You want to pick the right valve for your system. If you need high flow and good control, a motorized ball valve is often best. Electric ball valves are also strong and last a long time. These motorized valves are used in water treatment and HVAC. They are good when you need automation and to save energy. For quick on-off jobs, a solenoid valve or butterfly valve is common. These are used a lot in oil and gas and in cars. Ball valve designs, like pneumatic ball valves, can handle tough fluids and debris better than many solenoid valves.

Key Takeaways

- Motorized ball valves work well with strong flow and high pressure. They also handle dirty fluids better than solenoid valves. Solenoid valves turn flow on and off very fast. They fit well in tight spaces. Motorized ball valves save energy because they use power only when moving. Solenoid valves need power all the time to stay open or closed. Ball valves last longer and do not need much maintenance. But they cost more at first and take longer to put in. Solenoid valves are easier and cheaper to install and fix. But they may break faster if used a lot. Use motorized ball valves for careful flow control and saving energy. They are good for hard jobs with dirty or thick fluids. Pick solenoid valves for fast on-off control and clean fluids.

Comparison

Key Differences

When you pick between a motorized ball valve and a solenoid valve, you should look at some important things. Each valve works best in different jobs. Here are the main ways they are not the same:

- A motorized ball valve lets more fluid move through. It can fit bigger pipes. You use it when you need to move lots of water or other fluids. The ball valve design helps you control how much flows.

- Solenoid valves are good for turning flow on or off fast. They react quickly. This is helpful if you need to start or stop flow right away. These valves are small and fit in tight spots.

- Motorized ball valves can handle higher pressure. You can use them for tough work where strength is needed. Solenoid valves cannot take as much pressure. They might need extra parts for high pressure.

- Motorized valves last longer and work well in harsh places. The ball valve design does not wear out fast, even with dirty fluids. Solenoid valves can wear out sooner if you use them a lot.

- Solenoid valves are easier to fix. You can change parts fast. Motorized ball valves need more care and have more parts.

- Motorized ball valves only use power when opening or closing. This saves energy over time. Solenoid valves need power all the time to stay open or closed. They use more energy.

- You see motorized ball valves in water treatment, HVAC, oil and gas, and fire systems. Solenoid valves are used in cars, medical tools, and places that need fast switching.

Tip: If your system needs to move lots of fluid, handle high pressure, or deal with dirty fluids, pick a motorized ball valve. If you want fast switching and easy fixing, a solenoid valve may be better.

Quick Table

Here is a table to help you compare both valves:

| Specification | Motorized Ball Valve | Solenoid Valve |

|---|---|---|

| Flow Capacity | Higher flow, good for big amounts | Lower flow, best for small amounts |

| Pressure Rating | Handles higher pressures (145–5800 psi) | Lower pressure (0–3625 psi), may need help |

| Typical Size Range | 1/4 inch to 8 inch (can change) | 1/8 inch to 4 inch (can change) |

| Speed (Response) | Slower, controls flow well | Very fast, instant on/off |

| Durability | High, lasts a long time | Medium, can wear out with lots of use |

| Maintenance | Medium, harder to fix | Low, easy to fix |

| Energy Efficiency | Uses power only when moving | Needs power all the time |

| Media Handling | Good for dirty fluids | Can clog with dirt |

| Typical Applications | Water treatment, HVAC, oil & gas, fire systems | Cars, medical, fast-switching jobs |

- Ball valves let more fluid move with less pressure drop than solenoid valves.

- Motorized ball valves can fit bigger pipes and take more pressure.

- Solenoid valves work faster and are smaller but move less fluid and take less pressure.

- The ball valve wipes itself clean, so flow stays steady even with dirt.

- Electric ball valves are slower but let more fluid move.

You should pick the valve that fits your system’s needs. If you want strength, lots of flow, and long life, a motorized ball valve is a good pick. If you need speed and easy fixing, solenoid valves are a smart choice.

Operation

Motorized Ball Valve

Electric Actuation

A motorized ball valve helps you control flow automatically. It uses an electric actuator to move the ball inside. The actuator turns electricity into movement. This makes the ball turn to open or close the valve. You can pick from different actuator types, like electric, pneumatic, or hydraulic. Most people use electric actuators because they are simple to use and set up.

Electric actuators work with many power types. You can use AC, DC, or PWM. PWM saves energy and keeps the actuator cool by sending short bursts of power. Some actuators have safety parts like spring-return. These make sure the valve shuts if the power stops. Limit switches tell you if the valve is open or closed.

