam fast. |

| Protect Equipment | Good control stops pipes and machines from getting hurt by too much heat or pressure. |

| Withstand Harsh Conditions | They are made from strong metals to handle high heat and pressure. |

| Integration with Control Systems | Valves work with machines and controls to keep things running safely and smoothly. |

Key Functions

Industrial valves do many important things in steam systems. Each job helps the system work safely and without problems. Steam valves do more than just open and close. They help control the whole process.

- They control steam flow, pressure, and temperature so everything works right.

- They act as safety tools by closing on their own to stop too much pressure and damage.

- They let workers shut off parts of the system for fixing or checking.

- They give exact control for cleaning in food and medical places.

- They lower steam pressure from where it starts to where it is needed.

- They help keep the right temperature in steam systems.

- They make sure steam moves safely and well through the pipes.

Steam valves help save energy by stopping steam from being wasted. They also help products stay the same by keeping pressure and temperature steady. Industrial valves are used in many jobs, like making power or food, because they do all these important things.

Types of Industrial Valves

Industrial valves are very important in steam systems. There are many types, like globe valves, gate valves, ball valves, butterfly valves, check valves, plug valves, diaphragm valves, and electric steam valves. These valves are grouped by how they work and how they are made. Each valve uses different metals, like alloy steel, cast iron, bronze, copper, stainless steel, and brass. Gaskets and seals are often made from plastic or rubber. These materials help the valves handle high heat and pressure.

Globe Valves

Operation

Globe valves have a disk that moves up and down inside a round body. The disk opens or closes the valve. This lets you control how much steam goes through. You can move the disk to let more or less steam pass. The inside shape of the globe valve helps control the flow very well.

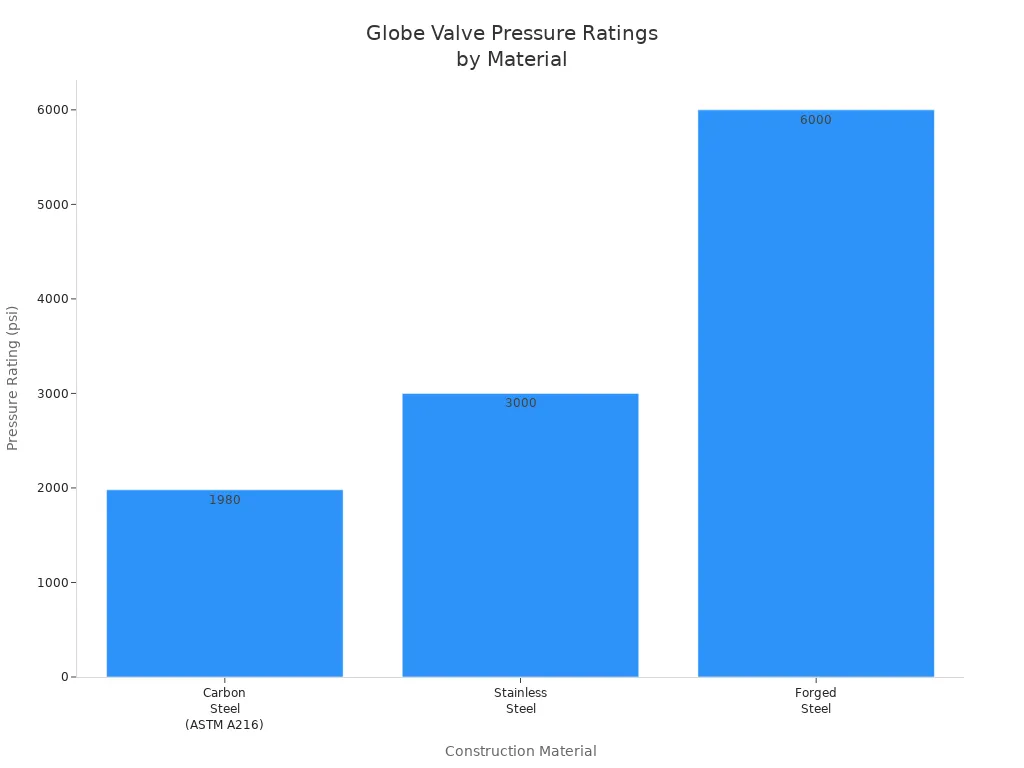

Globe valves are made from different materials for different jobs. The table below shows what materials are used and how much heat and pressure they can take:

