API 6D is a crucial standard set by the American Petroleum Institute that governs the design, manufacturing, and testing of pipeline valves, ensuring safety and superior performance across industries. Covering a wide range of applications, including ball valves, gate valves, and butterfly valves, this standard ensures compliance and reliability. From pneumatic and electric solutions to robust flanged ball valve designs, API 6D defines the benchmarks for quality and operational efficiency in modern pipeline systems.

Introduction

API 6D stands as a vital standard for ensuring the quality, safety, and performance of industrial pipeline valves. Its guidelines cover various valve types, including the precision of a pneumatic ball valve, the versatility of a 3-way ball valve, and the automation capabilities of an electric ball valve. The globe valve and pneumatic control valve are also integral to this standard, ensuring reliable flow regulation and control across pipeline systems.

Overview of pipeline valve standards for the oil and gas industry.

Pipeline valve standards establish guidelines for the design, manufacturing, and operation of valves used in oil and gas systems. These standards ensure compatibility, safety, and proper functioning across various applications. They include specifications for valve types such as ball valves, gate valves, and control valves, helping to regulate flow, prevent leakage, and maintain system integrity within pipeline networks.

Brief explanation of API and its significance in ensuring safety, performance, and reliability for pipeline systems.

API defines the standards for the design, manufacturing, and testing of pipeline valves used in oil and gas systems. It provides guidelines to ensure proper flow control, prevent leakage, and maintain operational efficiency. By setting clear requirements, API? supports uniformity and consistency across pipeline valve applications.

1. Understanding API

1.1 What Is API 6D?

Explanation of the API standard as defined by the American Petroleum Institute.

API 6D is a standard established by the American Petroleum Institute that outlines the requirements for the design, manufacturing, testing, and documentation of pipeline valves. It covers various valve types to ensure proper flow control, system functionality, and uniform practices in oil and gas operations. The standard is used to achieve consistency and compliance across the industry.

Its role in regulating the manufacturing, design, and testing of industrial valves, including ball valves and gate valves.

API 6D specifies the requirements for the design, manufacturing, and testing of industrial valves such as ball valves and gate valves. It ensures proper flow control, consistent practices, and operational compliance for systems in oil, gas, and other industries. The standard provides guidelines to maintain functionality and safety in pipeline operations.

1.2 Why API Is Critical for Pipelines

Importance of compliance with API for quality assurance.

Compliance with API ensures standardized practices in the design, manufacturing, and testing of pipeline valves. It helps maintain consistency, proper functionality, and system integrity across operations. Meeting these requirements supports quality assurance and adherence to industry regulations.

Discussion on the operational safety benefits for valves like butterfly valves and globe valves within pipeline systems.

API? provides guidelines for the design and function of valves, including butterfly valves and globe valves, within pipeline systems. These standards support operational safety by ensuring reliable flow control, minimizing risks of leakage, and maintaining system consistency. Compliance with these guidelines helps reinforce safe and efficient pipeline operation.

2. Types of Valves Covered Under API

2.1 Ball Valves and Their Variants

Overview of ball valves, including flanged ball valves, pneumatic ball valves, 3-way ball valves, and electric ball valves.

Ball valves are flow control devices designed for pipeline systems, available in various types such as flanged ball valves, pneumatic ball valves, 3-way ball valves, and electric ball valves. Each type serves specific operational needs, including directional control, automation, or system adaptability. These valves are widely used for their ability to provide consistent and efficient flow management in different settings.

Applications within pipeline sectors governed by the API standard.

API governs the use of ball valves in pipeline sectors involved in the transportation of oil, gas, and other fluids. These valves are applied in systems requiring reliable flow control, automation, and adherence to safety and performance standards. Compliance ensures compatibility and efficiency across industrial operations.

2.2 Gate Valves and Their Extensive Usage

Description of gate valves and their specific functionality under API? compliance.

Gate valves are flow control devices designed to start or stop fluid flow within pipeline systems. Under API? compliance, they are used in operations where full open or full closed functionality is required. These valves ensure system integrity, proper shut-off capabilities, and adherence to industry standards for pipeline safety and performance.

How gate valves ensure efficient flow control in pipelines.

Gate valves control fluid flow by providing a full passage when fully open and a secure shut-off when closed. This design minimizes flow resistance and supports efficient operation in pipelines. They are suitable for applications requiring precise flow control and compliance with operational standards.

