PTFE lined valve is essential components in industries that handle corrosive or high-temperature fluids. These specialized valves are lined with PTFE (Polytetrafluoroethylene). Offering excellent chemical resistance, durability, and a non-stick surface. Whether you’re considering a PTFE lined valve, PFA valve and PTFE valve, or a Teflon valve, these options deliver exceptional reliability and safety for industrial processes. Their unique features, such as resistance to harsh chemicals and extreme temperatures, ensure long-lasting performance and lower maintenance costs. Commonly used in chemical, pharmaceutical, and food processing industries, PTFE valves enhance operational efficiency and minimize risks. With options tailored for varied applications, PTFE lined valves are a trusted choice for optimizing performance in demanding environments.

ptfe lined valve Introduction

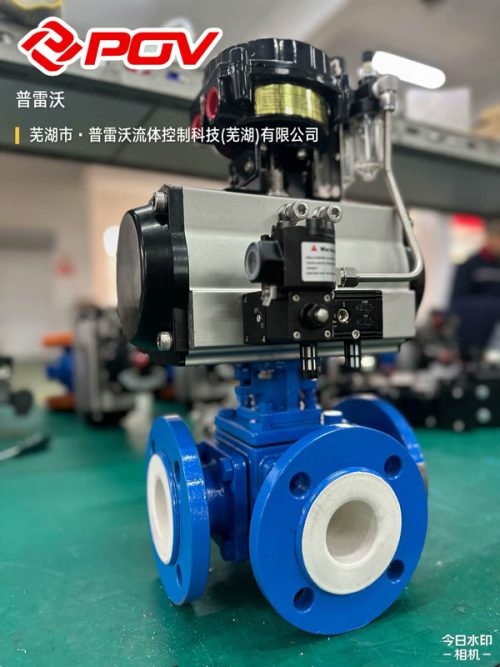

A PTFE lined valve is a specialized industrial valve designed to handle aggressive chemicals, extreme temperatures, and demanding operational conditions. Lined with PTFE, or Polytetrafluoroethylene, these valves offer exceptional chemical resistance, non-stick properties, and durability. Making them an indispensable component in industries such as chemical processing, pharmaceuticals, and food manufacturing. The PTFE lining acts as a robust barrier, protecting the valve’s internal surfaces from corrosion and wear while ensuring reliable performance under high-pressure or high-temperature scenarios.

Variants such as PFA valve and PTFE valve expand the range of applications. With PFA (Perfluoroalkoxy) offering enhanced mechanical strength in certain environments. Often referred to as Teflon valves, due to Dupont’s popularized name for PTFE, these valves stand out for their ability to prevent leaks and ensure consistent flow control. Whether it’s for ensuring safety, improving efficiency, or reducing maintenance costs. PTFE valves have become a trusted choice for industries requiring robust and reliable solutions for handling aggressive media. Their precision and design make them not only a technical asset but also a cost-efficient investment in operational excellence.

Section 1: What is a PTFE Lined Valve?

A PTFE lined valve is an industrial valve engineered with an internal lining made of PTFE (Polytetrafluoroethylene), a highly durable, chemically resistant material. The lining creates a protective barrier between the valve’s metal components and the corrosive or abrasive media it handles. Ensuring long-term reliability and extending the valve’s lifespan. PTFE lined valves commonly use in industries like chemical processing, pharmaceuticals, and food manufacturing. Where they manage aggressive chemicals, high temperatures, and demanding operational conditions.

Variants such as PFA valve and PTFE valve provide additional options. With PFA (Perfluoroalkoxy) offering enhanced flexibility and toughness in certain applications. Often referred to as Teflon valves, owing to the well-known brand name for PTFE, these valves are prized for their non-stick properties, resistance to wear, and ability to prevent leakage. Whether handling acids, solvents, or other hazardous fluids, PTFE valves deliver superior performance by ensuring smooth operation. Enhanced safety, and reduced maintenance. Their precise construction and versatility make them an essential solution for industries requiring reliable, high-performing flow control under challenging conditions.