Note: How fast and often the valve moves depends on motor speed and duty cycle. Gears slow things down for smooth and steady movement.

Flow Control

Motorized ball valves let you control flow very well. You can open the valve a little or a lot. This is good for systems that need careful changes. The ball valve design helps lower wear and tear. You can use these valves for water, chemicals, or dirty fluids. The valve cleans itself as it moves, so it works well for a long time. If you need to control flow in big pipes or high pressure, a motorized valve is a strong pick.

Solenoid Valve

Electromagnetic Action

Solenoid valves use magnets to control fluid flow. When you send power to the coil, it makes a magnetic field. This field pulls a plunger up and opens the valve. When you turn off the power, a spring pushes the plunger down and closes the valve. This simple setup makes solenoid valves quick and dependable.

There are different solenoid valve types. Some are direct-acting, using only the magnet to open. Others are pilot-operated and use fluid pressure to help move the plunger. Externally piloted valves use outside pressure for harder jobs. You can also pick two-way, three-way, or four-way valves for different flow needs.

Fast Switching

Solenoid valves turn on and off very fast. You get instant action when you need to start or stop flow. This is great for jobs where timing is important, like in safety or automation. Some solenoid valves use PWM to control flow better. By changing the current, you can move the plunger more or less and change how much fluid goes through. This helps you fine-tune the flow in special systems.

Tip: Solenoid valves work best in clean systems with small pipes and low or medium pressure. They are easy to put in and fix, so many people use them for quick jobs.

Performance

Flow and Pressure

You need to think about flow and pressure when choosing between a motorized ball valve and a solenoid valve. Solenoid valves work best in small pipes and with low flow rates. You often see them in irrigation, medical devices, and HVAC systems. These valves fit tight spaces and handle simple jobs. Motorized ball valves work better for large pipes and high flow. You find them in oil and gas, water treatment, and other big industries. Ball valves have fewer moving parts, so they last longer and need less fixing. They also handle higher pressures, sometimes over 6000 PSI. You can use them in very cold or hot places, from -196°C up to 450°C. This makes them a strong choice for tough jobs. Solenoid valves can give you some control over flow, but ball valves give you better shutoff and work well in harsh places.

Speed and Response

Speed matters in many systems. Solenoid valves act fast. Direct-acting types can open or close in about 30 milliseconds. Indirect-acting types may take up to 1000 milliseconds. This quick action helps when you need to start or stop flow right away. Motorized ball valves move slower. They usually take a few seconds to open or close. This slow movement helps prevent water hammer, which is a sudden pressure surge that can damage pipes. You should use solenoid valves for jobs that need fast switching, like in automation or safety systems. Motorized ball valves work better when you want smooth, steady flow changes. They also keep their position if the power goes out, which can help protect your system.

| Valve Type | Typical Response Time | Notes on Operation and Suitability |

|---|---|---|

| Solenoid Valves | 30 ms (direct-acting) to 1000+ ms (indirect-acting) | Fast-acting, good for rapid on/off control, high-cycle use. |

| Motorized Ball Valves | A few seconds | Slower, reduces water hammer, good for gradual flow control. |

Media Handling

You should match the valve to the type of fluid or gas in your system. Motorized ball valves handle many types of media. They work well with water, chemicals, gases, and even slurries. The full port design lets fluids move without much pressure drop. This design also stops build-up and keeps the flow steady. You can use these valves in oil and gas, chemical plants, and water systems. They come in many materials, like PVC, brass, stainless steel, and carbon steel. Solenoid valves work best with clean liquids and gases. They can clog if the fluid has dirt or debris. Ball valves are better for dirty or thick fluids. You also see them in food, beverage, and pharmaceutical jobs because they keep things clean and safe.

Tip: Always check the media type before picking a valve. The right choice will improve your system’s performance and reduce maintenance.

Applications

High Flow Systems

High flow systems are used in places like water plants, big coolers, and chemical factories. These jobs need valves that let a lot of fluid move easily. Ball valves are good for turning flow on or off in these jobs. They seal well and let fluid move with little pressure loss. Globe valves help when you want to change the flow slowly. Butterfly valves are light and small, so they fit big pipes well.

Here is a table showing common valve types for high flow jobs:

| Valve Type | Size Range (DN) | Max Pressure Differential (MPa) | Best Use Cases | Notes on Suitability |

|---|---|---|---|---|

| Ball Valve | 15 to 200 | 1.6 to 6.4 | On-off control, minimal pressure drop | Reliable sealing, easy automation |

| Globe Valve | 15 to 400 | 1.6 to 4.0 | Flow regulation, industrial process control | Good for gradual adjustments |

| Butterfly Valve | 50 to 1200 | 1.0 to 2.5 | Large pipelines, HVAC, water distribution | Compact, quick operation |

You should always pick a valve that matches your fluid, pressure, and temperature. This helps your system work well and stay safe.

