Description

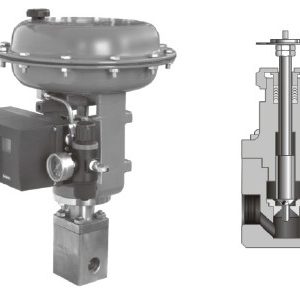

Pneumatic bottom discharge valve, also known as a discharge valve, is a specialized shut-off solution designed for installation at the bottom of storage containers. Featuring a streamlined valve body and a spherical single-seat valve core, this tank bottom valve ensures smooth and unobstructed media flow, making it ideal for handling various materials, including slurries and high-density fluids. Its robust design is perfect for industries such as polymerization, chemical fiber, food processing, fermentation, and more, offering exceptional performance and reliability.

To ensure seamless operation in diverse conditions, this discharge valve has been engineered with adaptability in mind. Key factors such as temperature, pressure, adhesion, and corrosiveness of the medium within storage containers must be considered when selecting this valve discharge solution. Beyond standard products, tailored non-standard configurations are available to meet unique application requirements, enabling flawless performance across a wide range of industrial scenarios.Structural Forms for Versatility

Upper Expansion Type

– The valve core moves into the reactor when opened, facilitating easy discharge of sediment accumulation from the bottom of the reactor tank.

– The medium within the tank applies force to the valve core, serving as a check mechanism to prevent backflow.

Lower Expansion Type

– When opened, the Bottom discharge valve core moves into the valve body, making this type particularly suitable when the reactor requires full stirring or operates under negative pressure (vacuum).

– This structure promotes effective closing under vacuum conditions and acts as a reliable check system during such operations.

Actuation Options

The pneumatic tank bottom valve can be configured with either a diaphragm actuator or a cylinder actuator, providing flexibility to align with various automation systems and operational demands.

| Body | Stainless steel,CF8,CF8M,CF3M, WCB | |

| Body style | Upward expansion valve, downward expansion valve | |

| Size | DN25-DN250 | |

| Seat | PTFE, Metal seal | |

| Connection | Flange, | |

| Actuator material | Aluminum Alloy | |

| Pressure | ASME B16.34 class 150-600LB, PN16-PN64 | |

| Air supply pressure | 5.5bar | |

| Pneumatic Actuator | Double acting,Single acting normally closed, acting,Single normally open | |

| Option | solenoid valve,?limit switch box?, filter, E/P positioner, hand wheel | |

FAQ

What is a discharge valve?

A discharge valve is a type of shut-off valve designed to control the flow of materials or fluids from storage tanks, reactors, or other containers. It plays a critical role in regulating and releasing substances efficiently, often found at the base or bottom of tanks to manage material discharge smoothly.

What are the primary functions of a discharge valve?

The primary functions of a discharge valve include sealing the bottom of storage containers, facilitating the controlled flow of media (such as fluids or slurries), and preventing backflow. Some discharge valves also serve as a check mechanism to maintain pressure or vacuum conditions within the container.

What industries commonly use discharge valves?

Discharge valves are widely used in industries like polymerization, chemical fiber, food processing, fermentation, and others. These industries often require efficient management of fluids, slurries, or high-viscosity materials, making discharge valves an essential component of their process systems.

Are?bottom discharge valve suitable for slurry and high-density fluid applications?

Yes, bottom discharge valve are particularly well-suited for handling slurries and high-density fluids. Their streamlined valve body and advanced designs, such as spherical single-seat valve cores, reduce flow resistance, ensuring effective operation even with thick or viscous materials.