?

Knife gate valves are designed to deliver reliable sealing, but understanding the potential for leaks is key to ensuring their optimal performance. Factors like seal wear, improper installation, corrosive environments, and actuator malfunctions in pneumatic knife gate valves can lead to leakage. Preventive measures, including regular maintenance, selecting high-quality materials, and sourcing valves from trusted knife gate valve manufacturers, are essential. Opting for actuated gate valves, such as pneumatic models, further enhances control and minimizes risks of improper closure. By addressing these areas, industries utilize valve knife gate solutions with confidence, maintaining efficiency and durability in demanding applications.

Introduction

Knife gate valves are essential components in industrial systems where robust flow control and versatility are paramount. Designed with a sharp-edged gate, these valves are particularly effective at cutting through and isolating challenging media. Such as slurries, viscous fluids, and solids. Their unique design enables them to operate efficiently in tough environments, including those with high-solid-content media. Which would typically compromise standard valve performance.

They are widely employed in industries such as mining, wastewater treatment, pulp and paper, chemical processing, and power generation. Where handling abrasive or corrosive substances is routine. The simplicity and durability of their construction allow for reliable sealing, reduced maintenance, and excellent wear resistance, even under extreme conditions. By facilitating precise and dependable flow control, knife gate valves play a critical role in optimizing operational efficiency and ensuring the long-term reliability of industrial processes. Making them indispensable in demanding applications worldwide.

What Are Knife Gate Valves?

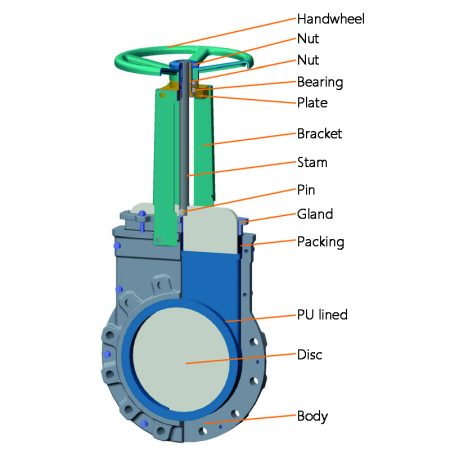

Knife gate valves are specialized flow control devices designed to manage the challenging demands of industrial applications. Their primary purpose is to regulate or isolate the flow of media, particularly in systems that handle high-solid-content materials like slurries, viscous fluids, and powders. The hallmark of their design is the sharp-edged gate, which allows the valve to “cut” through thick or abrasive media. Ensuring an effective seal and steady operation.

This gate slides into a seat to create a tight closure, preventing leaks even under high pressures. Unlike conventional valves, knife gate valves excel in handling tough, clog-prone environments. Making them indispensable in industries such as wastewater treatment, mining, and pulp and paper manufacturing. Their straightforward yet durable construction reduces blockages, ensures minimal pressure drop, and provides reliable performance in processes requiring precise flow control. By delivering consistent and efficient operation, these valves are critical for maintaining the functionality and productivity of heavy-duty industrial systems.

Do Knife Gate Valves Leak?

Knife gate valves are engineered with features that aim to minimize leakage and maintain optimal sealing under demanding conditions, but no valve is entirely immune to leakage. Their distinctive sharp-edged gate is designed to cut through media, ensuring a clean closure and reducing the risk of flow escaping. Many models are equipped with advanced sealing systems. Such as resilient or metal seats, to provide additional protection against leaks.

However, factors like wear and tear on the seals, improper installation, or operation in extreme conditions can compromise their integrity over time. High-solid-content media, abrasive substances, or frequent cycling of the valve are common stressors that may increase the likelihood of leakage. To mitigate these risks, regular maintenance is crucial to inspect and replace worn components before performance is impacted.

Additionally, sourcing valves from reputable manufacturers ensures that high-quality materials and precision engineering are employed, further enhancing the valve’s ability to prevent leaks. By combining robust design, proper upkeep, and quality manufacturing, industries can achieve reliable performance and minimize leakage in even the most challenging environments.

Common Reasons for Leaks in Knife Gate Valves

1. Seal or Packing Failure

Seals and packing in knife gate valves are critical components that ensure effective isolation and flow control, but continuous operation and exposure to abrasive media can lead to their gradual degradation. Over time, the friction generated by frequent cycling of the valve subjects the seals and packing to significant mechanical stress. Causing them to wear down. Similarly, when handling abrasive media such as slurries, sand, or particulate-laden fluids, these components face constant erosion. Which can compromise their ability to maintain a tight seal. This deterioration increases the risk of leaks, impacts the valve’s efficiency, and may even result in unplanned downtime if not addressed promptly. Selecting sealing materials that are specifically designed for high wear resistance and corrosive environments. Such as reinforced elastomers or advanced polymer compounds, is essential to mitigating these challenges.