Rapid Response Needs

Some jobs need you to start or stop flow very fast. In factories, you may need a valve that moves in just seconds. Pneumatic ball valves are great for this. Their actuators can open or close the valve in 1 to 3 seconds. This fast speed helps in emergencies or quick changes. You also get feedback on where the valve is, which helps keep things safe.

Solenoid valves also work fast. They turn on or off almost right away. You see them in small places where space is tight and quick action is needed. For bigger pipes or higher pressure, pneumatic ball valves give you the speed and trust you need.

Tip: Pick a valve that moves fast if you need safety, quick dosing, or emergency stops.

Particulates and Debris

Some jobs have fluids with dirt, sand, or other bits. You need a valve that does not clog up. Motorized ball valves are good because the ball cleans itself as it turns. This helps clear dirt and keeps the valve working well. You can use these valves in dirty water, mining, or any job with messy fluids.

Solenoid valves do not handle dirt as well. Small bits can get stuck and make the valve stop working. You might see coil burnout or hear noise from fast closing. Solenoid valves also close fast, which can cause water hammer and hurt pipes.

| Feature | Motorized Ball Valve | Solenoid Valve |

|---|---|---|

| Handling of particulates | Wiping action clears debris | Prone to clogging |

| Common failure modes | Wear over time, harder to service | Coil burnout, clogging, water hammer |

| Water hammer risk | Low due to slow closing | High due to fast closing |

If your job has fluids with dirt, pick a motorized ball valve. It will work better and need less fixing.

Pros and Cons

Motorized Ball Valve

A motorized ball valve lasts a long time. It works well in hard jobs. It has fewer moving parts than other valves. This means it does not break down as much. You do not have to fix it often. This saves you time on repairs. You can control it from far away. This is good for big systems or places that are hard to reach.

Here is a table to show the main pros and cons:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Reliability | More durable and reliable due to fewer moving parts; less wear and tear on motor compared to manual operation | Dependent on power supply; will not operate during power outages |

| Maintenance | Requires less maintenance because of fewer moving parts | Needs occasional maintenance; may require more frequent replacement than manual valves |

| Cost | Suitable for automation and remote control, adding operational value | Higher initial cost compared to manual valves |

Note: If the power goes out, the motorized ball valve will not work. You should have a backup plan for important systems.

You can use a ball valve when you need a strong shutoff. It also lasts a long time. The higher price at first is worth it. You do not have to replace it often.

Solenoid Valve

A solenoid valve opens and closes very fast. This is great for jobs where speed is important. You can use it in small spaces. It works well with modern electrical systems. Some types use very little power. This helps in places with not much electricity.

Here are the main pros and cons:

Pros:

- Opens and closes very fast, good for jobs that need speed.

- Uses little energy, especially in low-power models.

- Works well for remote control and automation.

Cons:

- You might need to change the coil during its life.

- Needs a control signal to keep working.

- Can get too hot if the voltage changes.

- Harder to fix than manual valves.

| Feature | Solenoid Valve Characteristics |

|---|---|

| Speed | Very fast opening and closing times, suitable for systems requiring immediate response |

| Energy Use | Requires electrical power, either continuously or on demand, which is a consideration in energy consumption |

| Maintenance | Moderate maintenance needed, including regular electrical wiring checks and coil inspections; more complex than manual valves |

Tip: Check your power supply and make sure you can do the extra maintenance. If you need fast action and easy automation, a solenoid valve is a good pick.

You can use a solenoid valve when you need quick switching. It is also good if you do not have much space. It works best with clean fluids and in systems that need a fast response.

Maintenance

Durability

When you choose a valve, you want it to last as long as possible. Motorized ball valves usually last between 8 to 10 years if you use them under normal conditions. Their lifespan depends on how often you use them, what kind of fluid flows through them, and the environment around them. If you use the valve in a place with lots of corrosion or with dirty fluids, it may not last as long. The material of the valve matters, too. Stainless steel, brass, bronze, and PVC all have different strengths. Stainless steel works well in harsh places, while PVC is better for less demanding jobs.

Solenoid valves can also last a long time, but their life depends on how often you turn them on and off. If you use them for rapid switching, they may wear out faster. High pressure or high temperature can also shorten their life. You should always keep the valve within its rated limits for temperature and pressure. If you push it too hard, the seals and other parts can break down quickly.

