Valve standards are the backbone of ensuring safety, efficiency, and reliability in numerous industrial applications. These standards provide critical guidelines for the design, manufacturing, and performance requirements of valves, including essential components like the steam control valve, steam flow control valve, steam pressure reducing valve, and steam pressure regulating valve. By adhering to predefined specifications, valve manufacturers can create systems capable of handling precise flow control, pressure management, and operational demands. Valve standards not only ensure compatibility across diverse system components but also enhance reliability in high-pressure and high-temperature environments. This comprehensive document explores the various types of valve standards, their applications across industries, and their indispensable role in maintaining operational integrity while meeting stringent regulatory and performance expectations.

Introduction to Valve Standards

Valve standards serve as essential benchmarks for ensuring the quality, performance, and reliability of diverse valve types used across industries. They provide clear guidelines for pressure regulating valve manufacturers, enabling them to produce solutions that adhere to precise operational and safety requirements. Standards also address the unique challenges of specialty valves such as the temperature regulating valve, which ensures consistent thermal control, or advanced options like the pneumatic diaphragm control valve and pneumatic globe valve, known for their precision in regulating flow and pressure.

Definition and purpose of valve standards

Definition

Valve standards are established guidelines that define the design, manufacturing, and performance criteria for valves, ensuring they meet specific safety, efficiency, and reliability benchmarks. These standards serve as a critical framework to safeguard operational integrity in industrial applications, dictating parameters such as material quality, pressure ratings, and environmental compatibility.

Purpose

The primary purpose of valve standards is to establish a structured framework that ensures safety, efficiency, and reliability across industrial operations. By defining clear guidelines for the design, material selection, and performance of valves, these standards maintain consistent quality regardless of the valve type or application.

Overview of global valve standards organizations

ANSI

The American National Standards Institute (ANSI) plays a pivotal role in the development of valve standards that prioritize safety, quality, and interoperability in both manufacturing and application processes. Renowned for its influence within the United States, ANSI standards provide comprehensive guidelines for critical areas such as pressure ratings, material specifications, and testing procedures. These standards ensure the consistent performance and reliability of valves in demanding industrial settings.

API

The American Petroleum Institute (API) is a leading authority in establishing valve standards specifically tailored to the needs of the oil and gas industry. API standards are integral to ensuring the safety, reliability, and efficiency of valve operations, particularly in challenging environments where precision and performance are critical. They provide detailed guidelines for various aspects, including valve design, material selection, and performance testing, enabling valves to withstand high pressures, extreme temperatures, and corrosive conditions.

ISO

The International Organization for Standardization (ISO) plays a central role in developing valve standards that prioritize global consistency, safety, and quality across manufacturing and application processes. ISO standards serve as a universal benchmark, bridging regional differences to facilitate seamless international trade and system interoperability. They provide comprehensive guidelines that cover critical aspects such as valve design, testing procedures, and performance criteria, ensuring that valves meet stringent operational requirements worldwide. By adopting ISO standards, industries benefit from enhanced reliability, reduced risk, and streamlined regulatory compliance. Their influence spans diverse sectors, including energy, water management, and chemical processing, underscoring their vital contribution to maintaining high standards in industrial operations worldwide.

Types of Valve Standards

Valve standards encompass a wide range of classifications, including international, national, and industry-specific guidelines, each tailored to address the diverse demands of valve operations. International standards, such as those developed by ISO (International Organization for Standardization), focus on global uniformity and interoperability. National standards, like ANSI (American National Standards Institute), address region-specific requirements, while industry-specific standards, such as those from API (American Petroleum Institute), cater to specialized sectors like oil and gas. These standards vary in scope and application, defining critical parameters like pressure ratings, materials, and performance metrics.

Overview of major types of valve standards

Pressure rating

Pressure rating is a critical parameter in valve standards, defining the maximum pressure a valve can safely withstand under specific conditions. Determined through rigorous testing and material analysis, pressure ratings ensure valves operate reliably without risking structural failure or leaks. These ratings guide engineers and operators in selecting suitable valves for diverse industrial applications, from low-pressure systems to high-pressure environments like oil refineries or power plants. By adhering to these specifications, industries maintain system integrity, reduce the risk of catastrophic failures, and protect personnel and equipment.

