The Type 135 3-Way Ball Valve is a critical solution for efficient fluid and gas control in various industries. This guide highlights its adaptability with T-port and L-port configurations, durability with 3 way stainless steel ball valve options, and precision in automated operations using pneumatic three way valves. Discover how the 3 three way ball valve and three way valve designs streamline processes, along with tips for selecting and maintaining the right valve for your needs.

Three way ball valve Introduction

Three way ball valves are a vital component in fluid and gas control systems. Celebrated for their exceptional versatility and industrial significance. Designed to manage complex flow paths with ease, these valves come in various configurations to suit diverse operational needs. Among these, the 3 three way ball valve stands out for its ability to redirect flow between three ports. Making it a preferred choice in applications requiring multi-directional control. The T-port configuration, often referred to as the three way ball valve t port. Is especially popular due to its robust design and capability to facilitate mixing, diverting, and shutoff operations. By streamlining processes and reducing the need for multiple valves. The 3 way valve enhances efficiency and reliability across sectors. Including chemical processing, water treatment, and industrial automation. Their adaptability and durable construction make them indispensable for ensuring seamless operations in demanding environments.

Brief overview f the Type 135 3-Way Ball Valve and its role in industrial applications

The Type 135 3-way ball valve is a versatile and robust solution engineered to meet the rigorous demands of modern industrial applications. This 3 three way ball valve designe for durability and exceptional performance. Even in the most challenging environments, thanks to its high-quality materials and precision engineering. Its flexible configurations, including the three way ball valve t port, provide unmatched adaptability for managing complex flow paths, allowing operators to direct, combine, or isolate flows with ease.

The T-port configuration is particularly beneficial in industries where intricate flow management is critical, such as chemical processing, water treatment, and manufacturing. By enabling precise flow control, the 3 way valve enhances operational efficiency, reduces waste, and ensures reliability under high-pressure and high-temperature conditions. Its seamless operation minimizes downtime and maintenance, making it a cost-effective choice over the long term. Whether automating processes or handling diverse media, the Type 135 proves to be a vital component in streamlining operations, reinforcing system functionality, and maintaining consistent performance across various industrial workflows.

Importance of understanding different configurations and operations

A comprehensive understanding of the various configurations and operations of three way ball valves, including the 3 three way ball valve, is essential for optimizing industrial processes. Different configurations, such as the three way ball valve t port, play a pivotal role in determining how fluid flows are directed, combined, or isolated within a system. For instance, the T-port configuration excels in managing complex flow paths, making it a suitable choice for applications requiring versatile directional control. By selecting the appropriate configuration, operators can ensure that the 3 way valve operates with maximum efficiency, aligning with the specific needs of processes like chemical blending, fluid distribution, or wastewater management.

This level of precision not only enhances system performance but also minimizes unnecessary wear and tear, reducing maintenance demands and preventing costly downtime. Additionally, understanding the operational nuances of different configurations fosters better decision-making. Ensuring that valves integrate seamlessly into complex industrial systems. The result is improved reliability, sustained operational efficiency. And significant cost savings over time, establishing the three way ball valve as a vital element in driving industrial success.

Understanding the Type 135 3-Way Ball Valve

The Type 135 3-Way Ball Valve is a versatile 3 way valve designed for precise flow control in demanding industrial environments. Featuring a robust design and configurations like the three way ball valve t port, it efficiently handles tasks such as mixing, diverting, and shutoff. This 3 three way ball valve simplifies operations by directing flow between three ports, reducing the need for additional components. Its adaptability and reliable performance make it a valuable asset in industries such as chemical processing, water treatment, and manufacturing, ensuring efficiency and streamlined operations.

