Handwheel valve play a vital role in the precise control of fluid flow, offering reliability and simplicity across diverse applications. This guide explores their importance, particularly in steam system management. Handwheel valve are often used in tandem with advanced solutions like Steam Control Valves and steam flow control valves to ensure accurate regulation in demanding environments. Their manual operation allows for effective fine-tuning, which is crucial in systems requiring a steam pressure reducing valve or a steam pressure regulating valve to maintain optimal performance. By understanding the design, functionality, and integration of handwheel valve within complex systems, professionals can enhance both safety and efficiency in applications ranging from industrial processes to energy management.

Introduction to Handwheel Valve

Handwheel valves serve as a fundamental component in fluid control systems, offering precision and reliability where manual adjustments are essential. These valves are indispensable in setups where fine-tuning is required, such as in temperature regulating valve applications or systems designed by pressure regulating valve manufacturers. Their adaptability allows seamless integration with advanced control systems like Pneumatic diaphragm control valves and Pneumatic globe valves, enhancing overall efficiency and functionality.

Overview of handwheel valve and their role in controlling fluid flow.

Handwheel valves are essential for fluid control, offering reliable and precise manual operation across a variety of systems. These valves allow operators to regulate flow rates with accuracy, making them ideal in industries requiring careful management of processes, such as manufacturing and energy production. Their design ensures adaptability, enabling them to function effectively in settings where automation may not be feasible or necessary.

Explanation of the handwheel mechanism and its importance in control valves.

The handwheel mechanism is a pivotal feature in control valves, enabling precise manual adjustments to fluid flow. By offering direct operator control, it ensures dependable functionality in applications requiring accuracy. This mechanism enhances the overall performance of control valves, particularly in systems where fine-tuning is essential, making it indispensable for achieving consistent and reliable fluid regulation across multiple industries.

Brief history of handwheel valve development.

Handwheel valves have evolved significantly since their inception, transitioning from basic flow control devices to precision-engineered components in modern systems. Early designs prioritized simplicity, but advancements in materials and manufacturing techniques have enhanced their durability and reliability. These innovations have allowed handwheel valves to become integral in complex fluid control technologies, shaping their role in industries requiring precise regulation and dependable performance.

Design and Functionality of Handwheel Valve

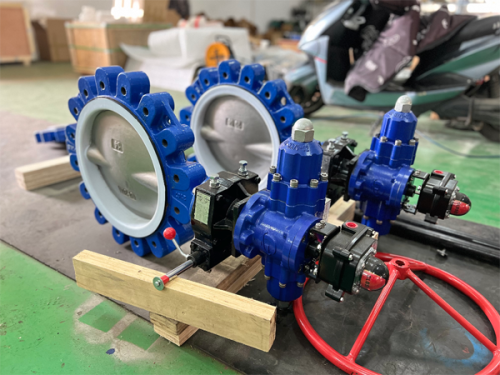

Handwheel valves feature a straightforward yet robust design, consisting of three primary components: the handwheel, stem, and valve body. The handwheel allows for manual operation, enabling users to precisely regulate fluid flow through rotational motion. This movement is transferred to the stem, which adjusts the internal valve element—such as a disc or plug—within the valve body to control or block fluid passage. This design ensures reliability and ease of operation without relying on external power sources.

The simplicity of construction not only enhances durability but also makes maintenance more manageable across diverse industrial applications. Furthermore, the manual control offered by handwheel valves provides unmatched precision and dependability, particularly in systems requiring intermittent adjustment or in environments where automated solutions are impractical. Their resilient design and functionality make them an indispensable choice for industries demanding consistent and efficient flow regulation.

Key components of a handwheel valve.

A handwheel valve comprises essential components like the handwheel, stem, and valve body. The handwheel provides manual control, translating rotational effort into precise linear motion via the stem. The valve body houses the mechanism that regulates fluid flow. Together, these elements ensure accuracy, reliability, and efficiency, making handwheel valves indispensable in applications requiring manual flow adjustments.

