Choosing the ideal 3 three way ball valve? for fluid control can significantly impact system performance and efficiency. With options like the T-Type, often referred to as the 3 way ball valve t port, and the L-Type, understanding their differences is essential. These versatile valves, including models like the 3 way ss ball valve and 3 way stainless steel ball valve, offer distinctive flow configurations suitable for diverse industrial applications. Whether you need precise flow redirection or mixing, this guide will help you evaluate which ball valve 3 way design aligns best with your system’s requirements.

Introduction 3 three way ball valve?

When it comes to efficient fluid control systems, the choice between different three way valves is crucial. A 3-way ball valve, with its versatile design, plays a key role in redirecting or mixing flows within various industrial processes. Options like the ball valve 3 way t port configuration or the durable stainless 3 way ball valve offer distinct advantages based on specific system requirements. By understanding the functionality and applications of these 3way ball valves, including the widely-used three way ball valves, you can select the optimal solution to meet your operational needs.

Brief overview of the 3 three way ball valve? and its importance in fluid control systems.

A 3 three way ball valve? is a vital component in fluid control systems, designed to manage and redirect flow with precision and efficiency. Its ability to mix or divert flows in multiple directions makes it an essential element in many industrial processes, from chemical processing to water treatment. By offering a compact yet durable solution, these valves help enhance process efficiency, reduce downtime, and maintain consistent performance in demanding environments. Their versatility and reliability have made them a preferred choice for engineers looking to optimize system operations.

Introduce the T-Type and L-Type configurations as the two primary designs for three-way ball valves.

The T-Type and L-Type configurations represent the two primary designs for three-way ball valves, each catering to distinct fluid control needs. The T-Type, also known as the ball valve 3 way t port, allows flow in multiple directions, including mixing and diverting, making it ideal for complex systems requiring versatile flow control. On the other hand, the L-Type is specifically designed for flow redirection between two ports, offering a straightforward solution for simpler applications. By understanding these configurations and their respective flow patterns, industry professionals can select the optimal three-way valve design to ensure precise control and system efficiency.

What is a 3 three way ball valve??

Definition and purpose of three-way ball valves in fluid control.

Three-way ball valves are a type of valve designed to regulate fluid flow in piping systems by providing three ports for fluid entry or exit. These valves operate by rotating a ball with internal pathways to open, close, or redirect flow between the ports. Common configurations include T-Type and L-Type designs, allowing for tasks such as mixing, distributing, or switching flow. Their purpose in fluid control systems is to streamline operations by enabling efficient direction and management of fluid flow within industrial and commercial applications.

Key components and how the valve works to divert or mix flow paths.

Three-way ball valves consist of a ball with internal ports, three openings or ports for fluid flow, a stem for ball rotation, and a sealing mechanism to prevent leaks. The internal ball rotates within the valve body to control fluid direction by aligning its pathways with the desired flow route. Depending on the configuration, such as T-Type or L-Type, the valve can either divert flow between different paths or mix two fluid streams into one. The stem, connected to a handle or actuator, enables precise control of the ball’s position, determining whether fluid is directed, combined, or shut off within the system.

Importance of material specifications and how it impacts durability and performance.

Material specifications play a critical role in determining the durability and performance of three-way ball valves. Factors such as the type of materials used for the valve body, ball, and seals affect the valve’s ability to withstand different pressures, temperatures, and chemical environments. For example, stainless steel is often chosen for applications requiring corrosion resistance, while other alloys may be selected based on the specific properties of the media being transported. The choice of sealing materials also directly influences leak prevention and operational longevity. Proper material selection ensures that the valve meets the requirements of the application, reducing maintenance needs and supporting efficient system performance.

Understanding T-Type and L-Type Configurations

T-Type Configuration

Design overview.

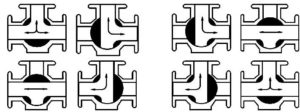

The T-Type configuration for three-way ball valves features a structure that facilitates flow in multiple directions. Its design includes a ball with a T-shaped bore, allowing fluid to pass through any two ports simultaneously or across all three ports, depending on system requirements. This configuration supports mixing and diverting operations in a single valve assembly. Its flow capabilities make it suitable for processes that require flexible directional control and multiple flow patterns within a single system.