| Construction Material | Typical Pressure Rating (psi) | Typical Temperature Rating (°F) | Key Properties and Notes |

|---|---|---|---|

| Carbon Steel (ASTM A216) | Up to 1980 | Up to 800 | Good heat resistance, common in steam valves |

| Stainless Steel | Up to 3000 | Up to 1000 | Excellent corrosion and heat resistance |

| Forged Steel | Exceeds 6000 | Up to 1050 | High strength for extreme pressure and temperature |

| Bronze | N/A | N/A | Used for moderate conditions, good corrosion resistance |

| Alloy Steel | N/A | N/A | Enhanced mechanical and corrosion resistance |

| Nickel Alloys | N/A | N/A | Superior heat and corrosion resistance |

Globe valves use seals made from graphite or PTFE. These seals help the valves work in hot places. Globe valves must follow strict rules to keep steam systems safe.

Uses

Globe valves are used when you need to control steam very carefully. They can close off parts of the steam pipes for fixing or checking. People use them to change how much steam moves and to control pressure. Globe valves are also found in pipes that go around other equipment. They close tightly so steam does not leak.

Industries use globe valves in many ways:

- Power plants use them to control steam in heating and water systems.

- Chemical plants use them to control steam during reactions.

- Food factories use them for cleaning and pasteurizing.

- Refineries use them to control steam in special loops.

Globe valves can handle big drops in pressure and make less noise with special designs. They are made from strong materials so they last in tough steam places.

Gate Valves

Operation

Gate valves have a flat or wedge-shaped gate that moves up and down. When the valve is open, the gate moves out of the way. This lets steam move through easily. This design means there is very little pressure lost. Gate valves can seal both ways, so steam can go either direction.

The table below shows the good and bad things about gate valves in high-pressure steam systems:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Fluid Resistance | Extremely low pressure loss when fully open | Slow opening/closing speed, prone to water hammer |

| Sealing | Bidirectional sealing with no flow direction restrictions | Sealing surfaces wear easily, resulting in high maintenance costs |

| Application Suitability | Suitable for high-pressure and high-temperature media (e.g., steam) | Large dimensions and opening height require more installation space |

Gate valves should not be used halfway open. If they are, they can get damaged and the steam flow can become unstable.

Uses

Gate valves are often used to shut off steam in many places. Power plants, oil and gas, chemical plants, and water treatment plants use them to control steam and close pipes. Their design lets steam move with almost no pressure lost. Gate valves can handle high heat and pressure, so they work well in tough places.

People use gate valves for:

- Shutting off steam pipes for repairs or emergencies.

- Controlling steam in power and chemical plants.

- Making sure steam can be stopped in high-pressure systems.

Gate valves last a long time and do not cost too much. This makes them a good choice for shutting off steam.

Ball Valves

Operation

Ball valves have a round ball with a hole in the middle. When you turn the handle, the ball turns to open or close the valve. This lets you open or close the valve quickly. Regular ball valves shut off steam fast but are not good for controlling flow slowly. V-Port ball valves have a V-shaped cut in the ball. This helps control the flow better, almost like globe valves.

Ball valves are strong and can handle high heat and pressure. Some ball valves have metal seats or are trunnion-mounted for steam use. Using the right materials, like stainless steel or Hastelloy, helps stop rust and damage.

Uses

Ball valves are used in steam systems that need to handle high pressure. People use them to shut off steam, switch flow, drain, or clean pipes. Ball valves close tightly and work fast, so they are good for stopping steam quickly.

Some common uses are:

- Boiler return lines in heating systems.

- Shutting off heating zones.

- Controlling steam in chemical plants.

- Managing steam in power plants.

