Choosing the right valve starts with knowing your system. Water, gas, and oil each have special needs. You must match the control valve to the media, pressure, and temperature. The valve must handle what it will face. For safety, you may pick a pneumatic control valve. You might use a pneumatic ball valve in dangerous places. If you need exact electric control, use an electric ball valve. It gives steady performance and works well.

Key Takeaways

- Always pick a control valve that fits the fluid type. Make sure it matches the pressure and temperature. This keeps things safe and helps the system work well.

- Pick the valve type your system needs. Use globe valves for control. Use ball valves for high pressure. Use butterfly valves for big pipes.

- Figure out the flow rate and Cv before picking a valve size. This helps you avoid flow problems and saves energy.

- Try to keep valve openings between 50% and 70%. This gives better control and makes the valve last longer.

- Choose valve materials that do not rust or wear out fast. This is very important with harmful fluids like oil or chemicals.

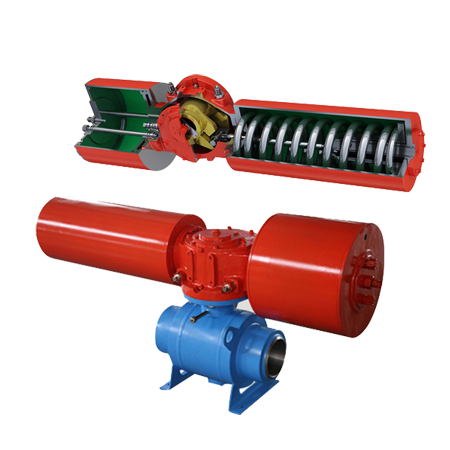

- Think about actuator types for your system. Pneumatic actuators are good for safety. Electric ones are good for accuracy. Hydraulic ones are strong.

- Check and maintain your valves often. This helps them work well and stops expensive problems.

Control Valve Basics

What Is a Control Valve

A control valve helps you control how liquids or gases move. You can open, close, or change how much goes through pipes. This keeps the system safe and steady. Picking the right control valve makes sure everything works well.

Functions in Fluid Systems

Control valves do many important things in a fluid system. Here are the main jobs:

- They help control how much material and energy moves.

- They keep flow rate and pressure steady.

- Safety features, like fail-open valves, stop dangerous pressure.

- You pick the right size and features for good results.

- You can change flow to fit what the process needs.

- Sensors with control valves help keep the system safe.

Tip: Always make sure your control valve fits your system’s needs.

Types of Control Valves

There are different control valves for different jobs. Each type works best in certain places. The table below shows common types and how they are used:

| Valve Type | Typical Use Cases and Characteristics |

|---|---|

| Globe Valve | You use this to control flow, pressure, and temperature. It is the most common control valve in process systems. |

| Butterfly Valve | You pick this for big pipes in water, sewage, and food plants. It saves space and costs less. |

| Ball Valve | You use this where it is hot or under high pressure, like in power plants and oil and gas. It shuts tight and does not leak. |

| Eccentric Plug Valve | You choose this when you need it to last long and be small. It works well where the stem seal must last. |

| Hydraulic Actuated Valves | You use these in very safe systems, like steam pipes and emergency shut-off in factories. |

Pneumatic control Valves

Pneumatic control valves work fast and are reliable. They use air pressure to move the valve. They are good for places where safety matters, like chemical plants.

Electric control valve

Electric control valves give you exact control. They use an electric motor to move the valve. They work well and are easy to use with automated systems.

Self-operated temperature control valve

Self-operated temperature control valves change by themselves when the temperature changes. They do not need outside power or signals. They help keep the system at the right temperature.

Self-operated pressure control valve

Self-operated pressure control valves keep pressure steady on their own. They sense pressure and adjust themselves. You use them in water supply and heating systems.

3 way control valve

A 3 way control valve mixes or splits flows in a system. It has three ports and can send flow in different ways. It is helpful in heating, cooling, and mixing jobs.

Media and Application Factors

Water, Gas, and Oil Differences

When picking a control valve, you need to know about the fluid. Water, gas, and oil are different in many ways. These differences change how you size and pick the valve. They also affect flow, pressure, and what the valve is made of.

Water Specific Gravity and Density

Water is used as the base for specific gravity, which is 1.0. It is denser than oil and gas. Most water systems use standard materials. But salt water or chemicals may need special coatings or elastomers. Water’s density helps you figure out the valve flow coefficient (Cv). This helps you choose the right valve size.

