You need to follow some important steps to pick a modulating control valve. First, look at what the application and process need. Then, pick the right valve type. This could be a ball valve, butterfly valve, electric ball valve, or pneumatic ball valve. Make sure you size the valve correctly. Learn about flow characteristics to get good control and steady operation. Pick the best materials and the right actuator, like pneumatic or electric. This helps the valve work well and last longer. Install the valve properly so it works as it should. Many industries use control valves. These include chemical plants, water treatment, and power generation. Control valves help keep flow control and reliability high.

Key Takeaways

- Pick the right valve type and size for your needs. This helps keep the flow steady and accurate. Match valve materials to the fluid, temperature, and pressure. This stops leaks, damage, and safety problems. Use the right sizing methods for the valve. Keep the valve open between 20% and 80%. This gives better control and makes the valve last longer. Choose the right actuator and control signal for your valve.

Modulating Control Valve Basics

What Is a Modulating Control Valve

A modulating control valve helps control how much liquid, gas, or steam moves in a system. It does not just open or close all the way. It can move a little at a time. This lets you keep the flow steady or change it when needed. The valve listens to a control signal. The signal can be pneumatic or electric. This tells the actuator how much to move the valve. The actuator moves the stem or disc to the right spot. Many valves use a positioner. The positioner makes sure the valve moves just as the system wants. Sensors and feedback help keep the flow at the right level.

Here is a table that shows the main parts and how a modulating control valve works:

| Principle/Component | Description |

|---|---|

| Control Signal | Pneumatic (3-15 psi) or electrical (0-10 VDC, 4-20 mA) signals tell the actuator where to move the valve. |

| Valve Actuator | Changes the control signal into movement, like raising or turning the stem or disc. |

| Valve Types | Rising stem globe valves and quarter-turn valves (ball, butterfly) are used for modulating control. |

| Positioners | Devices that turn control signals into exact valve movements; can be pneumatic or electro-pneumatic. |

| Feedback Mechanism | Flow meters or sensors give real-time data so the system can adjust the valve as needed. |

| Flow Characterization | V-port balls or trim discs help make flow changes match the valve’s position. |

| Operating Principle Summary | Get a control signal → move the valve the right amount → use feedback to keep the flow at the set rate. |

Modulating vs. On/Off Valves

You might wonder how a modulating control valve is different from an on/off valve. On/off valves only open all the way or close all the way. They are good for simple jobs like starting or stopping flow. You use them for emergency shutoff or just to move fluids. Modulating control valves can stop anywhere between open and closed. This lets you control the flow more exactly.

| Feature | On/Off Valve | Modulating Valve |

|---|---|---|

| Function | Only fully open or fully closed | Changes flow by moving the valve to any spot |

| Control | Just open or closed | Can adjust to any position between open and closed |

| Applications | Used for isolation, emergency shutoff, start/stop | Used for precise control, temperature, and process control |

| Efficiency | Fast and simple | Gives smooth control and less wear |

| Flow Control | Changes are sudden | Changes are slow and smooth |

| Complexity | Simple and easy to fix | More parts, needs feedback and control systems |

| Precision | Not very exact, no middle spots | Very exact, can make small changes |

| Cost | Usually costs less | Costs more because it is more complex |

You should pick a modulating control valve when you need steady and exact flow control. These valves help you save resources and keep your system working well.

Why Proper Selection Matters

Picking the right modulating control valve is very important. If you choose the wrong one or the wrong size, you can have problems. Bad choices can hurt valve parts like the seat or stem. You might see erosion, vibration, or leaks. The process can get unstable, and you may not control the flow well. This can use more energy, need more repairs, and even cause safety problems.

Tip: Always pick the valve type, size, and materials that fit your process. Good choices help you avoid downtime and keep your system safe and working well.

When you pick the right control valve, you make better products and save money. You also help your plant stay safe and run smoothly.

Application Assessment

Fluid Type

You need to know what kind of fluid you have. It could be a liquid, gas, or steam. Each one acts in its own way. This changes how the valve works. It also changes what materials you should use.

Liquid

Liquids can be thick or thin. This is called viscosity. Some liquids can damage the valve parts. You should:

- See if the liquid will harm the valve body, seat, or stem.

- Use stainless steel or bronze if the liquid is harsh.

- Pick valve materials that match the liquid to stop leaks or damage.

- The wrong material can cause rust or even be unsafe.

Gas

Gases move in a different way than liquids. They can be under high pressure. Gases can leak more easily. For gas, you should:

- Pick valve materials that do not break down with the gas.

- Make sure the seals are tight to stop leaks.

- Think about what the gas is made of, as some gases react a lot.

- Use special alloys if the gas is strong or very hot.

Steam

Steam is very hot and can hurt valve parts. It can also change pressure fast. For steam, you should:

- Pick valve materials that can take high heat.

- Make sure the seat and seals can handle heat and pressure.

- Do not use materials that can crack or break.

- Always think about safety, as steam leaks are dangerous.

Tip: Always pick valve material that matches the fluid type. This helps stop rust, leaks, and safety issues.

Temperature and Pressure

Temperature and pressure are very important when picking a valve. High heat can make some materials weak. High pressure can cause leaks or make the valve break. You should:

- Check the highest and lowest temperatures in your process.

- Make sure the valve can handle pressure changes and still work.

- Use pressure-independent control valves if pressure changes a lot. These valves keep flow steady and help your system work better.

- Stable temperature and pressure help keep your process safe and working well.

Flow Requirements

You need to know how much fluid, gas, or steam will go through the valve. This is called flow rate. To get the right flow, you should:

- Use actuators that move the valve to any spot between open and closed.

- Pick a valve with a positioner that matches your control signal.

- Choose trims like V-port balls or special discs for smooth flow.

- Make sure the valve size fits your needs. Too big or too small can cause trouble.

- Follow best steps like checking actuator type, supply pressure, and pipe layout.

Note: Good flow control helps you stop waste, keeps your process steady, and supports safety.

