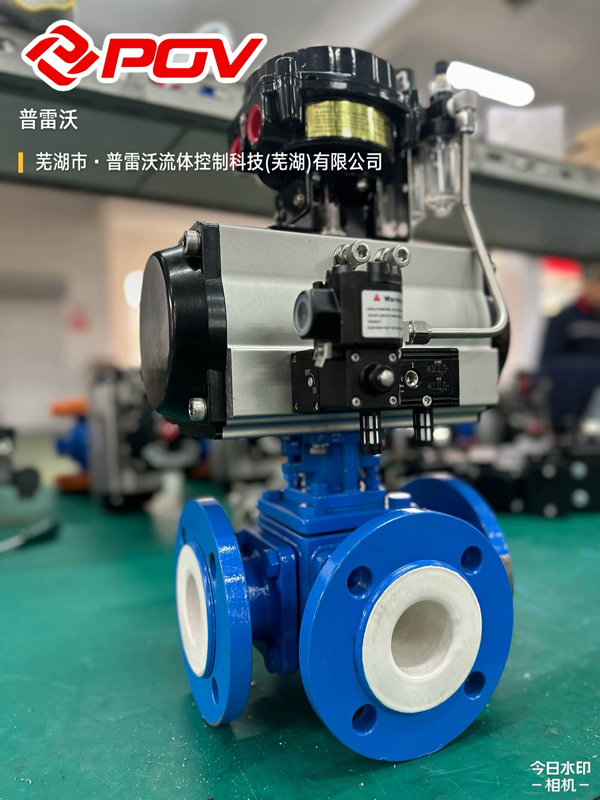

PFA lined valves are highly reliable and versatile solutions designed for handling corrosive and high-purity substances across various industries. These valves feature a robust Perfluoroalkoxy (PFA) polymer lining, which offers superior chemical resistance, high-temperature tolerance. And long-lasting performance. Compared to alternatives like the PTFE lined valve, Teflon valve, or FEP lined ball valve. PFA lined valves provide enhanced flexibility and resistance to stress cracking, making them a preferred choice in demanding applications.

Industries such as chemical processing, pharmaceuticals, oil & gas, and water treatment heavily rely on pfa lined valve systems for their durability and ability to maintain operational integrity under extreme conditions. Whether used in a lined ball valve configuration or for specialized tasks involving reactive chemicals. PFA-lined solutions meet stringent safety and efficiency requirements, underscoring their critical role in modern industrial operations.

Introduction

PFA lined valves are an advanced solution for industries requiring robust and reliable equipment to handle corrosive and high-purity substances. Featuring a Perfluoroalkoxy (PFA) polymer lining, these valves stand out for their exceptional chemical resistance, stress crack tolerance. And ability to perform under extreme temperatures and pressures. A pfa lined valve is frequently compared to other solutions such as ptfe lined valve, lined ball valve, fep lined ball valve, and teflon valve. But it offers unique advantages in terms of flexibility and durability. These attributes make PFA lined valves indispensable in industries like chemical processing, pharmaceuticals, water treatment, and oil & gas. Where operational integrity and safety are paramount. Whether utilized in a ball valve design to control fluid flow or incorporated into systems requiring high-purity standards. PFA lined valves deliver unmatched performance, meeting the critical demands of modern industrial applications efficiently and reliably.

What are PFA Lined Valves?

