Thermal oil and hot oil systems demand accuracy and reliability in fluid control to ensure operational efficiency and safety. The Three-Way Control Valve is a critical component in such systems, offering exceptional performance in blending, diverting, and regulating fluid flow. With its integration into steam control systems, this valve provides effective solutions for thermal management, making it indispensable across industries. Whether used alongside a steam control valve or a steam flow control valve, the Three-Way Control Valve enhances temperature regulation, especially in applications requiring consistent heat exchange. Additionally, its compatibility with steam pressure reducing valves and steam pressure regulating valves ensures precise control, enabling industries to achieve seamless, efficient operations without compromising system integrity.

節(jié)閥(白底800x800)-e1735098067822.jpg)

1. Introduction Three-Way Control Valve

The Three-Way Control Valve stands as a vital innovation in the realm of industrial fluid management, specifically for thermal oil and hot oil systems that require accurate and consistent operation. Renowned for its ability to blend or divert fluid flows, this valve ensures seamless control of temperature and pressure across diverse applications. Its precision pairs effectively with advanced systems, such as pneumatic diaphragm control valves and pneumatic globe valves, which contribute to optimal performance in demanding conditions.

By integrating seamlessly with temperature regulating valves, it maintains desired thermal conditions while minimizing energy consumption. Additionally, collaboration with trusted pressure regulating valve manufacturers ensures custom solutions that maximize efficiency, making the Three-Way Control Valve an essential component for achieving superior operational control and system reliability.

2. Functionality of Three-Way Control Valves

Functionality

Three-Way Control Valves are indispensable in thermal oil and hot oil systems, enabling precise regulation of fluid flow and temperature. By blending or diverting fluid streams, these valves maintain optimal operating conditions, ensuring system efficiency and reliability. Their ability to adapt to varying demands enhances performance, reduces energy waste, and supports seamless industrial operations under dynamic conditions.

Technical explanation of how Three-Way Control Valves operate to regulate fluid flow in blending and diverting processes.

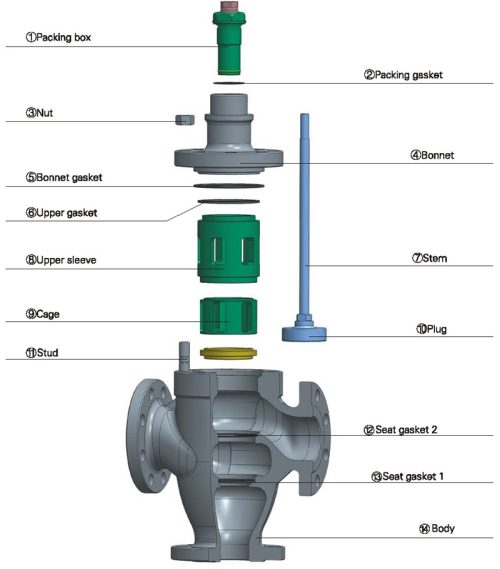

Three-Way Control Valves efficiently regulate fluid flow through precise internal mechanisms. For blending, two distinct fluid streams are merged into a single, controlled output. During diverting, the valve directs one fluid inlet to two separate pathways. Their design, featuring a movable valve plug and actuator, ensures accurate flow modulation, supporting seamless fluid dynamics in complex industrial applications.

Description of their role in maintaining accurate temperature control, similar to sophisticated temperature regulating valves.

Three-Way Control Valves excel in maintaining precise temperature control, akin to advanced temperature regulating valves. By blending or diverting fluid streams, they ensure consistent thermal conditions crucial for industrial operations. Their ability to adapt to dynamic system demands enhances efficiency, minimizes energy waste, and provides reliable performance, making them indispensable for managing temperature-sensitive processes in complex industrial applications.

節(jié)閥(白底800x800)-e1735097759514.jpg)

Discussion on compatibility with various actuator types like pneumatic globe valve and electric globe valve setups for diverse system demands.