Detailed look at how the handwheel mechanism operates within control valves.

The handwheel mechanism in control valves functions by converting manual rotational input into linear motion through the stem, which adjusts the valve opening. This precise motion allows operators to finely control fluid flow, ensuring accuracy and consistency. The mechanism’s design ensures dependable operation, making it a critical feature for applications where manual regulation and precision are paramount.

Materials commonly used in the construction of handwheel valve for durability and efficiency.

Handwheel valves are built using robust materials like stainless steel, brass, and cast iron, chosen for their strength, corrosion resistance, and thermal stability. Stainless steel ensures durability in harsh environments, while brass offers excellent machinability and corrosion resistance. Cast iron provides cost-effective toughness for industrial applications. These materials collectively enhance the reliability, longevity, and efficiency of handwheel valves across demanding operational conditions.

Applications of Handwheel Valve

Handwheel valves are extensively used across industries such as steam systems, water treatment, and chemical processing, where precise manual control is critical. These valves excel in scenarios requiring reliability and straightforward operation, particularly in applications with intermittent adjustments or those unsuitable for automated systems. For steam systems, their ability to handle high temperatures makes them an ideal choice. In water treatment, handwheel valves provide accurate flow regulation, ensuring consistent system performance.

Chemical processing operations also favor them for their durability and simple maintenance in demanding environments. Compared to automated valves, handwheel valves are cost-effective, easy to install, and require no external power, making them invaluable in situations where automation is unnecessary or impractical. Their versatility and robust design allow them to meet diverse industrial needs with dependable performance and control, making them a trusted choice for a wide range of applications.

Industrial Applications

Use of handwheel valves in manufacturing processes such as chemical production and oil refining.

Handwheel valves play a vital role in manufacturing processes like chemical production and oil refining, where precise fluid control is essential. These valves enable operators to regulate flow rates with accuracy, ensuring safe handling of volatile substances and optimal process efficiency. Their robust design and reliability make them indispensable for maintaining safety standards and achieving consistency in complex industrial operations.

Residential and Commercial Applications

Handwheel valve functionality in HVAC systems and water supply networks.

Handwheel valves are integral to HVAC systems and water supply networks, enabling precise flow management to maintain system efficiency and reliability. By allowing operators to manually adjust flow rates, they help balance pressure and optimize performance. Their robust design ensures durability and consistent operation, making them essential for critical applications like temperature regulation and water distribution in various settings.

Specialized Applications

Role of handwheel valves in high-pressure environments and precision-driven industries like pharmaceuticals.

Handwheel valves excel in high-pressure environments and precision-driven industries like pharmaceuticals, where safety and accuracy are critical. Their precise control mechanism ensures reliable fluid management, maintaining exact flow rates under extreme conditions. Built for durability and compliance with stringent standards, these valves play a pivotal role in safeguarding processes, supporting efficiency, and upholding quality in high-stakes industrial applications.

Advantages and Disadvantages of Handwheel Valves

Advantages

Handwheel valves offer unmatched advantages, including simplicity of operation, reliability, and precise flow control. Their adaptability across diverse applications makes them a versatile choice for industries ranging from manufacturing to water management. With a robust design and easy maintenance, these valves provide consistent performance, ensuring efficiency and reliability in operations that demand precision and durability.

Disadvantages

Handwheel valves, while reliable, have some limitations. Manual operation can be time-consuming, especially in systems requiring frequent adjustments. Over time, wear and tear on moving parts may impact their performance, necessitating regular maintenance. Additionally, their reliance on manual control means they may not be the best choice for automated or remote applications that demand rapid or precise actuation.

Maintenance and Troubleshooting Tips for Handwheel Valve

Regular maintenance of handwheel valves involves consistent inspections for leaks, corrosion, or worn components. Clean the valve to remove debris that might hinder operation, and apply manufacturer-recommended lubricants to reduce friction and prolong functionality. If you notice stiffness, address it by checking for misalignment or inadequate lubrication. Leaks often indicate worn seals or gaskets, requiring immediate replacement. Timely part replacements and adherence to maintenance schedules minimize operational failures, ensuring durable and efficient performance. For troubleshooting, document issues and follow repair guidelines to restore the valve’s precision and reliability. Proactive maintenance supports the valve’s long-term effectiveness in demanding applications.

