Valves play a critical role in industrial systems, ensuring the safe and efficient operation of processes involving fluids and gases. Among the most commonly utilized are the Pressure Control Valve and Flow Control Valve, each serving distinct purposes. A Pressure Control Valve, such as a steam pressure reducing valve or steam pressure regulating valve, manages and maintains system pressure to prevent damage or inefficiency. On the other hand, a Flow Control Valve, including types like the steam flow control valve, precisely regulates fluid or gas flow for consistency and accuracy. This article explores these two essential components, providing insight into their key differences, operational principles, and practical applications across various industries. Understanding these distinctions ensures optimized system performance and reliability.

Introduction Pressure Control Valve and Flow Control Valve

Pressure Control Valves and Flow Control Valves are indispensable components in industrial systems, ensuring operational safety and peak efficiency. A Pressure Control Valve, often utilized in collaboration with designs from top pressure regulating valve manufacturers, is critical for maintaining consistent system pressure to avoid equipment damage or instability. Similarly, a Flow Control Valve precisely regulates the flow of fluids, ensuring controlled processes like heating or cooling. Advanced technologies, including the Pneumatic diaphragm control valve and Pneumatic globe valve, provide enhanced precision and adaptability in dynamic environments. Additionally, systems often integrate features like a temperature regulating valve to maintain optimal conditions. These versatile solutions underline their significance across industries, making a clear understanding of their functions vital for efficient system management.

What is a Pressure Control Valve?

A Pressure Control Valve is a crucial industrial component designed to regulate and maintain system pressure within predefined limits. Its primary function is to ensure consistent pressure levels by adjusting the flow of fluids or gases as needed, preventing issues like overpressure or underperformance. Pressure control valves are typically employed in industries such as manufacturing, oil and gas, and power generation, where precise pressure management is vital. By maintaining safe operating conditions, these valves safeguard equipment, enhance efficiency, and promote system reliability, making them indispensable for ensuring stable and safe operations in complex and dynamic industrial environments.

Explanation of the function of a Pressure Control Valve in regulating and maintaining a predetermined pressure within a system.

A Pressure Control Valve is a vital component in industrial systems, designed to regulate and maintain a specific pressure level for optimal performance. These valves prevent excessive pressure that could damage equipment or disrupt processes by automatically adjusting the flow of fluid or gas. Operated through mechanisms such as springs, diaphragms, or pilot systems, they respond dynamically to pressure fluctuations, either opening to relieve excess pressure or closing to maintain the desired level. By ensuring steady and controlled pressure, they not only safeguard equipment but also enhance overall system efficiency and reliability. Their application spans various industries, where precision and safety are paramount, making them indispensable for maintaining operational stability in complex systems.

Overview of its key components and operational principles.

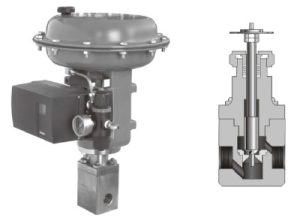

Pressure and flow control valves are intricately designed with key components like actuators, sensors, and control mechanisms that work in unison to regulate system parameters. Actuators, either pneumatic, electric, or hydraulic, drive the valves’ movements, enabling precise adjustments. Sensors continuously monitor variables such as pressure or flow rate, providing real-time data to the control mechanisms. These intelligent systems interpret the input from sensors to adjust the valve’s position, ensuring optimal pressure or flow within set parameters. The seamless integration of these components is critical to maintaining system efficiency, safeguarding equipment, and delivering accurate control, even in the most demanding industrial applications.

-e1735112445545.jpg)

Types of Pressure Control Valves (e.g., pressure relief valves, pressure-reducing valves).

pressure-reducing valves: Pressure control valves come in various types, each designed to address specific operational needs. Pressure relief valves protect systems from overpressure by automatically venting excess fluid or gas when a set threshold is exceeded, ensuring safety and preventing equipment damage. Pressure-reducing valves, on the other hand, maintain a consistent downstream pressure by reducing higher inlet pressure, making them ideal for systems requiring controlled, stable output.

pressure relief valves:? Other variations, such as back-pressure regulators, help maintain a set upstream pressure. These valves are integral to industrial processes, offering tailored solutions for pressure regulation while optimizing performance and safeguarding critical equipment in diverse applications.

