Valves play a crucial role in industrial systems, serving as essential components for controlling the flow of liquids, gases, and more. Whether it’s a ball valve, gate valve, or butterfly valve, the efficiency and performance of a system often hinge on selecting the right valve type. Among the most prominent options, pneumatic valve vs electric valve systems offer unique advantages tailored to specific applications. Choosing between these two technologies is not merely a matter of preference—it’s about aligning their characteristics with operational needs. This article dives into the differences, strengths, and applications of pneumatic and electric valves, offering valuable insights to help you make an informed decision.

Introduction Pneumatic Valve vs Electric Valve

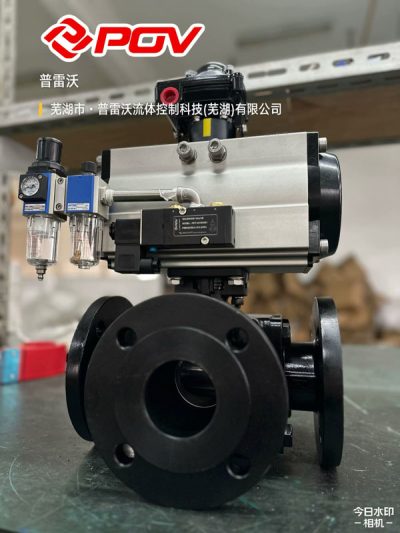

When comparing pneumatic valves to electric valves, distinct differences in operation and application become apparent. A pneumatic ball valve or pneumatic control valve leverages compressed air for quick and efficient actuation, making it ideal for high-speed operations. On the other hand, an electric ball valve offers precise control and suits processes requiring accuracy over speed. Design variations like the flanged ball valve or the versatile 3-way ball valve allow both technologies to adapt to diverse systems. Additionally, options such as the globe valve cater to specific flow regulation needs, emphasizing the importance of choosing the right valve type for optimal performance.

Understanding Valve Mechanics: Pneumatic Valves vs. Electric Valves

Explanation of pneumatic valve operation using compressed air.

Pneumatic valves operate by using compressed air to move internal components, such as actuators, to control the flow of fluids or gases. When air pressure is applied, it triggers the actuator to open or close the valve, enabling quick and reliable operation. These valves are commonly used in automation systems where speed and simplicity are essential for controlling processes efficiently.

Overview of electric valve mechanics, focusing on motor-driven actuation.

Electric valves rely on motor-driven actuation to open and close their internal components. The motor converts electrical energy into mechanical motion, allowing precise control over fluid or gas flow. These valves are often used in systems that require accurate adjustments, as their motorized design enables incremental positioning and reliable operation.

Discussion of how both valve technologies apply to systems featuring ball valves, gate valves, and butterfly valves.

Pneumatic and electric valves are widely used in systems that incorporate ball valves, gate valves, and butterfly valves. Pneumatic valves provide quick, efficient actuation, making them suitable for high-cycle operations. Electric valves, with their motor-driven precision, are ideal for applications requiring controlled and adjustable flow. Both technologies enhance the performance of these valve types depending on system requirements and operating conditions.

Design Differences in Pneumatic and Electric Valves

Key structural distinctions between pneumatic ball valves, electric ball valves, and pneumatic control valves.

Pneumatic ball valves use compressed air to operate, with simple actuators that enable fast opening and closing. Electric ball valves feature motor-driven components, designed for precise flow control through incremental adjustments. Pneumatic control valves differ by integrating additional mechanisms for modulating flow rates and pressure, offering more versatility in system regulation compared to standard ball valves.

Comparison of installation formats, such as flanged ball valves and 3-way ball valves, within pneumatic and electric setups.

Flanged ball valves and 3-way ball valves are used differently in pneumatic and electric systems based on installation needs. Flanged ball valves are commonly integrated into systems requiring secure, bolted connections and are compatible with both pneumatic and electric actuation. 3-way ball valves, offering multi-directional flow control, are adapted for pneumatic setups for rapid switching, while electric systems use them for precise, motorized adjustments in flow paths.

Brief mention of other valve types, like globe valves, in this context.

Beyond pneumatic and electric valves, other valve types, such as globe valves, play a significant role in flow control systems. Globe valves are specifically designed for regulating fluid flow and provide precise throttling capabilities due to their internal disk and seat configuration. Unlike the automated mechanisms of pneumatic and electric valves, globe valves typically rely on manual or basic actuated operations, making them suitable for applications requiring fine control. Understanding these design distinctions highlights the specialized functions each valve type offers within varied industrial systems.

