Description

Crafted from durable CF8 and CF8M stainless steel, the 3 Way Ball Valve with a pneumatic actuator ensures superior performance for industrial operations. Available in T port and L port configurations, this ball valve 3 way design offers flexible flow options for diverting, mixing, or isolating processes. Whether you need a 3 way SS ball valve or a 3 way stainless steel ball valve, it delivers reliable automation and precision. Ideal for demanding environments, the 3 way ball valve T port configuration enhances versatility

| Body | WCB, CF8M, CF8M or other | |

| Body stlye | T port, L port | |

| Ball | SS304,SS316,SS316L | |

| Seat | PTFE,RPTFE | |

| End | BSP, BSPT, NPT, Flange, Clamp, SW | |

| Size | 1/2”~8” | |

| Pressure | 1.6Mpa, 2.5Mpa, 4.0MPa | |

| Medium | Gas, Water and Oil, etc | |

| Pneumatic Actuator | Double acting,Single acting normally closed, acting,Single normally open | |

| Option | solenoid valve,?limit switch box?, filter, E/P positioner, hand wheel | |

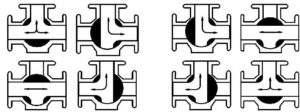

Three way T type flow diagram

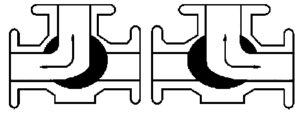

Three way L type flow diagram

FAQ

What is the difference between T port and L port configurations?

A T port configuration allows for more complex flow control, enabling the valve to divert, mix, or isolate flow between all three ports. An L port configuration, however, is designed to connect one inlet to one of two outlets, making it ideal for simple diversion operations. The choice depends on your application requirements.

Where are 3 Way Ball Valves typically used?

These valves are commonly used in industries such as chemical processing, water treatment, oil and gas, and HVAC systems. They serve applications requiring diversion, mixing, or isolation of fluids and gases.

What materials are used for 3 Way Ball Valves?

Common materials include stainless steel grades CF8 and CF8M, known for their excellent corrosion resistance and durability in high-pressure and high-temperature environments. PVC and CPVC options are also available for less aggressive conditions that prioritize chemical resistance.

Can 3 Way Ball Valves be automated?

Yes, they can be equipped with electric or pneumatic actuators for precise control in automated systems. These options enhance efficiency and accuracy in industrial processes.

How do I choose the right valve size?

Valve size selection depends on the flow rate, pressure, and pipe size required for your system. Consult valve sizing charts and flow coefficient (Cv) values to ensure the 3-way ball valve meets application needs.