Process Conditions

When you pick a modulating control valve, you need to think about more than just the fluid type or flow rate. You also have to look at the process conditions in your system. These conditions can change how well the valve works and how long it lasts. Some important process conditions are chemical compatibility, vibration, and turbulence.

Chemical compatibility means the valve materials must handle the chemicals in your process. If you use the wrong material, the valve can rust or break down. This can cause leaks or even make the system fail. For example, if your process uses strong acids, you may need a valve made from stainless steel or a special alloy. Picking the right material keeps your system safe and helps the valve last longer.

Vibration is another thing to watch for. Pumps or compressors can make pipes shake. If your valve gets a lot of vibration, it can wear out faster or get damaged. You can use tools like vibration analysis to check the valve’s health. These tools help you plan repairs before something goes wrong. This keeps your process running smoothly.

Turbulence happens when the flow inside the pipe is not smooth. High turbulence can make noise, cause wear, and waste energy. Some valves, like gate valves, have a straight path for the flow. This design helps lower turbulence and keeps the system working well. If your process has a lot of turbulence, pick a valve that can handle it without losing performance.

Here is a table that shows how these process conditions affect your valve choice:

| Process Condition | Influence on Modulating Control Valve Selection |

|---|---|

| Chemical Compatibility | Needs valve body materials (like stainless steel or special alloys) and seals that can handle harsh chemicals to stop damage and keep the valve working. |

| Vibration | Needs tools like vibration analysis and sound checks to watch valve health and plan repairs at the right time. |

| Turbulence | Affects which valve design you pick, so choose valves with straight flow paths (like gate valves) to lower turbulence and save energy, making the valve last longer. |

Tip: Always check your process conditions before picking a valve. This helps you avoid trouble and keeps your system safe.

You should also think about things like big temperature changes, sudden pressure jumps, and how often the valve will open and close. Each of these can change how the valve works. By knowing your process conditions, you can pick a valve that gives you steady and exact control.

Valve Types for Selection

Globe Valves

Globe valves are used a lot for modulating control. They have a disc that moves up and down inside the valve. The seat stays in one place. When you move the disc, you change how much fluid goes through. This design lets you make small changes to the flow. The stem has threads and turns many times. This helps you move the disc very carefully. When you turn the stem, the disc goes straight up or down. This makes it easy to control the flow rate very well.

Inside a globe valve, the flow changes direction. This causes the pressure to drop. The pressure drop helps with throttling and better flow control. You can pick globe valves with different flow types, like linear or equal percentage. This means you can choose what fits your process best. Globe valves are good for places like water treatment plants. They help keep the flow steady during things like filtration or adding chemicals. Because they can make small changes, they are a top pick for many control valve jobs.

Ball Valves

Ball valves are also used for modulating control. Regular ball valves do not give smooth flow when you turn the handle. But special ball valves can control flow better. V-port balls have a wedge-shaped hole. This shape lets the flow go up slowly as you turn the valve. You can also use trim discs to help control the flow more.

- Ball valves with these changes work well when you need a tight seal and want them to last longer.

- You can use electric or pneumatic actuators to make ball valves work by themselves.

- Ball valves are good for vacuum jobs or when you want to control things from far away.

- The actuator you pick depends on how much force you need and your site’s needs.

These special ball valves give you better flow control. You can use them in more types of control valve systems.

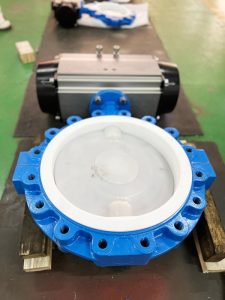

Butterfly Valves

Butterfly valves are light and small. They are easy to put in, even in small spaces. They use a disc that turns 90 degrees to open or close. This makes them fast for both on-off and modulating control.

- Butterfly valves cost less than many other valves and are easy to automate.

- They need less care, which saves you time and money.

- These valves work best in low-pressure systems because their seals are not as strong as globe or ball valves.

- The seals can wear out over time, which might cause leaks.

- Butterfly valves do not work well with high pressure or high heat.

- They can have problems like cavitation and erosion if the flow is too fast.

- Do not use them with very harsh or scratchy fluids.

Butterfly valves give good flow control in many cases, but they have limits. Always pick the right valve type for your process to get the best results.

Other Types

You can find many other types of valves used for flow control in different industries. Each type has its own strengths and best uses. Some common options include diaphragm valves, pinch valves, and sliding stem valves.

- Diaphragm valves use a flexible membrane to control flow. You often see these valves in water treatment and food processing. They work well with dirty or sticky fluids because the design keeps the fluid away from moving parts.

- Pinch valves use a rubber sleeve that pinches shut to stop flow. These valves handle slurries, powders, and thick liquids. You can use them when you need a simple design and easy maintenance.

- Sliding stem valves move a stem up and down to open or close the valve. These valves give you very precise control. You often use them in chemical plants and power stations where you need to handle high pressure drops.

Here is a table that shows how some of these valves compare:

| Valve Type | Flow Control Method | Suitable Applications | Advantages | Limitations |

|---|---|---|---|---|

| Diaphragm Valve | Linear (flexible membrane) | Water, food, corrosive fluids | Clean operation, easy to maintain | Not for high pressure or temperature |

| Pinch Valve | Linear (pinching sleeve) | Slurries, powders, thick liquids | Handles solids, simple design | Limited to low pressure, sleeve wears out |

| Sliding Stem Valve | Linear (stem movement) | High pressure, precise control | Accurate throttling, durable | More complex, higher cost |

Note: You should always check if a special valve type fits your process better than standard globe, ball, or butterfly valves. The right choice can make your system safer and easier to maintain.

Matching Valve to Application

You need to match the valve type to your process for the best results. Start by looking at what your process needs. Think about the fluid’s temperature, pressure, and if it is corrosive. Choose a valve made from materials that will not break down or rust. For example, stainless steel works well with harsh chemicals.