Section 2: Features of PTFE Lined Valves

PTFE lined valves are designed with advanced features that make them indispensable in managing demanding industrial applications. At the core of these valves is the PTFE (Polytetrafluoroethylene) lining, which offers exceptional chemical resistance, allowing them to handle corrosive fluids such as acids, alkalis, and solvents without degrading or wearing out. This resistance is a critical feature for industries like chemical processing and pharmaceuticals, where harsh substances are common.

PTFE lined valves are also incredibly durable, as the lining protects the internal metal components from corrosion and abrasion, ensuring longevity and reducing maintenance needs. The non-stick properties of PTFE, commonly associated with Teflon valves, prevent materials from adhering to the valve surfaces, which ensures smooth and uninterrupted fluid flow. For enhanced strength and versatility, variants like PFA valve and PTFE valve offer additional benefits; PFA (Perfluoroalkoxy) provides greater mechanical toughness and thermal stability for extreme environments. Furthermore, these valves excel in maintaining a high degree of safety, as their leak-proof designs eliminate the risk of chemical exposure or environmental contamination. Whether used in high-temperature settings or processes involving aggressive media, PTFE valves deliver reliable performance with features tailored to meet the challenges of specialized industrial operations.

Section 3: Benefits of PTFE Lined Valves

PTFE lined valves provide numerous advantages that make them a preferred choice for a wide range of industrial applications. These valves, known for their durable construction, excel in handling corrosive, abrasive, and high-temperature fluids, thanks to the superior performance of PTFE (Polytetrafluoroethylene) as a lining material. One of their primary benefits is exceptional chemical resistance, which allows them to safely control even the most aggressive substances, such as strong acids, alkalis, or solvents, without risk of degradation or failure. Their durability further extends their operational lifespan, reducing maintenance frequency and minimizing downtime, making them a cost-effective long-term investment.

For industrial environments with specific needs, variations like PFA valve and PTFE valve offer enhanced features such as greater mechanical strength and thermal resistance. Commonly referred to as Teflon valves, due to the branded name for PTFE, these valves also benefit from non-stick properties that prevent residue build-up and ensure smooth, uninterrupted flow, which is especially valuable in critical processes. Beyond these technical advantages, PTFE valves promote operational safety by eliminating leakages and mitigating the risk of hazardous chemical exposure. Overall, the versatility, reliability, and cost-efficiency of these valves make them an indispensable solution in industries such as chemical processing, food production, and pharmaceuticals, where robust performance is essential.

Section 4: Applications of PTFE Lined Valves

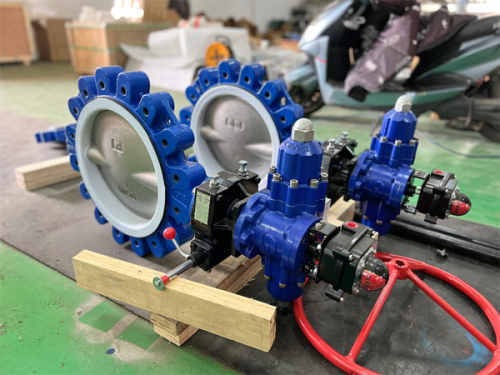

PTFE lined valves are indispensable across a wide array of industries due to their ability to withstand harsh operating conditions and handle aggressive substances with ease. These valves are particularly critical in the chemical processing industry, where they ensure safe and efficient management of corrosive liquids such as acids and solvents. The pharmaceuticals sector also heavily relies on PTFE valves, as their non-reactive and non-stick properties make them ideal for maintaining the purity of sensitive formulations. Food and beverage production processes benefit from Teflon valves, given their ability to resist contamination and support hygienic operations.