Three-Way Control Valves demonstrate exceptional compatibility with diverse actuator types, including pneumatic globe valves and electric globe valve setups. This adaptability ensures optimal performance across varying system demands. Their design accommodates precise control and responsiveness, allowing seamless integration into complex industrial processes. This versatility makes them a reliable solution for achieving efficiency and precision in demanding operational environments.

Pneumatic globe valve

Pneumatic globe valves offer precise flow regulation by utilizing air pressure to control valve movement, making them ideal for demanding industrial applications. Known for swift response times and reliability, they integrate seamlessly with Three-Way Control Valves, ensuring optimal performance in dynamic systems. Their durability and adaptability make them a preferred choice for efficient process control.

Electric globe valve

Electric globe valves provide precise and automated flow control using electric actuators, making them ideal for applications requiring high accuracy and reliability. Their energy-efficient operation and programmability enhance process optimization. Seamlessly compatible with Three-Way Control Valves, they support complex industrial systems, offering superior durability and precision for demanding temperature and flow regulation tasks.

Explanation of how these valves work seamlessly with pressure-regulated systems, including steam pressure regulating valves.

Three-Way Control Valves integrate seamlessly with pressure-regulated systems, including steam pressure regulating valves, to maintain balanced flow and consistent pressure levels. Their precise modulation capabilities ensure smooth operation in industrial processes by effectively controlling fluid dynamics. This synergy enhances system efficiency, minimizes pressure fluctuations, and provides reliable performance in demanding environments, making them essential for stable, optimized operations.

Steam pressure regulating valves

Steam pressure regulating valves ensure precise control over steam pressure in industrial processes, maintaining system stability and performance. By adjusting output to match demand, they prevent pressure fluctuations and energy loss. Their compatibility with Three-Way Control Valves enhances operational control, enabling efficient integration within complex systems to support consistent and reliable process performance.

3. Three-Way Control Valves Key Features and Advantages

Features

Three-Way Control Valves feature innovative designs that enable precise temperature and flow regulation. Their robust construction allows seamless integration into various industrial systems, ensuring reliability under demanding conditions. With exceptional versatility, they accommodate diverse media and operating requirements. These valves provide efficient operation, reduced energy loss, and enhanced process optimization, making them indispensable in complex industrial applications.

Advantages

Three-Way Control Valves offer significant advantages in industrial applications by enhancing operational efficiency and reducing energy consumption. Their adaptability to various system requirements ensures seamless integration and optimized performance. With precise control over temperature and flow, they minimize downtime and maintenance costs, making them a cost-effective solution for complex, demand-driven environments.

4. Industrial Applications

Use in thermal oil systems for industries such as chemical processing, HVAC, power generation, and textile manufacturing.

Three-Way Control Valves are crucial in thermal oil systems across industries like chemical processing, HVAC, power generation, and textile manufacturing. They ensure precise temperature regulation, improving system efficiency and energy utilization. By maintaining stable thermal conditions, they enhance process safety and optimize performance, meeting the demanding requirements of these industrial applications with reliability and adaptability.

Chemical processing

Three-Way Control Valves play a vital role in chemical processing by ensuring accurate temperature control, a critical factor for consistent chemical reactions. Their ability to maintain stable thermal conditions enhances process efficiency and safety, preventing thermal imbalances that could compromise production. These valves optimize operational reliability, meeting the rigorous demands of the chemical industry with precision and adaptability.

HVAC

Three-Way Control Valves are integral to HVAC systems, enabling precise temperature regulation for consistent climate control. By efficiently managing thermal oil flow, they enhance energy utilization, reduce operational costs, and maintain stable environmental conditions. Their adaptability ensures optimal performance in diverse applications, meeting the stringent requirements of modern HVAC systems with reliability and precision.

Power generation

Three-Way Control Valves are essential in power generation, optimizing thermal efficiency by accurately managing heat transfer fluids. Their precise control ensures stable energy output and reduces thermal inconsistencies, critical for maintaining operational reliability. By enhancing safety and minimizing energy losses, these valves meet the rigorous demands of power generation processes with exceptional performance and adaptability.

