Valves play a critical role in industrial systems, managing the flow of liquids and gases with precision and reliability. Among these, the DBB ball valve stands out for its innovative double block and bleed design, ensuring maximum safety and efficiency. Compared to other types like gate valves, butterfly valves, or flanged ball valves, the DBB ball valve is engineered for applications requiring tight seals and zero leakage. With advancements in actuation technologies, including pneumatic valves and electric valves, this design remains a cornerstone in industries demanding uncompromising performance.

Introduction DBB ball valve

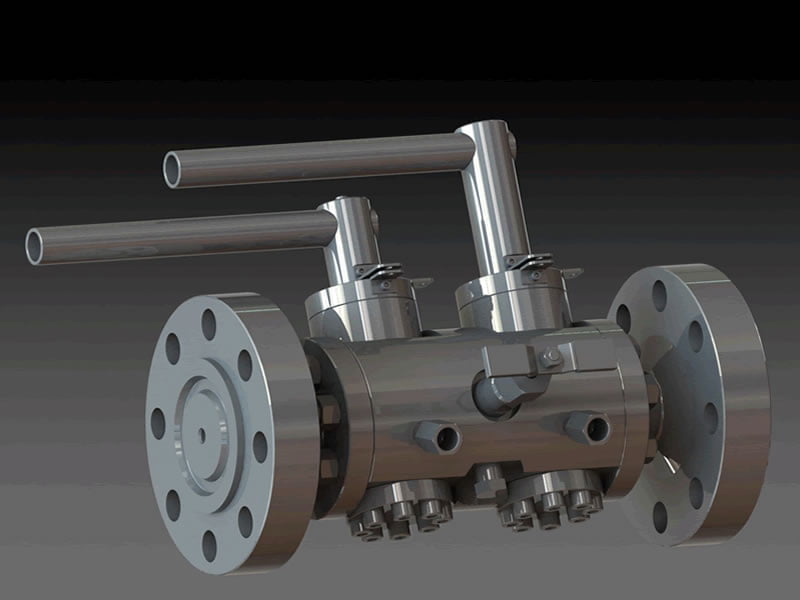

The DBB ball valve, or Double Block and Bleed ball valve, is a specialized solution for systems requiring high standards of safety and flow control. Unlike other options like globe valves or 3 way ball valves, the DBB ball valve offers a unique ability to isolate sections of a pipeline while simultaneously bleeding off pressure or trapped media. With advancements in actuation methods, such as pneumatic ball valves and electric ball valves, this design excels in critical operations, particularly in industries leveraging pneumatic control valves for precise management and efficiency.

Brief overview of valves in industrial applications (mention ball valve, gate valve, and butterfly valve).

Valves are essential components in industrial applications, regulating the flow of liquids and gases in pipelines. Ball valves provide reliable shut-off capabilities, gate valves are used for on-off control in straight-line flow, and butterfly valves handle flow isolation and throttling. Each type serves specific functions depending on system requirements and operational needs.

Ball valve

A ball valve uses a rotating ball with a bore to control the flow of liquids or gases. It operates by turning the ball to align the bore with the pipeline for flow or blocking it to stop flow. Its design allows for straightforward operation, making it widely used in various industrial systems.

Gate valve

Gate valves control the flow of liquids or gases by raising or lowering a gate inside the valve body. They are primarily used for starting or stopping flow in straight-line systems. When fully open, the gate moves out of the flow path, minimizing pressure drop, making them suitable for systems requiring unobstructed flow.

Butterfly valve

A butterfly valve uses a rotating disc to control the flow of liquids or gases. The disc stays in the flow path and rotates on a central axis to allow or restrict flow. Its compact design and simple operation make it suitable for managing flow isolation and regulation in various systems.

Define a DBB ball valve and explain its significance in fluid and gas handling systems.

A DBB ball valve, or Double Block and Bleed valve, is designed to isolate a section of a pipeline by using two sealing surfaces and a bleed mechanism. It allows safe maintenance, testing, or isolation of equipment by effectively separating fluids or gases. This design is commonly used to enhance safety and efficiency in fluid and gas handling systems.

Touch on the evolution of valve technology, including pneumatic valve and electric valve advancements.

Valve technology has developed over time to meet industrial demands, with advancements in pneumatic and electric valves broadening application possibilities. Pneumatic valves use compressed air for operation, providing precise control and reliability in automated systems. Electric valves utilize electric motors for actuation, enabling remote and programmable operation. These innovations have expanded the functionality and efficiency of valve systems across industries.

What Is a DBB Ball Valve?

Detailed definition of a Double Block and Bleed (DBB) design.

A Double Block and Bleed (DBB) design uses two sealing mechanisms with a bleed valve located between them to isolate sections of a system. This setup allows for the removal of pressure or trapped fluids between the seals, enabling safe maintenance or testing without disrupting upstream or downstream operations. It is widely implemented in processes requiring secure isolation in fluid and gas systems.