Typical industries and systems utilizing Pressure Control Valves.

Pressure control valves are indispensable in industries like oil and gas, manufacturing, and power generation, where precise pressure regulation is essential. In the oil and gas sector, these valves are critical for pipeline systems, ensuring safe transport and storage of volatile substances. Manufacturing facilities rely on them to maintain stable conditions in processes like chemical production or injection molding, preventing equipment damage and ensuring product quality. Similarly, in power generation, these valves regulate pressure in steam lines and turbine systems to optimize performance and safety. They are also critical in HVAC systems, maintaining proper pressure for efficient heating and cooling operations across diverse applications.

What is a Flow Control Valve?

A flow control valve is a critical component designed to regulate the flow rate of fluids within a system, ensuring consistent and precise operation. By managing the flow, these valves help maintain system efficiency, stability, and balance across various processes. Commonly used in hydraulic systems, water distribution networks, and process industries, they prevent fluctuations that could disrupt operations or damage equipment. Flow control valves are essential for applications requiring precise flow management, such as adjusting the flow rate in automated machinery or distributing water evenly in irrigation systems. Their ability to optimize performance makes them invaluable in industrial and commercial settings.

Definition of a Flow Control Valve and how it manages the flow rate of a liquid or gas in a system.

A flow control valve is a device designed to regulate the flow rate of liquids or gases within a system, ensuring consistent and efficient operation. It achieves this by using mechanisms such as adjustable openings or throttling, which allow for precise modulation of flow. This level of control is critical in applications like hydraulic systems, where flow impacts machine movements, water distribution systems that require uniform supply, or gas pipelines demanding stable delivery rates. By maintaining the ideal flow rate, flow control valves play a pivotal role in optimizing performance, preventing system disruptions, and safeguarding equipment from irregular pressure or flow.

Discussion of its role in ensuring consistent flow.

Flow control valves are vital for maintaining steady flow rates in diverse systems, ensuring operational consistency and preventing disruptive fluctuations. They regulate and fine-tune flow to match system demands, which is essential in industries like manufacturing, water treatment, and HVAC systems. For instance, they help maintain uniform water distribution in treatment plants or stabilize airflow in cooling systems. By adapting to changes in pressure or demand, flow control valves uphold system stability, enhance efficiency, and reduce risks such as equipment overload or process interruptions. Their precise modulation of flow guarantees reliable performance, safeguarding the operation and longevity of critical systems.

Types of Flow Control Valves (e.g., needle valves, globe valves).

Flow control valves are available in numerous types, each suited for specific applications. Needle valves, with their slender, tapered design, enable highly precise control of low flow rates, making them essential for calibration, sampling, and laboratory tasks where accuracy is critical. Globe valves, in contrast, are designed to regulate flow in larger systems, often used in water and steam operations due to their durability and efficiency in handling varying pressures and volumes. Selecting the appropriate valve type, whether it’s for intricate adjustments or high-capacity flow control, is vital to ensure system performance, operational reliability, and adherence to process demands.

Applications of Flow Control Valves, with examples from various sectors.

Flow control valves are indispensable in a wide array of industries, adapting seamlessly to diverse operational demands. In the oil and gas sector, they precisely regulate the flow of crude oil, natural gas, and process fluids, ensuring safe and efficient operations. Within the automotive industry, these valves control coolant and fuel flow, contributing to optimal engine performance and temperature regulation. They are equally crucial in water management systems, enabling efficient water distribution in utilities and irrigation networks. Their versatility across sectors highlights their role in achieving precision, system stability, and energy efficiency, making them essential for both industrial and commercial applications.