Gas Specific Gravity and Density

Gases are much less dense than liquids. Gas can be squeezed, so you need special sizing steps. If gas pressure is over 300 psi, you need a high-pressure control valve. Lower pressures can use regulators. Because gas is not dense, you must check pressure ratings and material safety.

Oil and Hydraulic Specific Gravity and Density

Oil is less dense than water, but it can be thick or thin. Oil’s thickness changes how it moves through a valve. You must think about thickness because it affects wear, leaks, and repairs. Oil and gas can have harmful things like carbon dioxide, hydrogen sulfide, and chlorides. These can hurt valves, so you need materials that do not rust.

Note: Oil processing uses many valve types because the fluid changes at each step. You must match the valve and its material to the oil or gas at each stage.

Here is a table to help you compare the main properties:

| Property/Aspect | Water | Oil | Gas | Impact on Valve Selection |

|---|---|---|---|---|

| Specific Gravity | 1.0 | <1.0 (varies) | Much lower | Changes Cv math and flow rate conversion. |

| Density | High | Lower | Very low | Affects valve size and what it is made of. |

| Fluid Phase | Liquid | Liquid | Gas | Gas needs special pressure ratings and sizing. |

| Material Choice | Standard or coated | Corrosion-resistant | Gas-compatible | Harmful fluids need special coatings or alloys. |

- Fluid thickness changes flow and valve wear.

- Harmful stuff in oil and gas can break valves.

- You must pick materials that do not rust for safety and long life.

Water Vapor and Steam

Water vapor and steam need special care. These fluids work at high heat and pressure. You must pick valves and materials that can handle these tough jobs. For steam, globe valves give good control. Ball valves shut tight and work well at high heat and pressure. Butterfly valves are small and good for changing flow, but not as exact.

| Valve Type | Special Considerations for Steam and Water Vapor |

|---|---|

| Globe Valve | Good control, handles high heat and pressure |

| Ball Valve | Tight shut-off, easy to use, not for slurries |

| Butterfly Valve | Small, good for changing flow, not as exact |

| Diaphragm Valve | Good for clean use, but not for high heat |

Tip: Always check the valve’s material and actuator for steam. Steel or stainless steel are best. Make sure the actuator can take the heat and pressure.

Application Scenarios

You will see many situations in water, gas, and oil systems. For water, you may need valves that do not rust in saltwater or chemical plants. For gas, you must use strong valves in pipelines. Oil systems need valves that can handle thick fluids and harmful stuff. Always match the valve to the fluid and the system’s needs. This helps you pick the right valve and keeps your system safe and working well.

Control Valve Selection Criteria

Pressure and Temperature

High vs. Low Pressure (Gas: 300 psi, Liquid: 500 psi)

You must always check the pressure rating before picking a control valve. High-pressure systems, like gas at 300 psi or liquid at 500 psi, need extra care. These systems use valves made from strong materials. Stainless steel, alloy steels, and titanium are often used. These materials do not rust and can handle strong forces. High-pressure valves often have bolted bonnet, welded bonnet, or pressure seal designs. Threaded connections are not good because they might leak under high pressure.

- High-pressure valves need:

- Strong, rust-proof materials

- Bodies with bolted or welded bonnets

- Actuators powered by electric, hydraulic, or pneumatic systems

- Flow paths that lower turbulence and pressure drop

Low-pressure systems do not need such tough materials. You can use simpler valve designs and manual actuators. ASME B16.34 class ratings help you pick the right valve for your system’s pressure and temperature.

Temperature Ranges

Temperature rating is also important when picking a control valve. You must know the highest and lowest temperatures your system will reach. High heat can make some materials weak and cause leaks. For hot water, steam, or oil, use valves made from steel or special alloys. For cold systems, make sure the valve does not get brittle. Always check the maker’s temperature limits for each valve.

Flow Rate and Cv

Flow Rate Determination

You need to know the flow rate before picking a control valve. Flow rate tells you how much water, gas, or oil moves in a set time. You measure flow rate in gallons per minute (GPM) for liquids or standard cubic feet per hour (SCFH) for gases. Flow rate changes the size and type of valve you need. If the valve is too small, you will not get enough flow. If it is too big, you lose control and waste energy.

