Description

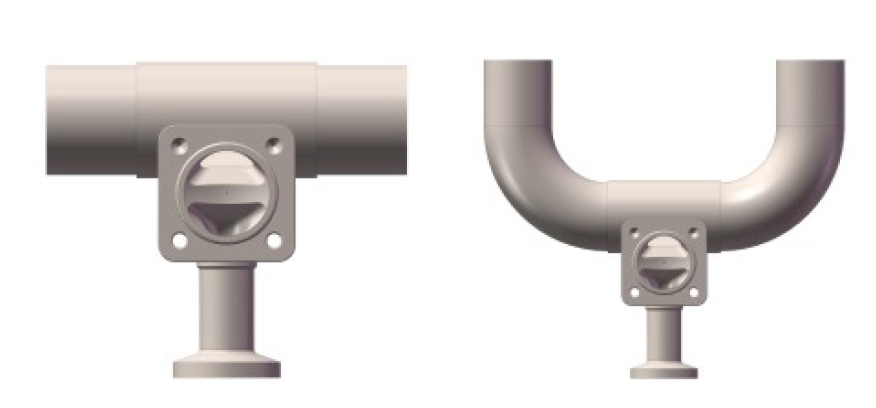

The 3-way diaphragm valve with a T Type Tri Clamp design offers precise flow control and unmatched versatility for sanitary applications. Its innovative design supports multiple flow paths, making it ideal for redirecting or mixing media in industries like pharmaceuticals and food processing. The Tri Clamp connection ensures quick installation and maintenance, while its hygienic construction complies with strict sanitation standards. Durable and efficient, the T Type Tri Clamp Valve is a reliable choice for high hygiene processes.

| Body | SS316,SS316L | |

| Diaphragm Material | EPDM, EPDM+PTFE | |

| Size | 3/8″-4″ | |

| Standard | ISO1127, DIN11850, | |

| Connection | Flange, Clam, SW | |

| Actuator material | Aluminum Alloy | |

| Pressure | PN10 | |

| Air supply pressure | 5.5bar | |

| Pneumatic Actuator | Double acting,Single acting normally closed, acting,Single normally open | |

| Option | solenoid valve,?limit switch box?, filter, E/P positioner, hand wheel | |

The three-way diaphragm valve comes in T-type and U-type configurations, primarily used for sampling or water intake in main pipelines. Its specific use depends on the application. Based on customer process requirements and installation needs, front and rear elbows matching the main pipe’s diameter can be chosen.

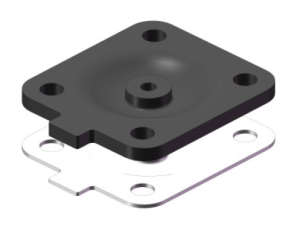

EPDM+PTFE Double layer diaphragm

The EPDM and PTFE diaphragm is engineered for durability and efficiency. When the valve is closed, the diaphragm’s design ensures a secure seal with the valve body, minimizing stress and extending its lifespan. Built to endure high temperatures and demanding working conditions, it offers reliable performance in challenging environments.

Specifications:

- Size range: DN25-DN100

- Double-layer diaphragm temperature tolerance: -20°C to 150°C

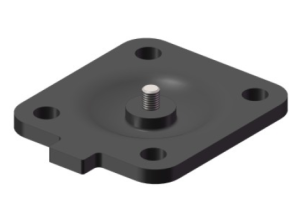

EPDM Single layer diaphragm

The single-layer diaphragm is reinforced with a vulcanized fiber layer, enhancing its mechanical strength and durability. Engineered for high sealing stability under rising pressure and temperature, it ensures reliable performance in demanding conditions. The diaphragm’s reinforcing fiber is hardened on stainless steel bolts, improving rubber-to-metal adhesion and overall cohesion. This design makes it particularly suitable for operations in vacuum environments.

Specifications:

– Size range: DN6-DN100

– Rubber diaphragm temperature tolerance: -10°C to 100°C

FAQ

What is a 3-way diaphragm valve?

3-way diaphragm valve is a flow-control device designed to manage multiple flow paths efficiently. It is particularly useful for diverting, mixing, or stopping the flow of media such as liquids, gases, or slurries in sanitary applications.

How does the T Type Tri Clamp design benefit users?

The T Type Tri Clamp design provides flexibility in directing flow, enabling quick switching between flow paths. It also allows for easy installation, removal, and maintenance, minimizing downtime while maintaining a secure and leak-proof connection.

What industries commonly use this valve?

Industries like pharmaceuticals, food and beverage processing, biotechnology, and cosmetics manufacturing frequently use 3-way diaphragm valves due to their ability to maintain strict hygiene and process control standards.

How does it ensure hygiene and safety?

The valve’s smooth, crevice-free interior prevents contamination by eliminating dead spaces where residues might accumulate. It supports Clean-in-Place (CIP) and Sterilize-in-Place (SIP) protocols, meeting stringent sanitation and safety requirements while maintaining product integrity.