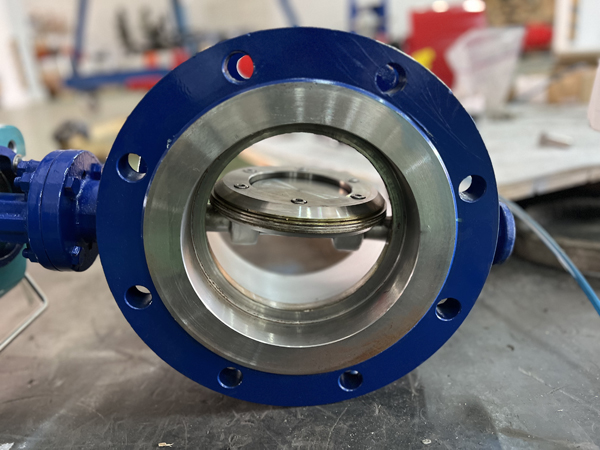

2.3 Butterfly Valves and Pressure Management

The role of butterfly valves within pipeline pressure regulation.

Butterfly valves regulate pressure in pipeline systems by controlling fluid flow through a pivoting disc mechanism. Their design allows for efficient modulation of flow rates, enabling operators to maintain desired pressure levels. These valves are used in applications requiring frequent flow adjustments and are valued for their compatibility with automated systems. By ensuring consistent pressure regulation, butterfly valves support the safe and efficient operation of pipeline networks.

How API 6D ensures durable performance for these valves.

Butterfly valves regulate pressure in pipeline systems by controlling fluid flow through a pivoting disc mechanism. Their design allows for efficient modulation of flow rates, enabling operators to maintain desired pressure levels. These valves are used in applications requiring frequent flow adjustments and are valued for their compatibility with automated systems. By ensuring consistent pressure regulation, butterfly valves support the safe and efficient operation of pipeline networks.

2.4 Globe Valves in Pipeline Systems

How globe valves allow for precise control and throttling of pipeline flows in API 6D applications.

Globe valves manage pipeline flow by adjusting the position of a movable disc against a stationary seat. This design enables precise regulation and throttling of fluid flow within API applications. The valves are suitable for operations requiring accurate flow adjustments while maintaining compliance with established safety and performance standards.

2.5 Pneumatic and Electric Control Valves

Overview of pneumatic valves and pneumatic control valves in automated pipeline systems.

Pneumatic valve and pneumatic control valves use compressed air to manage and regulate pipeline flow in automated systems. These valves operate through actuators, enabling remote and efficient control of fluid movement. They are designed for integration with automation technologies, ensuring precise flow adjustments and meeting operational requirements in pipeline applications.

Discussion of electric valves and their role in remote and efficient valve actuation.

Electric valves enable remote valve actuation by using electric motors to control the opening and closing mechanisms. These valves integrate with control systems to support automated pipeline operations. They allow precise adjustments to flow or pressure settings and are suited for managing complex systems with varying operational demands.

3. Technical Requirements of API

3.1 Design and Material Specifications

Industry standards for materials used in manufacturing API-compliant valves.

API includes strict standards for materials used in valve manufacturing to ensure safety and performance. These standards specify requirements for metal alloys, seals, and other components to handle pressures, temperatures, and flow conditions in pipeline systems. Valves must meet material testing protocols to verify compatibility with operational demands and compliance with industry regulations.

Testing and certifications required for ball valves, pneumatic valves, and other variants.

Ball valves, pneumatic valves, and other variants undergo testing and certification processes to ensure compliance with industry standards. These include pressure tests, leakage evaluations, and functional assessments to verify operational integrity. Certification requirements often align with standards like API, ensuring the valves meet criteria for performance, safety, and compatibility in pipeline systems.

3.2 Quality Control Measures

Detailed insights into quality control processes under API.

API? outlines quality control processes to verify the reliability and performance of valves used in pipeline systems. These processes include material inspections, machining accuracy checks, and pressure testing. Each valve undergoes verification steps to ensure it meets dimensional standards, operational requirements, and industry compliance criteria.

Inspection protocols for flanged ball valves, electric ball valves, and gate valves.

Inspection protocols for flanged ball valves, electric ball valves, and gate valves include dimensional checks, material verification, and operational testing. These protocols assess the valves’ ability to meet pressure, temperature, and flow requirements. Each valve type undergoes inspections to verify proper assembly, seal integrity, and compliance with applicable industry standards.

3.3 Performance Testing

Explanation of pressure and leakage tests mandated by API.

Pressure and leakage tests mandated by API evaluate the strength and sealing capabilities of valves. Pressure tests involve applying internal pressure to verify the valve’s structural integrity under operating conditions. Leakage tests assess seal performance by detecting any fluid loss when the valve is in a closed position. These tests ensure valves meet operational and safety requirements outlined in API 6D.

Impact on the performance and reliability of pneumatic ball valves and other pipeline valves.

Performance testing evaluates the operation and durability of pneumatic ball valves and other pipeline valves under various conditions. These tests measure factors such as pressure tolerance, flow control accuracy, and sealing capability. The results determine the valves’ suitability for specific applications and their compliance with operational standards, ensuring reliability across pipeline systems.

4. API 6D Certification Process

4.1 Steps to Achieve API 6D Compliance

Certification requirements for valve manufacturers.