Cv Calculation and Sizing

The flow coefficient, or Cv, helps you pick the right valve size. Cv shows how much flow passes through a valve at a set pressure drop. For liquids, you use flow rate, pressure drop, and specific gravity in the formula. For gases, you also think about compressibility and temperature. You want a valve with a Cv equal to or just above your calculated value.

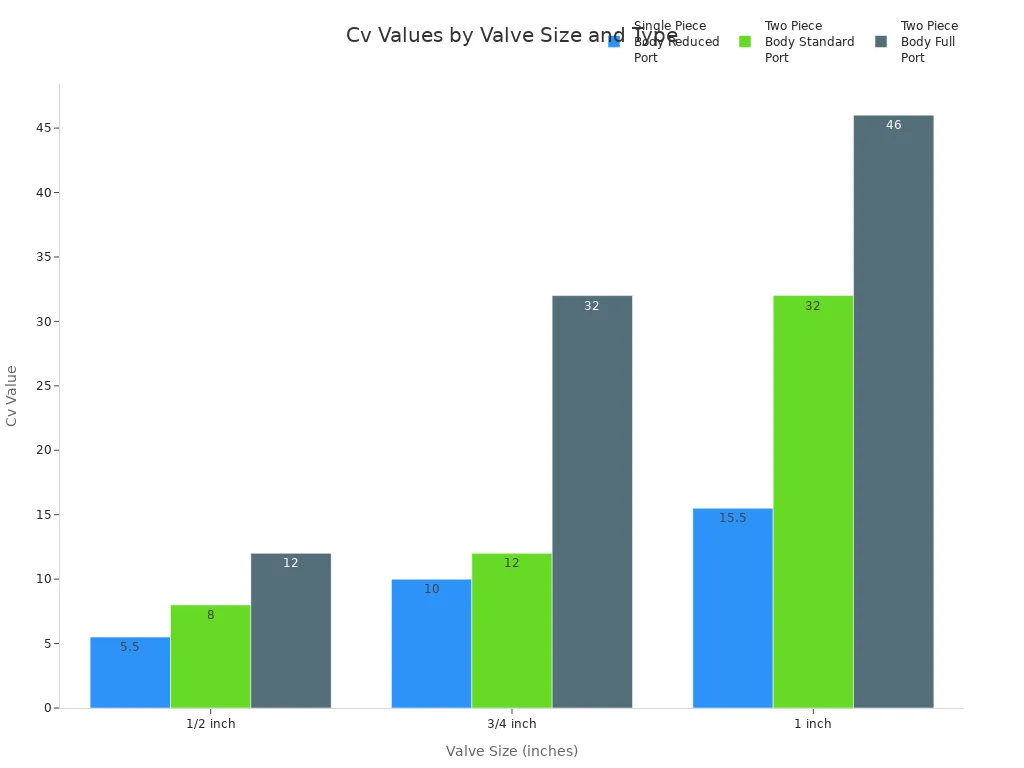

Here is a table to help you compare Cv values for different valve sizes and types:

| Valve Size (inches) | Single Piece Body Reduced Port | Two Piece Body Standard Port | Two Piece Body Full Port |

|---|---|---|---|

| 1/2 | 5.5 | 8 | 12 |

| 3/4 | 10 | 12 | 32 |

| 1 | 15.5 | 32 | 46 |

You can also see how Cv values change with valve size and type in this chart:

Picking the right Cv makes sure your valve meets your system’s flow needs. This step is very important for good and safe performance.

Tip: Always pick a valve with a Cv a little higher than your lowest need. This helps you control flow better and stops pressure drops.

Valve Opening Range

Optimal Opening Percentages

You want your control valve to work in its best range. Most valves work well when open between 50% and 70%. This range gives you steady flow, good efficiency, and a long valve life. Linear valves work best between 40% and 60% open. If you open a valve more than 80%, you might get turbulence and extra wear. If you keep the valve too closed, you lose control and might hurt the valve.

- Best ways to use valve opening:

- Keep most valves between 50% and 70% open

- Use 40% to 60% for linear valves

- Do not open above 80% to stop stress and noise

- Pick a valve size so it works in this range most of the time

Things like system pressure, fluid type, and pipe resistance change the best opening range. Good valve choice and sizing help you keep the valve in its best range. This makes flow control better and helps your system last longer.

Note: Fewer valve moves mean less wear and more steady performance.