Common maintenance practices to ensure optimal handwheel valves performance.

Regular maintenance is crucial for optimal handwheel valve performance. Key practices include routine inspections to detect wear and damage, ensuring proper lubrication of moving parts to minimize friction, and promptly replacing worn components to prevent failure. These measures not only maintain efficiency but also extend the lifespan of the valves, safeguarding their reliability in critical industrial applications.

Identifying and resolving issues such as wear and tear or inefficient flow control.

Proactively identifying issues like wear and inefficient flow control is essential for maintaining handwheel valve performance. Common symptoms include unusual noise, resistance during adjustment, or inconsistent flow rates. Resolving these problems involves inspecting and replacing damaged components, recalibrating the valve for precise operation, and ensuring adequate lubrication. Regular diagnostics minimize downtime, ensuring reliability and efficiency in demanding applications.

Guidelines for proper lubrication and replacement of parts.

Proper lubrication and timely part replacement are key to handwheel valve performance. Use manufacturer-approved lubricants to reduce friction and ensure smooth operation. Regularly inspect for wear, replacing components like seals and o-rings with appropriate materials to maintain valve integrity. Always adhere to manufacturer guidelines to optimize functionality, prevent failures, and extend the lifecycle of the valve in critical applications.

Future Trends in Handwheel Valve Technology

Future developments in handwheel valve technology focus on integrating smart capabilities, such as embedded sensors for real-time monitoring and data analysis, boosting operational precision and efficiency. Advancements in materials, including corrosion-resistant alloys and composites, enhance durability and extend valve longevity. Additionally, sustainable designs that prioritize energy efficiency and reduced environmental impact are gaining traction. These innovations are poised to streamline maintenance, improve performance under demanding conditions, and align with the increasing need for eco-friendly industrial solutions. By addressing industry-specific challenges, these trends ensure handwheel valves remain reliable and adaptable to the complexities of modern applications.

節(jié)閥1-e1736926158405.jpg)

FAQ handwheel valve

Q1: How does a handwheel valve compare to an electric globe valve in terms of control and functionality?

A1: A handwheel valve relies on manual operation, offering precise but slower adjustments, making it suitable for straightforward flow control tasks. An electric globe valve, on the other hand, provides automated actuation, enabling remote operation and high precision. While the electric globe valve is advantageous in modern, automated systems, a handwheel valve shines in applications requiring simplicity and low maintenance.

Q2: What are the advantages of using a handwheel valve over a pneumatic control valve?

A2: Handwheel valves are preferred for their simplicity and reliability in manual control settings. Unlike pneumatic control valves, which require compressed air systems and specialized components, handwheel valves function independently of auxiliary power sources. This makes them cost-effective and easy to maintain for basic flow adjustments, whereas pneumatic control valves excel in applications demanding rapid and frequent control changes.

Q3: Can a handwheel valve be integrated into systems that also use electric control valve?

A3: Yes, a handwheel valve can complement systems using electric control valves when manual overrides are necessary. While electric control valves automate processes, handwheel valves provide a fail-safe mechanism or backup for manual operation during power failures or maintenance. This combination ensures operational continuity and flexibility, particularly in complex industrial systems.

Conclusion handwheel valve

Handwheel valves remain an indispensable solution in industrial applications, valued for their reliability and precise manual control. While self-operated pressure regulating valves, self-operated regulating valves, and self-operated control valves offer automation and adaptability in managing flow and pressure without external power, handwheel valves excel in their simplicity and durability. This guide highlights their versatility, comparing them to automated counterparts and showcasing their essential role in both standalone and integrated systems.

節(jié)閥白底800x800-e1735112497864.jpg)