The Type 135 3-way ball valve is a sophisticated and reliable solution designed to meet the demands of complex industrial processes. This 3 three way ball valve is engineered with robust construction, ensuring durability and consistent performance in challenging environments. Its versatile configurations, including the three way ball valve t port, allow precise flow control, whether for redirecting, mixing, or isolating fluid pathways. The T-port configuration is particularly advantageous in systems requiring intricate flow management, as it facilitates seamless transitions between multiple operational modes. Beyond its adaptability, the 3 way valve boasts features that enhance efficiency, such as smooth operation, reduced pressure drops, and compatibility with a wide range of media.

Its versatility makes it a trusted choice for industries like chemical processing, water treatment, and manufacturing, where reliability and operational consistency are paramount. By incorporating the Type 135, operators benefit from a valve that not only optimizes performance but also reduces maintenance requirements and operational costs. Its balanced design and functionality make it a critical component in achieving streamlined and dependable industrial workflows.

Three way ball valve Configurations and Types

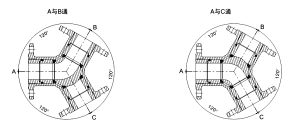

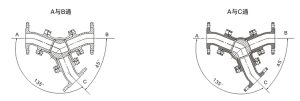

Three way ball valves are defined by their flexibility and the variety of configurations they offer. Making them vital in numerous industrial applications. The two primary configurations—T-port and L-port—provide distinct functionalities that cater to specialized flow control needs. The T-port, commonly referred to as the three way ball valve t port. Is designed to either mix or split fluids, enabling seamless operations in systems that require simultaneous flow to multiple outlets.

On the other hand, the L-port is ideal for diverting flow between two distinct pathways. Allowing users to isolate specific sections without disrupting overall operations. These configurations of the 3 three way ball valve simplify complex processes by integrating multiple functionalities into a single unit. Whether in chemical plants, water treatment systems, or industrial automation setups. The adaptability of the 3 way valve reduces the need for additional components, enhancing both efficiency and reliability. By carefully selecting the right configuration based on operational demands. Industries can optimize performance, streamline maintenance, and improve overall reliability.

Three way ball valve Industrial Applications

Three way ball valves are indispensable in industrial applications due to their versatility and efficiency. Streamlining complex flow control across various systems. Industries like chemical processing, water treatment. And manufacturing heavily rely on the flexibility of the 3 three way ball valve to optimize performance and maintain operational efficiency. With their ability to direct, mix, or isolate flow paths. These valves eliminate the need for multiple components, thereby reducing operational costs and simplifying system design.

The T-port configuration, widely regarded as a highly effective solution, plays a crucial role in applications requiring accurate flow management. Such as combining multiple streams or diverting flow to different outlets. This three way ball valve t port design is particularly valued in systems where precision and stability are essential to maintaining output quality and operational reliability. The durable and adaptable nature of the 3 way valve ensures it can handle demanding environments while contributing to the long-term reliability and cost-effectiveness of industrial processes.

Three way ball valve Pneumatic Operation

Pneumatic operation significantly enhances the performance of three way ball valves. Combining the efficiency and precision required for demanding industrial processes. By integrating pneumatic actuators, the 3 three way ball valve provides automated and accurate control over fluid or gas flow paths. Enabling seamless operation in environments where manual intervention is impractical or inefficient. These 3 way valves, equipped with pneumatic systems, excel in providing rapid response, consistent reliability, and improved safety, particularly in high-pressure or hazardous settings.

The T-port configuration, commonly known as the three way ball valve t port. Is especially beneficial in automated systems that demand flexible and complex flow management. It facilitates tasks like mixing or directing flow among multiple pathways with unparalleled precision. Optimizing system performance while reducing downtime. Pneumatic operation not only streamlines processes but also ensures consistent. Repeatable outcomes in industries such as chemical processing, manufacturing. And water treatment, offering a robust and cost-effective solution for modern automation needs.

Choosing the Right Valve

Selecting the right three way ball valve for industrial applications is a critical decision that directly impacts the efficiency and reliability of operations. When choosing a 3 three way ball valve, it is essential to assess the specific requirements of the application. Including flow direction, operating pressure, and temperature to ensure optimal performance. The 3 way valve is available in configurations such as the three way ball valve t port. Which offers flexibility for mixing or diverting flow between multiple pathways. This T-port design is particularly advantageous for systems that demand precise control and multifunctional flow management.