Flow Characteristics

Equal Percentage vs. Linear

It is important to know how a valve changes flow when you open it. This is called the valve’s flow characteristic. There are two main types: equal percentage and linear.

| Valve Characteristic | Typical System Conditions | Impact on Process Control | Valve Selection Guidance |

|---|---|---|---|

| Equal Percentage | The pressure across the valve changes as flow changes. This happens in systems with big pressure drops in pipes or pumps. | This type helps keep flow steady even if pressure changes. You get better control over the whole range. | Pick this for systems where pressure changes a lot. It helps you keep flow smooth and steady. |

| Linear | The pressure across the valve stays about the same as flow changes. This happens in systems with steady pressure. | The flow goes up in a straight line as you open the valve. This makes control easy when pressure does not change much. | Use this when your system has steady pressure. It gives you simple and steady control. |

The flow characteristic you choose affects how well you can control your system. Equal percentage valves work best when pressure changes as flow increases. They help you get a steady response, which is important for good control. Linear valves work best when pressure stays the same. If you pick the wrong type, your system may be hard to control or slow to react.

Tip: Always pick a valve flow characteristic that matches your system’s pressure and flow needs. This helps keep your process safe and steady.

Cavitation and Flashing

Cavitation and flashing can hurt your control valves. You need to know what causes them and how to stop them.

| Issue | What Happens | What Causes It | Effects on Valve | How to Reduce Damage |

|---|---|---|---|---|

| Cavitation | Bubbles form inside the valve and then pop. | Pressure drops below the liquid’s vapor pressure, then goes up again. | Loud noise, shaking, and rough spots inside the valve. | Use globe valves or special trims. Pick strong materials. Raise pressure before the valve or lower fluid temperature. |

| Flashing | Bubbles form and stay as vapor after the valve. | Pressure after the valve stays below vapor pressure. | Smooth, shiny wear inside the valve. Damage is slower than cavitation. | Use valves with high recovery factor. Pick hard materials. Control pressure and temperature. |

Cavitation happens when pressure inside the valve drops so low that vapor bubbles form. These bubbles pop when pressure rises again, making noise and causing damage. Flashing happens when pressure stays low, so bubbles do not pop but leave with the liquid. Both problems can wear out your valve and make it noisy.

You can stop these problems by picking the right valve type and material. Globe valves and special trims help control pressure drops. Hard materials like stainless steel last longer. You can also move the valve or change pressure and temperature.

Note: Cavitation and flashing can make your valve noisy and unsafe. Always check your system’s pressure and temperature to avoid these problems.

Noise Considerations

Control valves can make a lot of noise. This noise comes from air or gas moving fast, turbulence, and shock waves inside the valve. High flow speeds make the noise even louder.

- Main sources of valve noise:

- Air and gas moving through the valve and pipes.

- Turbulence when pressure changes quickly.

- Shock waves at high pressure.

- High flow speeds make noise much louder.

You can lower valve noise by using special designs and materials. Here are some ways to make valves quieter:

- Split the flow into smaller streams to lower noise.

- Use valves that drop pressure in steps, not all at once.

- Make the valve outlet bigger to slow down the flow.

- Add diffusers or silencers to the pipes.

- Use thicker pipes to stop shaking.

Valve makers use special software and follow rules from groups like the International Electrotechnical Commission to predict and control noise. You should always think about noise when you pick a valve, especially in places where people work nearby.

Tip: Lowering valve noise keeps your system safe and helps your equipment last longer.

Material and Design Considerations

Material Compatibility

You must pick a valve material that matches your fluid. Different fluids can react with metals and plastics in different ways. If you choose the wrong material, leaks or damage can happen. This could even make your system stop working. Always check what is in your water, gas, or oil. Some fluids, like acids or chlorinated water, can harm regular metals. Stainless steel and nickel alloys are good for many fluids. They do not rust and last a long time. For strong chemicals, you might need special plastics like PTFE or PVDF. These plastics can handle strong acids and bases. You also need to think about heat and pressure. Some plastics melt or get weak if it gets too hot. Metals like titanium or Hastelloy can take both heat and chemicals. Always make sure the material fits your fluid and system conditions.