Ball valves can be turned by hand or by machines. Machines can use air, electricity, or oil to move the valve. Full port ball valves let steam move with little pressure lost. Their strong build and quick action make them a good choice for many steam jobs.

Butterfly Valves

Operation

Butterfly valves have a round disc on a rod. When you turn the handle, the disc turns. It only needs a quarter turn to open or close. This makes steam flow or stop very fast. The disc sits in the middle of the pipe. When it turns, it lines up with the steam or blocks it. Butterfly valves are good for big steam pipes. They let a lot of steam move with little pressure lost. These valves are small and light. They fit well in tight places like boiler rooms. The quick turn helps when steam systems need fast changes. Some butterfly valves have metal seats. These can handle high heat and pressure. They seal tightly and last a long time.

Uses

Many factories use butterfly valves to control steam. Power plants, oil and gas, and chemical plants use them a lot. These valves are light, cheap, and easy to use. In power plants, they control steam, water, and cooling fluids. Their fast action helps make power without wasting time. In oil and gas, butterfly valves last long and work in tough places. They do not rust and can take high heat. This makes them good for steam and other hard jobs. Butterfly valves can be put in with different ends, like wafer or flanged. This helps workers change or fix them fast in big pipes.

Tip: Butterfly valves are a smart and low-cost way to control steam in big pipes. Their shape saves space and money. They help keep steam systems safe and working well.

Plug Valves

Operation

Plug valves have a plug with a hole in it. When you turn the plug, the hole lines up with the pipe. This lets steam move through. If you turn it again, it blocks the steam. Some plug valves lift the plug before turning. This makes them easier to use and last longer. Plug valves are made from strong metals like stainless steel or carbon steel. The seat is often made from graphite or PTFE. These help seal tight and stop leaks. The inside is smooth, so steam moves easily. Plug valves shut off steam well. This saves energy and keeps things safe. They turn fast with just a quarter turn. Plug valves have strong ends that hold them tight in pipes.

- Lifting the plug makes it last longer.

- Strong metals help the valve work in hot steam.

- Graphite or PTFE seats stop leaks and resist chemicals.

- Smooth inside means less pressure lost.

- Tight shut-off keeps steam from leaking.

- Quick turn lets you act fast.

- Strong ends keep the valve in place.

Uses

Plug valves are important in power plants. They control steam, water, and gas in turbines and coolers. They work well with high heat and pressure. Plug valves stop leaks and work fast. In power plants, they help control steam and cooling water. Expansion plug valves make a tight seal for high-pressure steam. These valves help move fluids safely and protect machines. They keep steam systems running well.

Check Valves

Operation

Check valves let steam go one way only. They have a part inside, like a poppet or ball, that stops steam from going back. Some check valves have a spring to keep them closed. Steam pushes the part open when pressure is high enough. When pressure drops or goes backward, the valve closes fast. There are different types of check valves. Swing check valves have a disc that swings shut. Piston or poppet check valves use a spring to close quickly. This helps stop water hammer. Picking the right size and material is important. This stops leaks and damage from dirt.

| Valve Type | How It Works and Stops Backflow | Common Problems and Issues |

|---|---|---|

| Swing Check Valve | Disc swings shut by gravity and reverse flow; must be flat. | May not seal well at low pressure; can get water hammer from slow closing. |

| Piston/Poppet Check Valve | Spring closes disc fast, stops backflow and water hammer. Works any way up. | Needs clean steam; dirt can break it. Fast closing helps stop water hammer. |

| General Failure Modes | Wrong size or pressure can wear out the valve fast. | Metal parts can wear out; dirt can cause leaks; water hammer can break the valve. |

Uses

Check valves do many jobs in steam systems. They protect pumps by stopping water from going back. In steam traps, they stop water from flowing the wrong way. This keeps machines safe from flooding. They also stop water hammer in pipes by blocking reverse flow. In boiler pipes, check valves keep water from going back into tanks. When there are many boilers, each one has a check valve. This stops steam from moving into boilers that are not working. Check valves also protect meters and other valves from damage. By letting steam go one way, check valves keep things safe and working right.