Tip: If you want your valves to last, pick the right material for your fluid and temperature. Avoid using valves with abrasive or dirty media unless they are designed for it.

Here are some key points to remember about valve durability:

- Motorized ball valves: 8–10 years typical lifespan under standard use.

- Lifespan drops with frequent cycling, high pressure, or abrasive media.

- Material choice affects how long the valve lasts.

- Solenoid valves: Lifespan depends on cycling rate and operating conditions.

- Keeping valves within their rated limits helps them last longer.

Service Needs

You need to take care of your valves to keep your system running smoothly. Solenoid valves usually need maintenance every 6 to 12 months. The exact timing depends on how you use them and what kind of fluid they handle. If your system uses harsh chemicals or cycles the valve on and off a lot, you may need to check them more often. Regular cleaning and inspection help you catch problems early.

Motorized ball valves need less frequent service, but you should still check them from time to time. Seals and seats are the parts that wear out the most. In high-pressure or high-cycle jobs, you might want to use a three-piece ball valve. This design lets you replace the seals and seats without removing the whole valve from the pipe. That saves you time and money.

Note: Proper installation by someone who knows what they are doing can reduce repair needs later. Always make sure cables and connections are dry and secure to prevent damage.

Here is a quick checklist for valve maintenance:

- Clean and inspect seals regularly.

- Watch for leaks or changes in how the valve moves.

- Replace worn seals or seats as needed.

- Monitor pressure, temperature, and fluid type.

- Use preventive maintenance to avoid sudden failures.

If you follow these steps, you can extend the life of both motorized ball valves and solenoid valves. Regular care keeps your system safe and helps you avoid costly downtime.

Energy

Power Use

You should think about how much power your valve needs. This can change your energy bill and how your system works. Motorized ball valves and solenoid valves use power in different ways.

- Solenoid valves, especially standard ones, use power all the time. They need electricity to stay open or closed. The coil inside keeps using energy as long as the valve is on. If you leave it on for hours, it keeps using power.

- Some solenoid valves are called latching solenoid valves. These only use power when they switch open or closed. They do not use power to hold their spot. This can help save energy in some systems.

- Motorized ball valves only use power when moving. The motor runs for a few seconds to open or close. After that, the valve stays put without using more power. Even if the power goes out, the valve stays in its last spot.

- Solenoid valves can lose their spot if the power fails. They go back to a default state, which might not be what you want.

- Both types use about the same power when switching. The big difference is when you need to hold a spot for a long time.

Tip: If your system needs the valve to stay open or closed for a long time, a motorized ball valve can help save energy.

Efficiency

Energy efficiency means doing more work with less energy. You want your system to run well and not waste power. How each valve uses energy changes your costs and how green your system is.

Here is a table to help you compare the two valve types:

| Feature | Solenoid Valve | Motorized Ball Valve |

|---|---|---|

| Energy Consumption | Lower when moving but needs power all the time to stay on | Uses more power when moving, but none to hold position |

| Power Usage Pattern | Needs power all the time to keep position | Only needs power when moving; holds spot with no power |

| Cost Considerations | Usually costs less at first | Costs more at first but can save money later by using less energy |

| Power Outage Resilience | Loses position if power goes out | Keeps position even if power goes out |

Solenoid valves may seem like they use less energy at first. But if you keep them open or closed for a long time, they can use more power than you think. Motorized ball valves use a bit more power when moving, but then stop using energy. This can make them better for systems where the valve stays in one spot for a long time.

Note: If you want to use less energy and save money, think about how often your valve moves. For systems where the valve stays put, motorized ball valves are often more efficient. For quick, short actions, solenoid valves can work well.