Globe valves give you precise throttling and handle high-pressure drops. You use these valves in chemical, power, and oil industries. Ball valves work well for pipelines and give you full flow when open. Butterfly valves fit large pipes and cost less, but they do not handle high pressure as well.

Here are some steps to help you pick the right control valves:

- Check the fluid’s properties, like how thick it is and if it can cause rust.

- Match the flow rate and pressure drop to the valve’s flow control style.

- Think about the working conditions, such as heat, pressure, and vibration.

- Make sure the valve material matches the fluid to stop leaks or damage.

- Pick the valve type based on how much control you need and how easy it is to maintain.

- Choose the right actuator, such as manual, pneumatic, or electric, for your system.

- Look for valves that are reliable and easy to fix.

- Make sure the valve meets industry rules and standards.

- Think about the total cost, including buying, running, and fixing the valve.

- Plan for future changes by picking valves that are easy to upgrade.

Tip: Always select control valves that fit your process needs. This helps you get stable flow, reduce downtime, and keep your system safe.

Sizing the Modulating Control Valve

Sizing Principles

You need to follow clear steps when you size a modulating control valve. Good sizing helps you get stable control and reliable performance. If you size the valve correctly, you avoid problems like hunting, noise, or poor flow control. You also make sure the valve lasts longer and works well in your system.

Here are some key principles for sizing:

- Always look at the properties of the process fluid. Check the density, viscosity, and if the fluid can be compressed.

- Know the flow rate you need for your process. This tells you how much fluid must pass through the valve.

- Calculate the pressure drop across the valve. This is the difference in pressure before and after the valve.

- Pick the right valve type and design for your application. Some valves, like V-port ball valves, give you better control.

- Choose an actuator that matches your control needs. Pneumatic or electric actuators can help you get precise movement.

- Use a step-by-step sizing procedure. First, define your process needs. Next, find the flow rate and pressure drop. Then, select the valve type and design. After that, size the valve using the right equations. Finally, pick the actuator and positioner.

| Aspect | Details |

|---|---|

| Process Fluid Properties | Check density, viscosity, and compressibility |

| Flow Rate Requirements | Find out the needed flow rate |

| Pressure Drop | Calculate the pressure drop across the valve |

| Valve Type and Design | Pick the best valve type and design for your process |

| Actuator Sizing and Selection | Choose the right actuator and positioner for control |

| Sizing Procedure | 1. Define needs 2. Find flow rate/pressure drop 3. Pick valve 4. Use equations 5. Select actuator |

| Sizing Equations | Use formulas for compressible or incompressible fluids |

| Outcome | Good sizing gives you stable performance and efficient control |

Tip: When you follow these principles, you help your system run smoothly and avoid costly mistakes.

Flow Coefficient (Cv)

The flow coefficient, or Cv, is a key part of control valve sizing. Cv tells you how much flow a valve can pass when it is fully open. It is defined as the number of gallons of water per minute (GPM) at 60°F that flows through the valve with a 1 psi pressure drop. You use Cv to match the valve to your process needs.

To find Cv, use this formula for water:

Cv = Q / sqrt(ΔP)

Q is the flow rate in GPM. ΔP is the pressure drop in psi. For example, if you need 10 GPM and have a 4 psi pressure drop, you get sqrt(4) = 2. So, Cv = 10 / 2 = 5.

For other fluids, you may need to adjust for specific gravity. The formula becomes:

Cv = Q * sqrt(SG / ΔP)

SG is the specific gravity of the fluid.

Picking a valve with the right Cv is important. If you choose a valve with a Cv that is too high, the valve will be oversized. This makes it hard to control flow and can cause the valve to react too quickly. If the Cv is too low, the valve will be undersized. It will not let enough flow through, and your process may not work as planned.

Note: Always use the Cv value to guide your sizing. This helps you get the best performance and control from your valve.

Sizing Range (20%-80% Open)

You should size your modulating control valve so it works between 20% and 80% open at maximum flow. This range gives you the best control and keeps your system stable. If you size the valve to be open less than 20% at full flow, the valve is too big. It will be too sensitive, and small changes in the control signal will cause big changes in flow. This makes it hard to get precise control.

If the valve is open more than 80% at full flow, it is too small. It cannot pass enough flow, and you may not reach your process goals. The valve will also wear out faster because it works too hard.

Here are the main reasons to use the 20%-80% sizing range:

- You get better control accuracy and stability.

- The valve uses most of its control range, so you can make fine adjustments.

- You avoid non-linear flow problems that happen at the ends of the valve’s travel.

- The valve lasts longer and needs less maintenance.

Remember: Sizing your valve to work in the 20%-80% open range helps you get the best performance and control for your process.

Avoiding Over/Undersizing

It is important not to pick a valve that is too big or too small. If the valve is too big, it will not work well at low flows. The valve might only open a little bit. This makes it hard to control how much flows through. Problems like noise, shaking, and cavitation can happen. The valve parts can wear out faster and might start to leak. Big valves can also push too hard on pipes and supports. This can break pipes or even make the system fail.

If the valve is too small, it cannot handle the highest flow you need. The valve will have to stay open almost all the way. This puts a lot of stress on the parts. Your system might not get enough flow and could shut down or work badly. Small valves can also make the actuator work too hard. If the actuator is too weak, it might not move the valve when you need it most, like in an emergency.

You should always size the valve using real data from your system. Look at the normal, lowest, and highest flow rates. Think about how often the valve will open and close. If the valve opens and closes a lot, the parts will wear out faster. Pneumatic actuators are better for jobs where the valve moves a lot. They last longer than electric actuators, which can fail if used too much.

Here is a table to show the risks:

| Problem Type | Oversized Valve Impact | Undersized Valve Impact |

|---|---|---|

| Flow Control | Poor accuracy, hunting, cavitation | Cannot reach peak flow, unstable operation |

| Wear & Damage | Premature wear, leaks, damage to valve and piping | Excessive stress, faster wear, possible failure |

| System Safety | High forces on supports, risk of system failure | May not operate in emergencies, unsafe |

| Maintenance | More repairs, shorter valve life | Frequent repairs, actuator overload |

Tip: Always check your sizing math and use real process data. This helps you avoid mistakes and keeps your system safe.

