Selecting the right diaphragm valve is critical for ensuring optimal performance and compliance in industries that demand precision and hygiene. This article explores the key differences between sanitary clamp and welded diaphragm valves, highlighting their distinct design features and performance benefits. From the versatility of sanitary diaphragm valves to the specialized applications of pneumatic diaphragm valves and 3 way diaphragm valves, understanding these options is essential for tailoring solutions to your system’s needs.

Introduction sanitary diaphragm valve

Sanitary diaphragm valves are vital for precision and cleanliness in demanding industries like pharmaceuticals and biotechnology. Designed to meet stringent hygiene standards, they offer unparalleled fluid control with the help of advanced air actuated diaphragm valves and diaphragm valve pneumatic actuator systems. Diaphragm valve manufacturers emphasize their reliability and adaptability, ensuring seamless integration into processes requiring sterile or high-purity conditions.

Understanding Diaphragm Valves

Diaphragm valves are vital components in sanitary systems, designed to regulate the flow of fluids with precision while maintaining strict hygiene standards. Their structure uses a flexible diaphragm to seal flow paths, ensuring sterile operation and minimizing contamination risks. These valves are critical in applications like pharmaceuticals and food processing, where cleanliness, reliability, and performance are paramount. Understanding their versatility helps in comparing variations, such as clamp and welded designs, for specific system needs.

What Are Diaphragm Valves?

Diaphragm valves are versatile flow control devices used to manage the movement of fluids or gases in a system. Their unique design incorporates a flexible diaphragm that presses against a seat to regulate or halt flow, ensuring precise operation. Commonly employed in sanitary and high-purity applications, these valves excel in providing reliable performance while minimizing the risk of contamination, making them essential in industries like pharmaceuticals, food processing, and biotechnology.

Explanation of the basic structure and functionality of diaphragm valves.

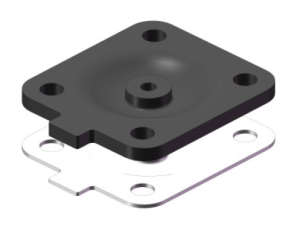

Diaphragm valves are constructed with a simple yet effective design that includes a flexible diaphragm, a valve body, and an actuator. The diaphragm, typically made from elastomer or other durable materials, serves as a barrier between the fluid and the actuator components, reducing the risk of contamination. When the actuator is engaged, it pushes the diaphragm against the valve seat, either restricting or completely stopping the flow. This streamlined structure not only ensures accurate flow control but also makes diaphragm valves easy to clean and maintain, especially in applications where hygiene and sterility are paramount.

Discuss applications and advantages, focusing on hygienic and sanitary environments.

Diaphragm valves are indispensable in hygienic and sanitary environments, such as pharmaceuticals, food processing, and biotechnology. Their design minimizes contamination risks by isolating the fluid from external components, ensuring sterility and compliance with strict industry standards. With easy cleaning and reliable control, they offer unmatched performance in systems requiring precision and cleanliness. These advantages make them a trusted choice for applications where purity and safety are paramount.

The Importance of Design in Sanitary Diaphragm Valves

The design of sanitary diaphragm valves is essential for achieving optimal hygiene, performance, and reliability in sensitive applications. Their construction, featuring smooth surfaces and minimal crevices, ensures effective fluid flow and reduces the risk of contamination. Built with durable materials, these valves withstand repeated use in demanding environments without compromising sterility. This thoughtful design also simplifies maintenance, enabling quick cleaning and minimizing system downtime, making them indispensable in industries such as pharmaceuticals and food processing.

Examination of how design impacts performance, durability, and maintenance for sanitary systems.

The design of sanitary diaphragm valves plays a critical role in determining their performance, durability, and ease of maintenance. Features such as streamlined flow paths reduce the risk of contamination, while durable materials enhance wear resistance and longevity in demanding environments. Additionally, design elements aimed at easy disassembly and cleaning improve maintenance efficiency, ensuring system reliability and adherence to strict hygiene standards. A well-considered design ensures these valves provide consistent, high-quality operation in sanitary systems.

Sanitary Clamp Diaphragm Valves

Sanitary clamp diaphragm valve are characterized by their quick-connect design, which allows for easy installation, removal, and maintenance. These valves excel in applications requiring frequent cleaning or system modifications, as the clamp connections simplify disassembly without compromising hygiene. Their smooth internal surfaces ensure sterile operation, making them ideal for industries like pharmaceuticals and food processing. The versatility and efficiency of clamp diaphragm valves make them a preferred choice when flexibility and cleanliness are critical.