Describe how DBB ball valves differ from other valves like flanged ball valve and globe valve.

DBB ball valves differ from flanged ball valves and globe valves in their ability to provide isolation using two sealing surfaces and a bleed mechanism. Flanged ball valves primarily offer simple flow control through a single ball mechanism with a flanged connection for secure installation. Globe valves regulate flow with a linear motion disk and seat design, enabling throttling control. Unlike these types, DBB ball valves combine double isolation and bleed functionality, making them suitable for applications requiring enhanced operational safety in fluid and gas systems.

Discuss the primary use cases and industries that rely on DBB ball valves.

DBB ball valves are used in industries like oil and gas, chemical processing, and power generation for isolating pipelines and testing system integrity. They are employed in applications requiring separation of fluids or pressure relief, ensuring safe maintenance and preventing contamination. These valves are integral to systems where secure isolation and operational reliability are prioritized.

How Does the Double Block and Bleed Design Work?

Explain the functionality of the DBB ball valve, focusing on its dual-sealing mechanism.

The DBB ball valve operates using a dual-sealing mechanism designed to isolate a section of a pipeline. It incorporates two independent sealing surfaces that block fluid or gas flow from both upstream and downstream directions. A bleed valve located between the seals allows for the removal of trapped pressure or fluids, ensuring isolation and facilitating safe maintenance or inspection of the system. This configuration helps maintain system integrity and prevent cross-contamination.

Compare the operational differences between DBB ball valves, pneumatic ball valves, and gate valves.

DBB ball valves provide isolation using a dual-sealing mechanism with a bleed valve for pressure relief and removal of trapped fluids. Pneumatic ball valves use compressed air to actuate the ball, enabling remote and automated operations for flow control. Gate valves regulate flow by raising or lowering a gate and are primarily used for on-off control in linear motion applications. Unlike pneumatic and gate valves, DBB ball valves integrate isolation and bleeding functions, making them suitable for systems requiring secure maintenance procedures.

Highlight the safety and maintenance benefits of using this design.

The Double Block and Bleed design enhances safety by isolating sections of a pipeline using two sealing surfaces and a bleed valve. This configuration allows for the release of trapped pressure or fluids, ensuring safe working conditions during inspection or repairs. The design minimizes the risk of cross-contamination and reduces downtime by enabling maintenance without disrupting upstream or downstream operations.

Common Applications of DBB Ball Valves

Discuss their use in high-pressure pipelines, oil and gas, and chemical industries.

DBB ball valves are used in high-pressure pipelines, oil and gas operations, and chemical industries to provide isolation and prevent leakage. They are employed to separate fluids, reduce pressure, and enable secure maintenance in systems handling hazardous or pressurized media. These valves support operational safety by ensuring reliable isolation between upstream and downstream sections during inspections or repairs.

Compare DBB ball valves with 3-way ball valves and electric ball valves in specific applications.

DBB ball valves are used for isolating and bleeding operations in systems requiring pressure containment and pipeline segmentation. 3-way ball valves are employed to direct or mix flow between three ports, making them suitable for applications needing flow redirection. Electric ball valves use electric actuators for automated flow control, often in systems requiring precise or remote operation. Unlike these alternatives, DBB ball valves integrate isolation and bleeding functions, making them suitable for maintenance or safety-critical tasks in high-pressure environments.

Explore their importance in systems requiring precise control, such as pneumatic control valve systems.

DBB ball valves are essential in systems like pneumatic control valve setups where precise flow and pressure control are needed. Their ability to provide reliable isolation and pressure relief ensures efficient operation by maintaining system stability during adjustments or repairs. These valves support operational accuracy by preventing unwanted flow disruptions or cross-contamination in control-sensitive processes.

Advantages of DBB Ball Valves

Outline the technical benefits of the DBB ball valve design, such as leak prevention and durability.

The DBB ball valve design offers technical benefits by providing dual-sealing capabilities that prevent leaks and ensure isolation in pressurized systems. Its robust construction supports long-term operation in demanding environments, minimizing wear from continuous use. The integration of isolation and pressure relief functions reduces maintenance complexities and enhances system efficiency by enabling safe operational processes.

Compare efficiency and reliability with other valves like globe valve and butterfly valve.

DBB ball valves provide integrated isolation and pressure relief functions, making them efficient for systems requiring combined operations. Globe valves are used for flow regulation and offer precise throttling but involve higher pressure drops due to their design. Butterfly valves are compact and suitable for large flow rates but may not ensure the same level of tight shutoff as DBB ball valves. The design of DBB ball valves supports enhanced performance in applications requiring simultaneous isolation and sealing.

Discuss compatibility with different actuation methods, including pneumatic and electric mechanisms.