Flow functionalities, including simultaneous mixing or distributing of media.

The T-Type configuration for three-way ball valves allows simultaneous mixing or distribution of media through its T-shaped bore. This design directs flow from one inlet to two outlets or combines flow from two inlets into a single outlet, depending on the system’s requirements. It provides operational flexibility by supporting multiple flow paths, enabling both mixing and diverting within the same component. This functionality makes it integral to processes that require combined or separated flow management in a single setup.

Suitable scenarios where T-Type valves are advantageous.

T-Type valves are advantageous in scenarios that require combining or diverting flow within a system. They are commonly used in industries such as chemical processing, water treatment, and food and beverage where processes involve mixing different fluids or routing media to multiple destinations. These valves support operations that demand simultaneous flow paths, making them suitable for systems with complex flow requirements or processes that involve switching between distribution and collection modes. Their ability to handle varying flow patterns within a single valve assembly simplifies system design and optimizes operational efficiency.

L-Type Configuration

Explanation of the “L” flow pattern for straightforward flow-switching between two ports.

The “L” flow pattern in the L-Type configuration for three-way ball valves is designed to facilitate direct flow-switching between two specific ports. The valve features a ball with an L-shaped bore, which enables fluid to flow between two connected ports while isolating the third. This setup allows for straightforward control over the direction of the flow, making it practical for applications that require alternating flow paths or selective fluid transfer between two points within a system. It is suitable for processes that involve segregated flow management without the need for simultaneous mixing or distribution.

Use cases where L-Type valves offer ideal control and efficiency.

L-Type valves are used in scenarios requiring straightforward control of flow between two ports. They are suitable for systems in industries such as oil and gas, pharmaceuticals, and water management, where selective redirection of fluids is essential. These valves facilitate efficient flow switching in processes like filling, transfer, or isolation. Their design is particularly effective in applications that demand segregated flow management, ensuring precise operation without simultaneous mixing or distribution, thus optimizing specific flow paths within the system.

Key Differences Between T-Type and L-Type

Flow Patterns

How T-Type enables mixing and diverting.

The T-Type configuration enables the mixing and diverting of media through its T-shaped bore, which allows fluid to flow through different paths within a single valve. The design facilitates the combination of media from two inlets into one outlet, providing efficient mixing. It also supports flow diversion by directing media from a single inlet to multiple outlets. This dual function is managed by rotating the ball within the valve to align the T-shaped bore with the desired flow pattern. These capabilities make the T-Type configuration effective for systems requiring flexible and controlled flow management.

How L-Type is restricted to diverting flow between two ports.

The L-Type configuration is designed to divert flow between two ports, utilizing a ball with an L-shaped bore. This bore permits the passage of fluid from one port to another while isolating the third port entirely. The flow is redirected by rotating the ball within the valve to align the L-shaped bore with the respective ports. This configuration limits its functionality to alternating flow paths between two connected points, making it suitable for applications where separating and redirecting flow is required without the need for combining or simultaneous distribution.

Design Complexity and Cost

Complexity of T-Type compared to the simpler L-Type design.

The T-Type configuration involves a more intricate design compared to the L-Type due to its ability to handle multiple flow paths, including mixing and diverting media within a single valve assembly. This added functionality is achieved through a ball with a T-shaped bore that allows fluid movement across three ports simultaneously or in combinations. Conversely, the L-Type relies on a simpler design with a ball featuring an L-shaped bore that redirects flow between two ports while isolating the third. The additional design features of the T-Type can impact manufacturing and maintenance costs, making it more suitable for situations requiring complex flow management, whereas the L-Type provides a cost-effective solution for straightforward flow-switching applications.

Pricing implications due to additional functionalities or design requirements.

Additional functionalities or design requirements in valve configurations directly influence pricing due to increased manufacturing complexity and material needs. Configurations like the T-Type, which support multiple flow paths and combined flow operations, require more intricate design and machining processes. This increases production time and costs compared to simpler configurations like the L-Type, which manage basic flow-switching between two ports. The integration of more features often results in higher costs for maintenance and replacement of parts over the valve’s lifecycle. These factors must be considered when selecting a valve configuration to balance performance needs with budget constraints.