Note: Check valves are very important for keeping turbines, boilers, and other machines safe. They stop backflow and help steam systems run safely all the time.

Diaphragm Valves

Operation

Diaphragm valves use a soft, bendy part to control steam. The diaphragm pushes down to block steam or lifts up to let it go. This keeps the moving parts away from the steam. The valve and diaphragm are made from strong materials that do not rust. These can be stainless steel or special plastics. The inside of the valve is smooth. This stops dirt and gunk from building up. There are no extra seals that can wear out or leak.

Key things about diaphragm valves:

- The bendy diaphragm makes a tight seal to stop leaks.

- The valve body uses strong materials that do not rust.

- The diaphragm keeps the inside safe from damage or dirt.

- The smooth inside stops mold and dirt from growing.

- The design makes cleaning and fixing easy.

Uses

Factories use diaphragm valves when steam is dirty or must stay clean. These valves work well where leaks or dirt can cause big trouble. Medicine, food, and chemical factories often pick diaphragm valves for their steam systems.

Main good things about diaphragm valves in hard jobs:

- They stop leaks, even with dirty steam.

- They do not get hurt by strong acids or chemicals.

- The design keeps the inside clean and safe from buildup.

- They work well in places that need to be very clean, like medicine or nuclear plants.

- They are easy to fix and last a long time.

Diaphragm valves help keep steam systems safe and clean. Their special shape makes them a great pick for tough or dirty steam.

Bellows Valves

Operation

Bellows valves use a metal tube called a bellows to seal the stem. The bellows moves up and down when the valve opens or closes. This stops steam from leaking out along the stem. The bellows is made from strong metals like stainless steel or nickel. These metals can take high heat and pressure. The bellows acts like a wall to keep bad steam inside the valve.

Good things about bellows valves:

- No leaks along the stem, even with high pressure.

- The bellows stops bad gases from getting out.

- The design lasts a long time and needs little fixing.

- The valve works in very hot or cold places.

- The strong build keeps workers and the air safe from bad steam.

Uses

Bellows valves are used where safety and clean steam are very important. Chemical plants, oil refineries, and nuclear power plants use these valves. The bellows keeps the stem safe from rust and stops leaks, even with dangerous or costly steam.

Common ways to use bellows valves:

- Steam pipes that carry dangerous or explosive stuff.

- Heat systems and vacuum pipes.

- Nuclear and heavy water plants.

- Systems that need no leaks and strong seals.

Bellows valves do not leak and keep people and machines safe. Their tough build makes them perfect for hard steam jobs.

Pressure Relief Valves

Operation

Pressure relief valves keep steam systems safe by opening if pressure gets too high. A spring holds the valve shut until the pressure is too much. When the pressure goes over the set point, the valve opens and lets steam out. This lowers the pressure and keeps things safe. When the pressure drops, the valve shuts again.

There are rules for how these valves are made and used. In the United States, the ASME Code says how to make and test these valves. Other places have their own rules, like EN ISO 4126 in Europe and JIS B 8210 in Japan. These rules make sure the valves work right and keep people safe.

| Region/Country | Standard/Code | Description |

|---|---|---|

| USA | ASME Boiler and Pressure Vessel Code (Sections I and VIII) | Rules for making and using pressure relief valves in boilers and tanks |

| Europe | EN ISO 4126 | Safety devices to stop too much pressure |

| Germany | TRD 421, TRD 721 | Safety valves for tanks and steam boilers |

| UK | BS 6759 | Rules for safety valves for steam, hot water, and other fluids |

| Japan | JIS B 8210 | Spring safety valves for steam boilers and tanks |

Uses

Pressure relief valves are safety parts in all steam systems. They protect boilers, pipes, and other gear from too much pressure. If something goes wrong, like a blocked pipe, these valves open to let out steam and stop explosions.

Ways people use pressure relief valves:

- Keeping boilers and pipes safe from too much pressure.

- Stopping leaks, breaks, and injuries in factories.

- Keeping pressure steady in power and chemical plants.