Cost

Upfront

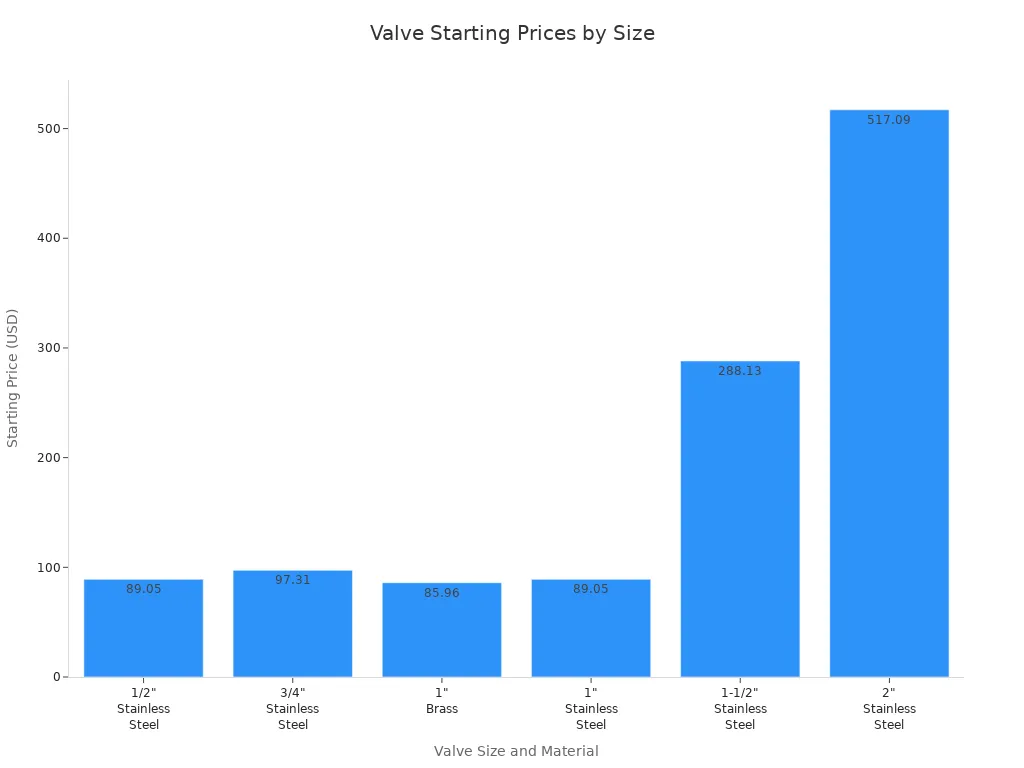

When you pick a valve, think about how much it costs at first. Motorized ball valves usually cost more than solenoid valves. The price changes with the size and what the valve is made of. For example, a 1/2″ stainless steel motorized ball valve starts at about $89.05. A 2″ stainless steel valve can cost up to $517.09. Brass valves and smaller sizes are cheaper. But motorized ball valves still cost more than most solenoid valves.

| Valve Size | Starting Price (USD) |

|---|---|

| 1/2″ Stainless Steel | $89.05 |

| 3/4″ Stainless Steel | $97.31 |

| 1″ Brass | $85.96 |

| 1″ Stainless Steel | $89.05 |

| 1-1/2″ Stainless Steel | $288.13 |

| 2″ Stainless Steel | $517.09 |

You also need to think about how hard it is to put in the valve. Motorized ball valves can take longer to install. They have more parts and need wiring. Solenoid valves are smaller and lighter. You can usually install them faster. If you want something easy to install, solenoid valves are a better choice. The total upfront cost is the price of the valve plus the work to install it.

Tip: If you do not have much money or need many valves, solenoid valves can help you save at the start.

Long-Term

The first price is not the only thing to think about. You should also look at how much the valve costs over time. This means energy use, fixing, and how often you need new parts. Motorized ball valves only use power when they move. If your valve stays open or closed for a long time, you save energy. Solenoid valves need power all the time to stay open or closed. If you use them a lot, your energy bill can go up.

Here is a table to help you compare long-term costs:

| Aspect | Motorized Ball Valves | Solenoid Valves |

|---|---|---|

| Initial Cost | Higher initial cost | Generally more affordable |

| Total Operating Cost | Lower total operating cost due to no continuous power needed to hold position | Potentially higher due to continuous power when energized |

| Energy Consumption | Lower over time, especially if valve remains in one position for long periods | Less energy during operation but requires continuous power to stay energized |

| Maintenance | Moderate, more complex due to internal components | Low, easy to replace parts |

| Durability | High, longer service life, less prone to clogging | Moderate durability |

| Power Outage Resilience | Maintains position without power | Loses position without power |

You might pay more for a motorized ball valve at first. But you can save money later. These valves last longer and do not break as much, even in hard jobs. Solenoid valves cost less to buy and put in. But you might spend more on energy and new parts if you use them a lot.

Note: Always think about how your system will work for many years. Sometimes, paying more at the start can help you save money later.

Selection Guide

Key Factors

When you pick between a motorized ball valve and a solenoid valve, you need to think about some main things. Every system is different, so you should choose the valve that fits your job. Here are the most important points:

- Flow rate and pressure: Motorized ball valves can handle more flow and higher pressure. Solenoid valves work better with less flow and lower pressure.