Corrosion and Wear

Corrosion and Corrosion happens when fluids eat away at metal parts. Wear happens when moving parts rub or grit scratches the valve. Both problems can cause leaks or make the valve stick. You can lower these risks by picking the right material. The table below shows which materials work best with different corrosive fluids:

| Corrosive Media | Recommended Valve Materials |

|---|---|

| Sulfuric acid | Stainless steel (SS316), Hastelloy, PTFE, Viton, Ceramic |

| Hydrochloric acid | PVDF, PTFE, Hastelloy C, Titanium |

| Nitric acid | Hastelloy C, Titanium, Zirconium, Stainless steel, PTFE, FKM |

| Chlorine | Hastelloy C-276, Titanium, Monel, PVC |

| Ammonia | Stainless steel 316, PTFE |

| Alcohols, Ketones | Stainless steel (alcohols); consult manufacturers for ketones and esters |

Oxygen differential cell corrosion can happen in valves. This happens when oxygen levels change in small spaces. It makes metal break down faster. Crevice corrosion can hide under insulation or coatings. Corrosion fatigue is another problem. It happens when stress and a corrosive fluid work together. This can crack the valve faster than normal. Sometimes, one metal in an alloy gets removed, like zinc from brass. This makes the valve weaker. To stop these problems, use materials that do not rust. Avoid sharp corners and lower stress on the valve. Special coatings and alloys can also help your valve last longer.

Severe Service and Special Designs

Some systems need valves that can handle very tough jobs. High pressure, high heat, and strong chemicals put extra stress on valves. You need special designs for these hard jobs. Here are some features you should look for:

- Valves made from strong alloys or stainless steel to stop rust and wear.

- Special coatings or hard sleeves to protect against scratching and wearing down.

- Designs like Straight-Thru Venturi valves to control cavitation, flashing, and turbulence.

- Inlet and outlet nozzles to help move fluid and lower noise.

- Tight shutoff features that get stronger as pressure goes up.

- High turndown ratios for good control, even at low flow.

- Construction that meets strict safety and reliability standards.

You find these features in valves for oil and gas, power plants, and chemical plants. Some valves can handle pressures up to 16,000 psig and heat over 800oF. Others use special trims or coatings to survive rough slurries. Always pick a valve with the right design for your system’s hardest jobs. This helps your valve last longer and work its best.

Valve core and valve seat selection

Single-seat control valve

A single-seat control valve is good for tight shut-off. It gives you precise control. This valve has one plug and one seat. The design is simple and easy to fix. It does not cost much. The sealing is very good, so leaks are rare. These valves work best with low pressure and small flow. They are used when you need strong sealing. You see them in water treatment and chemical dosing.

Advantages of single-seat control valves:

- Excellent sealing and tight shut-off

- Good for precision control

- Simple structure and lower cost

- High leakage tightness for strict requirements

Disadvantages:

- Limited ability to handle high pressure differences

- Smaller flow capacity

- Needs a larger actuator for operation

Tip: Pick single-seat valves for low pressure and small flow. Use them when sealing is very important.

Double-seat regulating valve

Double-seat regulating valves have two plugs and two seats. This design helps balance the inside forces. You can use these valves with higher pressure and bigger flow. The balanced design means less force is needed to move the valve. This is true even when pressure is high. But double-seat valves do not seal as tightly. You may see more leaks. They are not best for perfect shut-off.

Advantages of double-seat regulating valves:

- Handles higher pressure differentials (up to 280 kPa for DN100)

- Larger flow capacity (20%-50% higher than single-seat)

- Minimal unbalanced force due to balanced plugs

- Suitable for larger valves and high flow

Disadvantages:

- Higher leakage due to the design

- Not suitable for strict shut-off needs

- More complex flow path can lead to erosion

- Sealing limited to metal materials

Note: Double-seat valves are good for high flow and high pressure. Do not use them if you need tight shut-off.

Sleeve regulating valve

Sleeve regulating valves use a sleeve to guide the plug. This helps control the flow. They handle higher pressure better than single-seat valves. The sealing is still good, like single-seat valves. Sleeve valves are good if you need to control higher pressure. They are okay if you can accept a small loss in control accuracy.

Advantages of sleeve regulating valves:

- Improved pressure differential handling

- Good sealing, similar to single-seat valves

- Better economy for some applications

Disadvantages:

- Poorer linearity, which can affect control accuracy

- Limited temperature resistance

- Slightly higher cost than single-seat valves

Here is a table to help you compare these three valve types:

| Valve Type | Advantages | Disadvantages | Application Scenarios |

|---|---|---|---|

| Single-Seat Valve | Excellent sealing, precision control, simple and cost-effective | Limited pressure handling, smaller flow, needs large actuator | Low pressure, small flow, strict sealing needs |

| Double-Seat Valve | Handles high pressure, large flow, balanced operation | Higher leakage, not for strict shut-off, erosion risk | High flow, high pressure, where tight shut-off is not critical |

| Sleeve Regulating Valve | Better pressure handling, good sealing, improved economy | Poorer linearity, limited temperature resistance, higher cost | Medium to high pressure, where some loss in control accuracy is acceptable |

Remember: Always pick the valve type that fits your system’s pressure, flow, and sealing needs. This helps your system work well and last longer.