Performance Factors of Pneumatic Valves and Electric Valves

Analysis of actuation speed and precision, highlighting pneumatic valves’ quick response and electric valves’ precise control.

Pneumatic valves are noted for their fast actuation speeds, driven by the rapid movement of compressed air through the system. This makes them effective in applications where quick response is critical. Electric valves, on the other hand, prioritize precision, offering accurate control over positioning through motor-driven actuation. The balance between speed and precision in these systems provides flexibility for various operational requirements.

Discussion on energy efficiency and long-term operation costs.

When comparing energy efficiency and long-term operation costs, pneumatic valves often involve higher energy consumption due to the need for continuous air supply, which can increase operating expenses over time. Electric valves, powered by motors, typically offer more efficient energy use, especially in applications requiring sustained or precise position control. Assessing these factors helps in selecting the appropriate valve type for cost-effective and sustainable operation.

Case examples of pneumatic control valves in high-speed systems versus electric valves in precision control environments.

Pneumatic control valves are commonly used in systems requiring high-speed operation, such as emergency shutdown mechanisms, where rapid actuation is essential. Electric valves are better suited for environments demanding precise control, such as chemical processing systems, where fine adjustments in flow or pressure are critical. These examples highlight how each valve type aligns with specific performance needs.

Applications Across Industries

Breakdown of pneumatic valves in compressed air systems, including common uses in automation.

Pneumatic valves in compressed air systems are integral to controlling air flow and pressure, enabling efficient operation in automated environments. They are widely applied in tasks such as actuating cylinders, operating conveyor belts, and managing robotic systems. Their ability to provide reliable, on-demand control makes them a staple in industrial automation.

Exploring electric valves’ role in applications requiring energy-efficient actuation.

Electric valves are essential in applications prioritizing energy-efficient actuation, particularly where precision and sustained control are key. Frequently used in HVAC systems and water treatment facilities, these valves rely on motorized operation to minimize energy consumption while maintaining consistent performance. Their adaptability to automated processes further enhances efficiency across various industries.

Industry-specific insights into choosing between flanged ball valves, pneumatic ball valves, or electric ball valves.

Selecting between flanged ball valves, pneumatic ball valves, and electric ball valves depends on specific industry needs. Flanged ball valves are often chosen in sectors like oil and gas for their secure sealing and durability in high-pressure systems. Pneumatic ball valves are ideal for industries requiring rapid actuation, such as manufacturing automation. Electric ball valves, with their precise control, suit applications like water treatment and energy management, where efficiency and accuracy are critical. These distinctions help tailor valve selection to operational demands.

Advantages and Disadvantages of Pneumatic and Electric Valves

Pros and cons comparison, including durability, maintenance, and environmental adaptability.

Pneumatic valves are known for their durability in harsh environments and require minimal maintenance, but their reliance on a stable compressed air supply can limit adaptability in remote locations. Electric valves, while offering higher precision and energy efficiency, are more complex to maintain and may be less resilient in extreme conditions. Balancing these factors is essential when matching valve type to operational requirements.

Highlight examples of valve configurations like globe valve and butterfly valve in different environments.

Globe valves and butterfly valves serve distinct purposes in various environments. Globe valves are preferred in settings requiring precise flow control, such as chemical processing or steam systems, due to their ability to handle high pressures. Butterfly valves, with their compact design and quick actuation, are used in systems like wastewater management and HVAC where space-saving and ease of operation are priorities. Each configuration aligns with specific operational demands, emphasizing functionality over flexibility.

Explanation of when to choose 3-way ball valves or gate valves in pneumatic vs. electric systems.

3-way ball valves and gate valves are chosen based on functionality and system type. 3-way ball valves are ideal in pneumatic systems for diverting or mixing flows, offering quick actuation and reliability in automation. Gate valves, known for their ability to fully shut off or open flow, are often used in electric systems where precise flow isolation is needed in high-pressure settings. The decision depends on the operational goal, with each valve type serving distinct roles.

Choosing the Right Valve for Your Needs

Guidelines for selecting between pneumatic and electric valves based on operational parameters.