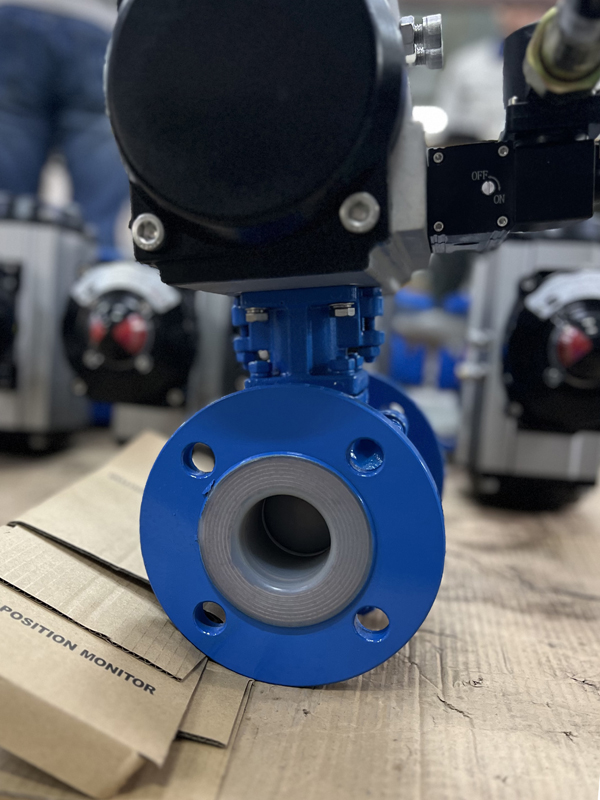

PFA lined valves, short for Perfluoroalkoxy polymer lined valves, are high-performance components crafted to handle corrosive liquids, gases. And high-purity mediums in demanding industrial environments. A pfa lined valve features a protective inner lining made of PFA, a fluoropolymer known for its exceptional chemical resistance, high-temperature tolerance, and flexibility. This makes it particularly effective for applications involving aggressive acids, alkalis, and solvents. When compared to a ptfe lined valve, PFA offers improved stress crack resistance and superior reliability in extreme conditions. Making it a preferred choice for long-term use.

Similarly, while other options like lined ball valve, fep lined ball valve, and teflon valve provide corrosion resistance. PFA stands out due to its enhanced durability and ability to maintain consistency in both high-pressure and high-temperature environments. Industries such as chemical processing, pharmaceuticals, oil & gas. And water treatment heavily rely on PFA lined valves for their ability to safeguard operations from contamination and material degradation. Whether in a ball valve configuration for precise flow regulation or as part of a larger system. PFA lined valves offer unmatched efficiency, ensuring both safety and operational excellence across various applications.

Benefits of PFA Lined Valves

PFA lined valves offer a range of advantages that make them indispensable in industries dealing with corrosive or high-purity substances. A pfa lined valve features a robust Perfluoroalkoxy polymer lining, which provides exceptional resistance to a wide variety of aggressive chemicals. Including strong acids, bases, and solvents. This superior chemical resistance ensures long-term durability and minimizes the risk of material degradation. Even in extreme operating conditions. Compared to alternatives like the ptfe lined valve, lined ball valve, fep lined ball valve, and teflon valve. PFA lined valves stand out for their enhanced flexibility, stress crack resistance, and consistent performance under high temperatures and pressures.

Their versatility also makes them ideal for various critical applications in industries such as chemical processing, pharmaceuticals, and water treatment. PFA lined valves are suitable for precise flow regulation in lined ball valve configurations while ensuring maximum operational safety and efficiency. Their ability to maintain structural integrity and resist contamination makes them a trusted solution for environments where reliable performance is paramount.

Applications of PFA Lined Valves

PFA lined valves are indispensable in a wide range of industries that require superior resistance to corrosive substances, high temperatures, and stringent purity standards. A pfa lined valve commonly use in chemical processing plants, where it safely handles aggressive acids, bases. And volatile organic compounds without degrading.

Similarly, these valves play a critical role in the pharmaceutical sector. Where maintaining contamination-free environments is essential. Their applications extend to water treatment systems. Ensuring the efficient regulation of fluid flow in processes that involve harsh chemicals. Compared to other solutions like the ptfe lined valve, lined ball valve, fep lined ball valve, and teflon valve. PFA lined valves deliver higher reliability and flexibility under extreme conditions.