Labyrinth valve seat

A labyrinth valve seat helps you control very high pressure drops in your system. You see this design in places where normal valves would wear out fast. The labyrinth seat uses a special path inside the valve. This path makes the fluid twist and turn many times before it leaves the valve. Each turn takes away energy from the fluid. This helps stop problems like cavitation, noise, and vibration.

How does a labyrinth valve seat work?

You find many small grooves or channels inside the valve seat. When fluid enters, it must move through these winding paths. The fluid slows down step by step. This design spreads out the pressure drop over many stages. You do not get one big drop in pressure. Instead, you get many small drops. This keeps the fluid from flashing or forming bubbles.

Tip: If you have high pressure and want to stop noise or damage, pick a labyrinth valve seat.

Advantages of labyrinth valve seats:

- You get less noise because the fluid slows down gently.

- The valve lasts longer since it stops cavitation and wear.

- You can use it with gases, steam, or liquids.

- It works well in severe service, like power plants or oil refineries.

Disadvantages:

- The design costs more than simple valve seats.

- Cleaning can be hard if your fluid has dirt or solids.

- You may need more space for the valve.

Here is a table to help you see when to use a labyrinth valve seat:

| Situation | Is Labyrinth Valve Seat a Good Choice? |

|---|---|

| High pressure drop | ? Yes |

| Cavitation risk | ? Yes |

| Clean fluids | ? Yes |

| Dirty or solid-filled fluids | ? No |

| Need for low noise | ? Yes |

You often see labyrinth valve seats in these places:

- Steam control in power plants

- High-pressure gas pipelines

- Oil and gas production

- Chemical plants with tough fluids

Note: Always check your fluid type before choosing a labyrinth valve seat. If your fluid has solids, you may need a different design.

A labyrinth valve seat gives you strong control and long life in tough jobs. You can trust it to keep your system safe and quiet.

Balanced valve core

A balanced valve core helps control high pressure and big flow. You see this design in many control valves for water, gas, and oil. The balanced core has holes or channels. These let pressure push on both sides of the valve plug. This makes it easier to move the valve. You can use a smaller actuator. This saves space and money.

How does a balanced valve core work?

The balanced core has a plug with holes or a special shape. When fluid moves through the valve, pressure pushes on the top and bottom of the plug. The forces almost cancel each other out. You do not need a strong actuator to open or close the valve. This makes the valve easy to control, even with high pressure.

Tip: Pick a balanced valve core if your system has high pressure or big flow. You will get smoother control and less wear on the actuator.

Key Advantages of Balanced Valve Cores

- Needs less force to move the valve plug.

- Uses smaller and cheaper actuators.

- Gives better control in high-pressure systems.

- Causes less wear on valve parts.

- Works well for large valves and big flows.

Disadvantages to Consider

- Sealing is not as tight as single-seat valves.

- More parts mean more things to check when fixing.

- Not the best if you need zero leaks.

When should you use a balanced valve core?

Pick a balanced valve core when your system has:

- High pressure drops across the valve.

- Large flow rates.

- Not much room for big actuators.

- Need for steady control with less effort.

You often see balanced valve cores in:

- Steam and gas control systems.

- Oil pipelines.

- Power plants.

- Chemical plants.

Here is a table to help you compare balanced and unbalanced valve cores:

| Feature | Balanced Valve Core | Unbalanced Valve Core |

|---|---|---|

| Force needed to operate | Low | High |

| Actuator size | Small | Large |

| Sealing performance | Moderate | Excellent |

| Best for | High pressure, big flow | Low pressure, tight shut-off |

| Maintenance | More complex | Simple |

Note: Always check your system’s pressure and flow before picking a valve core. A balanced core gives you better control in hard jobs, but you may need to check the sealing if leaks matter.

A balanced valve core helps you handle tough jobs with less effort. You get smoother operation and longer valve life. If you want easy control in a high-pressure system, this design is a smart choice.