Textile manufacturing

Three-Way Control Valves are critical in textile manufacturing, ensuring precise temperature control to achieve consistent dyeing, drying, and finishing processes. Their ability to maintain optimal thermal conditions enhances fabric quality and minimizes defects, while their energy-efficient operation reduces production costs. These valves provide the reliability and adaptability needed to meet the demanding requirements of modern textile production.

5. Three-Way Control Valve Comparison with Other Valve Types

Examination of Three-Way Control Valves versus single-direction valves.

Three-Way Control Valves outperform single-direction valves in versatility and functionality, offering superior control in complex fluid management systems. Unlike single-direction valves, which limit flow to one path, Three-Way Valves direct fluids between multiple circuits seamlessly. This capability ensures efficient heat transfer, precise temperature regulation, and flexibility in demanding applications, making them indispensable for industries requiring advanced thermal and process control solutions.

Three-way control valves are compared to complementary valve types such as pneumatic globe valves and electric globe valves.

Three-Way Control Valves stand out against pneumatic and electric globe valves by offering enhanced flexibility in directing flow between multiple circuits. While globe valves excel in precise throttling and linear control, Three-Way Valves provide seamless temperature and fluid management in complex systems. Their adaptability and ease of integration make them ideal for industries requiring versatile yet consistent thermal and process control solutions.

Highlight the unique features of three-way control valves that distinguish them from self-operated regulating valves and thermostatic valves.

Three-Way Control Valves excel over self-operated regulating valves and thermostatic valves with their unmatched operational flexibility and precision. Unlike self-operated models, which rely solely on process changes, and thermostatic valves with limited range, Three-Way Valves efficiently manage fluid direction and temperature across multifaceted circuits. This versatility makes them indispensable for intricate industrial systems demanding precise thermal and process control solutions.

For certain industrial needs, three-way control valves offer advantages over more traditional steam pressure reducing valves.

Three-Way Control Valves surpass traditional steam pressure reducing valves for specific industrial needs due to their superior versatility and precision. While steam reducers are limited to pressure modulation, Three-Way Valves efficiently manage fluid direction and temperature across interconnected circuits. This adaptability ensures seamless operation in complex systems, offering enhanced efficiency and reliability in processes demanding advanced control solutions.

6. Considerations Three-Way Control Valve for Selection

Factors to consider when choosing over conventional valves, including material compatibility, flow requirements, and actuator type.

Material compatibility

Material compatibility is critical in Three-Way Control Valves to ensure durability, efficiency, and safety across demanding industrial applications. Selecting materials resistant to high temperatures and corrosive fluids, such as stainless steel and specialized alloys, prevents wear and failure. Proper compatibility enhances valve longevity, reduces maintenance needs, and ensures reliable performance in complex systems handling thermal oil or hot oil operations.

Flow requirements

Understanding flow requirements is vital for optimizing the performance of Three-Way Control Valves in industrial systems. Accurate assessment of flow rate, pressure, and temperature dynamics ensures the valve’s efficiency in managing fluid distribution. Proper alignment with flow specifications minimizes inefficiencies, prevents system overload, and guarantees reliable operation in processes involving thermal oil or hot oil transfer across complex circuits.

Actuator type

The actuator type plays a crucial role in the performance of Three-Way Control Valves, determining precision and operational efficiency. Pneumatic, electric, and hydraulic actuators each offer unique advantages based on application needs. Accurately matching the actuator type to system requirements ensures precise flow control, reliable performance under varying conditions, and optimized functionality in managing thermal oil or hot oil systems.

Importance of ensuring compatibility with existing pressure and temperature control solutions.

Ensuring compatibility with existing pressure and temperature control solutions is essential for maximizing the efficiency and safety of Three-Way Control Valves. Proper integration minimizes risks of system malfunctions, aligns with established operational parameters, and enhances overall reliability. Compatibility also ensures seamless coordination within thermal oil or hot oil systems, optimizing performance for complex industrial processes demanding precise control solutions.