For example, in lined ball valve configurations, these valves provide precise control in operations involving high pressures and reactive chemicals. Additionally, their durability and chemical resistance make them ideal for handling substances in industries such as oil & gas, food processing, and semiconductor manufacturing. Whether used in high-purity applications or in systems requiring robust corrosion resistance. PFA lined valves consistently meet the diverse demands of modern industrial environments.

Industries that Rely on Lined Valves

Industries across the globe depend on the superior performance of pfa lined valves to handle demanding operational requirements while ensuring safety and efficiency. The chemical processing industry heavily relies on these valves to manage corrosive acids, alkalis, and reactive chemicals. As their PFA lining provides exceptional resistance to chemical attack and degradation. Similarly, the pharmaceutical sector uses pfa lined valves to maintain sterile and contamination-free environments critical for producing high-purity medications. Water treatment facilities also benefit from these valves in applications where aggressive disinfectants and chemicals are involved. Guaranteeing long-term reliability and durability.

Additionally, industries like oil & gas and food processing turn to lined ball valve configurations with PFA lining for their ability to withstand harsh environments. Ensuring precise flow control and operational stability. While alternatives such as ptfe lined valves, fep lined ball valves, and teflon valves offer notable chemical resistance. PFA excels in providing superior flexibility, stress crack resistance, and consistent performance in extreme conditions. Whether managing volatile compounds or high-temperature processes. PFA lined valves are a trusted solution for industries where operational integrity and safety are non-negotiable.

Comparison of PFA Lined Valves with Other Lined Valves

When comparing a pfa lined valve to other lined valve options like ptfe lined valve, fep lined ball valve, and teflon valve, it becomes evident that each material offers unique benefits tailored to specific industrial needs. PFA (Perfluoroalkoxy polymer) lined valves excel in chemical resistance, stress crack resistance, and durability. Making them an ideal choice for managing highly corrosive and reactive substances under extreme temperatures and pressures. Unlike ptfe lined valves. Which are also chemically resistant but less flexible, PFA’s polymer structure provides enhanced mechanical strength and better performance in dynamic environments.

Similarly, while fep lined ball valves share some high-purity and chemical resistance properties with PFA, they tend to have lower thermal stability and flexibility, limiting their use in more extreme conditions. The term teflon valves often refers to those lined with PTFE or similar fluoropolymers. But they can lack the same robustness and stress crack resistance that PFA offers. Especially in high-temperature or high-pressure applications. Furthermore, lined ball valves with PFA linings ensure precise and safe fluid control in aggressive chemical processing, water treatment, or pharmaceutical pipelines. Although all these materials demonstrate outstanding chemical resistance. PFA stands out as a versatile and high-performance lining solution for industries demanding ultimate reliability without compromising on safety or efficiency.

Selection Criteria for PFA Lined Valves

Selecting the right valve for industrial processes often involves a detailed comparison of criteria. Particularly when evaluating a pfa lined valve against alternatives like ptfe lined valve, fep lined ball valve, and teflon valve variants. One critical factor is chemical compatibility; PFA lining delivers exceptional resistance to a wide range of aggressive chemicals. Surpassing PTFE and FEP linings in handling more reactive substances over extended periods. Temperature resistance is another key consideration. With PFA’s ability to maintain integrity at higher temperatures, it is a preferred choice for environments that demand thermal stability, whereas ptfe lined valves and fep lined ball valves may? more limit in extremely high-heat scenarios.

Mechanical strength also sets PFA apart, as its superior flexibility and stress crack resistance allow it to endure dynamic operating conditions and prolonged use without compromising valve functionality. Cost-effectiveness can vary depending on the application. But the durability and long service life of PFA lined valves often provide better value in industries requiring long-term, reliable solutions.

Additionally, when choosing a lined ball valve, PFA linings ensure precise flow control even in highly corrosive or high-purity systems. While coverings like FEP or generic teflon valves may not match PFA’s performance under extreme demands. Therefore, the selection process hinges on balancing these factors to align with the specific operational requirements of applications in industries such as chemical processing, water treatment, and pharmaceuticals.