Sizing Tools

Today, you can use special tools to help size control valves. Many valve companies have software that guides you step by step. You type in details like flow rate, pressure, temperature, and fluid type. The software then tells you the best valve size for your job.

These tools do more than just simple math. They can show you how the valve will work in your system. You can see graphs that show flow and how the valve will act. This helps you know if the valve will give you steady control. Some programs also help you pick the right actuator. They check what the valve needs and match it with actuator types like rack and pinion or scotch yoke. This makes sure the actuator can move the valve every time.

In the past, people used slide rules or calculators for this work. Now, software does the hard math and checks for you. This saves time and helps stop mistakes. You still need to check the answers and make sure they fit your system.

Note: Always use the newest sizing tools from trusted companies. These tools help you pick the right valve and actuator, making your system safer and more reliable.

Flow Characteristics in Selection

Linear

A linear flow characteristic means the valve and flow match up. When you open the valve halfway, you get about half the flow. This makes it easy to know what will happen when you move the valve. You can look at the table below to see how this works:

| Flow Characteristic Type | Description | Effect on Process Control |

|---|---|---|

| Linear | Flow capacity goes up evenly as the valve opens | Gives steady, easy-to-predict flow changes, so you get good and stable control if the system is just right |

Linear valves work best when most pressure drops across the valve and the pressure before the valve stays the same. This helps you get steady and exact control. Linear valves let you make small flow changes right away. This is important for jobs that need careful flow control and strong performance.

But, real systems have pipes and equipment that can change how the valve acts. Sometimes, a linear valve might act like a quick opening valve after you put it in. This can make it harder to control the flow well. You should use linear valves if your system has steady pressure and you want simple, easy control.

Tip: Linear valves work best when pressure is steady and most of the pressure drop is at the valve.

Equal Percentage

Equal percentage valves work in a different way. When you open the valve by the same amount each time, the flow goes up by the same percent, not the same number. At first, the flow changes are small, but they get bigger as you open the valve more. This helps when the pressure drop changes as flow goes up.

- Equal percentage valves give you good control at low flows.

- They keep control steady even if pressure changes a lot.

- These valves are good for steam and places where pressure swings a lot.

- You get good results over many flow levels.

If your job needs careful control over lots of flow rates, or if pressure changes often, pick an equal percentage valve. This type helps keep your system steady and working well.

Modified Parabolic

A modified parabolic valve mixes parts of linear and equal percentage valves. The flow curve starts out gentle, like a linear valve, but gets steeper as you open the valve more. This gives you good control at low and medium flows, and faster changes at high flows.

You might pick a modified parabolic valve if you want both steady control and flexibility. These valves help you deal with changing conditions and still work well. They are a smart pick for many general control jobs.

Note: Picking the right flow characteristic helps you get the best control and results for your process.

Choosing the Right Characteristic

When you pick a flow characteristic, you want it to fit your process. The right choice helps keep flow steady and saves energy. It also keeps your system safe. You need to think about how your process works. You should also think about what kind of control you want. Look at how pressure changes in your system.

First, think about how your process acts. If pressure changes a lot, use an equal percentage valve. This valve gives you good control at low flows. It works well when pressure drop is not steady. If pressure stays the same, a linear valve is better. Linear valves make it easy to know how much flow you get.

You also need to think about the control range. If you need to control many flow levels, equal percentage valves are best. They let you make small changes at low flows. They also let you make bigger changes at high flows. For simple jobs, like keeping a tank level, you can use either valve. The tank size and how fast it fills or empties will help you choose.

Here is a table to help you match your needs to the right flow characteristic:

| Factor / Application Aspect | Recommended Flow Characteristic | Reason / Explanation |

|---|---|---|

| Process Dynamics | Equal Percentage | Good for changing pressure drops and fine low-flow control |

| Constant Pressure Drop | Linear | Best for steady pressure and simple control |

| Control Range | Equal Percentage | Handles wide flow ranges well |

| Type of Control Loop | Equal Percentage or Linear | Flow control: Equal percentage; Level control: Linear or equal percentage |

| Installed Pressure Drop (ΔP) | Equal Percentage or Linear | Equal percentage for big changes in ΔP; linear for steady ΔP |

| Turndown Ratio | Equal Percentage | Gives precise control at low flows |

| On-Off or Fast Action | Quick Opening | Needed for quick valve movement |

| Examples | Equal Percentage or Linear | Heat exchanger bypass: Equal percentage; Condenser level: Linear; Fuel gas pressure: Equal percentage |

You should also check the fluid type, its temperature, and if it is thick or thin. Some fluids need special valve designs or materials. If you pick the wrong valve, you might get leaks or damage. Always make sure your valve and actuator work well together. The actuator must move the valve to the right spot every time.

Tip: Use equal percentage valves for changing pressure or wide flow needs. Pick linear valves for steady, simple jobs. For fast open and close, use quick opening valves.

When you match the flow characteristic to your process, you get better control. Your valve lasts longer. This helps your plant stay safe and saves money on repairs.

Trim Types: Plugs and Seats

When you choose a modulating control valve, you need to pay close attention to the trim. The trim includes the plug and seat. These parts work together to control how much fluid passes through the valve. The design of the trim affects how well the valve can control flow, how tight it shuts off, and how long it lasts. If you pick the wrong trim, you might see leaks, poor control, or even damage to the valve.

Plug Types

The plug is a key part of the trim. It moves to open or close the flow path inside the valve. Different plug shapes give you different flow control. Here is a table that shows the main plug types and how they affect flow:

| Plug Type | Valve Category | Influence on Flow Control |

|---|---|---|

| Disc-shaped plug | Globe valves (rising stem) | Moves up or down for precise flow control; gives accurate modulation. |

| Ball (standard) | Ball valves (quarter-turn) | Mostly on/off; needs special trim for good modulation. |

| V-port ball | Ball valves (quarter-turn) | Special shape for smooth, gradual flow increase as you turn the valve. |

| Trim disc insert | Ball valves (quarter-turn) | Insert helps get proportional flow, like a V-port ball. |

| Butterfly plug | Butterfly valves (quarter-turn) | Turns for gradual flow increase; often has notches for better positioning. |

V-Port Plug

A V-port plug has a V-shaped notch. You get better control at low flows because the shape lets you make small changes. This trim works well in ball valves when you need precise flow control.