Selection between pneumatic and electric valves depends on operational parameters such as control precision, environmental conditions, and energy requirements. Pneumatic valves are better suited for systems needing quick, reliable actuation in extreme temperatures or hazardous environments. Electric valves, offering greater control and energy efficiency, are ideal for applications requiring precise adjustments or where an electrical power source is readily available. Evaluating these factors ensures alignment with specific system needs.

Factors to consider, such as system pressure, temperature, and automation requirements.

System pressure, temperature, and automation requirements are key factors in selecting the right valve. High-pressure systems may require durable options like gate or ball valves, while extreme temperatures might favor materials suitable for thermal resistance. Automation needs, such as remote operation or integration with control systems, guide the choice between pneumatic for faster actuation and electric for precise adjustments. Aligning these considerations ensures optimal valve performance.

How to evaluate whether a pneumatic control valve or an electric ball valve would better serve the application.

Evaluating whether to use a pneumatic control valve or an electric ball valve depends on the application’s requirements. Key factors include the availability of compressed air or electricity, the need for speed or precision, and the operating environment. Pneumatic control valves work well in systems with frequent actuation and harsh conditions, while electric ball valves offer precise operation and integration with automated control systems. The choice hinges on aligning the valve’s features with the system’s needs.

The Future of Pneumatic and Electric Valve Technologies

Advances in smart valve technology integrating with pneumatic control valve and electric systems.

Smart valve technology is advancing through improved integration with pneumatic and electric systems. These developments enable real-time monitoring, predictive maintenance, and seamless communication with control networks. Pneumatic control valves benefit from enhanced actuation speed, while electric systems gain more precise control and automated adjustments. These integrations optimize system performance and reduce operational disruptions.

Emerging trends in energy-efficient and environmentally friendly valve designs.

Emerging trends in valve design focus on energy efficiency and reduced environmental impact. Innovations include materials that lower emissions, designs that minimize energy consumption during operation, and systems that support renewable energy integration. These advancements ensure compliance with regulations while promoting sustainable practices in pneumatic and electric valve technologies.

Insights into evolving industrial standards for flanged ball valves, butterfly valves, and others.

Evolving industrial standards for flanged ball valves, butterfly valves, and others are focusing on improving safety, performance, and compatibility with automated systems. These standards address pressure tolerances, material specifications, and design features to meet stricter operational and environmental requirements. Adapting to these changes ensures reliability and compliance across diverse industrial applications.

FAQ Pneumatic Valve vs Electric Valve

Q1: What are the main differences between a pneumatic valve and an electric valve in terms of application?

A1: A pneumatic valve relies on compressed air for actuation, making it suitable for fast, repetitive operations in industrial settings. An electric valve uses electrical energy for actuation, providing more precise control and integration with automation systems. For example, a pneumatic valve might be preferred for fast actuation in a system using a gate valve, while an electric valve could be ideal for precise modulation in a flanged ball valve or butterfly valve application.

Q2: When should you choose a flanged ball valve over other valve types in pneumatic or electric systems?

A2: A flanged ball valve is optimal when dealing with high-pressure systems requiring secure sealing and easy maintenance. In pneumatic systems, it offers quick actuation, while in electric systems, it ensures precise control and integration with automated networks. Compared to a butterfly valve, which is better suited for larger volume flow, or a gate valve, which performs well in on/off scenarios, the flanged ball valve balances durability and performance.

Q3: How do pneumatic and electric valves differ in handling various valve types like butterfly valves or gate valves?

A3: Pneumatic valves are highly effective for fast actuation in butterfly valves, which often need rapid flow control adjustments in large system pipelines. On the other hand, electric valves work better with gate valves in precise, slow-moving applications where consistent control is critical. For applications requiring robust sealing and automation, such as those using flanged ball valves, electric valves often offer better integration with advanced control systems.

Conclusion Pneumatic Valve vs Electric Valve

Pneumatic valves and electric valves each offer unique advantages tailored to specific operational needs. A pneumatic ball valve and pneumatic control valve excel in applications requiring fast, repetitive actuation, especially in industrial environments with access to compressed air. An electric ball valve provides precise control, making it ideal for automation and integration with smart systems. A 3 way ball valve offers flexibility in directing fluid flow, catering to both pneumatic and electric systems depending on automation requirements. Similarly, a globe valve serves well in precise throttling applications, further showcasing how the choice between pneumatic and electric systems hinges on factors like control precision, speed, and energy availability. Understanding these key differences ensures optimal performance and system efficiency.