Maintenance and Longevity of PFA Lined Valves

When choosing a pfa lined valve, several critical selection criteria set it apart from other options like ptfe lined valve, fep lined ball valve, and teflon valve configurations. Chemical compatibility is often a primary factor. With PFA linings excelling in resistance to highly aggressive chemicals. Including strong acids and alkalis, outperforming PTFE and FEP linings in many applications. Temperature resistance also plays a pivotal role. As PFA can withstand higher thermal ranges without losing structural integrity. Making it ideal for processes involving elevated operational temperatures.

Meanwhile, ptfe lined valves and fep lined ball valves may exhibit limitations under extreme heat. Mechanical strength is another area where PFA stands out, offering excellent flexibility and superior resistance to stress cracks. Even in dynamic and demanding systems. This durability ensures long-term reliability under harsh operating conditions. Which some generic teflon valve options cannot consistently provide. Cost-effectiveness is equally important; while PFA lined valves may involve a higher initial investment. Their extended service life and reduced maintenance requirements often translate to lower total lifecycle costs. For industries requiring precise flow control, such as chemical processing, pharmaceuticals, and water treatment, lined ball valves with PFA offer unparalleled performance, delivering both safety and efficiency. By weighing these factors, businesses can identify the most suitable valve option to meet their specific operational needs.

FAQ

What does PFA stand for in valves?

PFA stands for Perfluoroalkoxy Alkane. It is a fluoropolymer known for its chemical resistance, non-stick properties, and high thermal stability, making it an excellent lining material for industrial valves.

What are PFA-lined valves?

PFA valves are industrial valves with an internal coating or lining of PFA. This lining provides exceptional resistance to corrosive chemicals and extreme temperatures, protecting the valve body and ensuring reliable performance in harsh environments.

What are the benefits of PFA-lined valves?

PFA-lined valves offer superior corrosion resistance, making them suitable for aggressive chemicals like acids, alkalis, and solvents. They also withstand high temperatures and provide a smooth, non-stick surface that minimizes wear and buildup, extending the valve’s service life.

What industries use PFA-lined valves?

PFA-lined valves are widely used in industries such as chemical processing, petrochemicals, pharmaceuticals, food and beverage, and power generation. They are particularly effective in applications involving highly corrosive or hazardous substances.

How do PFA-lined valves compare to PTFE-lined valves?

While both PFA and PTFE offer exceptional chemical resistance and thermal stability, PFA is more flexible and has a smoother surface finish. This makes PFA-lined valves more resistant to cracking and easier to clean, making them the preferred choice in applications requiring higher durability and hygiene.

Conclusion

PFA lined valves are a critical solution for industries requiring superior chemical resistance, durability, and high-performance flow control. Engineered with Perfluoroalkoxy (PFA) lining, these valves excel in handling highly corrosive substances, extreme temperatures, and demanding operating conditions. When compared to options like the ptfe ball valve, ptfe lined valve, fep lined ball valve, and teflon valve, PFA lined valves often stand out due to their enhanced stress crack resistance, mechanical strength, and thermal stability. These qualities make them ideal for aggressive chemical processing, water treatment, and high-purity pharmaceutical applications.

A lined ball valve with PFA lining ensures precise, reliable fluid control even in the harshest environments, outperforming other lined materials in long-term durability and safety. While PTFE and FEP valves also offer excellent chemical resistance, they may fall short in handling higher thermal ranges or dynamic stress scenarios where PFA demonstrates superior flexibility and longevity. Similarly, while Teflon valves are highly effective in standard applications, they may not consistently deliver the same robustness as PFA under extreme conditions. Overall, PFA lined valves offer a versatile, high-performance solution, ensuring operational reliability and safety across a wide range of demanding industries.