Parabolic Plug

A parabolic plug has a curved shape. You see this trim in globe valves. It gives you smooth and steady flow changes. You can use it for jobs that need accurate modulation.

Cage-Guided Plug

A cage-guided plug sits inside a cage. The cage keeps the plug steady and helps control flow. This trim handles high pressure drops and stops the plug from vibrating. You use it in tough jobs where the valve sees a lot of stress.

Characterized Plug

A characterized plug has a special shape or cut. This trim matches the flow curve you want, like linear or equal percentage. You can pick this trim to fit your process needs.

Seat Types

The seat is the part of the trim that the plug presses against to stop flow. The seat type affects how well the valve seals and how long it lasts.

Metal Seat

A metal seat uses metal-to-metal contact. You get a strong seal that can handle high pressure and temperature. Metal seats last a long time and work well in harsh jobs. They cost more and need expert care.

Soft Seat

A soft seat uses materials like rubber or PTFE. You get a tight seal at low pressure and normal temperatures. Soft seats are easy to maintain and cost less. They do not last as long in tough jobs and may crack or wear out.

Balanced Seat

A balanced seat has extra parts to balance the forces on the plug. This trim makes it easier to move the plug and helps the valve work better at high pressure.

Unbalanced Seat

An unbalanced seat does not have these extra parts. The plug feels all the force from the fluid. This trim is simple but may need a stronger actuator.

Selecting the Right Trim Type

You need to match the trim to your process. Here are some things to think about:

Considerations for Leakage Class

If you need zero leakage, pick a metal seat trim for high pressure or a soft seat trim for low pressure. The leakage class tells you how tight the valve shuts off. Always check what your process needs.

Service Conditions (Abrasive, Corrosive, High Temperature)

For abrasive or corrosive fluids, use a metal seat trim and a plug made from strong alloys. If you have high temperature, metal trim works best. For clean water or air, a soft seat trim may be enough.

Impact on Control Accuracy and Rangeability

The right trim gives you better control and a wider range of flow. A V-port or characterized plug trim helps you make fine adjustments. A cage-guided trim keeps the plug steady for tough jobs. Always pick the trim that matches your flow needs and process conditions.

Tip: Always talk to your valve supplier about your process. The right trim helps your valve last longer and keeps your system safe.

Bonnet Types for Control Valves

Standard Bonnet

You will find the standard bonnet on most control valves. The bonnet forms the top part of the valve body. It covers the stem and the packing. The main job of the bonnet is to keep the valve sealed and protect the moving parts inside. Standard bonnets work well for most normal temperature and pressure jobs. You can use them in water, air, and light chemical services.

A standard bonnet is simple and easy to maintain. You can remove it for repairs or to change the packing. This type of bonnet costs less than other types. You should pick a standard bonnet if your process does not have extreme temperatures or dangerous fluids.

Tip: Use a standard bonnet for general-purpose flow control. It gives you a good seal and is easy to service.

Extended Bonnet

An extended bonnet looks longer than a standard bonnet. You will see a long neck between the valve body and the packing area. This design keeps the packing and stem away from very hot or very cold fluids. You should use an extended bonnet when you work with cryogenic (very cold) or high-temperature fluids.

The long neck acts like a barrier. It stops heat or cold from reaching the packing. This helps the packing last longer and keeps the valve from leaking. You will often find extended bonnets in industries that use liquid nitrogen, oxygen, or steam.

Here is a table to help you see the difference:

| Bonnet Type | Best For | Key Benefit |

|---|---|---|

| Standard Bonnet | Normal temp/pressure | Simple, low cost |

| Extended Bonnet | Cryogenic/high temp | Protects packing, safer |

Note: Pick an extended bonnet if you need to control very hot or cold fluids. It helps your valve last longer and keeps your process safe.

Bellows Seal Bonnet

A bellows seal bonnet uses a flexible metal bellows to seal the valve stem. You will see this type when you need to stop leaks at all costs. The bellows forms a tight seal around the stem. This keeps dangerous or toxic fluids from escaping.

You should use a bellows seal bonnet in chemical plants, refineries, or places with hazardous gases. The bellows moves up and down with the stem but does not let fluid leak out. This design gives you extra safety and helps you meet strict environmental rules.

- Bellows seal bonnets reduce emissions.

- They protect workers and the environment.

- You can use them for toxic, flammable, or radioactive fluids.

Alert: Always choose a bellows seal bonnet if you must prevent leaks of dangerous fluids. This keeps your plant safe and meets safety standards.

Pressure-Sealed Bonnet

A pressure-sealed bonnet is a special type of bonnet you use in high-pressure systems. You will often see this design in power plants, oil refineries, and other places where the valve must handle very high pressure. The main job of a pressure-sealed bonnet is to keep the valve sealed tight, even when the pressure inside the valve gets very high.

This bonnet uses a clever design. When the pressure inside the valve goes up, the seal between the bonnet and the valve body gets tighter. The higher the pressure, the better the seal works. This is different from a standard bonnet, which can start to leak if the pressure gets too high.

Key features of a pressure-sealed bonnet:

- Uses a metal gasket or ring to create the seal.

- The seal improves as pressure increases.

- Handles very high pressures, often above 900 psi.

- Reduces the risk of leaks in critical systems.

You should pick a pressure-sealed bonnet if your process involves steam, hot water, or other fluids under high pressure. This design helps you avoid leaks that could cause safety problems or damage equipment.

Note: Pressure-sealed bonnets need careful installation. Always follow the manufacturer’s instructions to make sure the seal works as designed.