Furthermore, in environments requiring resistance to extreme temperatures and pressures, such as in power generation or petrochemical plants, PFA valve and PTFE valve options provide enhanced mechanical and thermal stability. These valves also feature prominently in wastewater treatment plants, handling abrasive and sludge-like materials without compromising on performance or durability. Their versatility extends even to industries like mining and semiconductor manufacturing, where precision and reliability are paramount. Overall, PTFE lined valves deliver unmatched efficiency and safety, proving essential in any application where robust flow control and protection against chemical wear are critical.

Section 5: Comparing PTFE Valves with PFA Valve

When comparing PTFE valves with PFA valves, it is crucial to understand their shared characteristics and distinguishing features to determine their most suitable applications. Both types fall under the category of Teflon valves. As they are made using fluoropolymer-based materials that offer exceptional chemical resistance. Making them ideal for handling aggressive substances such as acids, alkalis, and solvents. However, the key difference lies in their material construction and performance parameters. PTFE (Polytetrafluoroethylene) is a highly versatile material known for its low friction, non-stick surface, and broad temperature tolerance. Which makes PTFE valves highly effective for various industrial scenarios. Particularly in processes requiring minimal residue buildup and seamless flow control.

On the other hand, PFA (Perfluoroalkoxy alkane) takes these properties further by offering better mechanical strength and resistance to thermal cycling. Which is especially advantageous in applications involving frequent temperature variations or extreme operating conditions. PFA valve and PTFE valve designs both deliver exceptional reliability. But industries like pharmaceuticals and food processing often favor PTFE for its inert properties. While PFA valves are preferred in environments where enhanced durability under mechanical stress is essential. Such as in petrochemical refining or high-pressure systems.Understanding these differences ensures optimal selection for specific challenges, maximizing both performance and operational efficiency.

Section 6: Teflon Valves vs. PTFE Lined Valves

Teflon valves and PTFE lined valves share many similarities, as both rely on the exceptional properties of Polytetrafluoroethylene (PTFE), a material often branded as Teflon. However, key differences in their construction and design significantly influence their application and performance. Teflon valves generally refer to a broader category of valves made entirely or partially from PTFE. Offering excellent chemical resistance, non-stick properties, and a reliable seal against aggressive substances.

On the other hand, PTFE lined valves are designed with a structural metal body that is lined internally with a PTFE coating. Marrying the strength and durability of metal with the chemical resistance of PTFE. This makes PTFE valves particularly well-suited for applications involving high pressures and extreme mechanical demands. Such as in chemical processing or industrial flow systems, where metal reinforcement provides additional stability. Meanwhile, PFA valve and PTFE valve options cater to highly specialized needs depending on factors like thermal resistance and flexibility. Teflon valves, being less complex in design, are often favored for less demanding systems where pure PTFE is adequate to handle the process requirements. The choice between these two depends largely on operating conditions. Such as temperature, pressure, and the nature of the media, ensuring optimal performance in their respective roles.

ptfe lined valve Conclusion

PTFE lined valve represents the perfect combination of advanced materials and robust engineering. Delivering unparalleled reliability in industrial applications. By incorporating a protective lining of Polytetrafluoroethylene (PTFE). These valves offer exceptional chemical resistance, ensuring safe handling of aggressive substances like acids, alkalis, and solvents. Whether discussing PFA valve and PTFE valve options or the broader category of Teflon valves. The versatility of PTFE stands out as its defining feature. From its broad temperature tolerance to its low friction and non-stick surface. PTFE enhances the performance of critical flow control systems across industries such as chemical processing, pharmaceuticals, and food production.

PTFE valves, including both fully PTFE-lined and PFA-coated variants. Excel in high-pressure environments and extreme operating conditions where durability is key. Industries requiring precision and cleanliness often rely on these valves to ensure seamless and contamination-free operation. By choosing a PTFE lined valve, businesses not only gain the benefit of superior performance but also reduce maintenance costs and increase operational efficiency. For any industry demanding robust, high-performing, and reliable solutions. PTFE lined valves remain an indispensable option, providing the safety and excellence modern processes require.