- Making sure things are safe in food, medicine, and energy places.

Pressure relief valves are the last safety step in steam systems. They keep people, buildings, and nature safe by stopping bad pressure before it causes harm.

Steam Control Valves

Self-Actuated Temperature Control Valves

Self-actuated temperature control valves are important in steam systems. These steam control valves do not need outside power to work. They have a special fluid inside a sensor and thin tube. When things get hotter, the fluid gets bigger. This pushes through the tube and moves a part called an actuator. The actuator changes how open the valve is, so steam flow matches the temperature.

There are two main kinds of these valves:

- Liquid-filled systems move smoothly as it gets hotter or colder.

- Vapor tension systems use pressure from vapor to move the valve.

The valve moves more or less as the temperature changes. It is not just on or off. Normally open valves close when it gets hotter, which helps with heating. Normally closed valves open as it gets hotter, which helps with cooling. You can change the set temperature by making more or less room for the fluid. Disc springs keep the valve safe if it gets too hot. For big valves or high steam pressure, bellows or double seats help the valve work right.

People use these steam control valves for many jobs:

- Steam tracing keeps pipes from freezing.

- Freeze protection helps outdoor machines.

- Drain tempering and glycol tracing keep things safe.

- Scald protection and sample coolers control temperature.

- Mechanical seal water and pump relief keep machines safe.

- Thermal balancing helps process lines work right.

Industries like aerospace, electronics, plant care, and railroads use these valves. They save energy and protect machines by controlling steam flow on their own.

Self-Actuated Pressure Control Valves

Self-actuated pressure control valves keep steam pressure steady. They do not need outside power to work. These steam control valves use steam’s own pressure to move. Inside, a part senses when pressure changes. When pressure goes up or down, the actuator moves the valve to open or close it. This keeps the pressure even and safe.

The valve body sends steam the right way. The actuator moves fast to match the pressure needs. This design helps the valve keep the right pressure all the time. These valves save energy and do not need much fixing. They work well where there is no power or where steady pressure is very important.

Pressure and Temperature Regulation

三通球閥12-300x300.jpg)

Steam control valves help control both pressure and temperature. By changing steam flow, they keep machines safe and things working right. These valves work by themselves, so workers do not have to change them. This saves energy and stops damage from quick changes in heat or pressure.

The table below shows why self-actuated steam control valves are good:

| Benefit | Description |

|---|---|

| Energy Savings | Valves only let steam through when needed |

| Equipment Protection | Stops overheating and high pressure |

| Consistent Operation | Keeps temperature and pressure steady |

| Low Maintenance | Fewer parts mean less fixing |

| No External Power Needed | Works where there is no power |

Tip: The right steam control valves make things safer, save energy, and help steam systems work well.

Manual vs Automated Valves

Steam control valves can be manual or automated. Each type has good and bad points. The best choice depends on what the steam system needs.

Manual valves have a handle or lever. A worker must turn the handle to open or close it. This way is simple and works well. Manual valves do not need power or special tools. They are good where there is no electricity or during blackouts. Many factories use manual valves for simple on-off jobs or emergencies.

Automated valves are also called electric or motorized valves. They use an electric motor to move the valve. You can control them from far away. Workers use a control panel or computer to open or close them. Automated valves are great for modern steam systems. They give fast and exact control. These valves help save energy and stop waste by changing steam flow quickly.

The table below shows how manual and automated steam control valves are different:

| Feature | Manual Valves | Automated (Electric) Valves |

|---|---|---|

| Operation Mechanism | Handle or lever turned by worker | Electric motor moves valve |

| Control Precision | Depends on worker skill; less accurate | Very precise; accuracy often better than 0.1% |

| Response Time | Slow; takes minutes to adjust | Fast; adjusts in seconds |

| Integration | No system integration; manual only | Works with control systems for real-time changes |

| Safety Features | Simple, robust; safe in power loss | Advanced safety features and remote monitoring |

| Maintenance | Simple; more frequent adjustments | Complex; needs calibration and skilled workers |

| Cost | Lower upfront cost | Higher upfront cost; saves money over time |

Automated steam control valves have many good points. They are very exact and work fast. Workers can use them from a safe place. These valves work with sensors and control systems. This lets people watch and change things right away. These features help steam systems work safely and smoothly.