Material

Material selection is fundamental in valve standards, ensuring valves meet the diverse demands of industrial applications. Materials are meticulously chosen based on properties such as corrosion resistance, thermal stability, and mechanical strength to perform effectively in environments ranging from high-temperature chemical processes to water treatment systems. These standards specify the use of durable alloys, polymers, or composite materials tailored to industry-specific challenges. By adhering to material guidelines, manufacturers prevent valve failures, extend operational life, and maintain system reliability.

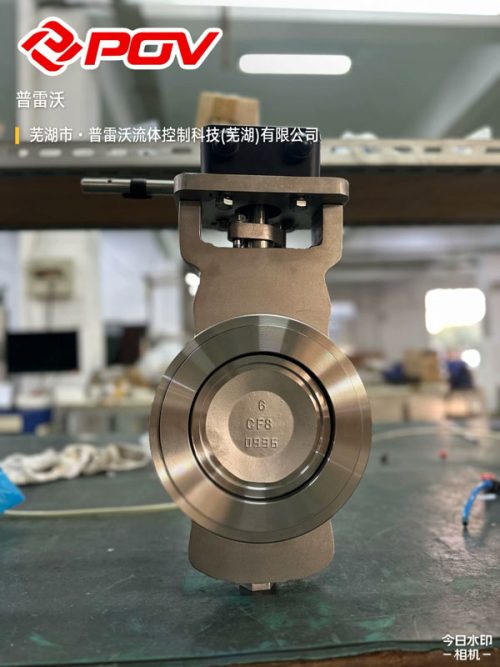

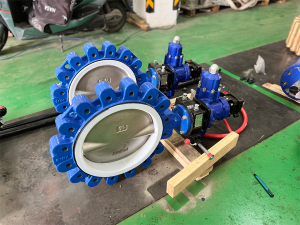

Design

Design plays a pivotal role in valve standards, ensuring valves meet stringent functional and safety requirements across a range of industries. By defining parameters such as flow patterns, sealing mechanisms, and structural configurations, design standards optimize valve performance for precise flow control, effective pressure management, and long-term durability. These standards address critical factors like stress tolerance, thermal expansion, and operational efficiency to ensure reliable functionality under demanding conditions.

Key standards for specific valve types

Gate valves

Gate valves are essential components in industrial systems, primarily designed for on-off control of fluid flow. Characterized by a sliding gate mechanism, these valves provide a tight seal when fully closed, making them ideal for applications requiring minimal leakage and the ability to handle high-pressure environments. Valve standards for gate valves establish specifications for materials, dimensions, pressure ratings, and operational criteria, ensuring consistent quality and performance across various industries. Their robust design and capability to operate efficiently under demanding conditions make gate valves indispensable in oil and gas, water treatment, and power generation.

Ball valves

Ball valves are versatile and durable components widely used in industrial applications for their precise control and quick shut-off capabilities. Featuring a spherical closure element, they excel in applications requiring tight sealing and minimal torque operation. Valve standards, such as API 608 and ISO 5211, provide rigorous guidelines for the design, materials, and performance of ball valves, ensuring they meet safety and operational demands across industries like chemical processing, oil and gas, and water treatment. Their robust construction and ability to function effectively in high-pressure and high-temperature environments make them indispensable for critical operations.

Check valves

Check valves are critical in industrial systems for their ability to prevent backflow and maintain consistent system pressure, safeguarding the integrity of fluid flow in pipelines. These valves operate automatically, allowing flow in one direction and closing when reverse flow is detected, making them indispensable in applications such as water distribution, oil and gas, and chemical processing. Standards like API 594 and ISO 14313 set stringent requirements for the design, materials, and performance of check valves, ensuring they meet the specific operational needs of diverse industries. Their robust construction and minimal maintenance requirements enhance reliability, while compliance with these standards guarantees safety and efficiency in various demanding environments.

Applications of Valve Standards in Various Industries

Oil and gas: How valve standards ensure operational safety in extreme environments

Valve standards are vital in the oil and gas industry, particularly for operations in extreme environments marked by high pressures and temperatures. These standards specify rigorous design, material, and performance criteria to ensure valves can endure such challenging conditions without compromising safety. By preventing leaks, failures, and malfunctions, they safeguard operational integrity and protect personnel from hazardous incidents.

Power generation: The role of valve standards in high-pressure and high-temperature conditions

Valve standards are critical in the power generation industry, where high-pressure and high-temperature systems demand unwavering reliability. These standards define precise design, material, and performance requirements to ensure valves can withstand the intense thermal and mechanical stresses of power plants. By adhering to these stringent criteria, operators prevent equipment failures that could disrupt power supply or endanger safety. Valve standards also enhance operational efficiency, enabling seamless regulation of steam and fluids in complex systems.