Design Features and Advantages of Sanitary Diaphragm Valves

Sanitary diaphragm valves feature smooth, crevice-free interiors and a flexible diaphragm that ensures precise flow control while maintaining strict hygiene. Their design enables quick cleaning and sterilization, reducing contamination risks in sensitive applications like pharmaceuticals and food processing. Engineered for durability and reliability, these valves perform consistently even in demanding environments. The use of high-grade materials and simplified maintenance procedures further enhances their efficiency, making them an ideal solution for sanitary systems.

Performance Insights for Pneumatic Diaphragm Valves

Pneumatic diaphragm valves offer superior operational efficiency and reliability, making them ideal for sanitary applications. Their automated design ensures precise control of fluid flow, reducing manual intervention while maintaining consistent performance. The use of high-quality materials and a crevice-free interior minimizes contamination risks, supporting hygiene-critical environments like pharmaceuticals and food processing. Additionally, their adaptability and ease of integration into existing systems boost overall flexibility and efficiency in complex operations.

Welded Diaphragm Valves

Welded diaphragm valves are designed for permanent installations, offering unmatched reliability and structural integrity in sanitary applications. Their welded connections eliminate potential leak points, ensuring a secure, contamination-free flow path. This robust design is ideal for systems with demanding requirements, such as continuous operations in pharmaceuticals or food processing, where hygiene and durability are paramount. By reducing maintenance needs and enhancing system stability, welded diaphragm valves provide a long-term, efficient solution for critical operations.

Key Design Considerations for 3 Way Diaphragm Valves

3-way diaphragm valves are engineered for versatile flow configurations, allowing fluid diversion, mixing, or isolation within a single valve body. Their design prioritizes smooth, crevice-free surfaces to maintain hygiene and streamline cleaning processes, making them ideal for sanitary applications. These valves offer precise control and flexibility, enabling efficient system design in industries like pharmaceuticals and food processing. Careful selection of materials and connection types further enhances their performance and ensures compatibility with demanding operational environments.

Durability and Applications with Air Actuated Diaphragm Valves

Air actuated diaphragm valves are built for exceptional durability, offering sturdy construction that withstands rigorous use in demanding environments. Their automated operation ensures consistent performance while reducing manual intervention, making them ideal for processes prioritizing efficiency and precision. These valves are particularly well-suited for hygiene-sensitive applications in industries such as pharmaceuticals and food processing, where their reliability and contamination-free flow paths support stringent operational standards. Their adaptability and low-maintenance design further enhance their value in complex system integrations.

Comparing Sanitary Clamp and Welded Valves

Air actuated diaphragm valves are built for exceptional durability, offering sturdy construction that withstands rigorous use in demanding environments. Their automated operation ensures consistent performance while reducing manual intervention, making them ideal for processes prioritizing efficiency and precision. These valves are particularly well-suited for hygiene-sensitive applications in industries such as pharmaceuticals and food processing, where their reliability and contamination-free flow paths support stringent operational standards. Their adaptability and low-maintenance design further enhance their value in complex system integrations.

Key Differences in Performance

Sanitary clamp diaphragm valves excel in ease of maintenance and rapid assembly, making them ideal for systems requiring frequent cleaning and flexibility. On the other hand, welded diaphragm valves prioritize long-term performance with their secure, leak-proof construction, which is better suited for permanent installations in demanding environments. While clamp valves offer versatility with their quick adaptability, welded valves provide enhanced stability and durability, ensuring reliable operation in critical sanitary applications. Both designs cater to distinct system needs based on operational priorities and hygiene requirements.

Head-to-head comparison of performance factors like pressure handling, flow optimization, and temperature tolerance.

Sanitary clamp and welded valves exhibit distinct performance characteristics in pressure handling, flow optimization, and temperature tolerance. Clamp valves are designed for moderate pressure environments and prioritize ease of flow adjustments, making them suitable for dynamic systems. Welded valves, however, excel in high-pressure applications with superior temperature tolerance due to their robust, sealed construction. These differences make clamp valves ideal for systems requiring frequent reconfiguration, while welded valves cater to demanding, high-stress environments where durability and stability are paramount.

Evaluating the impact of pneumatic diaphragm valve actuation methods in different setups.

Pneumatic diaphragm valve actuation methods significantly influence performance and adaptability in various system setups. For sanitary clamp valves, pneumatic actuation offers precise control and quick responsiveness, making them well-suited for systems that require flexibility and frequent adjustments. On the other hand, welded valves benefit from robust pneumatic actuation by delivering consistent performance in high-pressure and high-temperature environments, ensuring long-term reliability. The choice of actuation method plays a pivotal role in aligning valve functionality with the specific demands of a system, optimizing efficiency and durability.