Key Differences Between Pressure Control Valves and Flow Control Valves

Pressure control valves and flow control valves differ fundamentally in their function and application. Pressure control valves are designed to maintain system pressure within safe limits, protecting equipment and ensuring operational safety, while flow control valves focus on regulating fluid flow rates for consistent and precise performance. These distinctions influence their use in industries like oil and gas, manufacturing, and water treatment, where pressure control valves prevent overpressure scenarios, and flow control valves optimize flow for efficient processes. Selecting the right valve type is crucial to meet specific operational demands, safeguarding systems while enhancing performance and energy efficiency.

Applications and Practical Considerations

Pressure and flow control valves play vital roles across industries, including chemical processing, water treatment, and HVAC systems, where precise regulation ensures efficiency and safety. Pressure control valves are often used to safeguard systems from overpressure, while flow control valves maintain consistent flow rates critical in operations like water distribution or cooling. Practical considerations, such as proper installation to prevent leaks, regular maintenance for consistent performance, and compatibility with system pressure and flow requirements, are essential. Selecting the appropriate valve type based on application needs is key to achieving reliable, efficient operation and minimizing risks in complex industrial systems.

Advantages and Limitations of Each Valve Type

Pressure control valves and flow control valves each offer distinct advantages and limitations based on their design and application. Pressure control valves excel in maintaining system safety by precisely regulating pressure, protecting components from overpressure damage. However, they can face wear and require regular maintenance in high-stress environments. Flow control valves ensure efficient flow management, delivering stable flow rates crucial for balancing system operation. Their limitation lies in the potential for flow restrictions, which may cause pressure drops, impacting overall efficiency. Understanding these benefits and drawbacks helps professionals optimize their use within various industrial systems to enhance performance and reliability.

FAQ Pressure Control Valve and Flow Control Valve

Q1. What is the primary difference between a Pressure Control Valve and a Flow Control Valve?

A: The main difference lies in their function within a system. A Pressure Control Valve is designed to maintain a specific pressure by adjusting the flow of fluid or gas as needed. It ensures the system operates safely within desired pressure limits. On the other hand, a Flow Control Valve focuses on regulating the rate of fluid or gas flow to meet specific operational requirements. Both types of valves are critical in industrial processes, often integrated with advanced technologies like an electric globe valve or a pneumatic control valve to ensure precise system management.

Q2. How are electric control valves used with Pressure Control Valves and Flow Control Valves in industrial systems?

A: Electric control valves are commonly utilized for their accuracy and responsiveness in modern industrial setups. When paired with a Pressure Control Valve, they enable precise pressure adjustments by dynamically controlling fluid or gas movement, ensuring stability and safety. With a Flow Control Valve, electric control valves regulate flow rates with high precision, meeting operational demands in processes that require fine-tuned control, such as in chemical or pharmaceutical industries. Their adaptability makes them invaluable in complex systems, where efficiency and reliability are paramount.

Q3. Why are pneumatic control valves often used in conjunction with Pressure Control Valves and Flow Control Valves?

A: Pneumatic control valves are favored in industrial settings for their robust performance and flexibility. They are particularly effective when paired with a Pressure Control Valve, offering rapid and reliable pressure regulation through compressed air mechanisms. Similarly, they complement Flow Control Valves by efficiently managing flow rates in dynamic systems. For example, in high-temperature or high-pressure environments, pneumatic control valves, as well as devices like electric globe valves, provide enhanced durability and control, enabling smooth operation under demanding conditions.

Conclusion Pressure Control Valve and Flow Control Valve

Understanding the differences between a Pressure Control Valve and a Flow Control Valve is essential for ensuring the safety and efficiency of industrial systems. Each valve serves distinct purposes, with pressure control focusing on maintaining optimal pressure and flow control managing fluid movement. Advanced solutions, such as the self-operated pressure regulating valve, self-operated regulating valve, and self-operated control valve, highlight the technological innovations that enhance precision and reliability. By carefully selecting and integrating the right valve types, industries can optimize performance while safeguarding operations. A clear grasp of these critical components helps professionals tailor systems to meet specific operational needs, ensuring longevity and stability across various applications.

關(guān)切斷閥白底800x800-e1735112616226.jpg)