- Response time: Solenoid valves turn on and off very fast. Motorized ball valves move slower but work more smoothly.

- Power consumption: Solenoid valves use power the whole time they are open or closed. Motorized ball valves only use power when they open or close.

- Durability and maintenance: Motorized ball valves last longer and do not need fixing as often. Solenoid valves are easier to fix but might wear out faster.

- Clogging risk: Solenoid valves can get blocked if the fluid has dirt. Motorized ball valves do not clog as easily because the ball wipes itself clean.

- Size and weight: Solenoid valves are small and light, so they fit in tight spaces.

- Noise: Motorized ball valves are quiet when they run. Solenoid valves can make clicking noises.

- Bidirectional flow control: Motorized ball valves let fluid go both ways. Solenoid valves usually do not let fluid go both ways.

- Power outage resilience: Motorized ball valves stay in place if the power goes out. Solenoid valves go back to their normal spot when power is lost.

- Cost: Solenoid valves cost less at first. Motorized ball valves cost more but can save money later.

- Application suitability: Solenoid valves are good for quick jobs, clean fluids, and when you want to spend less. Motorized ball valves are better for big flows, dirty fluids, and when you need the valve to stay put if the power goes out.

Tip: Always check what your system needs for flow, pressure, and fluid type before you choose a valve.

When to Choose Motorized Ball Valve

Pick a motorized ball valve if your system needs strong and steady flow control. Here are the best times to use one:

- You have big pipes or high pressure.

- Your fluid is thick, dirty, or has small bits in it.

- You want the valve to open and close slowly to stop water hammer.

- You need to control the flow carefully, not just turn it on or off.

- You want to save energy by only using power when the valve moves.

- You want the valve to stay in place if the power goes out.

- You want the valve to last a long time and not need much fixing.

- You want to control fluids in big systems like water plants or factories.

A motorized ball valve gives you better control and works well in hard jobs. You can use it with many fluids, even ones with dirt. The design helps it last longer and not get clogged. If you need to control flow both ways, this valve is a good pick.

| Scenario | Why Choose Motorized Ball Valve? |

|---|---|

| High flow and pressure | Handles large volumes and strong pressure |

| Dirty or viscous fluids | Resists clogging, wipes itself clean |

| Precise flow control | Allows gradual, accurate adjustments |

| Power outage resilience | Holds position without power |

| Long-term savings | Lower maintenance and energy costs over time |

Note: Always make sure the valve material and actuator strength match your system’s pressure, temperature, and fluid for the best results.

When to Choose Solenoid Valve

Solenoid valves are best when you want fast, easy, and low-cost fluid control. Pick a solenoid valve if:

- Your system needs to turn on or off quickly, like in machines or dosing.

- You do not have much space and need a small, light valve.

- The fluid is clean and does not have dirt.

- You want to spend less money at the start.

- You want a valve that is easy to put in and fix.

- Your system uses short bursts of flow or switches a lot.

- You use the valve in HVAC, watering, or chemical dosing.

- You want the valve to go back to a safe spot if the power goes out.

Solenoid valves help you control flow fast and fit in small places. They are great for jobs where timing is important, like robots or automatic watering. You can also use them in systems that open and close many times each day.

Tip: Always make sure the valve material matches your fluid and the size fits your system to stop leaks or damage.

Use Cases

HVAC

Both motorized ball valves and solenoid valves are used in HVAC. Each one is good for different jobs. Solenoid valves help control refrigerant in air conditioners and fridges. You often see them near the expansion valve in the liquid line. This spot helps stop water hammer, which can break pipes. Solenoid valves work quickly and do not use much power. They are great when you need to turn flow on or off fast, like with refrigerant or fuel. Solenoid valves are also in heaters. They control gas or propane going to burners. The valve opens when it gets cold and closes when it gets warm again.

Motorized ball valves are best when you need a strong shut-off. They open or close with a simple turn. This gives you tight control and helps stop leaks. This is important in HVAC jobs that need to keep gases safe. Both types of valves must meet safety rules like ATEX and PED. These rules help keep things safe in tough places.

Tip: Use solenoid valves for fast on-off jobs. Pick motorized ball valves if you want tight, leak-proof control in your HVAC system.