Maintenance and Usability Insights from Diaphragm Valve Manufacturers

Diaphragm valve manufacturers emphasize the importance of maintenance and usability tailored to each valve type. Sanitary clamp valves are praised for their quick disassembly and reassembly, making them ideal for frequent cleaning and maintenance in dynamic environments. Conversely, welded valves are designed for minimal maintenance due to their permanent, leak-proof construction, which ensures consistent reliability in long-term applications. Manufacturers recommend choosing the valve type based on operational needs, hygiene requirements, and system accessibility to optimize performance and efficiency.

Comparison of maintenance requirements, including cleaning processes, part replacement, and downtime considerations.

Sanitary clamp valves and welded diaphragm valves differ significantly in their maintenance demands. Clamp valves are designed for quick disassembly, streamlining cleaning processes and reducing downtime, making them optimal for systems requiring frequent sanitization. Conversely, welded diaphragm valves prioritize durability with limited access for disassembly, which can extend the time needed for part replacement and cleaning but ensures fewer disruptions over long-term use. These contrasting requirements make clamp valves more user-friendly for dynamic setups, while welded valves suit applications where extended intervals between maintenance are acceptable.

Insights from leading diaphragm valve manufacturers on long-term cost efficiency.

Leading diaphragm valve manufacturers emphasize how thoughtful design and optimized maintenance protocols can significantly enhance long-term cost efficiency. Valve designs that streamline cleaning, minimize part replacements, and reduce downtime contribute to lower operational expenses over time. Additionally, durable materials and precise engineering extend valve lifespan, minimizing the need for frequent replacements. These insights highlight the critical balance between upfront investment and maintenance savings to achieve sustainable cost efficiency in demanding sanitary applications.

Choosing the Best Option for Your System

Selecting between sanitary clamp and welded diaphragm valves depends on your system’s unique demands. For operations requiring frequent cleaning or reconfiguration, clamp valves offer unmatched flexibility and convenience with their easy disassembly. Conversely, welded valves are ideal for permanent setups, providing superior durability and leak-proof reliability in long-term applications. Evaluate factors like system hygiene standards, maintenance intervals, and operational stability to identify the valve type that aligns best with your performance and efficiency goals.

Factors to Consider

When evaluating sanitary clamp versus welded diaphragm valves, key factors include the specific application needs, maintenance demands, and overall system compatibility. Clamp valves offer excellent versatility for systems requiring frequent cleaning or reconfiguration, while welded valves deliver robust, leak-proof performance for permanent installations. Carefully assess operational priorities, such as ease of access, hygiene requirements, and long-term reliability, to choose the valve design that optimally supports your system’s objectives.

Why Diaphragm Valve Pneumatic Actuator Systems Matter

Diaphragm valve pneumatic actuator systems play a vital role in optimizing efficiency, precision, and reliability across diverse applications. By automating the operation of diaphragm valves, these systems enable consistent control, faster response times, and reduced manual intervention. Their design enhances process accuracy, minimizes downtime, and supports stringent hygiene and operational standards, making them an essential choice for industries that prioritize high-performance, low-maintenance solutions in complex system environments.

FAQ sanitary diaphragm valve

Q1. What are the primary differences between sanitary clamp and welded diaphragm valves in terms of maintenance?

A1. Sanitary clamp diaphragm valves offer easy disassembly, making them highly convenient for maintenance in systems requiring frequent cleaning or reconfiguration. On the other hand, welded diaphragm valves are designed for permanent setups, providing a more robust, leak-proof solution. Both types of sanitary diaphragm valve are efficient, but the choice often hinges on how accessible the system needs to be for cleaning or servicing.

Q2. Can pneumatic diaphragm valves be used with both sanitary clamp and welded designs?

A2. Yes, pneumatic diaphragm valves can be utilized with both sanitary clamp and welded diaphragm valve designs. These automated systems enhance precision and efficiency by delivering consistent control and faster response times. Coupling pneumatic actuation with either valve design improves operational performance, especially in industries with stringent hygiene and reliability standards.

Q3. When should a 3 way diaphragm valve be selected over standard sanitary diaphragm valve?

A3. A 3 way diaphragm valve is ideal in applications requiring the diversion or mixing of fluids within the system. Unlike standard sanitary diaphragm valve, which typically handle flow in a single direction, 3 way configurations provide greater flexibility and control. Choosing between standard and 3 way designs often depends on the system complexity and the specific needs of the flow process.

Conclusion sanitary diaphragm valve

When determining the ideal choice between sanitary clamp and welded diaphragm valves, it’s essential to consider the specific operational and system requirements. Diaphragm valve manufacturers emphasize that sanitary diaphragm valves provide reliability and efficiency tailored to various industry needs. For applications demanding greater automation and precision, options like air actuated diaphragm valves and systems utilizing a diaphragm valve pneumatic actuator offer significant advantages. By evaluating factors such as maintenance, hygiene standards, and system compatibility, decision-makers can select the valve type that ensures optimal performance and long-term reliability.