Installation and Maintenance

Differences in installation requirements based on flow needs.

Installation requirements for valves vary based on flow needs and the configuration chosen. T-Type valves, with their ability to manage multiple flow paths, require careful alignment and additional considerations for accommodating three ports within the system. This can involve extra space and precise calibration to ensure proper flow control. L-Type valves, designed for simpler flow redirection between two ports, have more straightforward installation processes, as they focus on isolating and alternating flow between limited points. The differences in installation are driven by the functional design and intended flow patterns of each configuration, making it essential to assess application requirements and available infrastructure before selecting a valve type.

Impact on maintenance frequency and repair with each design.

T-Type and L-Type valve configurations differ in their impact on maintenance frequency and repair requirements due to their functional designs. T-Type valves, which accommodate multiple flow paths and operations, often demand more frequent inspection and potential adjustments to ensure consistent performance across all ports. Their additional components and complexity can result in higher wear over time, requiring specialized servicing. L-Type valves, with their focus on directing flow between two ports, tend to have fewer wear points, leading to less frequent maintenance needs. However, both configurations require regular monitoring to ensure alignment with operational flow conditions and to address any wear or damage that could arise from prolonged use or process demands.

Applications of T-Type vs. L-Type Valves

T-Type Applications

Industries relying on fluid mixing.

Industries such as chemical processing, pharmaceuticals, and food and beverage rely on fluid mixing for production processes. T-Type valves play a key role in these contexts by enabling controlled combining of multiple fluid streams within a single system. Their design facilitates efficient management of flow paths, ensuring process accuracy and consistency in applications that require precise mixing operations.

Systems requiring consistent multi-directional flow paths.

Systems requiring consistent multi-directional flow paths are common in industries such as water treatment and oil and gas processing. T-Type valves are used in these systems to manage and regulate simultaneous or alternating flows across multiple channels. Their design supports efficient flow distribution, ensuring operational demands are met in complex piping networks.

L-Type Applications

Simplified flow diversion in pipelines or processes with fewer redirections.

L-Type valves are used in pipelines and processes where flow diversion is simplified and involves fewer redirections. These valves efficiently manage the transfer of fluid between two ports, making them suitable for applications that require straightforward flow control without additional routing complexities.

Use in cooling systems, bypass systems, or simple flow alternations.

L-Type valves are utilized in cooling systems, bypass systems, and processes requiring simple flow alternations. Their design allows efficient switching between fluid paths, enabling effective flow management in applications that demand straightforward redirection without complex configurations.

Advantages of T-Type and L-Type Valves

T-Type Advantages

Greater flexibility with simultaneous mixing/distribution.

T-Type valves provide flexibility in systems requiring simultaneous fluid mixing and distribution. Their configuration supports the management of multiple flow paths, allowing operators to combine or distribute fluids within a single system. This capability enables efficient handling of processes that involve the regulation of complex flow patterns in industries relying on precise operations.

Ideal for complex fluid handling systems.

T-Type valves are suited for complex fluid handling systems due to their ability to manage multiple flow paths within a single configuration. These valves enable operators to direct, combine, or isolate fluid streams efficiently, ensuring seamless operation in systems that require precise control over flow distribution. Their design accommodates the requirements of industries where maintaining accurate flow management is critical to system performance.

L-Type Advantages

Easier to operate and maintain due to basic design.

L-Type valves are efficient to operate and maintain as a result of their straightforward design. Their configuration minimizes components and reduces potential points of failure, simplifying routine maintenance and operation procedures. This design supports reliable flow control in systems that require consistent performance without the need for complex adjustments or extensive oversight.

Cost-efficient for simpler flow switching applications.

L-Type valves offer cost efficiency for simpler flow switching applications due to their minimalistic design and functionality. Their straightforward structure reduces manufacturing and maintenance costs, providing an economical solution for systems that require basic flow redirection. This makes them a practical choice for industries focused on optimizing operational budgets while maintaining effective control over fluid systems.