Here is a quick comparison:

| Bonnet Type | Best For | Main Benefit |

|---|---|---|

| Standard Bonnet | Normal pressure | Simple, easy to maintain |

| Pressure-Sealed Bonnet | High pressure systems | Seal gets tighter with pressure |

Choosing the Right Bonnet Type

You need to choose the right bonnet type for your control valve to keep your system safe and reliable. The bonnet affects how well the valve seals, how easy it is to maintain, and how long it lasts.

Here are some steps to help you pick the right bonnet:

- Check your process temperature:

- Use a standard bonnet for normal temperatures.

- Pick an extended bonnet for very hot or cold fluids.

- Look at the pressure:

- Use a pressure-sealed bonnet for high-pressure jobs.

- Standard bonnets work for low or medium pressure.

- Think about safety:

- Choose a bellows seal bonnet if you handle toxic or dangerous fluids.

- This keeps leaks from reaching the outside.

- Consider maintenance:

- Standard bonnets are easy to take apart and fix.

- Pressure-sealed and bellows seal bonnets may need more skill to service.

- Check for special needs:

- If you work with cryogenic fluids, use an extended bonnet.

- For high-pressure steam, use a pressure-sealed bonnet.

Tip: Always match the bonnet type to your process needs. The right choice helps you avoid leaks, reduce downtime, and keep your plant safe.

If you are not sure which bonnet to use, talk to a valve expert or the manufacturer. They can help you pick the best option for your system. Remember, the right bonnet makes your control valve work better and last longer.

Material and Design

Body Materials

When you pick a modulating control valve, you need to think about the body materials. The body is the main part that holds the valve together. It touches the process fluid. You must pick the right material to keep your system safe and working well.

Some common body materials are:

- Plastic: Good for low-pressure jobs where corrosion is a problem. You often see plastic valves in water treatment or chemical plants.

- Brass and Bronze: These cost less and fight rust. You can use them for water and light chemicals.

- Iron: This is cheap. You can add coatings to iron valves to protect them from harsh fluids.

- Carbon Steel: Use carbon steel when you need a strong valve. It works well in high-pressure systems.

- Stainless Steel: This is strong and does not rust easily. You use stainless steel valves in tough places.

You should always match the body material to your process. Think about the pressure, temperature, and what kind of fluid you have. If the fluid is dirty, you may need a stronger material. The right choice helps stop leaks and keeps things safe.

Trim Materials

The trim is made up of the plug, seat, and stem inside the valve. These parts control the flow and get a lot of wear. Picking the right trim materials helps your valve last longer and keeps your system running.

Here is a table with common trim materials and what they do:

| Material/Coating Type | Key Benefits | Typical Application/Effect on Valve Performance |

|---|---|---|

| Stainless Steel | Fights rust and is strong | Used for most trim parts, lasts longer |

| Monel | Stands up to seawater and acids | Used in harsh places |

| Hardened Alloys | Very hard, resists wear | Good for rough or gritty flows |

| Carbide Coatings | Stops erosion | Protects trim in fast or rough flows |

| Ceramic Inserts | Handles lots of wear | Used in very rough or fast flows |

| Stellite Coating | Very hard, resists wear | Used for tough jobs, makes valve last longer |

| PTFE Coating | Does not react with chemicals, slippery | Used on seals and soft seats for tight shutoff |

You should use hard or coated trim if your process has sand or grit. This helps stop damage and keeps the valve sealing well. Precision trim sets are tested for tight shutoff and smooth control. Picking the right trim also helps keep your system safe by stopping leaks.

Coatings and Linings

Coatings and linings give your valve extra protection. You can use epoxy or phenolic liners to stop rust and wear. These are common in wastewater, slurry, and seawater valves. Carbide coatings, like tungsten or chromium carbide, protect trim from fast-moving wear.

Elastomer linings, such as PTFE or Viton, help with chemical safety and heat. These linings keep the valve sealing tight and help it last longer. Surface treatments like nitriding or nickel plating make steel trims harder and stop rust.

Tip: Always check if your process fluid needs a special coating or lining. This step keeps your valve safe and helps it last longer.

When you pick the right body, trim, and coatings, your valve works better and your system stays safe. You also spend less on repairs and avoid surprise breakdowns.

Compatibility and Durability

When you choose a modulating control valve, you need to make sure it will last in your system. Compatibility means the valve works well with the fluid, temperature, and pressure in your process. Durability means the valve can keep working for a long time without breaking down.

You should always check if the valve can handle the fluid in your system. Some fluids can cause rust or wear out the valve. For example, saltwater can damage iron valves. Acidic fluids can eat away at some metals. If you use the wrong valve, you might see leaks or even a system failure.

You also need to think about temperature and pressure. High temperatures can make some valves weak. High pressure can cause leaks or cracks. Always pick a valve that matches your system’s needs.

Here is a table to help you see what to check for compatibility and durability:

| Factor | What to Check | Why It Matters |

|---|---|---|

| Fluid Type | Will the fluid damage the valve? | Stops leaks and rust |

| Temperature | Can the valve take the heat or cold? | Prevents cracks and failures |

| Pressure | Can the valve handle high pressure? | Avoids leaks and bursts |

| Flow Rate | Is the valve sized for your system? | Keeps control steady |

| Cycle Frequency | How often will the valve move? | Reduces wear and tear |

Tip: Always ask your supplier for a valve that matches your process. This helps you avoid problems and keeps your plant safe.

You should also look at how often the valve will open and close. If your system cycles a lot, pick a valve made for frequent use. Some valves have special coatings or linings to help them last longer. These features protect the valve from harsh fluids and high temperatures.

You need to think about the environment around the valve. If the valve sits outside, rain or sun can cause damage. You can use covers or special paints to protect the valve. Good maintenance also helps your valve last longer. Check the valve often and fix small problems before they get worse.

When you choose the right materials, you get a valve that works well and lasts a long time. This saves you money and keeps your system running smoothly.