DBB ball valves are compatible with pneumatic and electric actuation methods, allowing integration into automated systems for remote or local control. Pneumatic actuators enable rapid operation in air-driven setups, while electric actuators provide precise positioning and consistent response for electrically operated systems. This flexibility ensures DBB ball valves can be adapted to various operational requirements and control strategies.

Key Features to Consider When Choosing a DBB Ball Valve

Materials, design standards, and certifications critical for high-quality DBB ball valves.

High-quality DBB ball valves are constructed with materials such as stainless steel and carbon steel to meet industry requirements for performance and durability. Design standards like ASME B16.34 and API 6D outline specifications for dimensions, pressure ratings, and operational parameters. Certifications such as ISO 9001 and fire-safe approvals ensure compliance with safety and quality benchmarks, making the valves suitable for critical applications in various industries.

Considerations for flanged ball valve and pneumatic ball valve configurations.

Flanged ball valve configurations offer secure connections for high-pressure systems and simplify installation and maintenance due to their bolted design. Pneumatic ball valve configurations are operated using compressed air, enabling quick and efficient automation for process control applications. Choosing between these configurations depends on system requirements, pressure conditions, and the need for manual or automated operation within the setup.

Recommendations based on specific industrial needs, emphasizing quality control and manufacturing expertise.

Selecting DBB ball valves for specific industrial needs requires analyzing operational conditions such as pressure, temperature, and medium type. Valves manufactured with rigorous quality control processes and adherence to recognized standards ensure reliability under critical conditions. Partnering with manufacturers that demonstrate expertise in precision engineering and material selection supports the efficient and safe operation of industrial systems.

Maintenance and Troubleshooting of DBB Ball Valves

Basic maintenance guidelines to ensure valve longevity and performance.

Basic maintenance of DBB ball valves includes regular inspection for leaks, wear, and debris in sealing areas. Cleaning the valve and ensuring lubrication of moving parts prevents operational issues caused by buildup or friction. Periodic checks of actuators and connections help maintain functionality and ensure alignment. Following the manufacturer’s guidelines for maintenance intervals and replacement of damaged components supports valve longevity and consistent performance.

Compare DBB ball valve maintenance to that of gate valves and globe valves.

DBB ball valve maintenance requires regular checks for leaks, debris, and lubrication, focusing on sealing surfaces and moving parts. Gate valves typically need attention to stem seals and seating surfaces due to their linear operation, while globe valves demand inspection of their plug and seat for wear caused by throttling. DBB ball valves offer simpler maintenance due to fewer components, with checks often emphasizing functional integrity over wear from flow regulation, unlike gate and globe valves.

Troubleshooting tips for valve issues in systems using pneumatic or electric actuation.

Troubleshooting valve issues in systems with pneumatic or electric actuation involves checking actuator alignment and verifying the power supply or air pressure levels. Inspect connections for leaks or faults that may disrupt operation. Test the control signal integrity and confirm that sensors and feedback devices are functioning correctly. Cleaning dirt or buildup from components ensures unobstructed movement, and recalibrating the actuator helps restore performance consistency. Follow manufacturer-recommended diagnostics to identify and resolve specific issues efficiently.

FAQ DBB ball valve

Q1: What distinguishes a DBB ball valve from other types like gate valves or butterfly valves?

A1: A DBB ball valve is designed to isolate and bleed off pressure in a system, ensuring complete block and bleed functionality. Unlike a gate valve, which uses a wedge mechanism for on/off control, or a butterfly valve that relies on a rotating disc, a DBB ball valve uses a spherical element to achieve tight shutoff. Its design allows for dual isolation within a single valve body, enhancing safety and reducing space requirements.

Q2: How do pneumatic and electric valves integrate with DBB ball valves?

A2: Pneumatic valves and electric valves are commonly used to automate the operation of DBB ball valves in industrial systems. A pneumatic valve uses compressed air to actuate the ball valve, providing rapid and consistent motion, while an electric valve relies on motorized control for precise operation. Both options enhance operational efficiency, offering flexibility for integration based on system requirements.

Q3: Can a DBB ball valve configuration include flanged connections, and how does it compare to other valve types?

A3: Yes, a DBB ball valve can be configured with flanged connections, which simplify installation and maintenance in high-pressure systems. Compared to gate valves and butterfly valves, a flanged ball valve provides superior sealing performance and improved durability under demanding conditions. This configuration is well-suited for applications requiring reliable isolation and pressure control.

Conclusion DBB ball valve

The DBB ball valve offers a reliable solution for achieving isolation and pressure control in critical applications. Its flexibility allows seamless integration with automation systems, using options like a pneumatic ball valve or an electric ball valve to enhance operational efficiency. While the DBB ball valve is specifically designed for double block and bleed functionality, alternatives like a 3 way ball valve or a globe valve may address unique flow control requirements in other setups. For advanced process control, pairing the DBB ball valve with a pneumatic control valve ensures precision and responsiveness, making it a crucial component in optimizing industrial system performance.