Installation and Maintenance

End Connections

You have to pick the right end connection for your control valve. The end connection changes how you put in, take out, and fix the valve. Each type has good and bad points. Here is a table to help you see the main types:

| Connection Type | Advantages | Disadvantages | Installation and Maintenance Impact |

|---|---|---|---|

| Flanged | Easy to put in and fix, seals well, works for high pressure or heat | Costs more, needs more room | Simple to take apart and put back, great for regular fixing |

| Threaded | Simple, cheap, seals well for low pressure | Not for high pressure or heat, may need tightening | Fast to put in; needs checks and sometimes tightening |

| Welded | Strong, no leaks, no gaskets or bolts, stands up to shaking | Needs skilled workers, takes longer, hard to remove | Hard to fix or swap; best for setups that stay the same |

| Socket Weld | Easier to take apart than welded, seals well, works for high pressure | Needs more space, can get weak over time | Easier than welded for fixing, but still needs skill |

| Compression | Easy to put in, quick to take out, seals well for medium pressure | Not for high pressure or heat, needs checks | Easy to put in and take out, good if you take it apart a lot |

You should always match the end connection to your system’s pressure, heat, and how you want to put it in. Flanged connections are good if you need to take the valve out to clean or fix it. Welded connections are best if you want a joint that will not leak and will stay in place.

Tip: If you plan to do a lot of fixing, pick a connection that is easy to take off and put back.

Actuation Methods

You need to choose the right way to move your control valve. The actuator opens or closes the valve. Your choice depends on how fast you want the valve to move, how much force you need, and what power you have. Here are the main types:

| Actuation Method | Description | Advantages | Disadvantages | Influencing Factors |

|---|---|---|---|---|

| Pneumatic | Uses air pressure | Fast, simple, safe in places with explosion risk, not expensive | Not as exact, needs air, might leak | Speed, force, air, safety, cost |

| Electric | Uses electric motors | Exact, easy to use, no exhaust | Needs power, costs more, harder to fix, not for places with explosion risk | Exactness, power, safety, cost |

| Hydraulic | Uses liquid pressure | Strong force, exact, good for big valves | Complicated, might leak, needs special liquids | Strong force, pressure, fixing, safety |

Think about where you work. If there is a risk of explosion, pneumatic actuators are safer. If you need very exact control, electric actuators are best. For big valves or high pressure, hydraulic actuators give the most force.

Note: Always check if you have the right power or air before you pick an actuator.

Maintenance Needs

You must keep your control valves in good shape so they work safely and well. Good care stops leaks, breakdowns, and big repair bills. Here are some good ways to take care of valves:

- Turn off flow and let out pressure before you start.

- Look for leaks, rust, worn spots, and loose parts.

- Clean all parts with the right cleaner. Do not use strong chemicals.

- Dry all parts before you put the valve back together.

- Oil moving parts with the right oil, but do not use too much.

- Only use oils that work with your fluid or gas.

- Check valves often for wear, leaks, and rust.

- Watch how the valve works. Check flow, pressure, and heat. Fix problems fast.

- Write down all checks, fixes, and parts you change.

- Teach your team how to use and care for valves safely.

- Follow the maker’s rules for tightening, oiling, and changing parts.

- Change seals, gaskets, or O-rings if you see problems.

- Test the valve after fixing by opening and closing it slowly. Watch for leaks or strange sounds.

Tip: Doing regular care helps your valves last longer and keeps your system safe.

System Integration

When you put in a control valve, you need to see how it fits with the whole system. Good system integration helps your valve work well with other parts. Your control valve should connect with sensors, controllers, and actuators. This makes your process safe and simple to manage.

Key Parts of System Integration:

- Sensors

Sensors check things like flow, pressure, and temperature. You connect these sensors to your control valve. The valve uses this data to open or close at the right time. For example, a flow sensor tells the valve when to let more water pass. - Controllers

Controllers are like the brain of your system. They get information from sensors and send signals to the valve. You can use simple controllers or advanced ones like PLCs. The controller helps keep the process steady. - Actuators

Actuators move the valve open or closed. You can use pneumatic, electric, or hydraulic actuators. The actuator must fit your system’s needs. If you need fast movement, pick a pneumatic actuator. - Communication

Your system may use digital or analog signals. You must check that your valve and controller use the same kind. Common signals are 4-20 mA, 0-10 V, or digital types like Modbus. Matching signals helps your system work smoothly.

Tip: Always check the wiring and signal type before you hook up your valve.