Additionally, regular maintenance, including inspections and timely replacement of worn seals or packing, ensures the valve continues to perform reliably even in harsh conditions. Proper usage, such as adhering to recommended pressure and temperature limits, further extends the lifespan of these essential components. Helping industries maintain efficient and uninterrupted operations.

2. Improper Installation

Improper installation of knife gate valves, particularly issues like misalignment or incorrect torque application, can significantly compromise their ability to maintain a proper seal and result in leaks. Misalignment occurs when the valve is not correctly positioned within the pipeline. Leading to uneven pressure distribution and gaps between the sealing surfaces. Similarly, over-tightening or insufficient torque on bolts can distort the valve body or fail to generate the compression necessary for an effective seal. These installation errors not only increase the risk of immediate leakage but also accelerate wear on the seals and other critical components. Reducing the valve’s overall lifespan and operational reliability.

To avoid these problems, it is essential to follow manufacturer guidelines during installation. Ensuring proper alignment, application of the specified torque, and adherence to any additional instructions tailored to specific models or applications. Employing trained personnel and using appropriate tools can further enhance installation precision. Proper installation is a crucial step in optimizing the performance of knife gate valves. Enabling them to deliver reliable, leak-free operation in demanding industrial environments.

3. Material Corrosion or Wear

Knife gate valves operating in corrosive or high-pressure environments face significant challenges that can degrade their materials and compromise performance over time. Corrosive media, such as acidic or alkaline fluids, can trigger chemical reactions with the valve’s metal components. Leading to pitting, stress corrosion cracking, or general material loss, particularly in unprotected or incompatible materials. High-pressure conditions, on the other hand, subject the valve body and internal components to sustained mechanical stress. Which can result in material fatigue, deformation, or even structural failure under extreme circumstances.

The combination of chemical exposure and elevated pressure further accelerates the deterioration process, impacting the valve’s sealing integrity, efficiency, and overall reliability. To address these challenges, it is critical to select materials specifically engineered for durability in harsh conditions. Stainless steel alloys, nickel-based materials, or coated components offer enhanced corrosion resistance. While robust designs with reinforced bodies ensure the valve can withstand high-pressure loads. Additionally, advanced manufacturing processes and strict quality control measures further improve the valve’s structural integrity. Enabling long-term, reliable operation in the most demanding industrial applications.

4. Actuator or Pneumatic System Issues

Actuators play a pivotal role in the operation of pneumatic knife gate valves, providing the force necessary to move the sharp-edged gate for effective flow control. However, actuator malfunctions can significantly hinder the valve’s ability to achieve proper closure, compromising its performance and sealing capabilities. Common issues such as inconsistent or insufficient air supply can prevent the actuator from generating the required force to fully close the gate, leading to partial closure and potential leakage. Mechanical wear, including degraded seals within the actuator or corroded components, further exacerbates these problems by reducing the actuator’s efficiency and responsiveness.

These malfunctions not only affect the valve’s operational integrity but can also cause disruptions in industrial processes and increase maintenance costs. Regular maintenance, including inspection of air lines, lubrication of moving parts. And timely replacement of worn actuator components, is essential to ensuring reliability. Additionally, adhering to manufacturer-recommended operating conditions and employing skilled technicians for troubleshooting can help prevent actuator-related issues. Allowing pneumatic knife gate valves to deliver consistent and efficient performance in demanding applications.

Preventing Leaks in Knife Gate Valves

1. Routine Maintenance

Routine maintenance practices such as inspecting seals, lubricating components, and cleaning knife gate valves are essential for ensuring long-lasting, reliable performance. Regular inspection of seals allows for the early detection of wear, cracks, or other damage that could compromise sealing integrity and lead to costly leaks. Lubrication plays a vital role in minimizing friction and wear on moving parts, preventing mechanical strain. And allowing the valve to operate smoothly even under demanding conditions.

Thorough cleaning is equally important, as debris, scale, or other buildup can obstruct the gate movement or erode critical components, leading to performance inefficiencies and potential failures. These maintenance steps not only help prevent performance issues but also extend the overall lifespan of the valve. Reducing the need for premature part replacements or costly downtime. By adhering to a proactive maintenance schedule tailored to operating conditions, industries can safeguard the reliability of their knife gate valves. Ensuring consistent operation and reduced long-term costs.