Choosing the Right Valve for Your Application

Factors to consider when selecting between T-Type and L-Type valves.

Flow direction requirements.

T-Type and L-Type valves differ in their ability to manage flow direction, making this an important factor when choosing between the two. T-Type valves are designed to handle multiple flow paths simultaneously, enabling operators to mix or distribute fluids across complex systems. L-Type valves, on the other hand, are structured for straightforward flow switching between two paths, making them suitable for simpler redirection needs. Understanding the specific flow direction requirements of a system helps in determining which valve configuration provides the most efficient and practical solution.

Cost-efficiency vs. functionality.

When selecting between T-Type and L-Type valves, cost-efficiency versus functionality is a key consideration. T-Type valves offer the capability to manage fluid mixing and distribution in systems with more complex flow requirements, which can result in higher costs due to their design and operational flexibility. L-Type valves, with their simpler configuration, focus on cost-efficiency by addressing basic flow switching needs while requiring lower manufacturing and maintenance expenses. Evaluating the balance between budget constraints and the functional demands of the system ensures the appropriate valve is chosen for the application.

Operating conditions.

Operating conditions play a critical role in choosing between T-Type and L-Type valves. T-Type valves are designed to handle systems requiring complex flow configurations, which may involve higher pressures or the need for simultaneous flow paths. L-Type valves are better suited for applications with simpler requirements, such as straightforward flow switching under standard operating parameters. Assessing the pressure levels, temperature ranges, and fluid characteristics specific to the system ensures the valve selected matches the operational demands effectively.

Stress the importance of matching valve selection to operational goals.

Matching valve selection to operational goals is essential to ensure system efficiency and reliability. Each valve type is designed to fulfill specific roles, such as regulating flow, controlling pressure, or directing fluid movement. Selecting a valve without considering the operational requirements can lead to diminished performance, increased wear, or compatibility issues. Evaluating factors such as flow conditions, pressure limits, and the purpose of the valve within the system helps in aligning the choice with the goals of the application, minimizing risks and optimizing system performance.

FAQ 3 three way ball valve?

Question 1:What are the key differences between T-Type and L-Type configurations in 3 way valves?

Answer:T-Type and L-Type 3 way valves differ in flow path design and application suitability. A T-Type valve, also referred to as a T port valve, allows for more complex configurations such as mixing or distributing flow between multiple channels. On the other hand, an L-Type 3-way valve is designed for simpler flow switching, directing fluid between two paths at a time. Understanding the system requirements helps determine which configuration aligns with operational needs.

Question 2:When should a T-Type 3-way valve be chosen over an L-Type?

Answer:A T-Type 3-way valve, or T port valve, is ideal when the system requires the ability to mix or distribute flow simultaneously to multiple channels. It is commonly used in applications where complex flow configurations are necessary. Conversely, an L-Type valve is typically selected for straightforward switching between two flow paths when mixing or distribution is not required. The choice depends on the specific functional demands of the system.

Question 3:What factors should be considered when selecting a three way ball valve for industrial applications?

Answer:Selecting a three way ball valve involves evaluating system requirements such as flow paths, pressure levels, and temperature conditions. For applications needing simple redirection of flow between two paths, an L-Type 3 way valve may suffice. For systems requiring fluid mixing or simultaneous flow to multiple outlets, a T-Type 3-way valve, also known as a T port valve, is more suitable. Ensuring that the selected 3-way valve matches operational goals minimizes wear and enhances system performance.

Conclusion 3 three way ball valve?

Selecting the appropriate 3 three way ball valve? for an industrial application requires a clear understanding of system demands and operational requirements. The choice between a T-Type and L-Type configuration depends on factors such as flow complexity, pressure levels, and functional goals. A 3 way ball valve t port is well-suited for applications involving fluid mixing or simultaneous flow distribution, while an L-Type 3 three way ball valve? is ideal for simpler flow switching. Options like the 3 way ss ball valve and the 3 way stainless steel ball valve offer durable solutions for handling diverse media and operating conditions. Proper evaluation of system needs ensures that the selected ball valve 3 way design aligns with performance expectations, enhancing efficiency and reliability.3 three way ball valve?