Water Systems

Motorized ball valves work great in water systems. You can use them for drinking water, watering plants, or cleaning dirty water. These valves come in brass, stainless steel, or UPVC. Stainless steel is safe for drinking water. UPVC does not rust in dirty water. Motorized ball valves let lots of water move and only use power when moving. This saves energy and helps stop water hammer, which keeps pipes safe.

| Feature/Aspect | Motorized Ball Valves Details |

|---|---|

| Materials | Brass, 304 Stainless Steel, UPVC |

| Performance | High flow, energy efficient, anti-water hammer, long-lasting, low maintenance |

| Integration | Easy with automated systems, supports remote operation |

| Application Areas | Water treatment, irrigation, industrial automation, HVAC, chemical processing, wastewater management |

| Compared to Solenoids | Higher flow efficiency, better for large volumes, reduces water hammer |

You can use 3-way electric ball valves to move water between pipes. This stops mixing and lets you add chemicals safely. Using motorized valves with automation gives you better control and fewer mistakes.

Industrial

In factories, you need the right valve for your job. Motorized ball valves are good for high flow and high pressure. They work well with fluids that have dirt or bits in them. You can use them to control flow exactly and for jobs where fluid goes both ways. These valves come in many materials, so you can pick what works with your chemicals. You can also choose electric or pneumatic actuators and add manual controls if needed.

Solenoid valves are small and act fast. They are best for low flow and low pressure jobs, like safety shut-off or emergency vents. You see them in HVAC and places with little space. Solenoid valves switch on and off quickly and are good for jobs that need lots of cycles.

| Feature | Motorized Ball Valve | Solenoid Valve |

|---|---|---|

| Flow Capacity | High, for large volumes | Low, for small-scale flow |

| Pressure Rating | Handles high pressures | Limited to lower pressures |

| Response Time | Slower, seconds | Fast, milliseconds |

| Cycle Life | Moderate | High |

| Media Compatibility | Wide range, good for particulates | Best for clean fluids/gases |

| Power Outage Resilience | Holds position | Loses position |

Note: Use motorized ball valves for hard, high-flow jobs. Pick solenoid valves for quick, low-flow tasks in your factory system.

High Temperature and High Pressure Media

If you work with very hot or high-pressure fluids, you need a strong valve. Motorized ball valves are a good choice for these tough jobs. They can be made from metals like stainless steel, bronze, carbon steel, or special alloys such as Hastelloy. These materials help the valve handle very high pressure and heat. Some valves can take thousands of psi and very hot temperatures. You can pick how the valve connects to your pipes. There are threaded, flanged, or tri clamp ends. This helps you fit the valve into many kinds of systems.

Solenoid valves usually work best at lower pressures. Most can only handle a few hundred psi. They are often made from stainless steel or brass. These metals limit how much heat and pressure the valve can take. If you need to control steam, hot oil, or high-pressure gas, a motorized ball valve is usually safer.

Tip: Always check the valve’s pressure and temperature ratings before you use it. Pick materials like stainless steel or Teflon-coated alloys for tough jobs.

You should also think about the actuator. For high-pressure or high-temperature jobs, use actuators with the right voltage and torque. Some actuators have safety features that close the valve if the power goes out. This helps keep your system safe.

| Valve Type | Max Pressure Range | Material Options | Best For |

|---|---|---|---|

| Motorized Ball Valve | Hundreds to 10,000+ psi | Stainless steel, bronze, alloys | High temp/pressure, steam, oil |

| Solenoid Valve | Up to several hundred psi | Stainless steel, brass | Lower temp/pressure, clean fluids |

Corrosive and Acidic/Alkaline Media

Fluids like acids or alkalis can hurt many valves. You need to choose the right materials to keep your system safe. Both motorized ball valves and solenoid valves need strong, non-reactive materials for these jobs.

- Stainless steel 316L works well with acids and fluids with chloride.

- Hastelloy, a nickel alloy, is good for strong chemicals and high heat.

- PTFE (Teflon) and PVDF are good for seals and parts that touch the fluid.

- Do not use brass for strong acids or alkalis because it can corrode fast.

You should also check the inside parts of the valve. Seats, stems, and packing must resist chemical attack. Some valves have special coatings or smooth finishes to stop corrosion.

Note: Always match the valve material to your fluid. This helps stop leaks, keeps your fluid clean, and makes the valve last longer.

Keep your valves clean and check them often. Cleaning-in-place and regular checks help you find problems early. Always follow the maker’s instructions for care and cleaning.

Powder and Particulate Media

Powders and fluids with dirt or sand can clog valves. This is a big problem for solenoid valves. Dirt can get inside and make the moving parts stick. If the valve is not used for a long time, dirt and water can make it fail. You can use filters before the valve to catch dirt. Dust covers and special seals also help keep out debris.