2. Choosing High-Quality Materials

Corrosion-resistant materials and seals are fundamental to leak prevention in knife gate valves. Particularly in harsh environments where exposure to aggressive substances or extreme conditions is common. These materials, including alloys such as stainless steel or nickel-based compounds, are engineered to withstand chemical reactions that would typically degrade standard components. By resisting pitting, stress corrosion cracking, and other forms of material breakdown, corrosion-resistant materials help maintain the structural integrity of the valve under demanding conditions. Equally important are seals crafted from advanced, chemically inert materials like PTFE or elastomers, which provide robust sealing performance while resisting swelling, cracking, or degradation caused by exposure to corrosive media.

Choosing the right combination of materials for the valve body and seals tailored to the specific operating environment not only ensures long-term leak prevention but also reduces the need for frequent maintenance or sudden replacements. This strategic selection enhances the overall reliability and cost-efficiency of knife gate valves, enabling them to perform consistently in challenging industrial processes.

3. Selecting the Right Manufacturer

When selecting knife gate valves, opting for manufacturers renowned for their focus on quality and compliance with industry certifications is crucial for ensuring reliable performance and safety. Reputable manufacturers uphold rigorous quality control processes, conducting extensive testing to verify the durability, sealing capabilities, and overall functionality of their valves under various conditions. They utilize premium, industry-approved materials that are designed to endure the demanding requirements of industrial applications, ensuring long-lasting service.

Certifications such as ISO 9001 or API compliance demonstrate their commitment to adhering to globally recognized standards, offering customers confidence in the product’s integrity and performance. Partnering with such trusted manufacturers not only enhances operational reliability but also ensures compliance with regulatory requirements and minimizes risks of failure or costly repairs. Ultimately, investing in high-quality valves from certified manufacturers translates into reduced maintenance costs, extended product lifespan, and peace of mind in critical industrial environments.

4. Opting for Actuated Gate Valves

Actuators are integral to the precise and reliable operation of knife gate valves, ensuring optimal flow control while significantly reducing the likelihood of improper gate closure. By automating valve operation, actuators eliminate the inconsistencies associated with manual handling and provide consistent, repeatable performance even in demanding conditions. Pneumatic actuators, in particular, offer a range of advantages, including the application of uniform force for seamless gate movement, regardless of process variability.

Their adaptability to diverse industrial environments makes them a preferred choice for systems requiring frequent and accurate valve adjustments. Pneumatic actuators also enhance safety and efficiency by enabling remote operation. Reducing the need for direct human interaction in hazardous areas. This combination of precision, consistency, and adaptability minimizes the risks of incomplete gate closure. Ensuring uninterrupted performance and safeguarding the integrity of industrial processes.

FAQ

1. What materials are knife gate valves made from?

Knife gate valves are typically manufactured using durable materials like stainless steel, cast iron, or specialized alloys. These materials are chosen based on the application’s requirements, such as corrosion resistance, abrasion resistance, or high-pressure capabilities.

2. Can knife gate valves handle high-pressure applications?

While knife gate valves are mostly designed for low to medium pressure environments, there are high-pressure variants constructed with reinforced materials and advanced packing systems to handle higher pressures.

3. What is the difference between knife gate valves and actuated gate valves?

Knife gate valves specifically refer to valves designed to cut through tough or solid-laden media. Actuated gate valves, on the other hand, describe gate valves that integrate actuators (manual, pneumatic, electric, or hydraulic) to automate their operation. Pneumatic actuators are a common choice for knife gate valves.

4. How do knife gate valve manufacturers ensure quality?

Reputable manufacturers ensure quality by adhering to strict industry standards, using high-grade materials, and implementing comprehensive testing procedures for pressure, sealing performance, and durability. Additionally, certifications and compliance with international standards verify their reliability.

5. What are the advantages of choosing pneumatic knife gate valves for industrial applications?

Pneumatic knife gate valves provide fast, precise, and automated control, reducing manual effort and improving efficiency. They are highly durable, require minimal maintenance, and are suitable for harsh environments, making them a cost-effective solution in demanding settings.

Conclusion

Leaks in knife gate valves can arise from a variety of factors. Including worn-out seals, improper installation, or material degradation due to exposure to corrosive or abrasive media. These issues can disrupt operations, compromise safety, and result in costly downtime if not addressed. However, the risk of leaks can be significantly mitigated through a comprehensive approach combining proper valve selection, diligent maintenance, and sourcing from high-quality manufacturers. Selecting a valve tailored to the specific application, with corrosion-resistant materials and durable sealing mechanisms, is critical to ensuring reliable operation.

Regular maintenance practices, such as inspecting seals, lubricating components, and removing debris, further contribute to preserving valve integrity over time. Additionally, partnering with reputable manufacturers known for their rigorous testing procedures and compliance with industry certifications ensures access to valves engineered for longevity and performance. This cohesive strategy not only minimizes the likelihood of leaks but also enhances overall system reliability and cost efficiency.