Manual valves are still used in many places. They are easy to use and fix. Workers trust them when there is no power. Manual valves also cost less to put in. But someone must be there to use them. This can make things slower and less exact.

Tip: Automated valves help big or tricky steam systems work better and safer. Manual valves are best for simple jobs or places with no steady power.

Advantages & Limitations

Performance

Steam valves are very important for how well steam systems work. Each type of valve has its own good points and some limits. Globe and ball valves can control steam flow very exactly. Gate and butterfly valves let a lot of steam move with little blocking. Picking the right valve helps the system work better and keeps it safe.

Engineers use different ways to see how well a steam valve works. These ways help them pick the best valve for each job. The table below lists important things to check and how they matter:

| Performance Metric | Impact on Industrial Steam Valve Effectiveness | Monitoring/Measurement Approach |

|---|---|---|

| Valve Flow Characteristics | Directly affects steam distribution and overall turbine efficiency | Evaluated using ASME Performance Test Code 6 (PTC 6) standards |

| Responsiveness | Influences turbine cycle response times and power output | Monitored via real-time data analytics and performance benchmarks |

| Heat Rate | Reflects fuel efficiency; lower heat rate indicates better efficiency | Assessed through cycle performance testing and thermodynamic modeling |

| Leakage Rates | Higher leakage reduces cycle performance and efficiency | Analyzed using mechanical models and 3D computational fluid dynamics |

Valves that react fast help power plants run without problems. Valves that do not leak save steam and energy. But some valves are slow and may not work for every job. Some valves can leak if not taken care of. To pick the best valve, you must look at these things and match them to what the system needs.

Note: A valve that is good for one job may not be right for another. Always check if the valve’s performance fits the job.

Maintenance

Taking care of steam valves keeps them safe and working for a long time. Every valve type, like ball, gate, globe, and check valves, needs regular care. Maintenance stops leaks, rust, and damage.

Valves can break because of:

- Rust from steam or chemicals

- Damage from fast-moving steam

- Parts wearing out from lots of use

- Wrong size or bad installation

To keep valves working well, workers should:

- Pick the right valve type and size for the job.

- Use valves only in their safe temperature and pressure range.

- Check seals and packing often to stop leaks.

- Oil moving parts, especially in plug valves.

- Clean valves to get rid of dirt and buildup.

- Look for damage and change old seals or seats.

Workers need tools like wrenches, brushes, oil, sealant, and testers to fix valves. Following the maker’s rules helps stop mistakes.

Tip: Doing regular maintenance makes valves last longer, stops breakdowns, and saves money on fixing them.

Valves in hot and high-pressure steam systems need even more care. Workers should use a checklist and change old parts before they break. Good care keeps steam systems safe and working well, even in hard jobs.

Industrial Applications

Power Plants

Power plants use steam valves for many jobs. These plants need strong valves to control steam. Globe valves help workers change how much steam goes to turbines. Gate valves let workers close off pipes for repairs. Ball valves shut off steam fast in emergencies. Butterfly valves move lots of steam in cooling systems. Check valves stop steam from going backward and protect machines. Pressure relief valves let out extra pressure to keep things safe.

Steam valves help power plants keep machines safe and working. For example, boilers use globe valves to control steam going into the main pipe. Gate valves close pipes when workers fix things. Ball valves drain pipes quickly. Butterfly valves move steam in big pipes. Check valves stop water from going the wrong way. Pressure relief valves stop dangerous pressure from building up.

Workers in power plants must pick the right valve for each job. The right valve keeps people safe and helps machines work better.

Chemical Processing

Chemical plants use many steam valves for different jobs. These plants need to control heat and pressure very well. Globe valves help control steam flow in reactors and heaters. Diaphragm valves work where steam must stay clean or chemicals might hurt other valves. Bellows valves stop leaks of bad steam or chemicals. Plug valves work with thick or dirty liquids.