Actuator and Control Signal

Picking the right actuator and control signal is very important. The actuator moves the valve to the right spot. The control signal tells the actuator what to do. You must match both to your system for safe use.

Actuator Types

There are three main actuator types for modulating control valves. Each type uses a different power source and moves in its own way.

Pneumatic

Pneumatic actuators use air to move the valve. They work well when you need fast action and a simple setup. You often see them on ball, butterfly, and globe valves. Pneumatic actuators are easy to fix and last a long time. Some use a spring to close the valve if air stops. Others use air to both open and close. Use pneumatic actuators if you have steady air and need quick control.

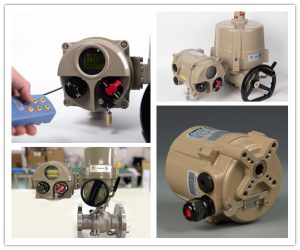

Electric

Electric actuators use electricity to move the valve. They can turn or push the valve open and closed. Electric actuators give you very exact control. They work well with digital systems. These actuators are quiet and do not make much mess. They are good for places without air supply. Many electric actuators have feedback, stall protection, and backup batteries. Pick electric actuators if you want accurate valve movement and easy setup with your control system.

Hydraulic

Hydraulic actuators use oil under high pressure to move the valve. They give strong force and are best for big valves or hard jobs. You see hydraulic actuators in heavy work where you need lots of power. They are more complex and need regular checks. But they can move big valves that other actuators cannot.

Here is a table to help you compare actuator types:

| Actuator Type | Power Source | Motion Type | Best For | Key Features |

|---|---|---|---|---|

| Pneumatic | Compressed air | Rotary/Linear | Fast, reliable, easy to maintain | Good for high-cycle, simple control valves |

| Electric | Electricity (AC/DC) | Rotary/Linear | Precise, quiet, digital integration | Best for accurate control and feedback |

| Hydraulic | High-pressure oil | Rotary/Linear | Large valves, high force, tough jobs | Handles heavy-duty, fail-safe control valves |

Tip: Always check your power source and space before picking an actuator. The right choice helps your valve work better and last longer.

Control Signals

Control signals tell the actuator how much to open or close the valve. There are different types of signals for control valves.

Pneumatic actuators use air signals. These give fast response and help the valve close safely if something goes wrong. Pneumatic actuators are good for places with lots of cycles and tough conditions. Electric actuators use signals like 4-20 mA or digital inputs. These signals give very exact control. You can set the valve position very carefully. Digital signals, like HART, let you send and get data. This makes it easy to watch and change the valve from a control room.

Electric actuators with 4-20 mA signals often have special features. These include servo systems and feedback sensors. These features help you keep the valve steady and accurate. You can also set start and end spots easily. If the power goes out, some electric actuators can lock in place to keep things safe.

Note: The type of control signal you use changes how fast, exact, and safe your valve control will be.

Matching Actuator to Valve

You must match the actuator to the valve and your needs. Here are some steps to help you pick:

- Check the valve type. Use linear actuators for globe or gate valves. Use rotary actuators for ball, butterfly, or plug valves.

- Look at your power source. Pick electric actuators if you have electricity. Use pneumatic actuators if you have air. Choose hydraulic actuators for big valves that need lots of force.

- Think about space. Small rotary actuators fit better in tight places.

- Decide on the job. If you need modulating control, pick actuators with positioners and high cycle life.

- Make sure the actuator gives enough torque. It should be 10-30% more than the valve’s breakaway torque.

- Think about how often you will use the valve. For lots of movement, pneumatic actuators last longer. Electric actuators may get too hot if used too much.

- Check the speed. Fast actuators are best for quick control. Slow actuators work for steady, careful changes.

- Plan for safety. Pick actuators with fail-safe features, like spring return or battery backup, to keep the valve safe if power is lost.

Always match the actuator and control signal to your valve and process. This helps you get safe, steady, and efficient control valves.

Installation and Maintenance

Installation Needs

You must follow the right steps to install a modulating control valve. How you install the valve affects how well it works and how long it lasts. Here are some simple steps to help you:

- Put the valve in the right spot and position. This stops problems and helps the valve work right.

- Keep the valve and area around it clean. Dirt can block the valve and make it less reliable.

- Make sure the valve fits the fluid type. Check that it can handle the right pressure and flow.

- Look at the valve for damage before you finish. Watch for signs like rust, leaks, or worn parts.

- Clean strainers and filters before starting the system. This keeps the flow good and stops clogs.

- Add oil or grease to moving parts if the maker says so. This helps the valve move easily and last longer.

- Test the valve after you put it in. Make sure it opens, closes, and listens to control signals.

Tip: Careful installation helps stop early problems and keeps your system working well.

Maintenance Factors

Doing regular maintenance helps your control valve work better and last longer. You should check the valve often for leaks, rust, or odd sounds. Clean the valve and filters to stop clogs. Add oil or grease to moving parts to stop them from wearing out. If you see damage, fix it fast so it does not get worse.

You should also test the valve sometimes to make sure it works right. This helps you find problems early. Always follow the care plan from the maker. Good maintenance keeps your valve reliable and stops surprise shutdowns.

Accessibility

You need to think about how easy it is to reach the valve when you install it. Put the valve where you can get to it for checks and repairs. If the valve is hard to reach, you might skip important care. This can make the valve less reliable and repairs take longer.

A good setup gives space for tools and safe spots for workers. You should also put a clear label on the valve. This helps you find it fast during checks or emergencies. Planning for easy access helps keep your system safe and working well.

System Balancing and Performance

Pressure Drop

You need to understand pressure drop when you work with control valves. Pressure drop means the difference in pressure before and after the valve. This drop helps you control the flow. If the pressure drop is too high, you waste energy and may damage the valve. If it is too low, you lose control accuracy. You should always check the pressure drop to keep control valve performance at its best.