Table: Common Integration Points

| Component | What It Does | Why It Matters for Valves |

|---|---|---|

| Sensor | Measures flow, pressure | Tells valve when to move |

| Controller | Sends commands | Controls valve position |

| Actuator | Moves the valve | Opens or closes the valve |

| Network | Shares data | Links all parts for fast response |

Best Practices for System Integration:

- Test all wires before you start the system.

- Use shielded cables to block electrical noise.

- Label wires and ports for easy fixing.

- Keep a wiring diagram for your team.

- Update software and firmware when needed.

You should plan your system integration before you put in the valve. This helps you avoid mistakes and keeps your process safe. Good integration lets you control flow, pressure, and temperature with less work. You also get better data for tracking and fixing problems.

Note: If you are not sure about wiring or signals, ask an expert. Good system integration saves time and money later.

Common Mistakes and Best Practices

Selection Errors

You can stop many problems if you watch for common mistakes. Some people pick a valve just because of size or price. This can cause leaks or bad control. Sometimes, the whole system can fail. You should always match the valve to your fluid, pressure, and temperature. If you do not check if the material fits, the valve can rust or wear out fast. Some people forget to figure out the right Cv or do not check the best opening range. This can make the valve work outside its best zone. That lowers how well it works and makes it wear out faster.

Common mistakes to avoid:

- Picking a valve just for size or cost

- Not thinking about the fluid or temperature

- Skipping the Cv math or sizing step

- Not checking if the material fits the media

- Using the wrong flow type for your system

Tip: Always use a step-by-step way to pick a control valve. This helps you stop mistakes and keeps your system safe.

Reliability Tips

You can make your valves safer and last longer by using best practices. Experts say you should do a few things to keep valves working well.

- Train your team: Make sure workers learn how to use and care for valves. Show them safe ways to handle and fix valves.

- Do regular maintenance: Check, test, and clean valves on a set schedule. Look for leaks, worn parts, or other problems before they get worse.

- Use smart tools: Add sensors and monitors. These can warn you early if something is wrong and help you make good choices.

- Plan your system well: Pick the right valve type and size. Set up your control loops and use backup systems if you need them.

- Think about safety: Teach your team what to do in an emergency. Show them how to work with dangerous fluids. Make sure everyone wears the right safety gear.

Note: Good training and regular checks help you find problems early. This keeps your system running well and safely.

When to Consult Experts

Sometimes, picking a valve can be hard. You might see too many choices or have a special problem. In these times, you should ask an expert before you decide.

- If you feel lost with all the valve parts or designs

- When you need help to match the valve to your process

- After you know your system’s needs but before you buy the valve

You can talk to your company’s engineers, other plants, or trusted valve makers. Industry meetings and groups can also help. Experts can help you compare choices and pick the best valve for your job.

Tip: Asking an expert early can save you time, money, and problems later.

You can select the right valve by looking at your system’s needs. Check the pressure, temperature, flow, and what fluid you use. Match the valve type, size, and material to your application. Use methods like STAMPED to guide your choice. If you face tough conditions, ask an expert. Apply these steps to keep your system safe and efficient.

FAQ

What is the most important factor when choosing a control valve?

You must always match the valve to your fluid type, pressure, and temperature. This step helps you avoid leaks and keeps your system safe.

Can I use the same valve for water, gas, and oil?

No, you should not use the same valve for all fluids. Each fluid has different needs. You must pick a valve that fits your specific application.

How do I know if my valve material is compatible with my fluid?

Always check the chemical properties of your fluid. Use charts from valve makers. Stainless steel works for many fluids, but some chemicals need special materials.

Why does valve sizing matter?

Valve sizing affects flow control and safety. If you pick a valve that is too small, you will not get enough flow. If it is too big, you lose control and waste energy.

What is the STAMPED method?

STAMPED stands for Size, Temperature, Application, Media, Pressure, End connections, and Delivery. You use this method to make sure you pick the right valve for your system.

How often should I maintain my control valves?

You should check your valves every few months. Look for leaks, rust, or worn parts. Regular checks help your valves last longer and work better.

What should I do if my valve makes noise?

Noise often means high flow speed or pressure drop. Try using a valve with a special trim or a larger outlet. You can also add a silencer.

When should I ask an expert for help?

If you feel unsure about valve selection, sizing, or material, ask an expert. Experts help you avoid mistakes and keep your system safe.