Achieving API 6D compliance requires meeting specific standards outlined by the American Petroleum Institute. Manufacturers must establish documented procedures for design, production, and quality control. Regular audits are conducted to verify compliance with material selection, testing, and manufacturing processes. Companies need to maintain traceability of components and ensure proper documentation of valve performance tests. Certification involves submitting all required records, passing facility inspections, and adhering to continuous improvement practices based on periodic standards updates.

Importance of meeting API 6D standards for global recognition in valve manufacturing.

Meeting API 6D standards ensures alignment with internationally recognized specifications for pipeline valves. Compliance demonstrates a manufacturer’s capability to produce valves that meet safety, performance, and reliability benchmarks. This establishes credibility with industry stakeholders, facilitates marketability across various regions, and supports participation in projects requiring adherence to strict industry frameworks.

4.2 The Role of Third-Party Audits

How third-party audits ensure adherence to API 6D for valves such as 3-way ball valves and electric valves.

Third-party audits evaluate compliance with API 6D by assessing the design, manufacturing, and testing processes of valves such as 3-way ball valves and electric valves. Auditors review documentation, inspect facilities, and verify material traceability to ensure processes meet the required standards. These assessments identify non-conformities and help manufacturers implement corrective actions, ensuring consistent adherence to API 6D requirements.

5. Selecting the Right API 6D Valves for Your Needs

5.1 Choosing Between Valve Types

Factors to consider when selecting between ball valves, gate valves, and butterfly valves for API 6D applications.

Selecting between ball valves, gate valves, and butterfly valves for API applications requires evaluating factors such as the specific operational conditions, pressure class, and flow control requirements. Ball valves are suited for tight shut-off and control, gate valves offer solutions for on-off services with minimal flow restriction, and butterfly valves are optimized for larger pipelines and throttling functions. Compatibility with the medium, maintenance needs, and installation space also play critical roles in the decision-making process.

Use-case scenarios for pneumatic control valves versus electric ball valves.

Pneumatic control valves are often used in applications requiring precise modulation of flow in systems powered by compressed air, such as process industries. Electric ball valves are typically suited for automated on-off operations in systems with electrical power availability, including remote or distributed control setups. The selection depends on factors like power source, control requirements, and response times needed for the application.

5.2 Importance of Flanged Connections

Advantages of flanged ball valves for durability and ease of maintenance.

Flanged ball valves provide secure connections that support durability and simplify maintenance. The flanged design allows for easy installation and removal without excessive system downtime. This feature enables straightforward inspection, cleaning, and replacement of components. Additionally, the connections reduce the likelihood of leaks, ensuring dependable performance in various environments.

6. The Future of API 6D Valves in Modern Pipelines

6.1 Innovations in Valve Technology

Emerging technologies in electric valves and pneumatic ball valves for enhanced pipeline automation.

Emerging technologies in electric valves and pneumatic ball valves focus on integrating advanced control systems and diagnostics for pipeline automation. Smart actuators in electric valves enable remote operation and monitoring, while pneumatic ball valves increasingly incorporate positioners for precise flow control. These advancements improve system responsiveness and compatibility with modern automation frameworks, supporting efficient pipeline operations.

6.2 The Ongoing Evolution of Standards

How API 6D is adapting to new challenges in the oil and gas industries.

API is evolving to address new challenges in the oil and gas industries by incorporating requirements for advanced materials, updated testing protocols, and enhanced safety features. These changes aim to accommodate higher pressure systems, extreme temperature environments, and the integration of automation technologies. The standard ensures that valves continue to meet operational demands while maintaining compliance with industry regulations.

FAQ API 6D

Q1: What is API, and which valves does it cover?

A: API is the standard for pipeline valve specifications in the oil and gas industry, addressing design, manufacturing, testing, and documentation requirements. It covers valves such as ball valves, gate valves, and butterfly valves, ensuring they meet stringent performance and safety criteria for high-pressure pipeline applications.

Q2: How does API? apply to automation technologies like pneumatic and electric valves?

A: API? ensures that both pneumatic valves and electric valves meet operational reliability and control standards required for automated pipeline systems. This includes compliance with testing protocols for actuated valves to maintain safety and efficiency across various operational setups.

Q3: Why are flanged ball valves significant in API applications?

A: Flanged ball valves are emphasized in API? due to their reliable connections and ease of maintenance. The standard ensures these valves meet specifications for durability, leak prevention, and suitability for high-pressure environments, which is critical for safe and efficient pipeline operations.

Conclusion

API 6D establishes essential API standards for valves used in pipeline systems, encompassing design, performance, and safety requirements. These standards ensure reliable operation across various valve types, including pneumatic ball valves, plug valves, 3 way ball valves, electric ball valves, globe valves, and pneumatic control valves. By addressing critical elements like pressure ratings, API supports the demand for efficient and dependable flow control solutions while ensuring compliance with industry regulations. Adhering to API? standards is vital for preserving the integrity, safety, and performance of modern pipeline infrastructure.