In chemical plants, steam valves help heat, clean, and move chemicals. For example, a reactor uses a globe valve to control steam for heating. Diaphragm valves keep things clean in medicine making. Bellows valves stop leaks in pipes with toxic steam. Plug valves move sticky or harsh fluids.

A table shows how chemical plants use different valves:

| Valve Type | Typical Use in Chemical Plants |

|---|---|

| Globe Valve | Reactor and heat exchanger control |

| Diaphragm Valve | Clean steam and sensitive processes |

| Bellows Valve | Leak prevention in toxic lines |

| Plug Valve | Handling thick or corrosive fluids |

Food & Beverage

Food and drink factories use steam valves to keep food safe and good. Steam is used for cooking, cleaning, and pasteurizing. Diaphragm valves keep steam clean and stop germs from getting in. Globe valves help control steam for cooking and cleaning. Ball valves shut off steam fast when cleaning. Check valves stop water from going backward and keep lines safe.

In food factories, steam valves help control heat for cooking and pasteurizing. Diaphragm valves stop leaks and keep things clean. Globe valves change steam flow for ovens and kettles. Ball valves make cleaning quick and easy. Check valves stop dirty water from getting into clean steam pipes.

Steam valves in food and drink plants must be easy to clean. Picking the right valve helps keep food safe and high quality.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems use steam valves to control heat and air in big buildings. You can find these systems in places like hospitals, schools, offices, and factories. Steam valves help move steam to heaters, radiators, and humidifiers.

Globe valves let workers control steam flow very well. They help keep rooms warm or cool. Ball valves and butterfly valves are good for turning steam off fast. Workers use these valves to stop steam during repairs or emergencies. Check valves stop steam from going the wrong way. This keeps machines safe and working right.

Pressure relief valves keep HVAC systems safe from too much pressure. If pressure gets too high, these valves open and let out steam. This stops pipes and heaters from breaking. Diaphragm valves are used when clean steam is needed, like in hospitals or labs. Their design keeps steam clean and stops leaks.

Many new HVAC systems use automated valves. These valves connect to building computers. Workers can control them from a main panel or computer. Automated valves save energy by changing steam flow for each room. Manual valves are still used in old buildings or for easy jobs.

Tip: Checking and fixing steam valves often helps stop leaks and keeps heating and cooling working well.

Other Uses

Steam valves are used in many other jobs. In textile factories, steam valves control heat for coloring and drying cloth. Paper mills use steam valves to set the right heat in paper machines and dryers. Drug factories use diaphragm and bellows valves to keep steam clean when making medicine.

Ships use steam valves in engine rooms and for heating. Oil and gas platforms need strong valves for high-pressure steam in tough places. Science labs use small, careful valves for tests that need exact steam control.

A table below shows more ways valves are used:

| Industry | Valve Types Used | Main Purpose |

|---|---|---|

| Textile | Globe, Ball, Check | Control heat for dyeing and drying |

| Paper & Pulp | Butterfly, Gate, Relief | Manage steam in paper machines |

| Marine | Gate, Ball, Check | Engine room and heating control |

| Pharmaceuticals | Diaphragm, Bellows | Clean steam for safe production |

| Oil & Gas | Plug, Bellows, Relief | High-pressure steam management |

These examples show that many industries use steam valves. Each job needs the right valve for safety, clean steam, and saving energy.

Note: Picking the right steam valve helps every industry keep machines safe, save energy, and protect workers.

Selecting a Steam Valve

Material Selection

Choosing the right material for a steam valve is very important. The material must handle the heat, pressure, and chemicals in the system. Engineers look at several things when picking materials:

- Heat Resistance: The valve must stay strong at high temperatures, sometimes up to 400°C. This stops the valve from breaking or wearing out too fast.

- Erosion and Corrosion Resistance: Steam can carry small bits of dirt or chemicals. These can wear down or rust the valve. Materials like stainless steel and alloy steel resist this damage.