A good pressure drop helps you get stable flow. You can use a table to see how pressure drop affects your system:

| Pressure Drop | Effect on System |

|---|---|

| Too High | Wastes energy, causes noise |

| Too Low | Poor control, unstable flow |

| Just Right | Good control, saves energy |

Tip: Always size your valve so the pressure drop stays in the right range. This step helps you reach energy optimization and keeps your system safe.

Eliminating Excess Pump Head

Many systems use pumps to move fluids. Sometimes, pumps give more pressure than you need. This extra pressure is called excess pump head. If you do not remove it, your control valve must handle the extra force. This can hurt control valve performance and waste energy.

You can fix this by balancing your system. Adjust the pump or use a bypass line. This step lowers the pressure before the valve. You get better performance and save energy. You also help your valve last longer.

- Check your pump size and settings.

- Use only the pressure you need.

- Remove extra pressure to protect your valve.

Note: Removing excess pump head is a key part of system optimization. You get better control and lower energy costs.

Ensuring Stability

Stability means your system keeps the flow steady. If your control valve moves too much or too fast, you get unstable flow. This can cause noise, vibration, or even damage. You need to set up your valve and system for stable control valve performance.

You can follow these steps for better stability:

- Size your valve for normal flow, not just the maximum.

- Keep the valve working in the 20%-80% open range.

- Use the right actuator and control signal.

- Check for fast changes in pressure or flow.

Remember: Stable systems give you better performance, less wear, and lower energy use. Good stability is the goal of every energy optimization plan.

Control Valve Selection Tips

Common Mistakes

You can stop many problems by learning from common mistakes. Some people forget to ask about process details. They do not check the fluid type, temperature, or pressure. Pipe size and flow rates are sometimes missed too. Some people buy a valve too fast without checking everything. This can make the valve work badly and not last long.

Here are some mistakes you should look out for:

- Picking the wrong valve type for your job.

- Not thinking about how much the valve needs to open or close.

- Forgetting to check how old valves worked or if there is enough space.

- Not matching the valve material to the fluid or where it will be used.

- Not using sizing software or skipping the selection checklist.

- Using the valve at too high pressure or opening and closing it too quickly.

Tip: Always use a full checklist and sizing tools before you pick a control valve. This helps you find the best valve for your job and makes your system work better.

Troubleshooting

If your control valve does not work right, you can follow some easy steps. First, see if the valve moves when it gets a signal. If it does not move, check the actuator and power. Make sure nothing is blocking the valve.

Next, look at how the valve was put in. Sometimes, if the valve is not lined up or is in a tight spot, it can get stuck. Check for leaks around the valve body or bonnet. If you see leaks, look at the seat and seals for damage.

You should also check the control system. Make sure the signal matches the actuator type. Pneumatic actuators need steady air. Electric actuators need the right voltage. If the valve opens and closes too fast or too slow, change the positioner or feedback settings.

| Problem | What to Check | Possible Solution |

|---|---|---|

| Valve not moving | Actuator, power, debris | Clean, repair, or replace |

| Leaks | Seat, seals, body | Replace seals or trim |

| Poor control | Signal, actuator, sizing | Adjust or resize valve |

| Fast wear | Material, cycling, pressure | Upgrade trim or actuator |

Note: Checking your valve often and fixing problems quickly helps your system stay safe and work well.

Practical Advice

You can make better choices and improve your system by following these tips:

- Always start by writing down all your process details. Include fluid type, temperature, pressure, and flow.

- Use valve sizing software to check your picks. Save your reports for later.

- Match the valve type and trim to your job. Think about how much control you need.

- Pick materials that do not rust or wear out fast. This helps your valve last longer.

- Make sure you have enough space to put in and fix the valve.

- Look at how old valves worked in your plant. Learn from what went well or badly.

- Do not let the valve open and close too fast or let pressure jump up and down. This can break the valve.

- Work with good suppliers or experts. They can help you choose and fix valves.

Remember: Picking the right control valve helps your system work better and last longer. Good planning and regular checks keep your plant safe and running well.

Picking the right modulating control valve means you need to follow some careful steps. First, you must know what your process needs. Next, pick the right valve type and the best materials for your job. Make sure the valve is the right size so the flow stays steady. Match how the flow changes to what your system needs. Balance everything in your system so it works its best.

If your job is tricky, ask a valve expert or the company that makes the valve for help. Use this guide as a checklist every time you start a new project. Planning ahead helps you keep your flow safe, steady, and working well.

FAQ

What is the main difference between a modulating control valve and an on/off valve?

A modulating control valve can stop anywhere between open and closed. This means you can set the flow to any level you want. An on/off valve only lets you start or stop the flow. There is no way to pick a middle spot with an on/off valve.

How do you choose between pneumatic and electric actuators?

Pick pneumatic actuators if you need quick and often movement. They are simple to set up and work well for fast jobs. Electric actuators are better if you want very exact control. They are easy to use with digital systems. Always check what power you have and what your system needs.

Can you use a ball valve for precise flow control?

You can use a ball valve for careful flow control if it has a V-port or special trim. Regular ball valves do not give smooth control. Always pick the right trim for your job to get good results.

Why does valve sizing matter so much?

Getting the size right helps keep the flow steady and control good. If you pick the wrong size, you might hear noise or see the valve wear out. The valve may not work well. Always use real data and sizing tools to choose.

What should you check before installing a control valve?

Look at the valve for any damage before you put it in. Make sure it fits your process and the actuator works with your control signal. Clean the area around the valve. Test the valve after you install it to see if it works right.

How often should you maintain a modulating control valve?

Check and take care of your valve often. Look for leaks, worn parts, and make sure it moves smoothly. Follow the maker’s plan for cleaning, oiling, and changing parts. This keeps your valve working well.

What is a positioner, and do you need one?

A positioner helps the actuator move the valve to the right spot. It listens to the control signal and makes sure the valve goes where it should. You need a positioner for careful control, especially if your system changes a lot or has friction.

Can you use one valve for both liquid and gas applications?

Do not use the same valve for both unless it is made for both fluids. Always check if the valve’s materials and design fit the fluid, temperature, and pressure. This helps stop leaks or damage.