Additionally, material compatibility with the media being transported should be considered to maintain durability and minimize maintenance demands. By carefully selecting a valve that aligns with operational needs. Industries benefit from streamlined processes, reduced downtime, and enhanced cost-efficiency. The right valve ensures the long-term reliability of industrial systems. Making it a smart investment for applications ranging from chemical processing to water treatment and manufacturing.

?Maintenance and Troubleshooting

Regular maintenance is essential to ensure the optimal performance and longevity of a 3 three way ball valve. Particularly in demanding industrial environments. Routine tasks like inspecting for visible wear, cleaning debris from internal passages. And lubricating moving parts help maintain smooth operation and prevent common issues such as sticking or reduced functionality. For 3 way valves with configurations like the three way ball valve t port.

Additional care require to monitor how the valve directs or mixes flows between pathways, as buildup or contamination in the T-port mechanism can disrupt performance. Troubleshooting common problems, such as leaks, often involves checking seals and gaskets for damage or wear. While blockages typically require disassembling and cleaning the valve interior to restore proper flow. Actuator malfunctions can be resolved by testing and recalibrating the pneumatic or mechanical components to ensure synchronization with the valve’s movement.

By adhering to a regular maintenance schedule and addressing problems promptly. Industries can significantly reduce downtime, enhance efficiency, and extend the operational lifespan of these versatile valves. Understanding the specific configuration, like the T-port, makes diagnosing and resolving issues more precise. Minimizing disruption to critical processes.

?FAQ three way ball valve

Q1. What is the warranty period for your three-way ball valves?

Our three-way ball valves come with a standard warranty period of 12 months (1 years) from the date of delivery. This warranty covers manufacturing defects and materials under normal operating conditions as specified in the product manual.

Q2. How are three-way ball valve prices determined?

Prices for three-way ball valves are influenced by several factors. Including the valve’s size, material composition (e.g., stainless steel, brass, or PVC), pressure ratings, end connection types. And any additional customisation or certifications required. Specialised features such as fire-safe designs or anti-static devices can also impact the cost.

Q3. What is the standard delivery time for a three-way ball valve?

Our standard delivery time for three-way ball valves is 4–6 weeks, depending on the order size and customisation requirements. For urgent requests, we offer expedited delivery options upon request.

Our logistics partners ensure fast and reliable delivery to meet engineering project timelines, regardless of location.

Q4. Common Applications of Three-Way Ball Valves

A three-way ball valve is a versatile valve type designed with three ports for fluid flow. These ports can be configured to allow various functions. Such as mixing, diverting, or completely shutting off flow. Many three-way ball valves feature an L-port or T-port design. Which determines how the flow paths are arranged and controlled.

Three way ball valve Conclusion

The Type 135 3-way ball valve stands out as a vital component in a range of industrial applications. Offering unparalleled versatility, efficiency, and reliability. With its advanced design and options for configurations such as the T-port. This 3 three way ball valve is capable of managing complex flow paths. Making it an essential tool in systems requiring directional control or mixing capabilities. Selecting the correct configuration is critical to align with specific operational needs. Ensuring seamless functionality and cost-effectiveness.

Maintenance and troubleshooting practices, such as regular inspections and addressing common issues like leaks or actuator malfunctions, further extend the valve’s lifespan and enhance efficiency. Additionally, the integration of pneumatic operation amplifies its performance, providing precise automation and safety in demanding environments. By leveraging these features, the Type 135 3 way valve not only optimizes operational processes but also reduces downtime and long-term costs. Whether in chemical manufacturing, water treatment, or other industrial settings, the Type 135 serves as a dependable solution, reinforcing system reliability and ensuring smooth operation in even the most challenging applications.