Chemical and pharmaceutical sectors: Standards for specialty valves in corrosive environments

Valve standards are indispensable in the chemical and pharmaceutical industries, where specialty valves operate in highly corrosive environments. These standards specify advanced material and design requirements to ensure valves withstand aggressive substances, maintain durability, and prevent leaks. By adhering to these stringent guidelines, manufacturers safeguard product purity, avoiding contamination risks that could compromise quality or regulatory compliance.

Water distribution and treatment applications

Valve standards play a vital role in water distribution and treatment applications by ensuring the safety, efficiency, and reliability of the systems managing water flow and quality. These standards set precise material and performance specifications that help prevent leaks, safeguard against contamination, and maintain the integrity of pipelines and treatment facilities. Adherence to these guidelines guarantees a clean and consistent water supply, essential for public health.

Challenges in Adhering to Valve Standard

Adhering to valve standards presents several challenges for industries, stemming from the evolving nature of these standards and the complexity of ensuring compliance across diverse operations. Constant updates from organizations like ANSI, API, and ISO require manufacturers to frequently revise designs, processes, and materials, which can impose significant costs. Additionally, the intricate requirements—for dimensions, pressure ratings, materials, and performance—demand specialized expertise and rigorous quality control systems. Failure to meet these standards risks compromising safety, reducing operational efficiency, and causing costly downtime or liability issues. Despite these obstacles, staying aligned with current standards is non-negotiable.

Future Trends in Valve Standard

Future trends in valve standards are increasingly influenced by the integration of smart technologies and a growing emphasis on sustainability. The rise of intelligent valve systems, equipped with sensors and IoT capabilities, is driving the need for standards that address data collection, real-time monitoring, and predictive maintenance to enhance operational efficiency and safety. At the same time, sustainability considerations are pushing for stricter standards on materials, energy efficiency, and emissions reduction, fostering environmentally friendly practices. These advancements are reshaping the valve industry by encouraging innovation while addressing global demands for greener and smarter infrastructure.

FAQ Valve Standard

Q1: How do valve standards ensure the safety and reliability of an electric globe valve?

A: Valve standards establish critical guidelines for the design, materials, and performance of electric globe valves, ensuring they meet stringent safety and reliability requirements. These standards cover aspects such as pressure ratings, temperature tolerances, and operational consistency. For electric globe valves, which are commonly used for precise flow control in automation systems, adherence to standards guarantees their ability to handle demanding applications with accuracy and durability. By following these regulations, manufacturers ensure that electric globe valves operate safely and efficiently under various industrial conditions.

Q2: What is the role of valve standards in improving the efficiency of a pneumatic control valve?

A: Valve standards play a vital role in optimizing the design and functionality of pneumatic control valves, ensuring they deliver efficient and reliable performance. Standards define parameters for pressure control, air flow, and material compatibility, all of which directly impact the valve’s operational efficiency. For pneumatic control valves, which are widely used across industries for modulating flow in process systems, these standards provide a benchmark for quality. Compliance ensures enhanced efficiency, reduced energy loss, and minimal system downtime, making the valves a dependable choice for complex fluid handling operations.

Q3: How are valve standards adapting to advancements in electric control valve technology?

A: The evolution of electric control valve technology is driving updates to valve standards to address new capabilities and applications. Modern electric control valves, equipped with features like IoT connectivity and advanced motor-driven actuators, require guidelines for data integration, real-time monitoring, and predictive diagnostics. Updated standards ensure these valves are not only structurally robust but also proficient at meeting the demands of smart infrastructure and automation. By facilitating smoother adoption of new technologies, these standards help industries enhance system reliability, reduce maintenance costs, and achieve higher levels of operational precision.

Conclusion Valve Standard

Valve standards are the backbone of safety, efficiency, and reliability in industries, ensuring optimal functionality across diverse valve types. For self-operated pressure regulating valves, self-operated regulating valves, and self-operated control valves, these standards provide critical guidelines for design, performance, and material integrity. By adhering to these specifications, industries achieve precise flow control, maintain system pressure, and enhance overall operational reliability. Valve standards also address the unique requirements of self-operated valves, ensuring they deliver consistent performance in demanding environments. Ultimately, these standards foster innovation, support system integrity, and secure long-term operational success, reinforcing their indispensable value in modern industrial applications.