- Pressure Tolerance: Valves in high-pressure applications need to keep their shape and not leak. Carbon steel and chrome-molybdenum steels work well for these jobs.

- Compatibility: The material must not react with steam or any chemicals in the system.

Common materials include:

- Stainless Steel (304, 316): Good for resisting rust and strong at high heat.

- Carbon Steel: Strong and good for high pressure, but not as good against rust.

- Bronze: Works for lower pressure and temperature, and costs less.

- Alloy Steels: Used when the system gets very hot or has lots of pressure.

Seals and gaskets also matter. Graphite and PTFE seals help stop leaks in hot steam. Standards like ASME B16.34 and EN 12516 help make sure the materials are safe and tested. Stainless steel is often chosen for systems that need to be suitable for steam applications because it lasts long and does not rust easily.

Tip: Always check if the valve material matches the system’s pressure, temperature, and chemical needs.

Safety

Safety comes first when picking a steam valve. The right valve keeps workers and equipment safe from harm. Engineers look for valves that can handle the highest pressure and temperature in the system. They also check if the valve can close quickly in an emergency.

A good steam valve should:

- Meet safety codes and standards for the industry.

- Have strong seals to stop leaks.

- Work well even if the system changes quickly.

- Be easy to shut off in case of danger.

Many factories use pressure relief valves to stop accidents. These valves open if the pressure gets too high. This keeps pipes and machines from bursting. Safety also means picking valves that do not leak steam, which can burn workers or damage equipment.

| Safety Feature | Why It Matters |

|---|---|

| Strong Seals | Prevents leaks and burns |

| Quick Shut-Off | Stops accidents fast |

| Code Compliance | Meets legal and safety rules |

| Pressure Relief | Protects against explosions |

Note: Regular safety checks help find problems before they cause harm.

Maintenance Needs

Steam valves need regular care to work well and last a long time. Some valves need more fixing than others. Globe and ball valves are easy to check and clean. Gate and plug valves may need more work if used often.

Key maintenance steps include:

- Checking for leaks or rust.

- Cleaning dirt from inside the valve.

- Replacing seals and gaskets when worn out.

- Lubricating moving parts to stop them from sticking.

Workers should follow the maker’s guide for each valve. Using the right tools and parts helps prevent mistakes. Valves in high-pressure applications need extra care because they face more stress.

A simple checklist for valve maintenance:

- Inspect the valve every few months.

- Test the valve to make sure it opens and closes.

- Change seals if there are any leaks.

- Clean the valve to remove buildup.

Regular maintenance saves money and keeps the steam system safe and reliable.

Steam valves are very important in many places that use steam. Globe, gate, ball, and butterfly valves work best for different jobs in power plants, food factories, and chemical plants. Picking the right valve makes things safer and helps machines work better. You should look at the pressure, temperature, and what materials are needed for each job. It is smart to talk to experts or suppliers before you pick a valve.

Good planning helps every steam job stay safe and work well.

FAQ

What is the main job of a steam valve?

A steam valve controls how much steam moves through pipes. It helps keep machines safe and working well. Workers use steam valves to start, stop, or change the flow of steam.

How does someone choose the right steam valve?

Engineers look at pressure, temperature, and what the valve will do. They also check the material and if the valve needs to be manual or automated. Talking to experts helps make the best choice.

Why do steam valves need regular maintenance?

Regular maintenance stops leaks and keeps valves working safely. It also helps find problems early. Workers clean, check, and fix valves to make sure steam systems run well.

Can one valve type work for every steam job?

No, each valve type fits different jobs. For example, globe valves control flow well, while gate valves shut off steam. Picking the right valve keeps the system safe and efficient.

What safety features should a steam valve have?

A good steam valve should have strong seals, quick shut-off, and meet safety codes. Pressure relief valves protect against dangerous pressure. These features help keep workers and equipment safe.

How do automated steam valves help factories?

Automated valves let workers control steam from a distance. They react fast and adjust flow quickly. This saves energy and helps factories run smoothly.

Tip: Always follow the maker’s guide for safe valve use and care.