Motorized ball valves handle dirt better. The ball wipes itself clean as it turns. This helps clear away dirt. Still, you should clean the valve and check for blockages during regular maintenance.

- Put filters (like 25-micron or finer) before the valve.

- Use dust covers and protective covers for solenoid valves.

- Lubricate moving parts with the right oil to stop sticking.

- Check valves at least once a year, or more often in dirty places.

Tip: Place valves upright with the moving part facing up. This helps stop dirt from settling inside.

If you keep your valves clean and use the right protection, you can avoid most clogging problems and keep your system working well.

Chemical Coatings and Paint Applications

When you work with chemical coatings or paint, you need a valve that can handle tough fluids. Paints and coatings often have solvents, pigments, and thick materials. These can clog or damage many valves. You want to pick the right valve to keep your system running smoothly.

Motorized ball valves work well in paint and coating systems. The ball inside the valve turns and wipes itself clean. This action helps prevent buildup from sticky or thick fluids. You can use these valves with many chemicals if you choose the right materials. Stainless steel and PTFE (Teflon) seats resist most solvents and acids found in coatings. You can also find ball valves with special coatings for extra protection.

Solenoid valves can work in some paint systems, but you need to be careful. Many solenoid valves have small openings. Thick paint or coatings can clog these parts. If you use a solenoid valve, pick one with a large orifice and strong materials like stainless steel or PTFE. You should avoid using solenoid valves with heavy or gritty coatings.

| Valve Type | Best For | Key Material Options | Clogging Risk | Maintenance Needs |

|---|---|---|---|---|

| Motorized Ball Valve | Thick, sticky, or gritty fluids | Stainless steel, PTFE | Low | Moderate |

| Solenoid Valve | Thin, clean coatings | Stainless steel, PTFE | High | Frequent |

Tip: Always check the chemical compatibility chart for your valve materials. Some solvents or pigments can damage seals or metal parts.

You should also think about cleaning. Paint and coatings can dry inside a valve if you do not flush the system. Motorized ball valves are easier to clean because you can open them fully. This lets you flush out any leftover paint. Solenoid valves may trap paint in small spaces, which can lead to clogs.

Best practices for paint and coating systems:

- Use valves with smooth, non-stick surfaces.

- Flush the system after each use to remove leftover paint.

- Inspect seals and seats often for wear or swelling.

- Choose valves with easy-to-replace parts.

If you need to automate your paint line, motorized ball valves give you better control and last longer with thick or gritty coatings. Solenoid valves work best for fast on-off control with thin, clean fluids. Always match the valve type and material to your paint or coating for the best results.

Pick a motorized ball valve if you need to move lots of fluid, have dirty fluids, or want to save energy. Solenoid valves are better for quick on-off jobs and for small, clean systems. Always look at what your system needs before you pick a valve. Think about how long it takes to install and how much it costs. If you are not sure about which valve to use or how to put it in, ask a supplier or an expert for help.

FAQ

What is the main difference between a motorized ball valve and a solenoid valve?

You control a motorized ball valve with an electric motor. You control a solenoid valve with an electromagnetic coil. Motorized ball valves work well for high flow and dirty fluids. Solenoid valves switch faster and fit small spaces.

Can I use a solenoid valve for dirty or thick fluids?

You should avoid using solenoid valves with dirty or thick fluids. Dirt or debris can clog the small openings. Motorized ball valves handle these fluids better because the ball wipes itself clean as it turns.

Which valve saves more energy in long-term use?

Motorized ball valves save more energy over time. They only use power when opening or closing. Solenoid valves need power the whole time they stay open or closed. This can increase your energy costs.

How do I choose the right valve size for my system?

Check your pipe size and flow needs. Use the valve’s flow chart or ask your supplier for help. Pick a valve that matches your system’s pressure and flow rate. Always check the valve’s material for compatibility with your fluid.

What happens if the power goes out?

A motorized ball valve stays in its last position during a power outage. A solenoid valve returns to its default state, usually closed. For safety, always plan for power loss in your system.

Are these valves easy to install?

Solenoid valves are usually easier and faster to install. They are small and light. Motorized ball valves take more time because they have more parts and need wiring. Always follow the manufacturer’s instructions.

Can I use these valves for both liquids and gases?

Yes, you can use both types for liquids and gases. Always check the valve’s rating and material. Some valves work better with certain fluids or gases. Ask your supplier if you are unsure.

How often should I maintain these valves?

You should check solenoid valves every 6 to 12 months. Clean and inspect them for wear. Motorized ball valves need less frequent checks. Inspect seals and seats regularly for leaks or damage.