Recommendations for collaboration with experienced pressure regulating valve manufacturers for customization and optimization.

Partnering with experienced pressure regulating valve manufacturers is vital for customizing and optimizing Three-Way Control Valves. Expertise ensures tailored solutions that address specific industrial needs, enhancing system performance and reliability. Skilled manufacturers provide valuable insights into design, material selection, and compatibility, ensuring precision in operations. Collaborative efforts streamline implementation, reduce downtime, and deliver advanced control solutions for demanding thermal oil systems.

7. Three-Way Control Valves Maintenance and Troubleshooting

Maintenance

Regular maintenance of Three-Way Control Valves is essential for sustaining optimal performance and minimizing unexpected failures in industrial settings. Routine inspections, cleaning, and timely replacement of worn components enhance reliability and operational efficiency. Proactive maintenance also extends valve lifespan, reduces downtime, and ensures consistent performance under the demanding conditions of thermal oil systems.

Troubleshooting

Effective troubleshooting of Three-Way Control Valves focuses on identifying common issues such as improper sealing, actuator failure, or flow imbalances. Implementing prompt and accurate solutions minimizes operational disruptions and ensures system reliability. Proactive diagnosis, supported by technical expertise, helps maintain consistent performance, reduces downtime, and safeguards the efficiency of demanding industrial thermal oil systems.

8. Three-Way Control Valve Future Trends and Innovations

Advancements in Three-Way Control Valves center on smart technologies and innovative materials. Enhanced by digitalization, these valves now integrate IoT sensors, enabling real-time performance monitoring and predictive maintenance. Future trends also include lightweight, corrosion-resistant materials for improved durability and efficiency. Such innovations promise greater precision, reduced downtime, and optimization of complex thermal oil system operations in industrial settings.

9. FAQ Three-Way Control Valve

Q1: What is the role of an electric globe valve in a Three-Way Control Valve system?

A1: An electric globe valve complements the functionality of a Three-Way Control Valve by providing precise flow control in thermal oil systems. Its electric actuator enables automated adjustments to ensure accurate temperature and pressure management, making it ideal for applications requiring high levels of precision and reliability.

Q2: How does a pneumatic control valve differ from a Three-Way Control Valve in industrial applications?

A2: A pneumatic control valve uses compressed air for actuation, offering fast response times and high durability under extreme conditions. While a Three-Way Control Valve manages fluid mixing or diversion, the pneumatic control valve specializes in regulating pressure or flow, often serving as an auxiliary controller in complex thermal oil systems.

Q3: Can an electric control valve enhance the performance of a Three-Way Control Valve system?

A3: Yes, an electric control valve enhances performance by integrating seamlessly with Three-Way Control Valve assemblies. Its advanced digital features, such as IoT connectivity, enable real-time adjustments and monitoring, resulting in greater system efficiency and reduced downtime in demanding industrial processes utilizing thermal or hot oil.

10. Conclusion Three-Way Control Valve

A Comprehensive Guide to Thermal Oil/Hot Oil Three-Way Control Valve and Their Industrial Applications highlights the vital role these valves play in maintaining efficient and precise operations in demanding systems. The Three-Way Control Valve’s versatility and adaptability make it indispensable for thermal oil applications. Integrating self-operated pressure regulating valves, self-operated regulating valves, and self-operated control valves into the system enhances functionality by providing independent and energy-efficient control mechanisms.

These self-operated solutions eliminate the need for external power sources, reducing overall operational costs while improving reliability. With advancements in design and technology, Three-Way Control Valves, paired with self-operated systems, continue to set new standards in durability, functionality, and energy efficiency, reinforcing their importance in modern, high-performance industrial environments. This integration not only optimizes system performance but also ensures operational continuity and long-term dependability in thermal oil and hot oil applications.